Page 5 of 6

Posted: Oct 08, 2012 10:11 AM

by jamesohoh7

1st 5er wrote:jakeb wrote:

That's a lot of wires....

I think I'd rather have a tooth pulled.

pulled then surgically re-implanted upside down ... would STILL be less painful!

Posted: Oct 08, 2012 10:13 AM

by jakeb

haha, why do people hate wiring so much? It's really NOT that scary. Once you spend hours upon hours of reading and looking at schematics.

Posted: Oct 08, 2012 10:40 AM

by Brad D.

jakeb wrote:haha, why do people hate wiring so much? It's really NOT that scary. Once you spend hours upon hours of reading and looking at schematics.

I'm the same way. I don't really get the general fear of wiring that so many have. Dare I say I actually enjoy wiring.

Posted: Oct 08, 2012 5:45 PM

by jakeb

Little bit by little bit....

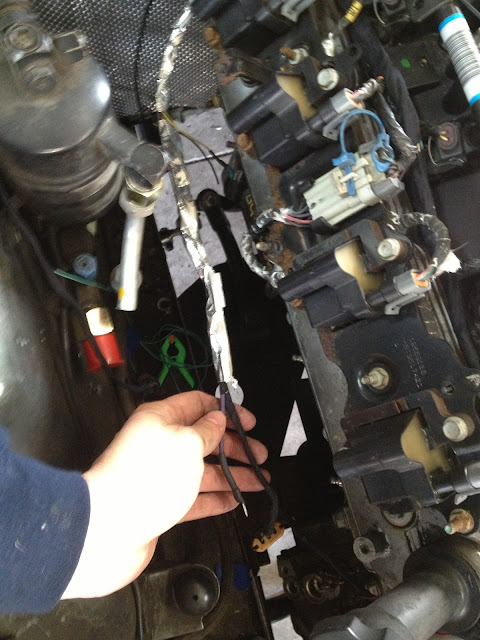

Wires going to the crank sensor, starter solenoid, and gauge temp sensor. Wraped in heat tape as they are all pretty close to the exhaust. That is how GM does it as well so...

New harness tied into the e12 fuse box. These wires will get wrapped.

AC pressure fitting that needs to be brazed together

A couple other things done but no pictures...or really pictures required.

Negative cable to block/battery

fuel line connected

Posted: Oct 09, 2012 8:28 AM

by tn535i

jakeb wrote:

sound deadening on the firewall

covered with some heat reflection stuff

Been watching this and have a question about the sound deadening and heat reflection material. What have you used here. Looks good and might consider on our e30 project. That rubbery piece of stuff from our cars wasn't worth trying to re-install.

Posted: Oct 09, 2012 8:30 AM

by jakeb

It is two different products. First a stick on sound deadening type material. Dynamat style...lots of different brands out there.

Then the heat reflection stuff I use is DEI Floor and tunnel shield. I get it from summit racing.

Posted: Oct 09, 2012 12:31 PM

by jamesohoh7

Brad D. wrote:jakeb wrote:haha, why do people hate wiring so much? It's really NOT that scary. Once you spend hours upon hours of reading and looking at schematics.

I'm the same way. I don't really get the general fear of wiring that so many have. Dare I say I actually enjoy wiring.

Once you let the smoke out of the wires, it's really hard to get it back in is all...

Posted: Oct 09, 2012 11:14 PM

by jakeb

Plugged the PCM in about 30 minutes ago and powered it all up. PCM primed the fuel pump and is working. Did a read entire with HP tuners so I can pull out VATS and other unneeded things. VATS is like EWS in the BMW world.

I did have one issue with how the unloader relay works...when I turned the key to on (not crank) the engine started cranking. I used a start relay because that is how GM does it and the fuse/relay panel I got came wired that way. I will just have to run a wire direct to the starter solenoid the way BMW wants it. Easy fix....

e12 with an OBDII Port connected to a laptop.......

Posted: Oct 10, 2012 8:40 AM

by tn535i

Since the key 'run' position sends power to the unloader relay coil it gets immediately energized but only de-energized when you apply power to the starter solenoid since the unloader coil is actually grounded through the starter coil. So the unloader 'unloads' when you apply power to the starter coil. If you put the GM start relay in that position it probably gets enough power from the current passing through the unloader relay coil to energize the GM relay. You probably already figured that out.

You will have to split out the BMW unloader relay and take it to the coil energize output of the GM relay to get the unloader to work as intended I think. Then apply the start signal to the GM start relay. A separate wire from the BMW start may still be tied into the unloader in the harness. If you just run a separate wire to the GM relay you would have the same problem. If you lift the start altogether from a grounded termination then the unloader relay will never energize. Or will you just eliminate the GM relay?

Hope I said that right. You probably know this anyway.

Anxious to see this going and following your progress.

Posted: Oct 10, 2012 8:44 AM

by jakeb

I plan to just run the start wire direct to the starter like BMW wants it. Then the unloader will get ground when not in cranking mode. I checked the start pin on my e28 with the c101 unplugged and I was also seeing 12v so it is the same as the e12.

Posted: Oct 11, 2012 8:04 PM

by jakeb

Intake setup is made...the filter might need to change to something a little smaller...not sure if the hood will close. But it will work for now.

Posted: Oct 13, 2012 12:21 PM

by jakeb

It's running!!

I can never remember how to flip the iphone to get the right orientation for youtube....

Either way here are a couple videos. I will get some better ones eventually.

The little light in the engine bay is a oil pressure light. You can hear it quiet down once the light goes off.

This is the first start

http://www.youtube.com/watch?v=39tCSraGwUE&feature=plcp

A little blip...you can hear a slightly choppy idle from the cam.

http://www.youtube.com/watch?v=tv6A3z0JotU&feature=plcp

Posted: Oct 14, 2012 4:20 PM

by 1st 5er

That makes it all worth it.

Congrats.

Posted: Oct 14, 2012 10:08 PM

by Mark 88/M5 Houston

Great sounding E12 there sir!

Posted: Oct 15, 2012 6:06 PM

by jakeb

thanks guys, glad it is running! After a little research it looks like the pushrods are a little short. So I have a set of 7.450 on order. The ones in it now are 7.400. That should add a bit more preload on the lifters and quiet down the valve train some.

Worked on the AC lines today.

These are the crimped low side to compressor (short line) and high side from compressor to condenser.

In the tool and pre crimp

post crimp

Entire crimping tool/setup

Heater hoses also done...AC lines feeding up to the drier (not connected yet) and the low side to the evap.

Bad picture...but where it goes up front..

Other side before it goes to the condenser.

Hooking to the condenser

Posted: Oct 18, 2012 8:28 PM

by jakeb

Master cylinder is back on....getting those lines all hooked up was a BITCH. Mostly the ones on the bottom. Hard to push up and turn at the same time.

Either way it is hooked up......#5 coil will have to be relocated a little to clear the reservoir.

Upper radiator hose and efan. I looked for a single hose but couldn't find anything to do what I wanted/needed. So two hoses with a coupler will work. efan is a 16" puller...high and low speed controlled by the GM PCM.

As luck would have it the lower hose worked out being the left over piece/bend from the upper hose hooked to the radiator.

alternator/belt/etc are all on

Posted: Oct 19, 2012 7:53 PM

by jakeb

Posted: Oct 23, 2012 11:24 AM

by jakeb

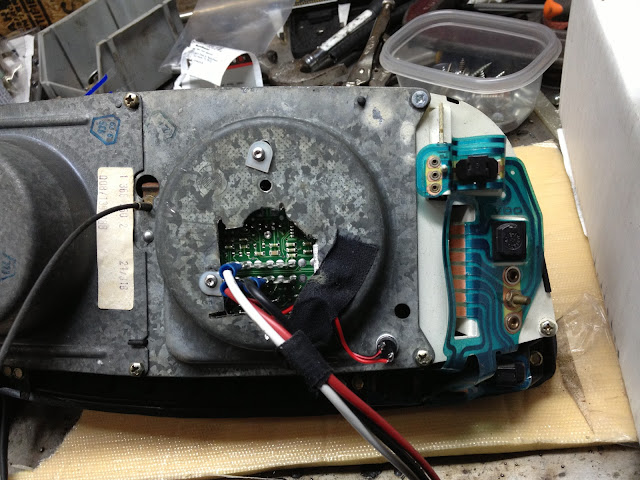

So the e12 has a mechanical speedo.... The t56 does not have a speedo drive but it does have a VSS sensor and the PCM has a VSS output.

So....electric speedo conversion.

Electric VDO Speedo glued to the old metal face.

New face on the left...to be glued to the gauge on the right. The stock e12 needle will get pushed on.

Glued on...the bottom little white bit with get trimmed off. I just needed something to hold onto while it was being glued

Will reassemble into the gauge cluster later today.

Posted: Oct 23, 2012 12:08 PM

by Jelmer538i

Nice speedo! I like it when people think about things like this!

Posted: Oct 23, 2012 8:32 PM

by jakeb

Speedo is done...

I was going to mount the odometer/trip button in the under column panel but then I noticed how the odometer reset worked for the mechanical speedo.

Add a button..

All put together

In the car

How it all works..... I think it came out pretty stock looking.

http://www.youtube.com/watch?v=g-d8tOvXeekl

Posted: Oct 28, 2012 9:11 PM

by jakeb

E12 came off the lift today and made a small loop around the block. The sway bar mounts are not fully welded so I didn't want to drive all that much.

Things are coming together....a couple small things that need to be tended too. Exhaust leak from one of the couplers, alternator not charging....

Back on the ground and in the day light...

Quick walk around video

http://www.youtube.com/watch?v=BqNou_hcY3g

Posted: Nov 06, 2012 12:25 PM

by unt0uchable

That's awesome. I hope I get to see this when I come up for the mini "tankfes". It's looking awesome, as always.

Posted: Nov 06, 2012 2:25 PM

by Adam W in MN

This thread is fantastic, glad I discovered it because Steve didn't tell me he was embarking on this V8 E12 quest! Now I know so I can hit him up for a ride when it's all done.

Posted: Nov 10, 2012 7:46 PM

by jakeb

I have been fixing a couple small things the past couple weeks. Small exhaust leaks, oxygen sensor not giving a reading (bad connector not allowing the heater to work), etc

Here is the bad O2 sensor connector. It was pushing the mating connector out and not allowing them to plug together.

Because of the lack of room I wasn't able to use a flange to keep the pipes together so I had to use band clamps. They were not sealing...mostly because I wasn't cranking them down enough. 70-80ft lbs and now they are sealing.

Leaks are sealed up...got it aligned today. And now on to doing some adjustments to the tune. The PCM is from a 2002 camaro but then I blind adjusted it somewhat and it needs more fueling from what I have logged so far. The PCM will pull it back with the O2 sensors to stoich but it is much better to have the tune very close and not need the PCM to adjust so much.

A couple pictures of the just about finished engine bay. Still need to swap the AC drier, fill the AC, and put the strut tower brace back on.

Posted: Nov 10, 2012 10:17 PM

by pleasefixitup

you do great work.