Blunttech e12 LSx / t56 swap

What part of MI? (I was just there for a week+. Muskegon area.)jakeb wrote:hahaha

I am in Michigan...the humidity is just as bad as the heat actually probably makes it worse.

I have a HUGE ass fan pulling air in which makes it better but the temp in the garage is still hotter than outside.

Noice.jakeb wrote:Also picked this up last week for my wife...

More progress on the exhaust... Two 2.25" pipes coming from the passenger side is way way tight. But there is 1/4" or so clearance at any given point.

Passenger side how they snake around...

I really liked this joint so I had to take a picture. I make all my cuts with a sawzall. Now this was an angle cut on one side and straight on the other. It was the first cut and I normally just mark one side and go for it.

Same pipe..

There will be another hanger up in the front...but it is all tacked together

Still need to extend the tail pipe out. It's going to be a straight 4" exit.

Cam showed up today as well!

Passenger side how they snake around...

I really liked this joint so I had to take a picture. I make all my cuts with a sawzall. Now this was an angle cut on one side and straight on the other. It was the first cut and I normally just mark one side and go for it.

Same pipe..

There will be another hanger up in the front...but it is all tacked together

Still need to extend the tail pipe out. It's going to be a straight 4" exit.

Cam showed up today as well!

-

unt0uchable

- Posts: 2265

- Joined: Jul 21, 2011 8:05 PM

- Location: Rochester Hills, Michigan

- Contact:

-

Mark 88/M5 Houston

- Posts: 8548

- Joined: Feb 12, 2006 12:00 PM

- Location: Far North Houston

thanks guys!! I must say this exhaust was the trickiest I have made but I think it is also one of the best I have made too.

Yup...a sawzall. I have a chop saw and horrizontal band saw but for exhaust I really like the sawzall...it's quick, not as messy as the chop saw, and not as loud either.

Most of the leaves and such were hiding behind the old firewall insulation. It will get vacuumed up. Remember this build is about function more than looks.

Yup...a sawzall. I have a chop saw and horrizontal band saw but for exhaust I really like the sawzall...it's quick, not as messy as the chop saw, and not as loud either.

Most of the leaves and such were hiding behind the old firewall insulation. It will get vacuumed up. Remember this build is about function more than looks.

Here is how the BMW master cylinder will bolt up to the GM hydro boost...

From top to bottom....BMW master cylinder, plate to bolt to MC, adapter pin, short piece of pipe, plate to bolt to hydro boost, hydro booster, plate to bolt to firewall.

Plate to bolt to firewall...this one is centered but the one currently on the hydro boost is offset some.

Pin to go inside the MC plunger....nice to have friends with CNC lathes.

All stacked up...plates will be welded to the pipe.

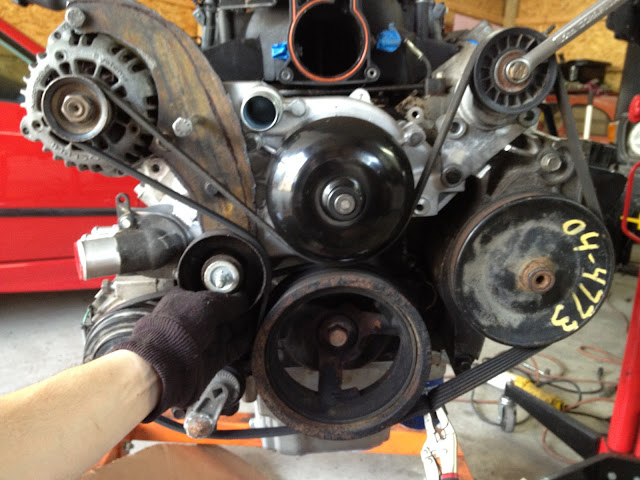

I am using as many of the truck accessories and have to move some things around. There will be a bracket that bolts off the head and two spots on the water pump to hold the alternator. Also need to make a new bracket for the tensioner.

Debating adding another idler to allow a bit more belt wrap on the crank pulley. Leaning towards using the idler rather than not.

with...

without

From top to bottom....BMW master cylinder, plate to bolt to MC, adapter pin, short piece of pipe, plate to bolt to hydro boost, hydro booster, plate to bolt to firewall.

Plate to bolt to firewall...this one is centered but the one currently on the hydro boost is offset some.

Pin to go inside the MC plunger....nice to have friends with CNC lathes.

All stacked up...plates will be welded to the pipe.

I am using as many of the truck accessories and have to move some things around. There will be a bracket that bolts off the head and two spots on the water pump to hold the alternator. Also need to make a new bracket for the tensioner.

Debating adding another idler to allow a bit more belt wrap on the crank pulley. Leaning towards using the idler rather than not.

with...

without

-

mooseheadm5

- Beamter

- Posts: 23035

- Joined: Apr 08, 2009 10:30 PM

- Location: Charlottesville, VA

- Contact:

-

mooseheadm5

- Beamter

- Posts: 23035

- Joined: Apr 08, 2009 10:30 PM

- Location: Charlottesville, VA

- Contact:

-

Kyle in NO

- Posts: 17638

- Joined: Feb 12, 2006 12:00 PM

- Location: Nasty Orleans------> Batten-Rooehjch------>More Souther LA

yeah the firewall is pretty thin....the bad part is going to get cut out and new welded in in the next few days.

A bit more progress today....the list is getting shorter.

ST Front sway bar in

Blunttech SS brake lines in

Suspension all tightened up

255lph fuel pump is in

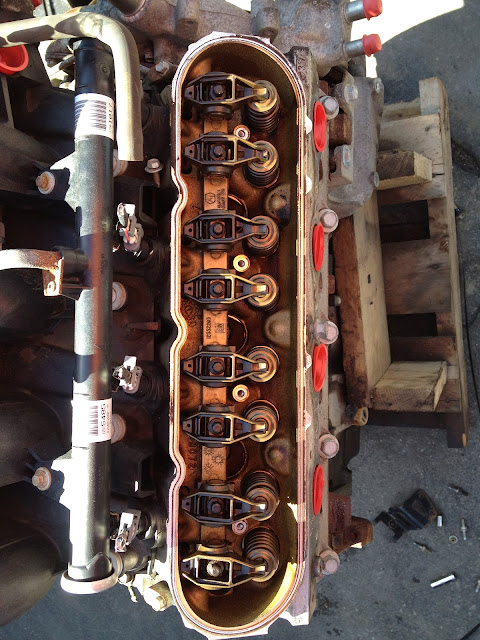

TSP 224R cam, pac springs, and upgraded push rods installed. This was the first time I did this so it was a bit of a learning process and went a bit slow. By the last set of springs things were going quicker.

I didn't take many pictures through all of this as it isn't that exciting really...

parts laid all out

Old springs...

New springs...really doesn't look very different

Taking up the entire garage today....wife has to park outside. I really need more space!

A bit more progress today....the list is getting shorter.

ST Front sway bar in

Blunttech SS brake lines in

Suspension all tightened up

255lph fuel pump is in

TSP 224R cam, pac springs, and upgraded push rods installed. This was the first time I did this so it was a bit of a learning process and went a bit slow. By the last set of springs things were going quicker.

I didn't take many pictures through all of this as it isn't that exciting really...

parts laid all out

Old springs...

New springs...really doesn't look very different

Taking up the entire garage today....wife has to park outside. I really need more space!

My ceiling is 10' and I have a baseplate lift from greg smith. It is a little pain with the bump on the floor but more than ok to overcome to have a lift. The lift was a GREAT purchase and was only $1600. More than paid for itself, saves my back, and I can work soooo much faster.

We are going to build a new house in the next 5 years (we have a wooded lot around an acre) and I will have a dedicated 30x50 (at least) shop with 12' ceilings and a second floor. But for now what I have works out well. 24x36...10' ceilings

We are going to build a new house in the next 5 years (we have a wooded lot around an acre) and I will have a dedicated 30x50 (at least) shop with 12' ceilings and a second floor. But for now what I have works out well. 24x36...10' ceilings

-

unt0uchable

- Posts: 2265

- Joined: Jul 21, 2011 8:05 PM

- Location: Rochester Hills, Michigan

- Contact:

Just a small update...

Fixed the hole in the firewall. Blunt wanted functional over looking good. It's nothing fancy but it will stop it from rusting more and fill the hole.

You can see the hole in the firewall here....

Some paint just to cover the bare metal...back side also was painted. This will all get covered up anyway with new insulation.

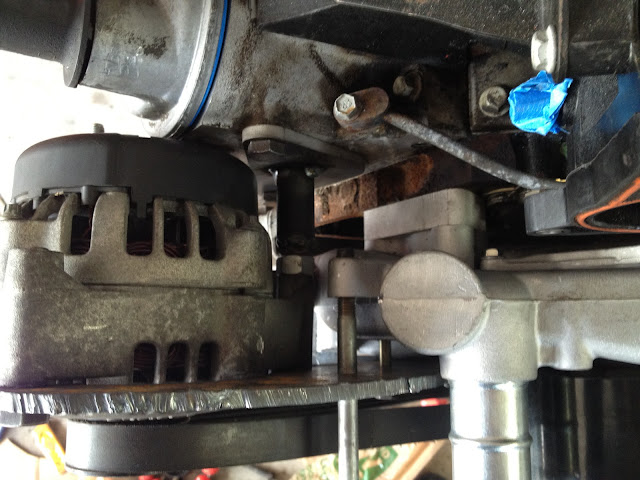

Relocating the alternator to make room....

Made a bracket, love my new plasma cutter. This will get drawn into cad and cut on a water jet for the final version.

Also mounts to the head. This may or may not stay.... There will also be spacers between the water pump and new bracket.

I'm not sure which idler I like better yet. I have another one coming to try too. Plate will be drilled and tapped for the idler pulley.

Fixed the hole in the firewall. Blunt wanted functional over looking good. It's nothing fancy but it will stop it from rusting more and fill the hole.

You can see the hole in the firewall here....

Some paint just to cover the bare metal...back side also was painted. This will all get covered up anyway with new insulation.

Relocating the alternator to make room....

Made a bracket, love my new plasma cutter. This will get drawn into cad and cut on a water jet for the final version.

Also mounts to the head. This may or may not stay.... There will also be spacers between the water pump and new bracket.

I'm not sure which idler I like better yet. I have another one coming to try too. Plate will be drilled and tapped for the idler pulley.