After starting this thread I did the following:

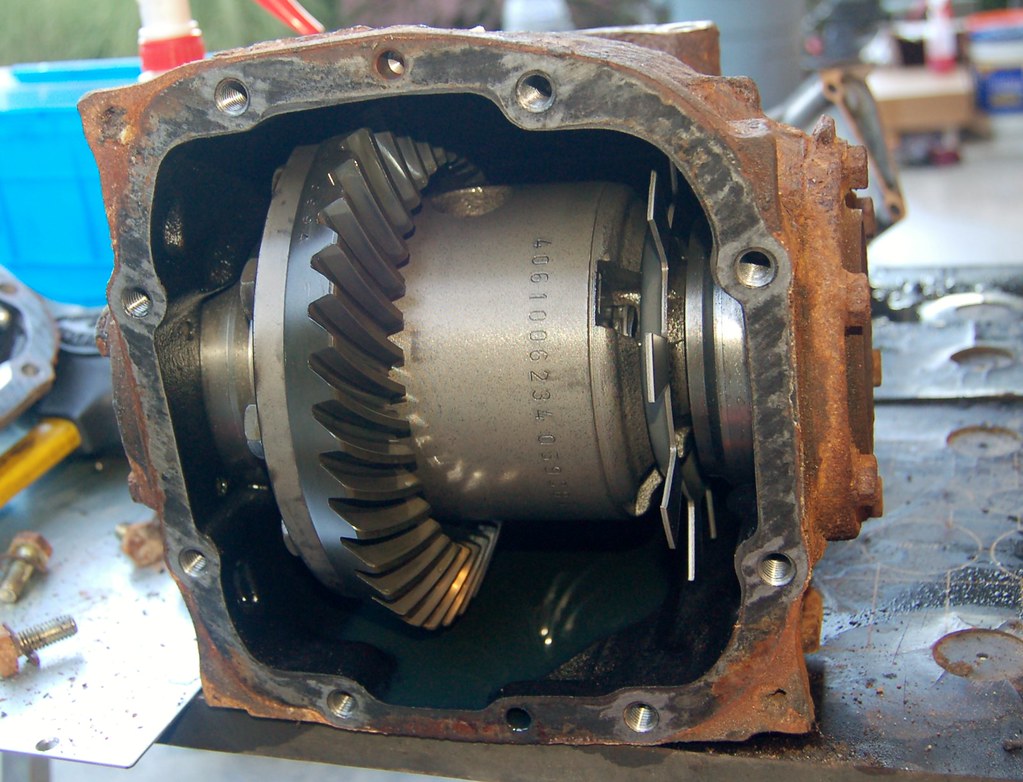

1) I sourced a 3.46 LSD locally and installed that in Maytag.

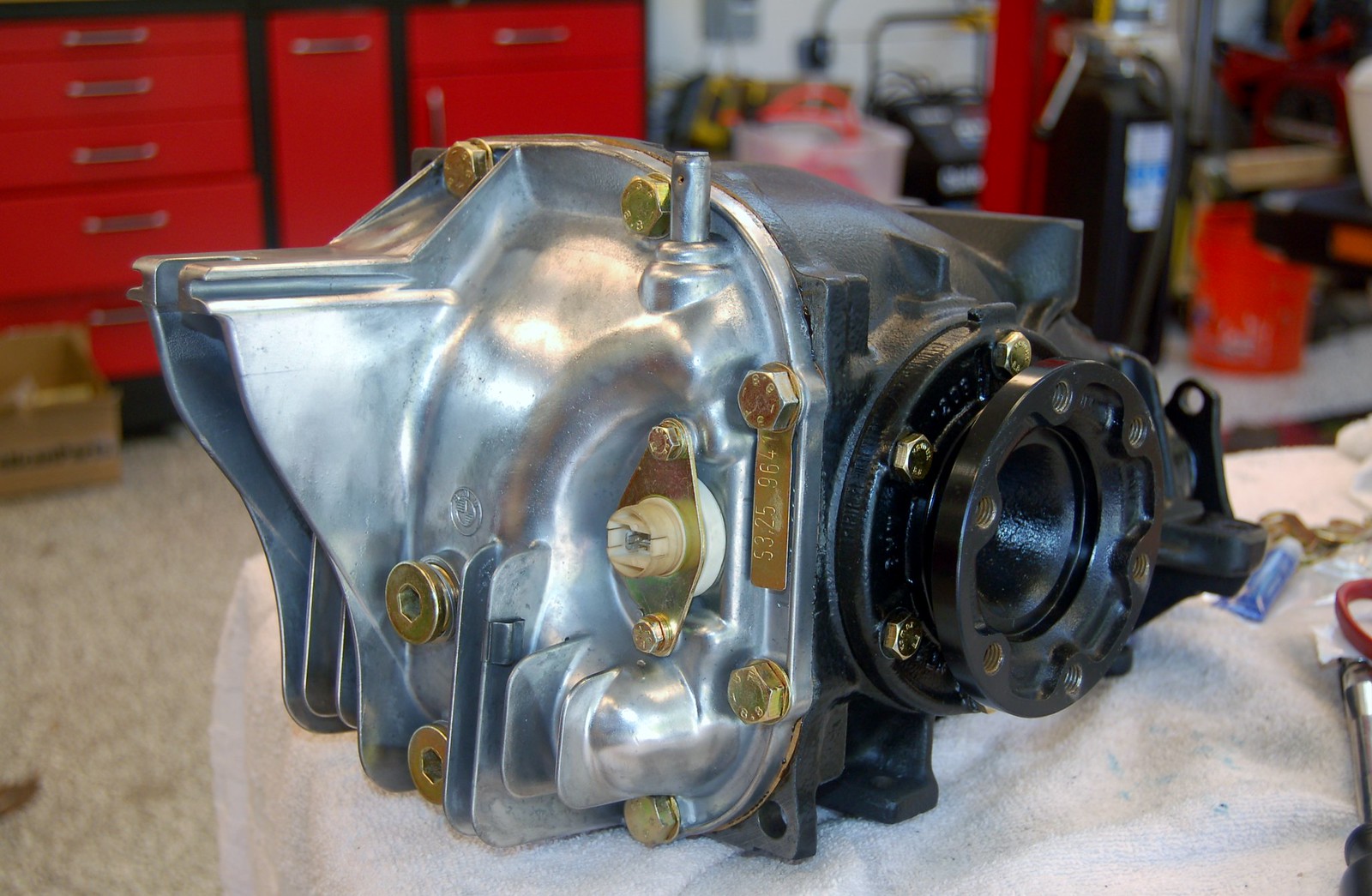

2) Found another 3.25 LSD that's not a clump of rust.

Thus I have 3 diffs lying around: The 2.93 that WAS in Maytag, the rusty 3.25S, and the non-rusty 3.25S.

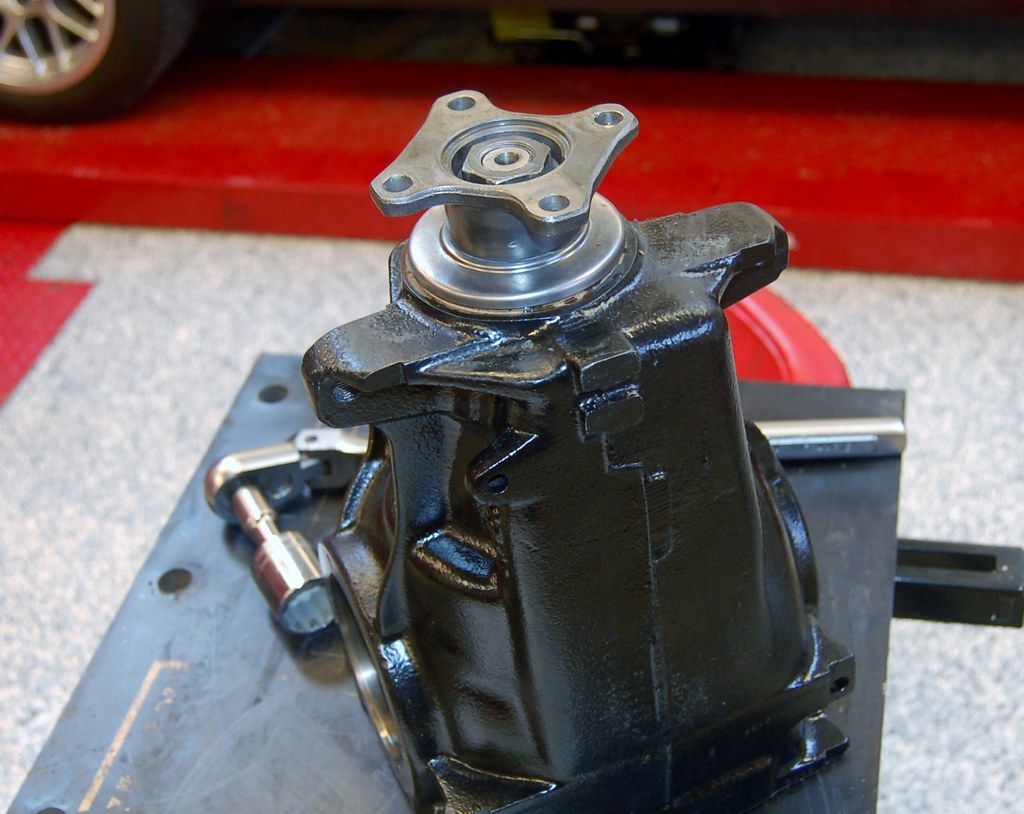

Today I decided to tear into making at least one good 3.25S that I could put in Maytag because the 3.46S is too short for my tastes.

I have questions. Please answer them.

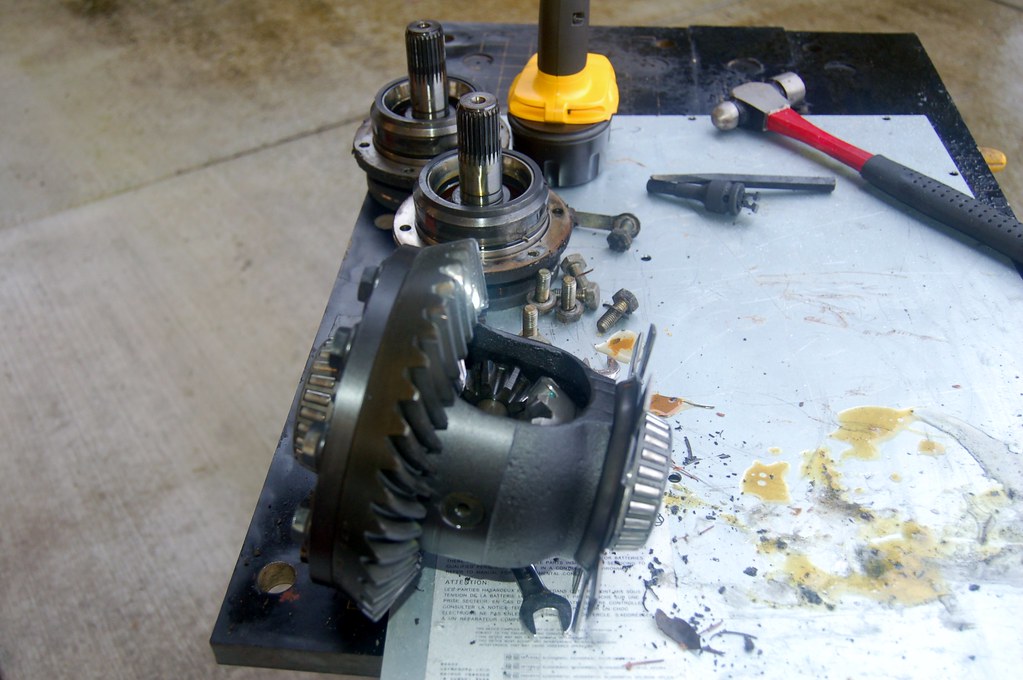

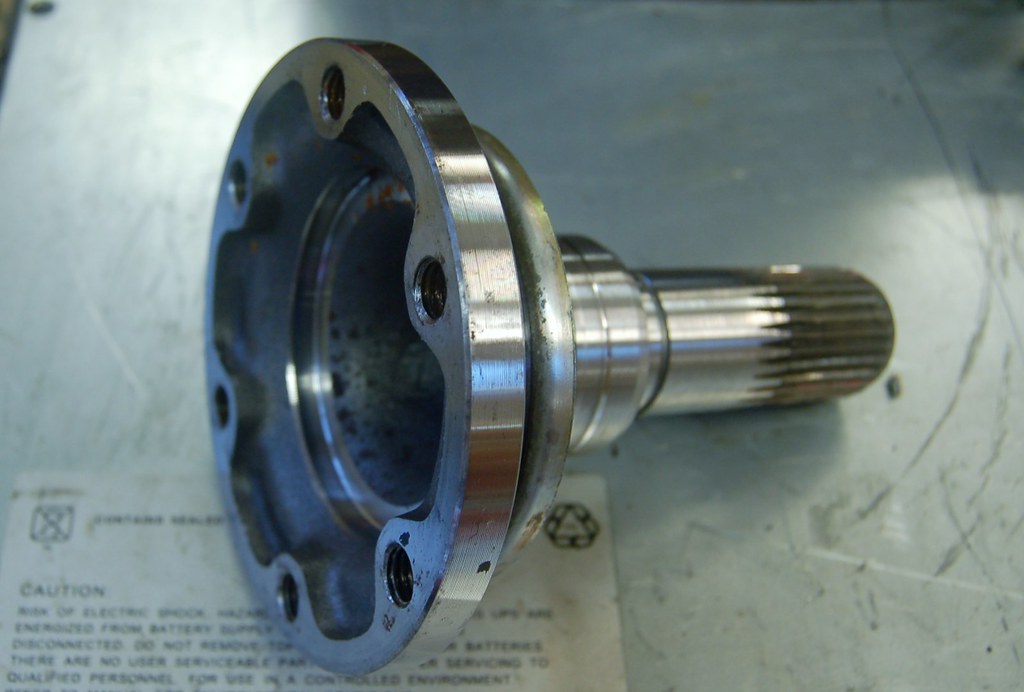

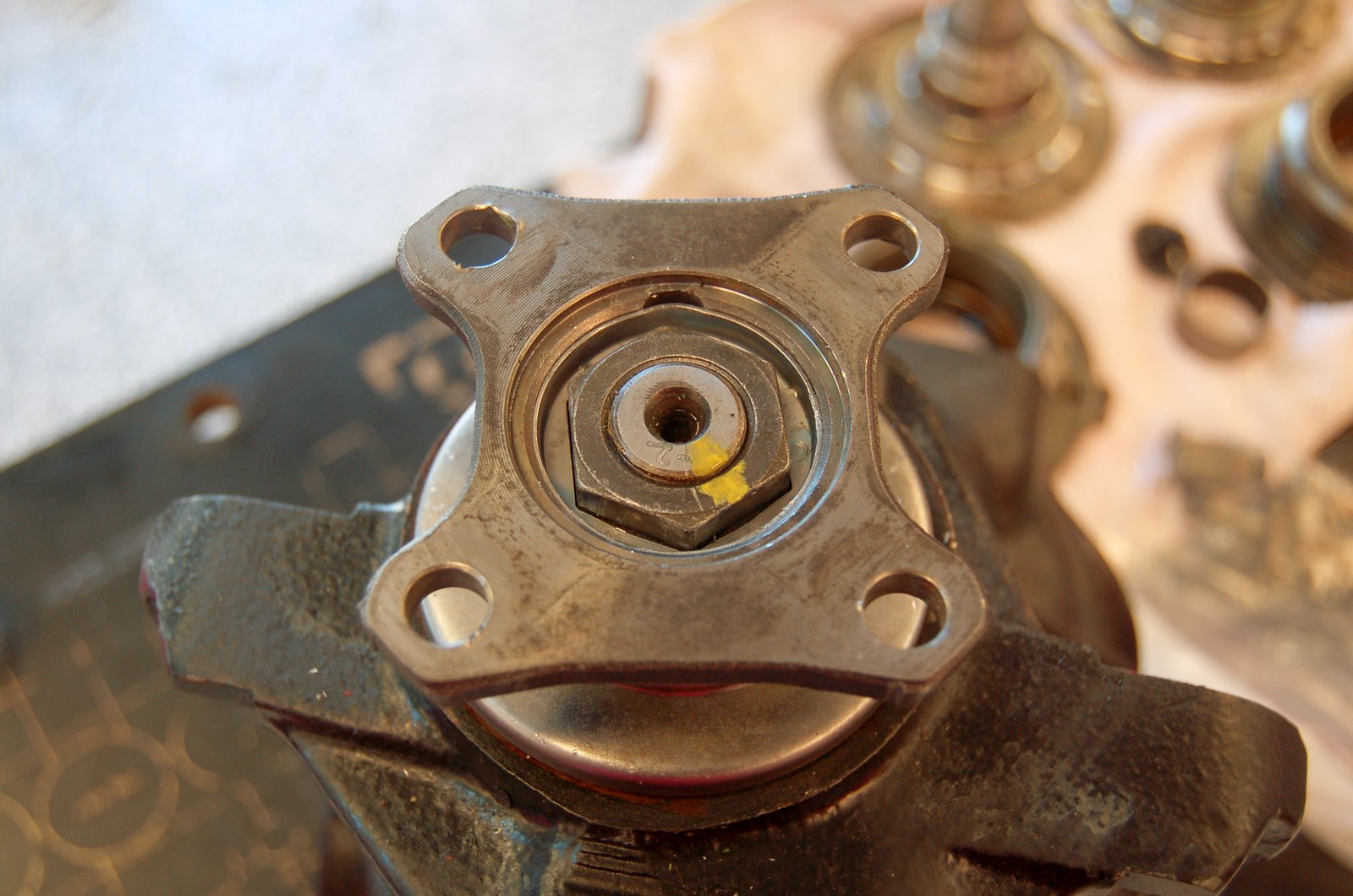

First, I dove into the 2.93 non-LSD because neither of the 3.25s came with output flanges and I figure I can use them. Lame that sellers didn't include them!

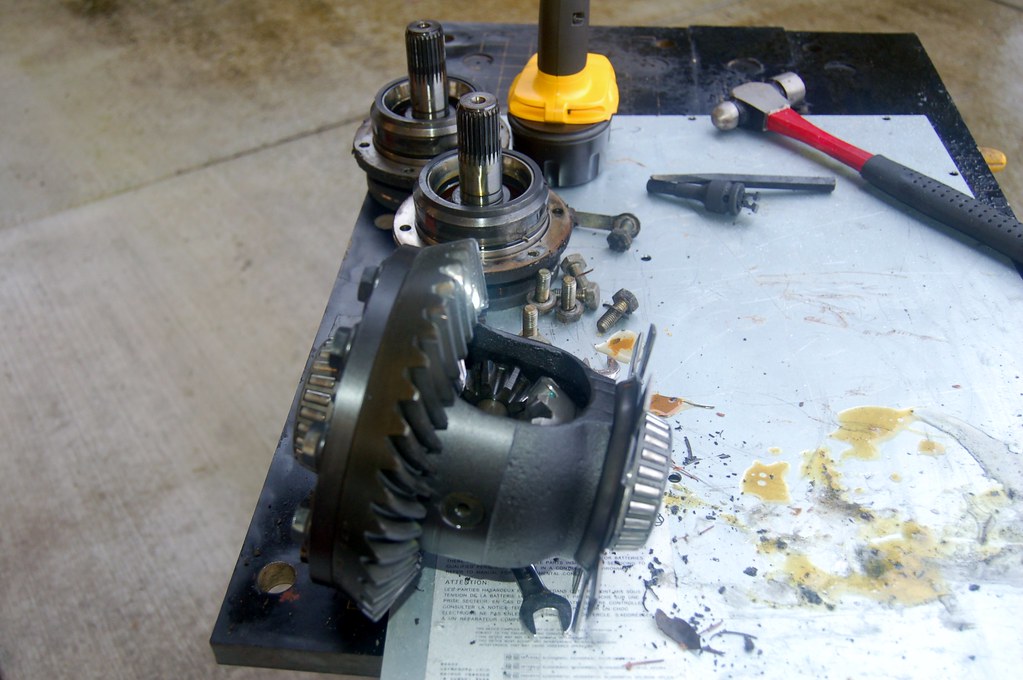

I was surprised at how easy the diff came apart once the outer flange mounting cover thingies were removed. When I worked on the diff for my FJ40 it seemed way more complicated.

The input bearing in this case feels a little rough. It is the best case of the 3.

First question: I can't find the input-shaft/gear on RealOEM. Is there any difference between this part on LSD/Non-LSD diffs?

First question: I can't find the input-shaft/gear on RealOEM. Is there any difference between this part on LSD/Non-LSD diffs?

In other-words, can I just slap one of the LSD diff units into this case?

Next, I pulled apart the 2nd 3.25S that I bought. And dropped the cover, breaking the speed sensor. Which made me notice just how much gunk is on the speed sensor. Which made me think the speed sensor is actually a magnet and all this gunk is metal filings. Which makes me think this diff has not been wearing very well.

Am I right that the sensor is magnetic? And that this amount of metal is a bad sign? The other diffs I disassembled did not have anywhere this much gunk on them.

Am I right that the sensor is magnetic? And that this amount of metal is a bad sign? The other diffs I disassembled did not have anywhere this much gunk on them.

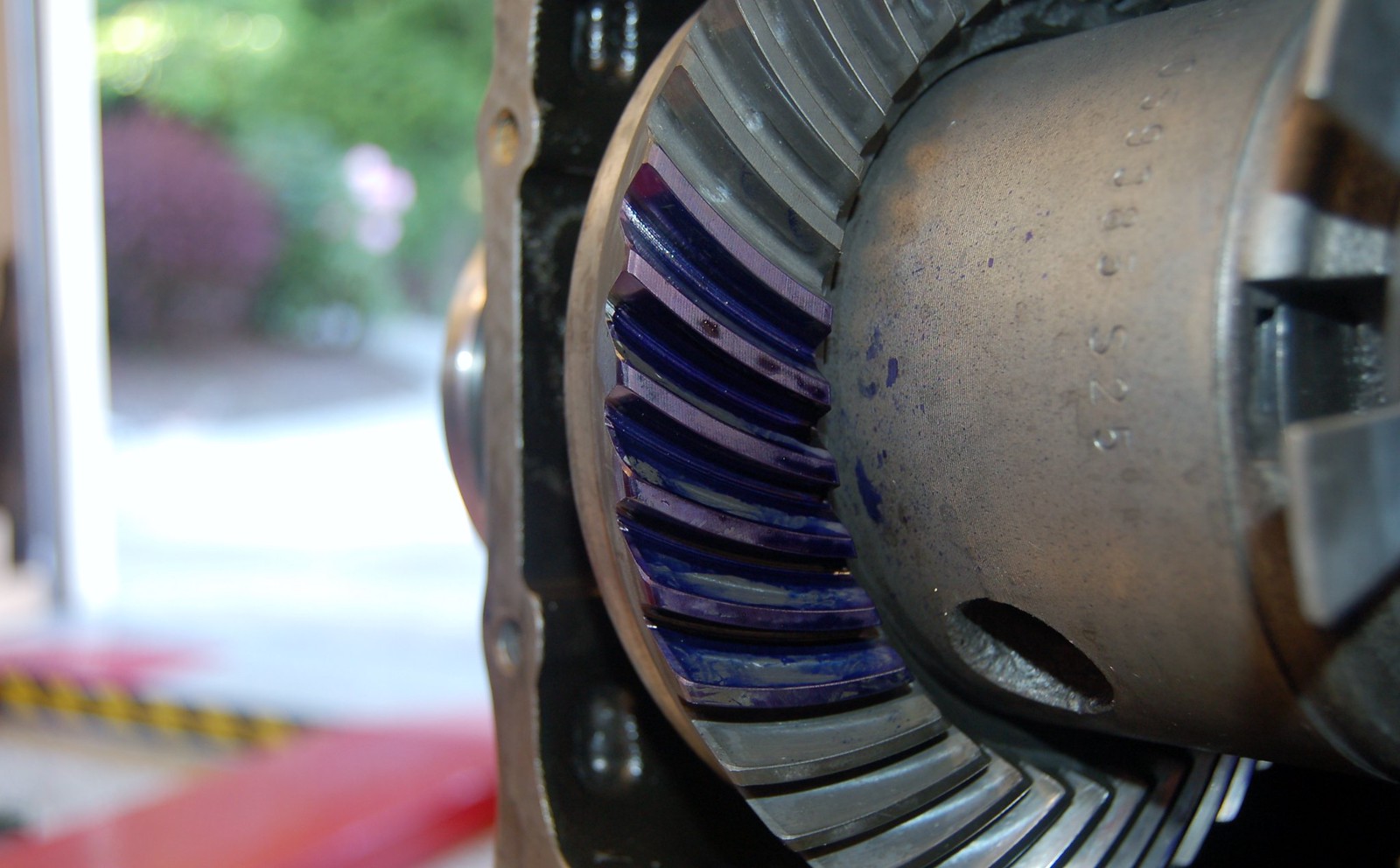

Compared to the rusty diff, this one just looks more worn. No obvious teeth missing or severe wear that I can see, just dirtier and the gears look slightly less crisp.

Should I bother replacing the bearings? I probably will for the input shaft since none of the 3 that I have feel smooth. Do the output shaft bearings wear?

Should I bother replacing the bearings? I probably will for the input shaft since none of the 3 that I have feel smooth. Do the output shaft bearings wear?

FWIW, I have a rough idea of what it takes to put the diff back together. I need to set the ring & pinion backlash, preload the pinion and carrier, etc... Doesn't look too hard. I will need to buy some tools. Heh. Apparently there's a good thread on the Ohio Bimmer forum, but it requires registration/activation and that hasn't happened for me yet (this link:

http://www.ohiobimmers.com/forum/showthread.php?t=3624). Should be fun.