Q: How'd you get the Jesus nut (crank) off?

A: With a good air compressor and impact wrench, I just pounded away for about 2 minutes with a 36mm impact socket. Others have heated it up and used a breaker bar.

Remove the oil pan. Wedge a hard rubber mallet between a crank rod throw and the inside of the engine block, effectively locking the crankshaft. Use the same technique during reassembly.

Q: Can I re-use head bolts?

A: No, but your new bolts will not come with washers so save your old ones!

Damn head bolts. For the last fricken time, our head bolts are not torque to yield and do not need replacing. The confusion is that the torque sequence includes a torque to angle step. Torque to yield bolts have large diameter threads tapering to a very narrow shank and then taper back up to a large bolt head. Torque to yield bolts must be replaced after every use. In every single case that I've run across where a torque to yield bolt is used, the torque sequence includes at least one torque to angle step in the sequence, such as torque to 50 ftlbs then an additional 90 degrees. The final torque on ours is somewhere around 60 ftlbs. and while the sequence includes a torque to angle step, it doesn't mean they are torque to yield bolts. The yield strength of an m12, grade 10.9 is 92 ft lbs lubed and 123 ftlbs dry. As you can see, at 60 ftlbs you are about 25% below the yield strength of the bolt. The difference in the lubed and dry spec illustrate the need not only to lube the bolts for proper torque but also the importance of cleaning the threads for the correct torque to be achieved. Installing dirty lubed bolts has the equivalent effect of installing them dry as the increased friction of dirty threads reduces the final torque reading. In other words if you install the bolts dry and torque them to 60 ftlbs, the actual torque is about 30% less or approximately 40 ftlbs. Since some threads are cleaner and some are dirtier the result is uneven clamping force and a propensity for warped heads and subsequent repeated head gasket failure. Replacing these head bolts is an idiotic waste of money, especially if it makes you feel good.

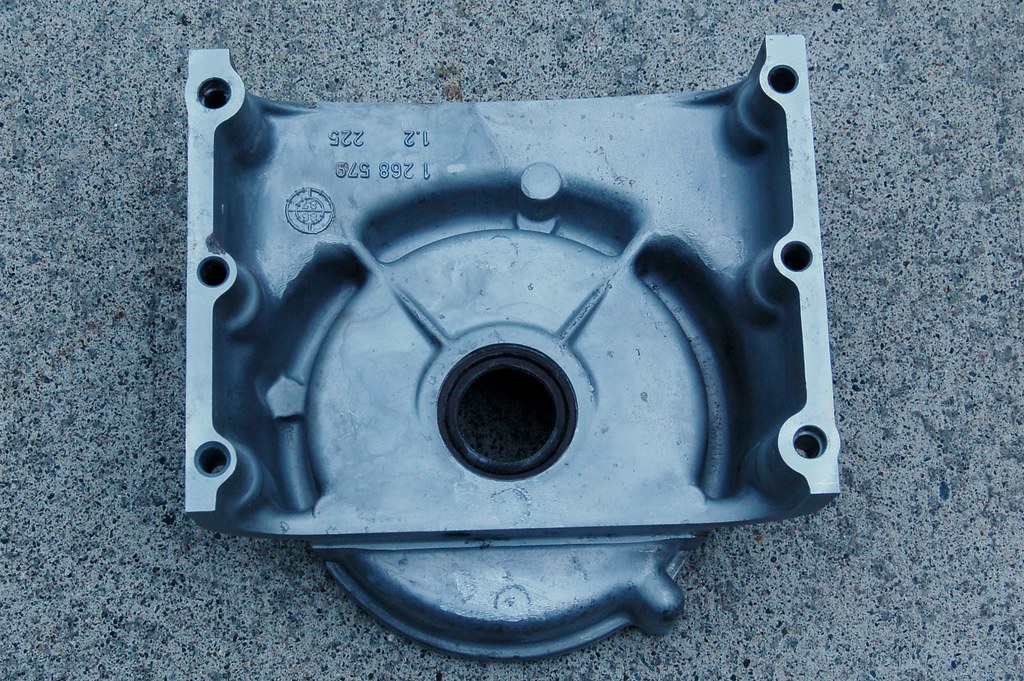

Where do I use sealants and what type to prevent leaks on my brand new soda blasted/cleaned/zinc plated enginz?

The two sealants that you will need are Permatex aviation gasket sealant and RTV silicone. Anywhere you have two mating surfaces that are free of major imperfections use the aviation gasket sealant. For example front timing cover to block, water pump to housing, etc. Anywhere there is a complex joint, such as the head/block/front timing cover joint, or anywhere there is a void to be filled, use the silicone. Additionally anywhere you have a gasket that seals a joint of two separate components, like the oil pan to block/timing cover, a small dab of silicone should be used compensate possible height differences (fill the void).

This from turbodan:

I'm on the other side of the fence on sealant. I have had excellent results using nothing but a gasket. Water pumps, oil pans, timing cases, etc. With clean, undamaged sealing surfaces an ordinary gasket is perfectly sufficient. Sealant can be good for filling imperfections but should not be used in place of proper surface prep.

Absolutely agree. Especially on surface prep....clean, clean, clean AND DEGREASE.

How do I clean my rusty ass block, and then what paint can I use?

Elbow grease. Purple power degreaser, scrub and rinse. Any high temp engine paint is fine. However there is one step in preparing any cast iron component that needs to be taken, otherwise the paint will start flaking in short order. Cast iron is very porous and even if it is dry to the touch, it still contains moisture that needs to be removed. Enter the common propane torch. Simply play the flame on every surface of the block, head or manifold. You will see the moisture precipitate out of the metal. Additionally any remaining grease or oil will be burned off. Once the metal is truly dry you can paint and it will wick into the cast iron ensuring complete adhesion. If you leave the moisture in the metal it will precipitate out during normal heat cycling and cause the paint to flake. Light surface rust is okay, use a steel brush to remove anything more.

4. Media Removal: I inadvertently hit the interiors of some valve covers with aluminum oxide media. (Now I read cek's advice about avoiding this). What does anyone suggest about removing the oxide media? Hot dip power wash? Gasoline? Pressure washer?

Aluminum oxide....on an aluminum part.....bare aluminum oxidizes rapidly when exposed to oxygen forming......aluminum oxide....with embedded aluminum oxide....wash it off, scrub it with a brush....it's trapped and not going anywhere.

Powder Coating: Should one powder coat the Oil Pan and Differential Cover or is this not recommended due to heat dissipation issues?

Theoretically yes, practically? No. Just drive faster to compensate. Not an option on a VW so don't powder coat that engine.