Moar direction of rotation is always gooder.George wrote:Yes, 2 directions of rotations.

I weld

Re: I weld

Re: I weld

I guess 2 independent axes of rotation is a better description but you get the point. It's great for small automotive fabrication projects.

Re: I weld

I'm technically a professional and your setup is soooo much better than mine.

Re: I weld

You should see his underwear drawer.bkbimmer wrote:I'm technically a professional and your setup is soooo much better than mine.

-

EventuallyAyrton

- Posts: 975

- Joined: Oct 12, 2015 11:47 PM

- Location: Wherever the E28 happens to be parked- Morrisville, NY

Re: I weld

Because it's fun to strike an arc and lay down an insane amount of material. It's frustrating when you start but once you get used to it, it's quite enjoyable. Ever tried to TIG weld a building together? No fun at allGeorge wrote: Ya know, I've been welding for almost 15 years now. About half of that time I did it as a profession and I still have no idea how to stick weld. Nor am I sure why stick welding would be preferable to TIG. Can you enlighten me?

Re: I weld

as a professional, would you say it's better than yours?oldskool wrote:You should see his underwear drawer.bkbimmer wrote:I'm technically a professional and your setup is soooo much better than mine.

Re: I weld

Wouldn't MIGing be preferable for something like that? Or is it more reserved for really thick materials?EventuallyAyrton wrote:Because it's fun to strike an arc and lay down an insane amount of material. It's frustrating when you start but once you get used to it, it's quite enjoyable. Ever tried to TIG weld a building together? No fun at allGeorge wrote: Ya know, I've been welding for almost 15 years now. About half of that time I did it as a profession and I still have no idea how to stick weld. Nor am I sure why stick welding would be preferable to TIG. Can you enlighten me?

99% of my welding is/has been automotive fabrication related so no buildings...

This has probably been the largest things I've ever welded and it went together fine with a MIG:

Re: I weld

Da fuq? Is that art? (I guess it must be, if I have to ask).George wrote:

Re: I weld

lol. art.

crossfit workout rig.

crossfit workout rig.

-

EventuallyAyrton

- Posts: 975

- Joined: Oct 12, 2015 11:47 PM

- Location: Wherever the E28 happens to be parked- Morrisville, NY

Re: I weld

MIG is fine but it's the easiest, the "weakest", and the most boring (in my opinion). You're not at all involved in the process, you just pull the trigger and it does everything for youGeorge wrote:Wouldn't MIGing be preferable for something like that? Or is it more reserved for really thick materials?EventuallyAyrton wrote:Because it's fun to strike an arc and lay down an insane amount of material. It's frustrating when you start but once you get used to it, it's quite enjoyable. Ever tried to TIG weld a building together? No fun at allGeorge wrote: Ya know, I've been welding for almost 15 years now. About half of that time I did it as a profession and I still have no idea how to stick weld. Nor am I sure why stick welding would be preferable to TIG. Can you enlighten me?

99% of my welding is/has been automotive fabrication related so no buildings...

This has probably been the largest things I've ever welded and it went together fine with a MIG

Re: I weld

Opinions are funny things.

Re: I weld

Funny things have opinions.bkbimmer wrote:Opinions are funny things.

Funny, things have opinions.

Funny things; have opinions.

Funny. Things. Have opinions.

Re: I weld

I've done some construction type stick welding. Stick smokes like a forest fire.

When you are outdoors its not a problem but for shop type welding its going to taste guacala.

When you are outdoors its not a problem but for shop type welding its going to taste guacala.

Re: I weld

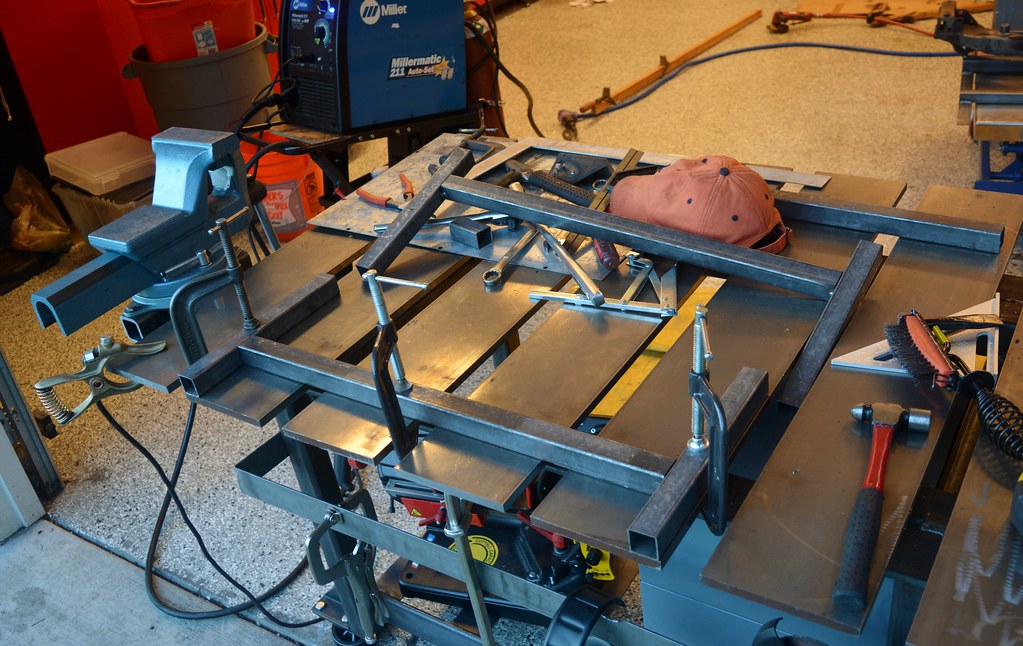

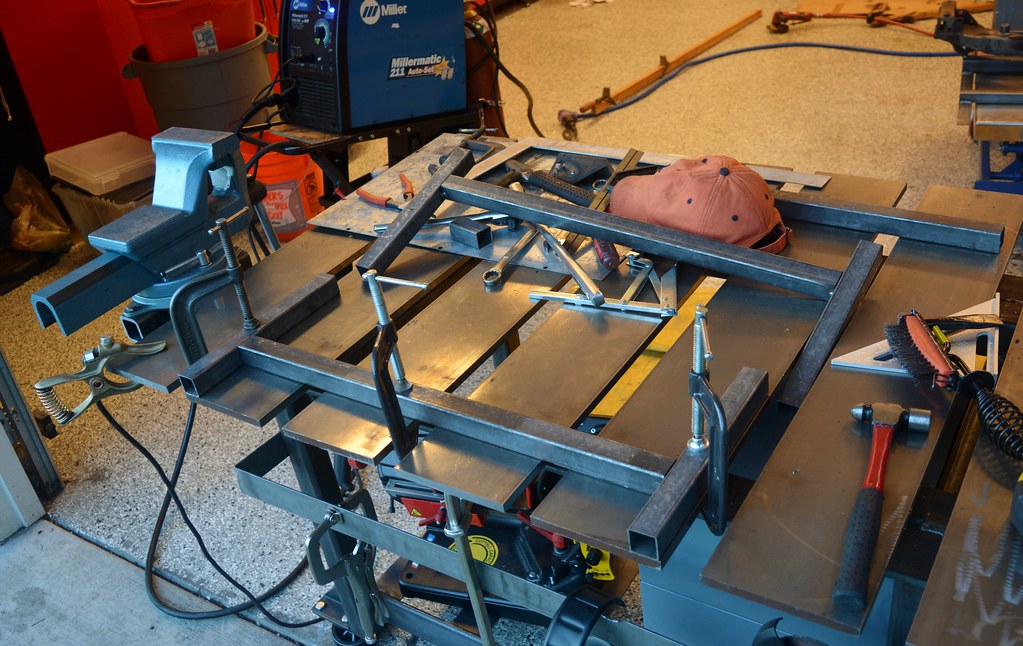

I've been thinking about this ever since I first dropped the M30B34 out of the bottom of Vlad on the 4-post lift.

It didn't work very well. I almost died.

When I found my Vestil 800lbs lift cart on Craigslist I immediately visualized the solution: A cradle/cart that the lift cart can hoist up and down.

Today I (mostly) completed it.

The idea is to remove the steering/suspension stuff and attach this thing to the sub-frame. When it's done there will be a support for the front of the oil pan (I'm thinking of something adjustable so M20/M30/S54 will all work; that front cross bar lines up directly under the flywheel on an M30). There will also be a support sticking off the rear to support the back of the engine & transmission; again, something adjustable.

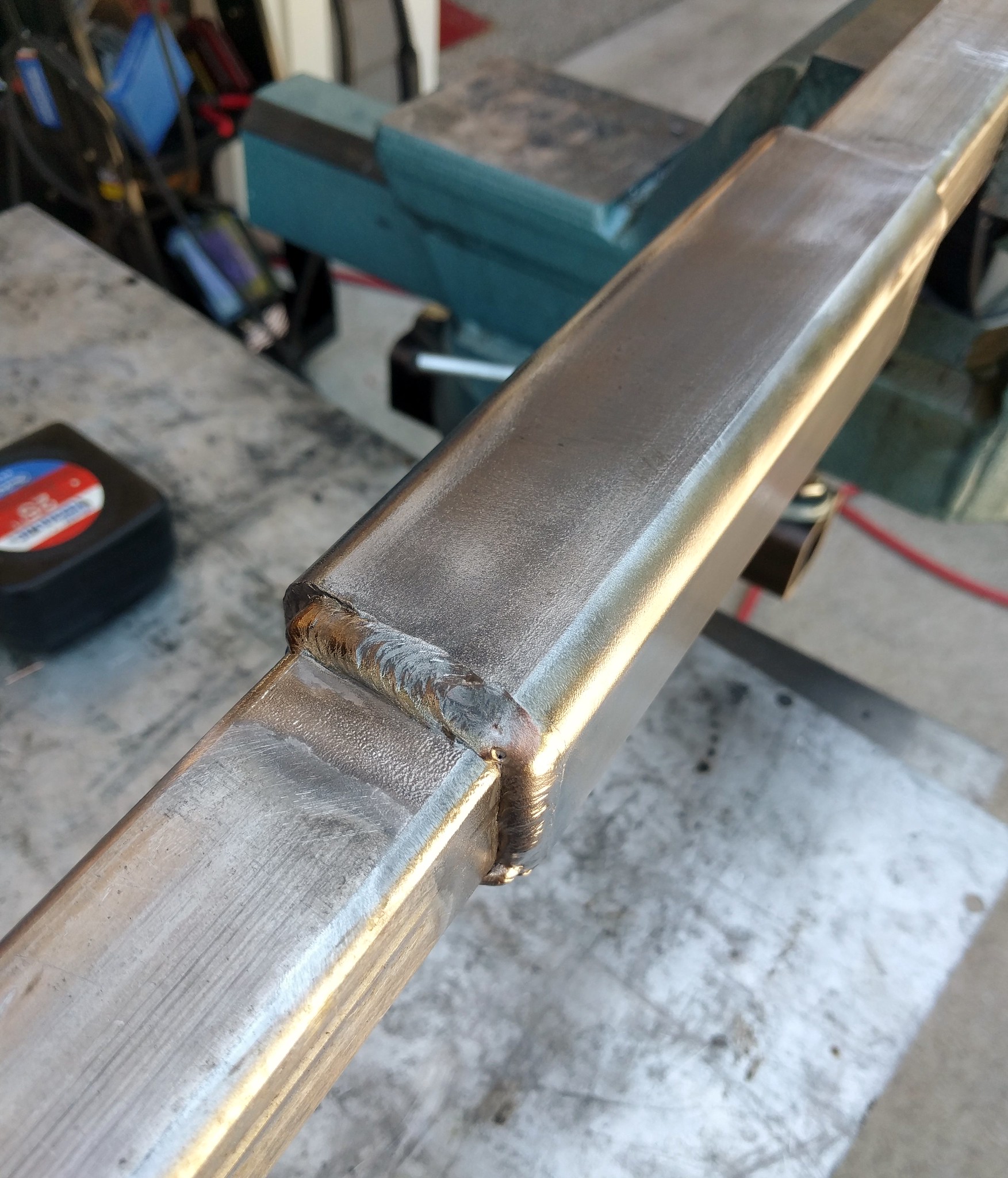

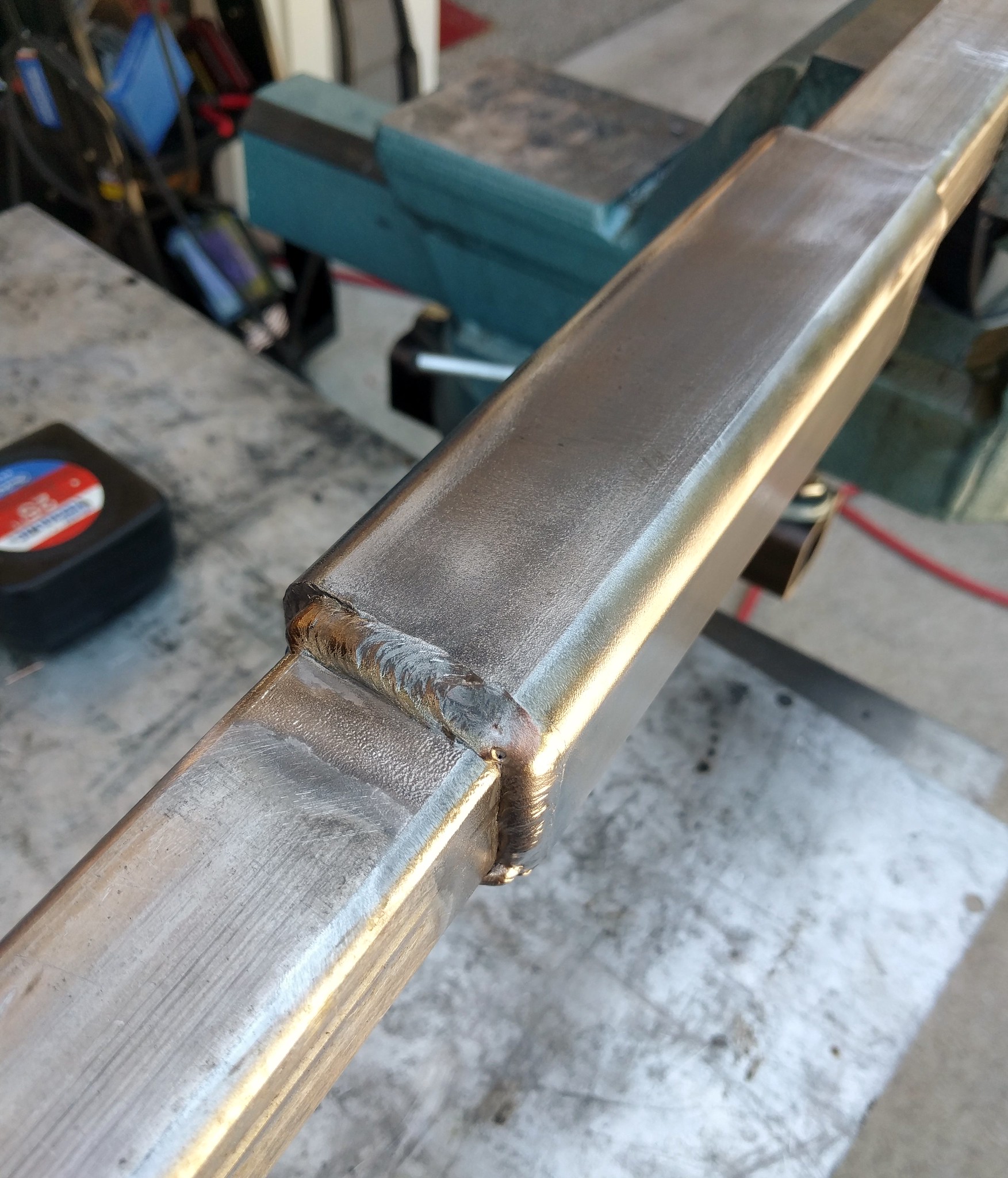

I had a beat up set of LCAs lying around and cut them to make a positive-connection to the sub-frame. Originally, my idea was to just have the cradle be a cradle. I like this better. I also like this weld:

Made good use of my welding table!

I haven't bought the casters so you'l have to use your imagination for how it touches the floor when the lift cart is at its lowest.

Yes, this will only work with E28s. But if I ever need to use it on something else, I can easily modify it...Because I now can fu*king weld!

It didn't work very well. I almost died.

When I found my Vestil 800lbs lift cart on Craigslist I immediately visualized the solution: A cradle/cart that the lift cart can hoist up and down.

Today I (mostly) completed it.

The idea is to remove the steering/suspension stuff and attach this thing to the sub-frame. When it's done there will be a support for the front of the oil pan (I'm thinking of something adjustable so M20/M30/S54 will all work; that front cross bar lines up directly under the flywheel on an M30). There will also be a support sticking off the rear to support the back of the engine & transmission; again, something adjustable.

I had a beat up set of LCAs lying around and cut them to make a positive-connection to the sub-frame. Originally, my idea was to just have the cradle be a cradle. I like this better. I also like this weld:

Made good use of my welding table!

I haven't bought the casters so you'l have to use your imagination for how it touches the floor when the lift cart is at its lowest.

Yes, this will only work with E28s. But if I ever need to use it on something else, I can easily modify it...Because I now can fu*king weld!

Re: I weld

Mine is way better.

-

Das_Prachtstrasse

- Posts: 5616

- Joined: Sep 10, 2006 7:06 AM

- Location: Melbourne, Doooown Under

Re: I weld

Now THAT is a work of art.bkbimmer wrote:Mine is way better.

Re: I weld

Being poor helps hone your creative side.Das_Prachtstrasse wrote:Now THAT is a work of art.bkbimmer wrote:Mine is way better.

Re: I weld

First time capping square tubes.

Welding nuts in place has become second nature. My grinding skills need work.

Other than the adjustable supports from front of engine/tranny, which won't go on until I have an actual test subject, and maybe paint, she's done.

Video of the contraption in action: https://www.instagram.com/p/BQ_2BJ2jI7r/?taken-by=cekzy

Welding nuts in place has become second nature. My grinding skills need work.

Other than the adjustable supports from front of engine/tranny, which won't go on until I have an actual test subject, and maybe paint, she's done.

Video of the contraption in action: https://www.instagram.com/p/BQ_2BJ2jI7r/?taken-by=cekzy

Re: I weld

The outdoor range I shoot at no longer provides target stands.

I could have done what everyone else does and use wood or PVC pipe. Nah.

Made with some 1x2" 14ga angle iron left over from the 3-drawer cabinet I bought for the welding table. I had to make the vertical post holders by welding together 5" lengths of the angle iron to make a 1x2" square tube. Total serendipity that I had this stuff laying around.

Also, i realized I never posted the welding table with the drawers I added...

I could have done what everyone else does and use wood or PVC pipe. Nah.

Made with some 1x2" 14ga angle iron left over from the 3-drawer cabinet I bought for the welding table. I had to make the vertical post holders by welding together 5" lengths of the angle iron to make a 1x2" square tube. Total serendipity that I had this stuff laying around.

Also, i realized I never posted the welding table with the drawers I added...

Re: I weld

I can't put my finger on it but that table is missing something.

Re: I weld

Now I plasma cut.

Via weldingweb.com I learnt that the Hypertherm Powermax45 is da bomb. So for the last 6 months I've been looking for one to come up used on CL or something. Last week on a local gun nut forum one was posted for sail at a killer price. Picked it up this morning.

OH MY GOD. Using a plasma cutter is SO MUCH FUN. That's 1/2" plate up top. Went through it like a warm knife through butter.

Via weldingweb.com I learnt that the Hypertherm Powermax45 is da bomb. So for the last 6 months I've been looking for one to come up used on CL or something. Last week on a local gun nut forum one was posted for sail at a killer price. Picked it up this morning.

OH MY GOD. Using a plasma cutter is SO MUCH FUN. That's 1/2" plate up top. Went through it like a warm knife through butter.

Re: I weld

Nice! I have a powermax 30 that's accumulated thousands of cuts over the last 10 years. Its been an incredible useful and reliable tool.

Re: I weld

Hub seized on the seadoo trailer. Wheel came off. Thankfully it fell inward and didn't fly all the way off.

New axle came, but is too short. Thought I measured 54" but the original was longer.

Fixed:

New axle came, but is too short. Thought I measured 54" but the original was longer.

Fixed:

Last edited by tig on Jul 29, 2017 8:39 PM, edited 1 time in total.

Re: I weld

I want to see the wakeboard that requires its own special trailer.

Re: I weld

Brain fade. Fixed.Karl Grau wrote:I want to see the wakeboard that requires its own special trailer.