In-tank Fuel Pump Modification

Re: In-tank Fuel Pump Modification

my one complaint with my 255, it is loud as hell. given i have no interior in my trunk... but still

Re: In-tank Fuel Pump Modification

Hey guys,

Thanks for info, i got some inspiration from this thread and i attached a picture of my primitive assembly.

As it seemes the top part of my gas tank is pretty rusty and it kept braking my fuelpumps...so i got fuel tank restoration kit from the Eastwood company (can't link the product atm because their website down) but will post followup on how that kit is working, meanwhile i just grabed a new pump from pepboys ( Spectra SP1067 that pushes fuel with around 2,5 - 5 psi to the inline pump, attached to this is the Carter strainer STS-9).

And now to the actual point why i am writing this: first of all i read about some people here saying that the in tank pump might be usless and that a stronger pump in the tank or under the vehicle would suffice, well the thing is that those german engieers did know what they are doing and let me tell you why, there is aso called drag coefficient that applies to liquid too, not just to aerodynamics, in other words, hypothetically speaking your pump is pushing with 10psi 10 gallons per hour on a straight pipe, which is just fine, as longer the pipe as more the pressure drops at the destination, and then here starts our problem, the fuel delivery sistem on the cars is not straight, there is formula in fizics that determins the coefficient of drag for each and evey curving that is in the fuel delivery line, this drag makes your pressure drop a lot. Don't ask me about thay formula, try googling it lol.

This is where my issue was, after my in tank pump broke (who knows when that happened...) my vehicle was just working fine until the in line broke too, which is a strong one, 90-125psi. This in line pump broke exactly because of this drag coefficient: in order for that pump to be able to deliver an avrage of 100psi to your injectors it has have that fuel delivered to its door step, because if not the pump has to do sucking and the pushing, this also lowers its performance and the psi with which the fuel gets delivered....plus all the

This is why they made the system with two pumps...

Thanks for info, i got some inspiration from this thread and i attached a picture of my primitive assembly.

As it seemes the top part of my gas tank is pretty rusty and it kept braking my fuelpumps...so i got fuel tank restoration kit from the Eastwood company (can't link the product atm because their website down) but will post followup on how that kit is working, meanwhile i just grabed a new pump from pepboys ( Spectra SP1067 that pushes fuel with around 2,5 - 5 psi to the inline pump, attached to this is the Carter strainer STS-9).

And now to the actual point why i am writing this: first of all i read about some people here saying that the in tank pump might be usless and that a stronger pump in the tank or under the vehicle would suffice, well the thing is that those german engieers did know what they are doing and let me tell you why, there is aso called drag coefficient that applies to liquid too, not just to aerodynamics, in other words, hypothetically speaking your pump is pushing with 10psi 10 gallons per hour on a straight pipe, which is just fine, as longer the pipe as more the pressure drops at the destination, and then here starts our problem, the fuel delivery sistem on the cars is not straight, there is formula in fizics that determins the coefficient of drag for each and evey curving that is in the fuel delivery line, this drag makes your pressure drop a lot. Don't ask me about thay formula, try googling it lol.

This is where my issue was, after my in tank pump broke (who knows when that happened...) my vehicle was just working fine until the in line broke too, which is a strong one, 90-125psi. This in line pump broke exactly because of this drag coefficient: in order for that pump to be able to deliver an avrage of 100psi to your injectors it has have that fuel delivered to its door step, because if not the pump has to do sucking and the pushing, this also lowers its performance and the psi with which the fuel gets delivered....plus all the

This is why they made the system with two pumps...

Re: In-tank Fuel Pump Modification

You forgot something.Dvs wrote:Hey guys,

Thanks for info, i got some inspiration from this thread and i attached a picture of my primitive assembly.

And the rest...

Dvs wrote: As it seemes the top part of my gas tank is pretty rusty and it kept braking my fuelpumps...so i got fuel tank restoration kit from the Eastwood company (can't link the product atm because their website down) but will post followup on how that kit is working, meanwhile i just grabed a new pump from pepboys ( Spectra SP1067 that pushes fuel with around 2,5 - 5 psi to the inline pump, attached to this is the Carter strainer STS-9).

And now to the actual point why i am writing this: first of all i read about some people here saying that the in tank pump might be usless and that a stronger pump in the tank or under the vehicle would suffice, well the thing is that those german engieers did know what they are doing and let me tell you why, there is aso called drag coefficient that applies to liquid too, not just to aerodynamics, in other words, hypothetically speaking your pump is pushing with 10psi 10 gallons per hour on a straight pipe, which is just fine, as longer the pipe as more the pressure drops at the destination, and then here starts our problem, the fuel delivery sistem on the cars is not straight, there is formula in fizics that determins the coefficient of drag for each and evey curving that is in the fuel delivery line, this drag makes your pressure drop a lot. Don't ask me about thay formula, try googling it lol.

This is where my issue was, after my in tank pump broke (who knows when that happened...) my vehicle was just working fine until the in line broke too, which is a strong one, 90-125psi. This in line pump broke exactly because of this drag coefficient: in order for that pump to be able to deliver an avrage of 100psi to your injectors it has have that fuel delivered to its door step, because if not the pump has to do sucking and the pushing, this also lowers its performance and the psi with which the fuel gets delivered....plus all the

This is why they made the system with two pumps...

Re: In-tank Fuel Pump Modification

I'm not sure I understand the logic of the rest above... The main higher pressure pump has NO Problem with a few extra turns and length of tube if it is moved to the tank. The FPR means it runs at a lower pressure than it is capable of. And it doesn't work harder if the in tank pump is out... it might actually use less current... but it is more prone to cavitation then get hot from lack of fuel cooling and that is more likely the problem along with vapor in the fuel being delivered to the rail.

My guess is that at the time of development the main pressure pump wasn't certified or considered 'safe' for inside the fuel tank. So it was an external pump with a wimpy little 'safe' in tank lift pump. Now that there are perfectly good in tank main pump solutions it's a better system choice.

My guess is that at the time of development the main pressure pump wasn't certified or considered 'safe' for inside the fuel tank. So it was an external pump with a wimpy little 'safe' in tank lift pump. Now that there are perfectly good in tank main pump solutions it's a better system choice.

Re: In-tank Fuel Pump Modification

while the science above is true that by no means doesnt mean that the 255 cant handle an m30 or even a turbo m30 on their own. subarus only have one pump and the walbo 255 is the go to fuel pump upgrade for bigger turbos pushing 350+hp

Re: In-tank Fuel Pump Modification

does anyone consider it being a potential problem of the walbo trying to pump fluid but being restricted by having to pump through the weaker stock in line pump? anyone have a walbro with their in line still installed?

Re: In-tank Fuel Pump Modification

I think it would be a mistake to try that, you may have little to no flow and not maintain pressure and heat the fuel excessively. Generally bad idea.

Re: In-tank Fuel Pump Modification

thats currently what is on my 302 car, it hasnt really been driven far at all on the setup. im having issues with pressure at the rail, like not really any at all haha. enough to start up but then it cant keep running.

the car sat for a year while doing the swap with a full tank of gas. im thinking it spoiled the filter, ill delete the inline while im at it. other than that an the regulator I shouldn't have any problems at all.

the car sat for a year while doing the swap with a full tank of gas. im thinking it spoiled the filter, ill delete the inline while im at it. other than that an the regulator I shouldn't have any problems at all.

Re: In-tank Fuel Pump Modification

Yeah, just delete the inline; it only makes sense to yank it out when you've got a good in-tank pump. And while you're deleting that and replacing the filter, you might as well replace all of the soft fuel lines at the back of the car while you're at it.BDKawey wrote:thats currently what is on my 302 car, it hasnt really been driven far at all on the setup. im having issues with pressure at the rail, like not really any at all haha. enough to start up but then it cant keep running.

the car sat for a year while doing the swap with a full tank of gas. im thinking it spoiled the filter, ill delete the inline while im at it. other than that an the regulator I shouldn't have any problems at all.

Re: In-tank Fuel Pump Modification

You can leave the in-line in place, just bypass it.

I can't see how enough fuel can be passed through it to accommodate runability.

That probably contribites to the cause of main pump failure

after the stock in-tank pump fails,

overworking itself pulling fuel through the failed pump.

I can't see how enough fuel can be passed through it to accommodate runability.

That probably contribites to the cause of main pump failure

after the stock in-tank pump fails,

overworking itself pulling fuel through the failed pump.

Re: In-tank Fuel Pump Modification

The in tank pump is a centrifugal impeller and fuel can pass pretty easily while the main pump is probably a roller and fuel will not pass easily.

If you leave the inline in place and plumb around it be SURE to remove the lead wires or it will still run, but run dry, probably burn up and maybe blow the fuse.

If you leave the inline in place and plumb around it be SURE to remove the lead wires or it will still run, but run dry, probably burn up and maybe blow the fuse.

Re: In-tank Fuel Pump Modification

Yeah itll get ditched next week. Did everyone solder the walbo wire to the little tab at the top of the housing?

I bought a housing off someone because mine was trashed but the ground tab on the connector on the housing was snapped off and rusted and still in the pigtail he sent me too.

I was thinking wiring the positive though the connector and then i might have to drill a tiny tiny hole in the top of the housing and feed the ground right through it and silicone around the hole to make sure it sealed and not leaking.

Anyone else maybe have a better idea?

I bought a housing off someone because mine was trashed but the ground tab on the connector on the housing was snapped off and rusted and still in the pigtail he sent me too.

I was thinking wiring the positive though the connector and then i might have to drill a tiny tiny hole in the top of the housing and feed the ground right through it and silicone around the hole to make sure it sealed and not leaking.

Anyone else maybe have a better idea?

Re: In-tank Fuel Pump Modification

I soldered the positive to the connector at the top, but then used the eyelet on the ground wire to connect to something on one of the tubes using a screw. Works fine. I think I had to turn the machine screw around so the nuts were on the inside because the end of it was interfering with the assembly going into the tank.BDKawey wrote:Yeah itll get ditched next week. Did everyone solder the walbo wire to the little tab at the top of the housing?

I bought a housing off someone because mine was trashed but the ground tab on the connector on the housing was snapped off and rusted and still in the pigtail he sent me too.

I was thinking wiring the positive though the connector and then i might have to drill a tiny tiny hole in the top of the housing and feed the ground right through it and silicone around the hole to make sure it sealed and not leaking.

Anyone else maybe have a better idea?

From Page 3 of this thread:

-

maybeillbuyit

- Posts: 535

- Joined: Feb 01, 2014 12:00 PM

- Location: Vancouver BC

Re: In-tank Fuel Pump Modification

I've had the walbro 255 for about a year and I've had it with the high pitched whining. ( reminds me of myself) I guess I'll be going to the TRE. When I first put it in it was a little noisy but I figured I could live with it. Its gotten louder over the last little while especially standing on the passenger side with a 1/4 tank. Sounds awful, you can hear it 15 feet away. Anyway its on the list.

Re: In-tank Fuel Pump Modification

Thank you. Posts very helpful. I may try the TRE pump.

Does anyone remember how much it cost?

Does anyone remember how much it cost?

Re: In-tank Fuel Pump Modification

No but I bet the TRE website does.pauly wrote:Thank you. Posts very helpful. I may try the TRE pump.

Does anyone remember how much it cost?

Re: In-tank Fuel Pump Modification

About $70.cek wrote:No but I bet the TRE website does.pauly wrote:Thank you. Posts very helpful. I may try the TRE pump.

Does anyone remember how much it cost?

Re: In-tank Fuel Pump Modification

I contacted TRE. No instruction sheets are provided. The constant noise is driving me crazy. I am going the TRE route.

I am very mechanically and electrically capable. I can do the job.

Before I get into it, would you please provide me with answers to the following questions.

1. Any cutting involved.

2.Any soldering of wires involved?

Could yo provide a brief instruction sheet of each step. Does not have to be very detailed.

Thank for the excellent information on your thread.

Finally;do you live in Northern Calif?

I am very mechanically and electrically capable. I can do the job.

Before I get into it, would you please provide me with answers to the following questions.

1. Any cutting involved.

2.Any soldering of wires involved?

Could yo provide a brief instruction sheet of each step. Does not have to be very detailed.

Thank for the excellent information on your thread.

Finally;do you live in Northern Calif?

Re: In-tank Fuel Pump Modification

Would you mind posting a simple instruction sheet with steps

on what the TRE pump conversion entails?

Can you modify any brand stock pump?

I would be modifying a Bosch pump.

1985 E28

on what the TRE pump conversion entails?

Can you modify any brand stock pump?

I would be modifying a Bosch pump.

1985 E28

Re: In-tank Fuel Pump Modification

It's all in the thread.pauly wrote:Would you mind posting a simple instruction sheet with steps

on what the TRE pump conversion entails?

Can you modify any brand stock pump?

I would be modifying a Bosch pump.

1985 E28

You can purchase a modified housing.

Then all you'd need was pump, hose, and clamps.

P.S.

Don't know anything about a Bosch pump.

Hope you're not talking about the OEM main pump.

Re: In-tank Fuel Pump Modification

Oops, I did it again...

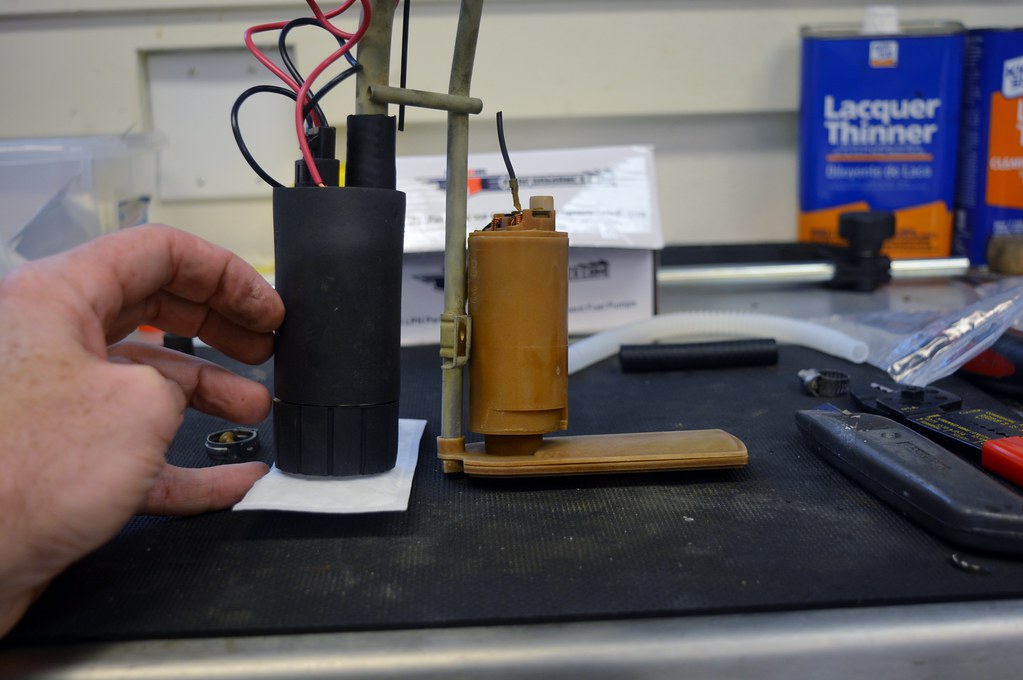

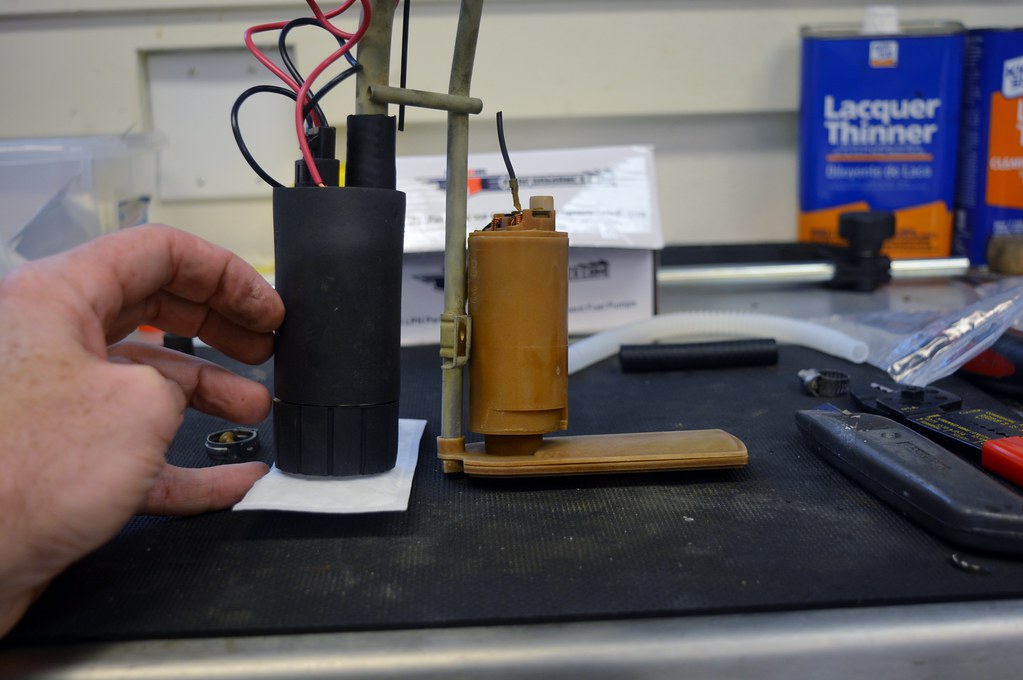

I needed to do this on my 528e (Maytag) and since this is the third time I've done one of these I figured I'd take more pictures and share additional details.

Recall, the idea here is to replace the prone-to-fail in-tank "transfer pump" with a modern, high-performance pump. By doing this you also will delete the main fuel pump that sits by the right rear wheel next to the fuel filter.

You'll need the following:

Assembly is easy.

First, take the original rubber connector that goes from the original transfer pump and cut it in half, where the smaller diameter section meets the larger diameter section.You'll use the smaller diameter piece INSIDE your 12x13 tubing to step the size down.

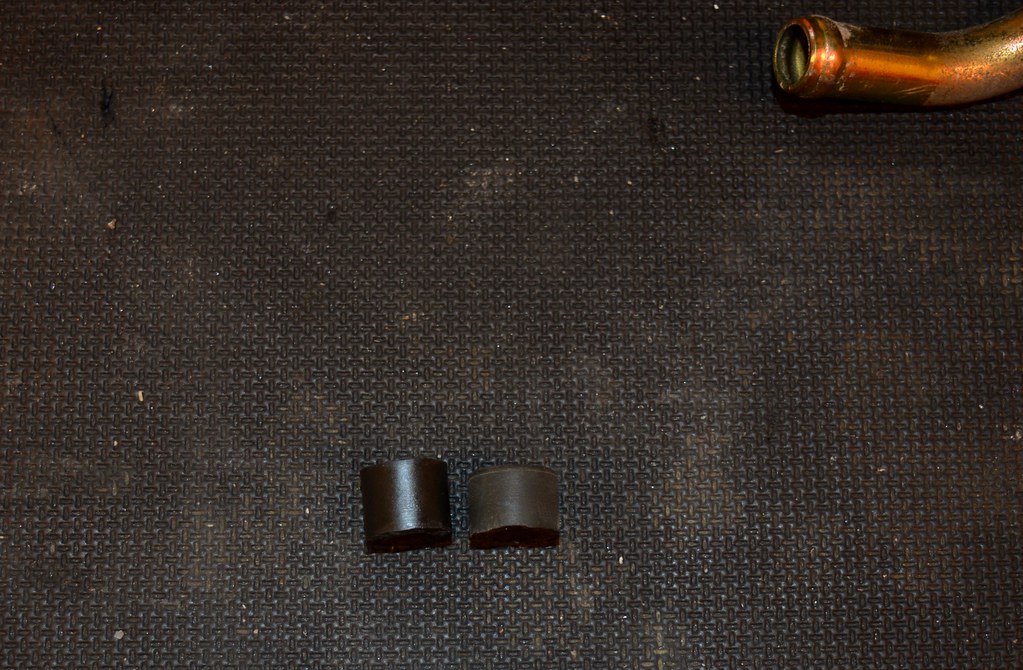

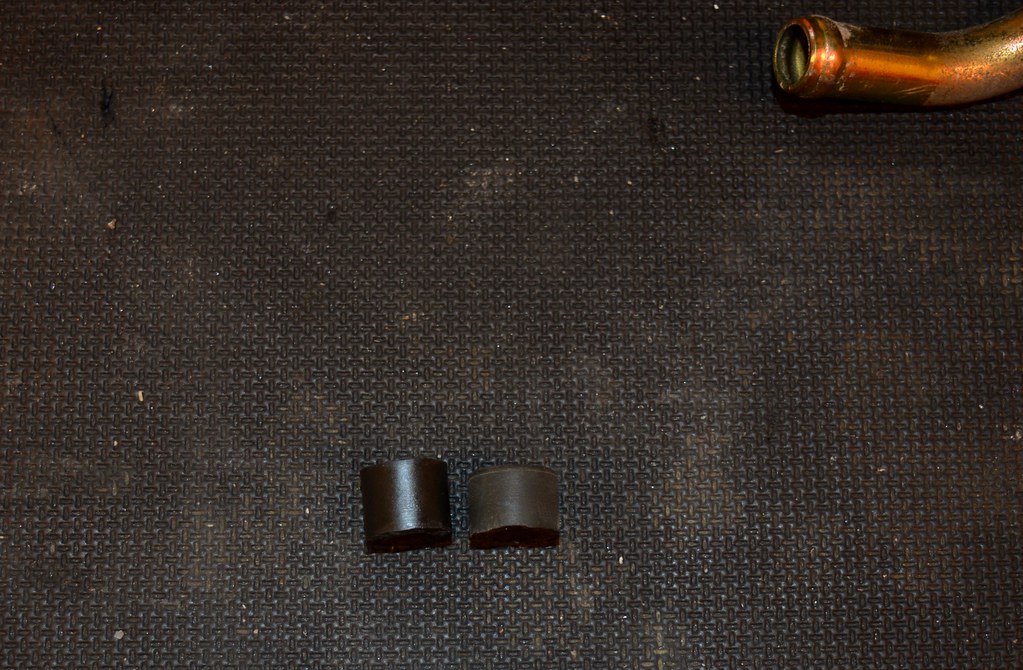

Cut the smaller section into two peices, approximately as shown:

The shorter piece will step down the connector you'll make between the new TRE pump and your hanger. The length of this piece is pretty critical because it is what will determine the overall length of your pump/hanger, enabling the little filter on the bottom of the pump to be all they way at the bottom of your tank.

Slide this over the output nipple on the TRE pump. Slide the other end over the input nipple on the hanger.

Before clamping double check the overall height. In this picture I determined my height was too tall, so I used the shorter piece of tubing you see in the picture above, making it just right.

Get out your soldering iron and de-solder the old power lead. Then cut the new lead to length and solder it in. Solder a new eye-clamp to the ground wire, after cutting to length and use the screw that was already there to affix it.

Use hose clamps (I prefer Oetiker clamps because they are much smaller and make getting the pump into the tank easier).

Make sure the filter is oriented right. Use the original pump as a guide. You want it pointing the opposite direction as the vent inlet nipple on the top of the hanger.

When installing the hanger, be VERY careful because the rubber condom that comes with the TRE pump is fragile and can easily tear.

Under the car you need to remove the original main pump, filter, and hanger assembly.

Tie off the power wires for the original pump and seal the ends up so they don't short out. They'll never be used again.

Use the other piece of tubing you salvaged from the old in-tank pump to size-reduce the 12x18 line coming from your tank to the filter.

Use a piece of 8x13 to curl around out of the filter output to the nipple for the hard-line that goes to the engine bay.

Re-hang the filter, selling the old main pump to someone who, for some strange reason doesn't want to do this awesome upgrade.

I needed to do this on my 528e (Maytag) and since this is the third time I've done one of these I figured I'd take more pictures and share additional details.

Recall, the idea here is to replace the prone-to-fail in-tank "transfer pump" with a modern, high-performance pump. By doing this you also will delete the main fuel pump that sits by the right rear wheel next to the fuel filter.

You'll need the following:

- Your original OEM in-tank fuel pump hanger assembly.

- Several feet of 12x18 BMW fuel line

- Several feet of 8x13 BMW fuel line

- Soldiering iron

- A TRE "TRE-340" 255 LPH fuel pump (~$79 shipped)

Assembly is easy.

First, take the original rubber connector that goes from the original transfer pump and cut it in half, where the smaller diameter section meets the larger diameter section.You'll use the smaller diameter piece INSIDE your 12x13 tubing to step the size down.

Cut the smaller section into two peices, approximately as shown:

The shorter piece will step down the connector you'll make between the new TRE pump and your hanger. The length of this piece is pretty critical because it is what will determine the overall length of your pump/hanger, enabling the little filter on the bottom of the pump to be all they way at the bottom of your tank.

Slide this over the output nipple on the TRE pump. Slide the other end over the input nipple on the hanger.

Before clamping double check the overall height. In this picture I determined my height was too tall, so I used the shorter piece of tubing you see in the picture above, making it just right.

Get out your soldering iron and de-solder the old power lead. Then cut the new lead to length and solder it in. Solder a new eye-clamp to the ground wire, after cutting to length and use the screw that was already there to affix it.

Use hose clamps (I prefer Oetiker clamps because they are much smaller and make getting the pump into the tank easier).

Make sure the filter is oriented right. Use the original pump as a guide. You want it pointing the opposite direction as the vent inlet nipple on the top of the hanger.

When installing the hanger, be VERY careful because the rubber condom that comes with the TRE pump is fragile and can easily tear.

Under the car you need to remove the original main pump, filter, and hanger assembly.

Tie off the power wires for the original pump and seal the ends up so they don't short out. They'll never be used again.

Use the other piece of tubing you salvaged from the old in-tank pump to size-reduce the 12x18 line coming from your tank to the filter.

Use a piece of 8x13 to curl around out of the filter output to the nipple for the hard-line that goes to the engine bay.

Re-hang the filter, selling the old main pump to someone who, for some strange reason doesn't want to do this awesome upgrade.

Re: In-tank Fuel Pump Modification

good work, hopefully that will be the last thing that needs to be said now that its presented nice and clear.

anyone questioning the integrity of the fuel pump should just go ahead and do this. single pump is the way to go and isnt even that hard to get in and out. whole project could be done in as little as 30 minutes. especially when you've done it 3 times

i have the walbro, ordered it from catuned. doesnt come with a nice condom like the tre but whatever, its loud but i like it. lets me know its working. my car is gutted anyway

anyone questioning the integrity of the fuel pump should just go ahead and do this. single pump is the way to go and isnt even that hard to get in and out. whole project could be done in as little as 30 minutes. especially when you've done it 3 times

i have the walbro, ordered it from catuned. doesnt come with a nice condom like the tre but whatever, its loud but i like it. lets me know its working. my car is gutted anyway

Re: In-tank Fuel Pump Modification

How old is the oldest pump you have that is TRE and is it loud? I have replaced my external with a new one last year and my internal with Intrex (the cheap versa version) but internal one is making a lot of noise again and getting tired of it. I like the idea of one pump and am interested in this conversion.cek wrote:Oops, I did it again...

I needed to do this on my 528e (Maytag) and since this is the third time I've done one of these I figured I'd take more pictures and share additional details.

Recall, the idea here is to replace the prone-to-fail in-tank "transfer pump" with a modern, high-performance pump. By doing this you also will delete the main fuel pump that sits by the right rear wheel next to the fuel filter.

You'll need the following:

- Your original OEM in-tank fuel pump hanger assembly.

- Several feet of 12x18 BMW fuel line

- Several feet of 8x13 BMW fuel line

- Soldiering iron

- A TRE "TRE-340" 255 LPH fuel pump (~$79 shipped)