Re: 1985 Arktisblau M535i Renovation - Progression

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

To expand on that, while I'm no expert on Continental or any modern HU, I can't imagine that whomever makes these made them with any significant change regarding their internal circuitry. Meaning, that while my experience was with the bottom model, I believe that by adding a CD player and BT would not necessarily change the audio EQ in the output nor radio; they only thing it adds are the chips or programming for those two extra devices/inputs. So while you have additional interfaces and sources in their higher decks, it doesn't mean it sounds any better or is capable of higher quality sound.

My opinion only, could be wrong.

My opinion only, could be wrong.

Last edited by vinceg101 on Mar 27, 2023 9:21 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Some more...

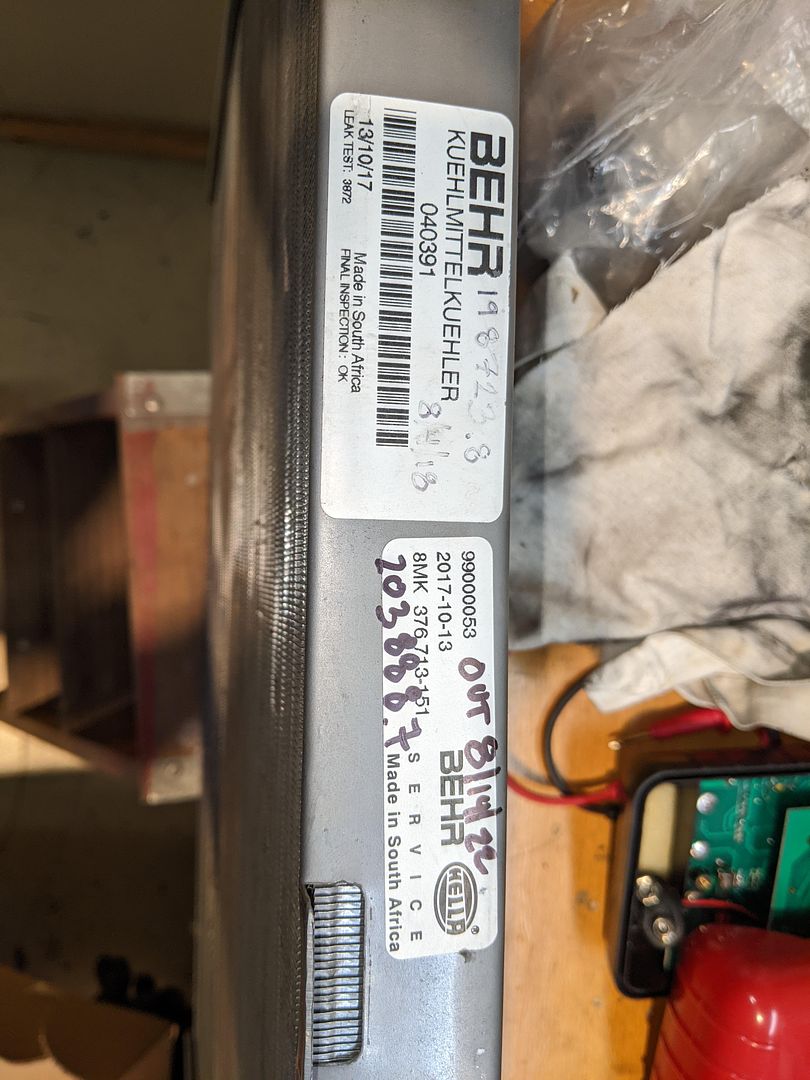

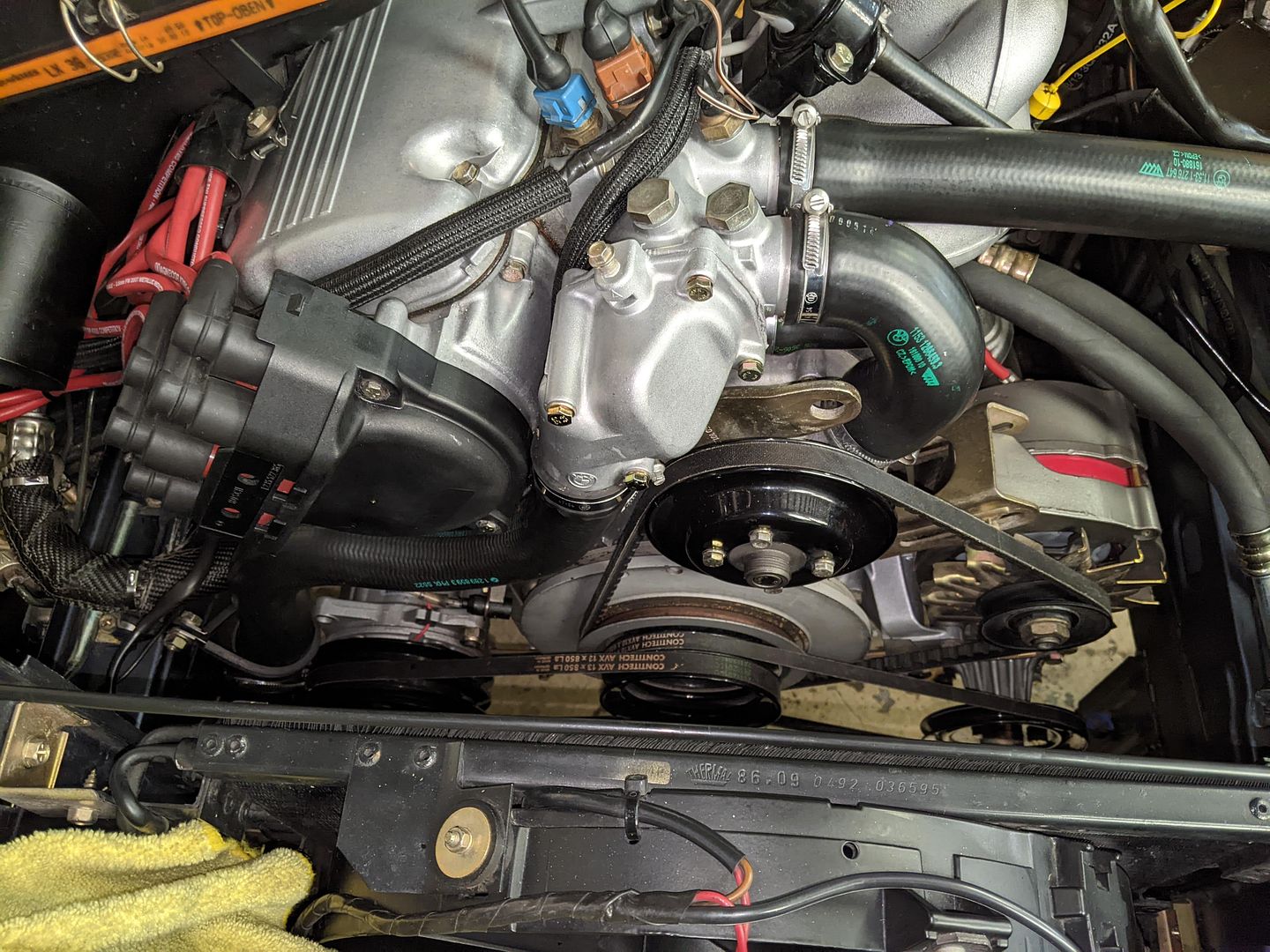

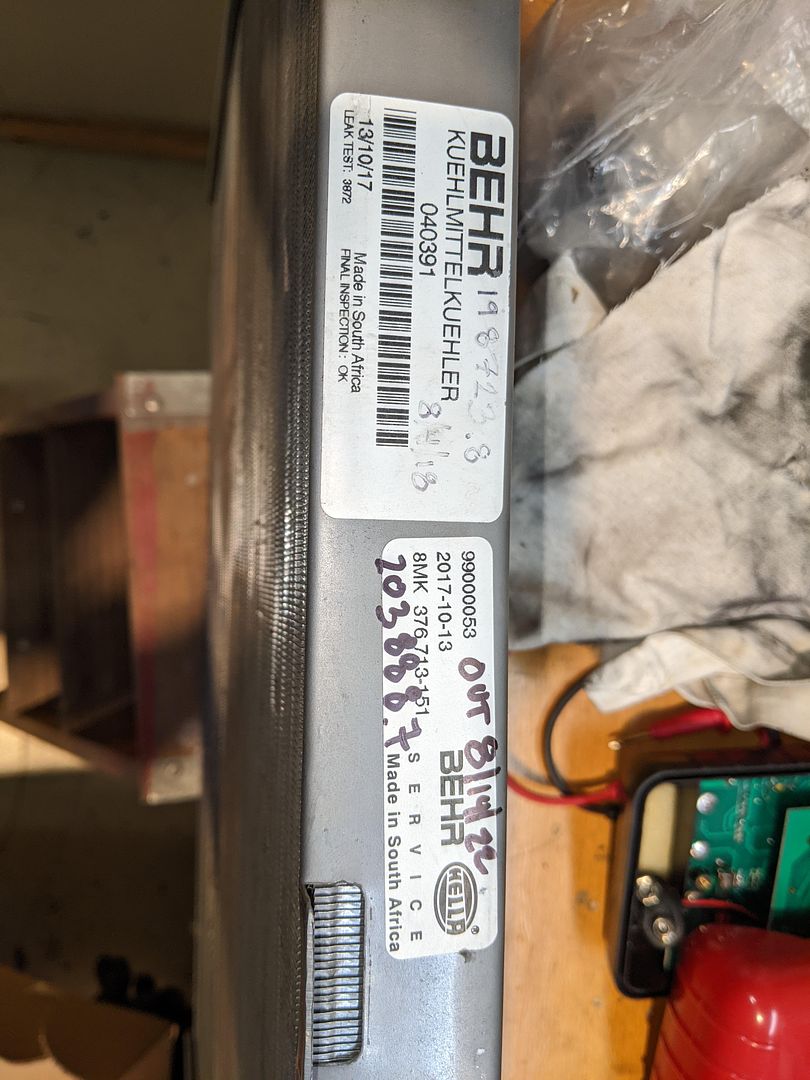

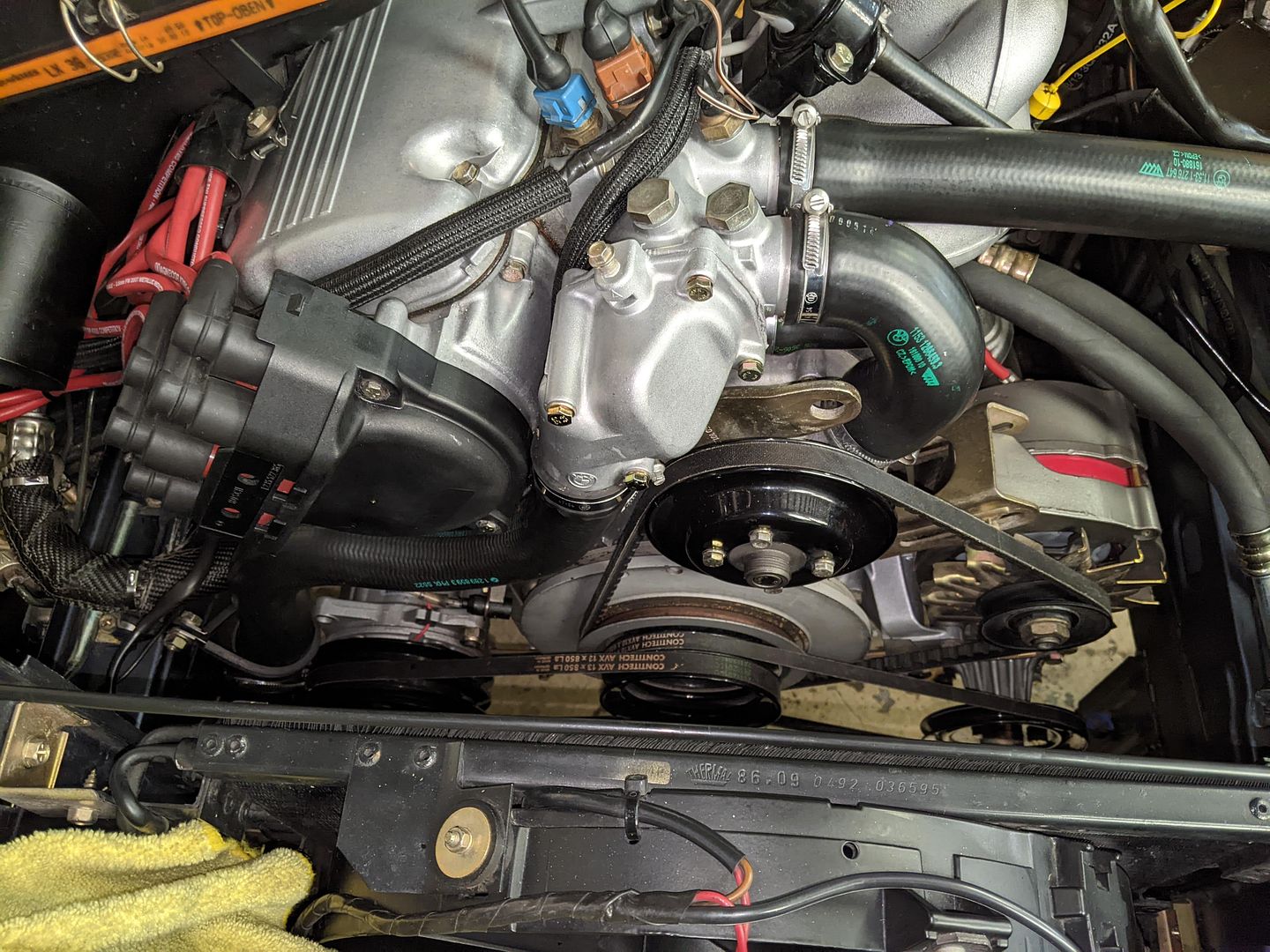

Cooling System:

This is was a carryover from the big project and the troubleshooting items then. I had been having issues with erratic and higher than ‘normal’ (normal from this cars’ past performance) mostly under strain and load. If you look through my threads in the past you will find the issues I had with South African Behr Radiator replacements and their failures (new out of the box). Turns out the SA Behrs underwent an internal design change in their cooling tubes and chambers that results in weaker performance. For the longest time, the SA Behr’s were superior to Nissens but not anymore. (Oddly, the OEM BMW unit, also made by Behr but under the older designs, still are superior but at a premium cost.)

I also decided to revert back to the colder Thermostat; this may result in slightly poorer fuel economy but it’s a favorable trade-off in my mind since I don’t drive this car that often (not that it got great MPG before). I replaced both and am holding new sensors in reserve to see if they need to get replaced also, but so far not necessary.

The good news is that during that drive in September in the 100’s over prolonged driving, the engine temps were right at 3/8’-1/2 and rock steady even going up grades.

Door Latch Adjustments:

I replaced all the Door Strikes (the ones on the body) during the Interior project with new ones. I was originally going to just replate them (which I ended up doing anyway) but it was actually cheaper just to buy new ones. I replaced them but could never get the final adjustments done in order to completely cinch the doors closed. It is a frustrating process of back and forth, micro adjustments; the solution is kind of counterintuitive that in end, by my own humble & embarrassing admittance, was accomplished by someone else (thank you wkohler; he schooled me and did it in under 5 minutes ).

).

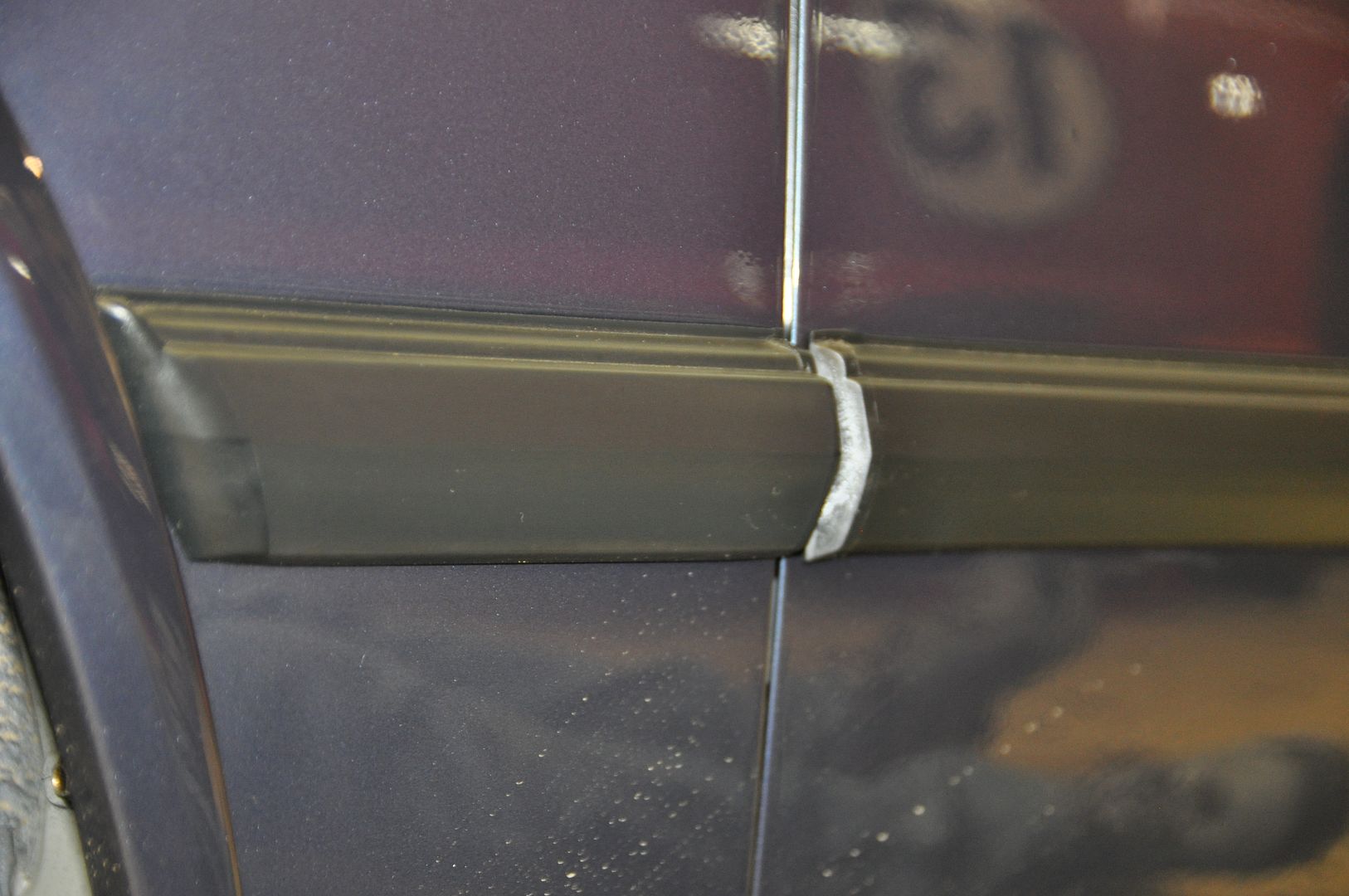

Body Repairs: Lower Rockers:

Okay, so this doesn’t really have any documentation to go with this but it was a major deal that needed to happen. Going all the way back to the Exterior Body Work section of the Front End Overhaul portion of this thread, you will remember that when I removed the M-Tech Side Skirts I discovered rust and rot at the rear jack points and Lower Rocker Panels. Due to timing with Doug’s shop and his schedule back in 2021, I opted to wait to tackle these later. Last July was later. In short he cut out of the cancerous sections and spliced in grafts I got from a donor car years ago. Then he repainted the Lower Rockers and pretty sure he did the whole Side Skirts also. (Which reminds me I have to install the double-stick tape on these for a complete installation. I am kind of waiting to execute another ‘upgrade’ project which repairing/replacing the forward frame rails damaged by careless jacking).

Here are the offending 'before' photos (sorry no 'after' at the moment as I would have to remove the Side Skirts to expose it all). Suffice it say, it's all been repaired and re-painted now:

Cooling System:

This is was a carryover from the big project and the troubleshooting items then. I had been having issues with erratic and higher than ‘normal’ (normal from this cars’ past performance) mostly under strain and load. If you look through my threads in the past you will find the issues I had with South African Behr Radiator replacements and their failures (new out of the box). Turns out the SA Behrs underwent an internal design change in their cooling tubes and chambers that results in weaker performance. For the longest time, the SA Behr’s were superior to Nissens but not anymore. (Oddly, the OEM BMW unit, also made by Behr but under the older designs, still are superior but at a premium cost.)

I also decided to revert back to the colder Thermostat; this may result in slightly poorer fuel economy but it’s a favorable trade-off in my mind since I don’t drive this car that often (not that it got great MPG before). I replaced both and am holding new sensors in reserve to see if they need to get replaced also, but so far not necessary.

The good news is that during that drive in September in the 100’s over prolonged driving, the engine temps were right at 3/8’-1/2 and rock steady even going up grades.

Door Latch Adjustments:

I replaced all the Door Strikes (the ones on the body) during the Interior project with new ones. I was originally going to just replate them (which I ended up doing anyway) but it was actually cheaper just to buy new ones. I replaced them but could never get the final adjustments done in order to completely cinch the doors closed. It is a frustrating process of back and forth, micro adjustments; the solution is kind of counterintuitive that in end, by my own humble & embarrassing admittance, was accomplished by someone else (thank you wkohler; he schooled me and did it in under 5 minutes

Body Repairs: Lower Rockers:

Okay, so this doesn’t really have any documentation to go with this but it was a major deal that needed to happen. Going all the way back to the Exterior Body Work section of the Front End Overhaul portion of this thread, you will remember that when I removed the M-Tech Side Skirts I discovered rust and rot at the rear jack points and Lower Rocker Panels. Due to timing with Doug’s shop and his schedule back in 2021, I opted to wait to tackle these later. Last July was later. In short he cut out of the cancerous sections and spliced in grafts I got from a donor car years ago. Then he repainted the Lower Rockers and pretty sure he did the whole Side Skirts also. (Which reminds me I have to install the double-stick tape on these for a complete installation. I am kind of waiting to execute another ‘upgrade’ project which repairing/replacing the forward frame rails damaged by careless jacking).

Here are the offending 'before' photos (sorry no 'after' at the moment as I would have to remove the Side Skirts to expose it all). Suffice it say, it's all been repaired and re-painted now:

Last edited by vinceg101 on Mar 27, 2023 9:07 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Next Chapter Done

Next...

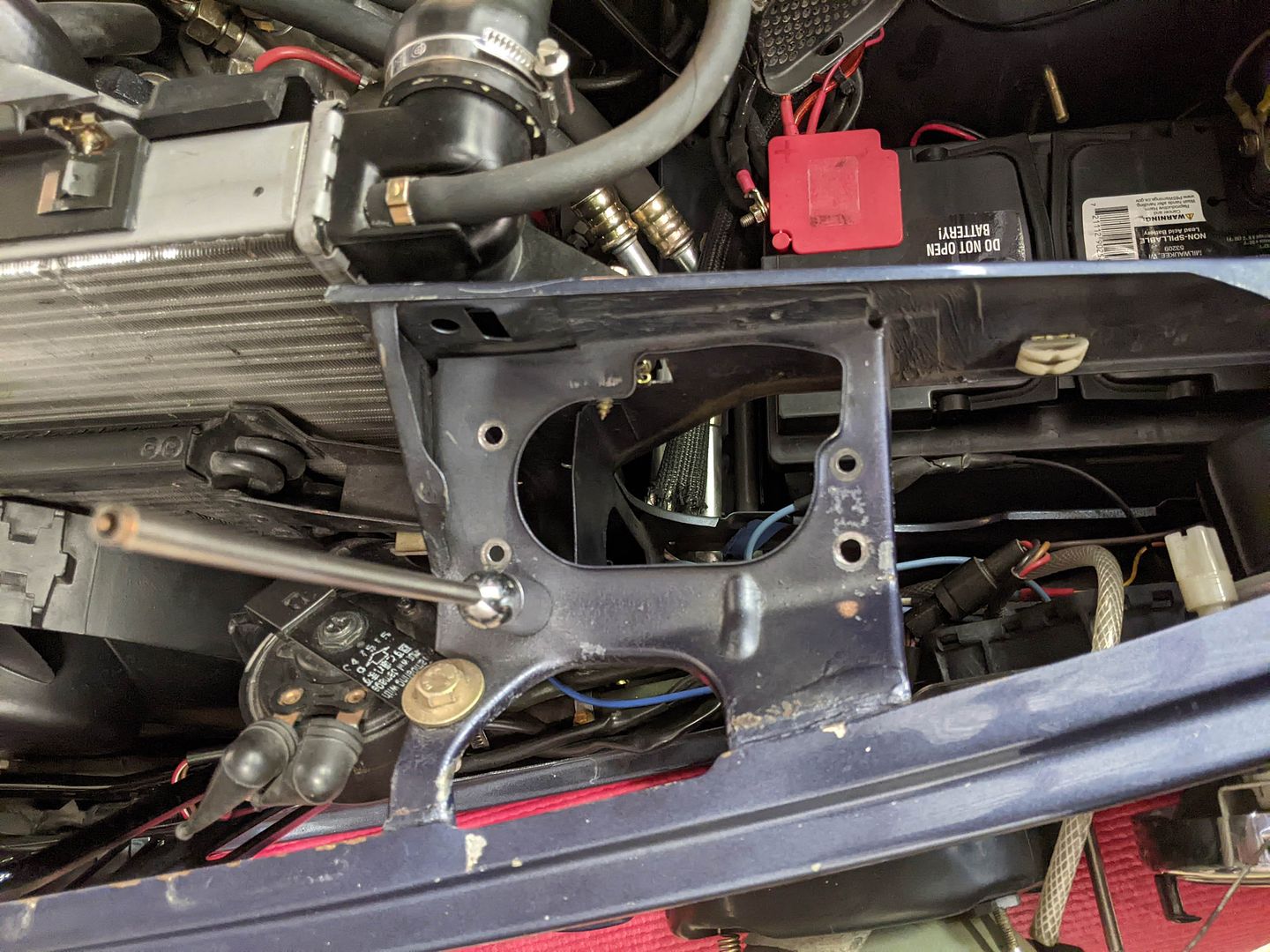

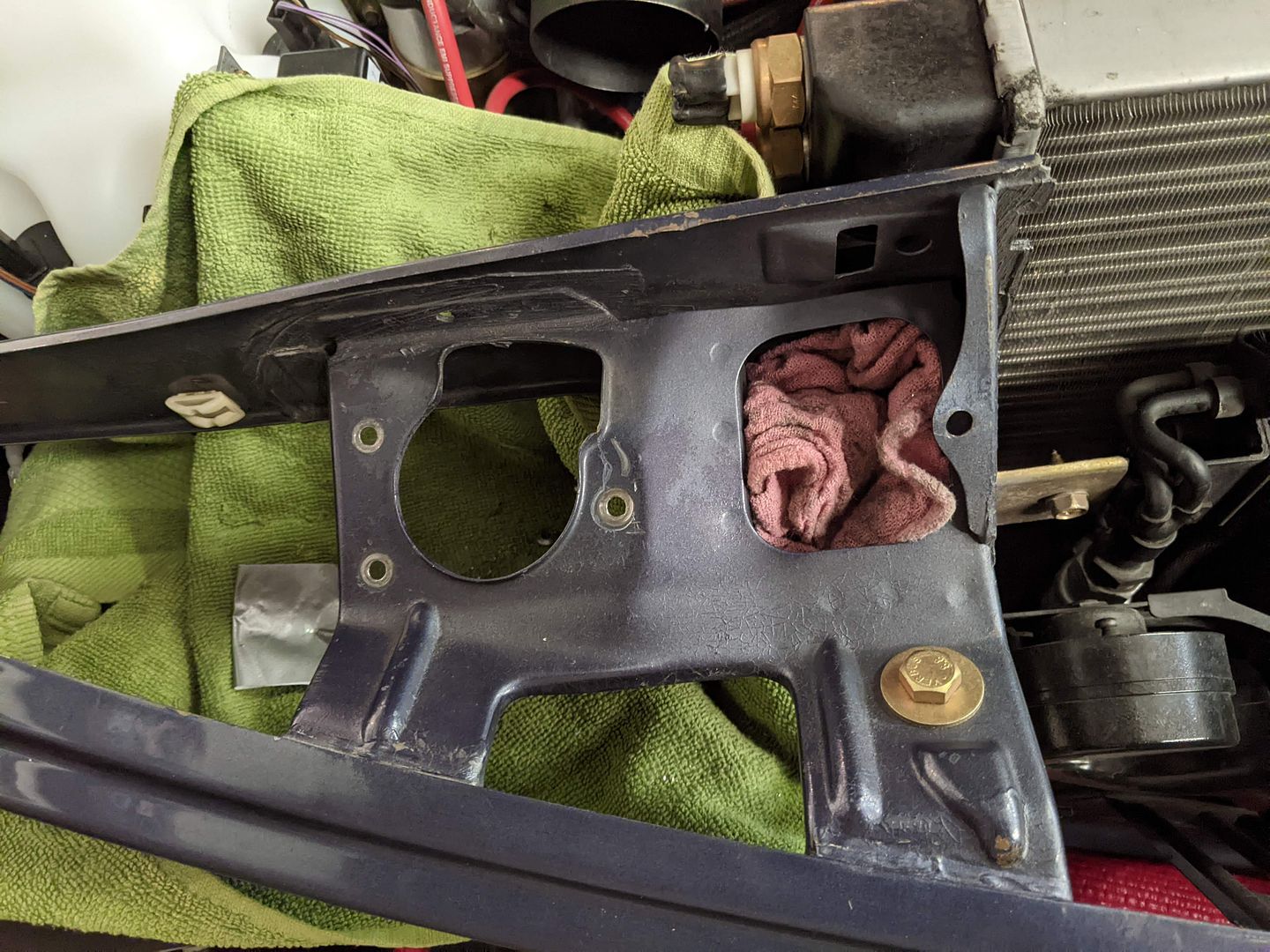

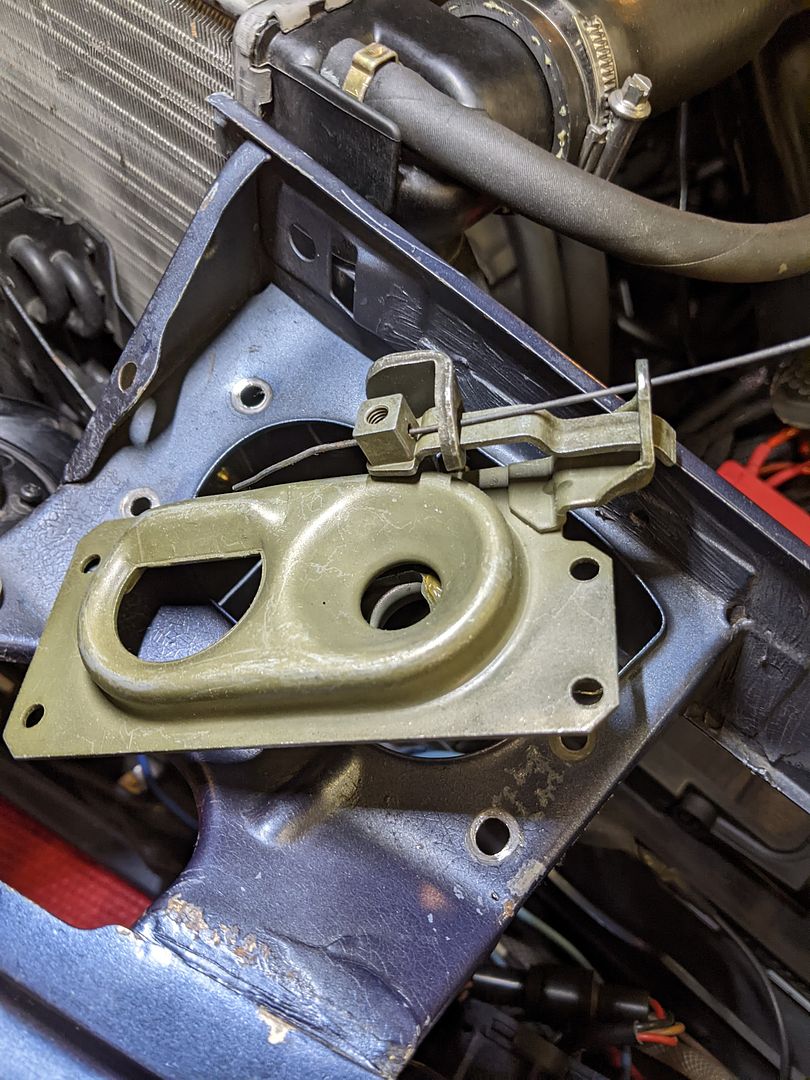

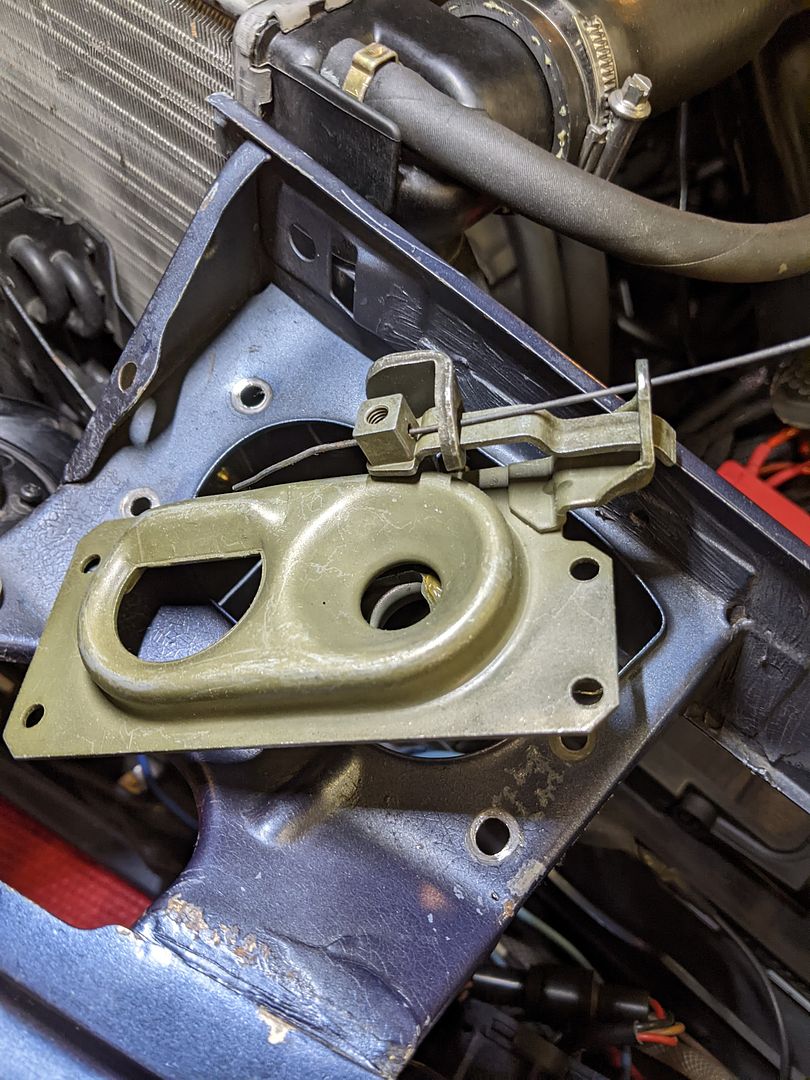

Hood Latches:

This was to correct a mistake/misstep I did back in 2016 wherein I re-plated them in yellow zinc. They are supposed to be a form of Green Cad, a finish that is very hard for modern platers to match (at least the ones I know around here). At the time (early 2022) all four components were still available from BMW, so that’s what I did.

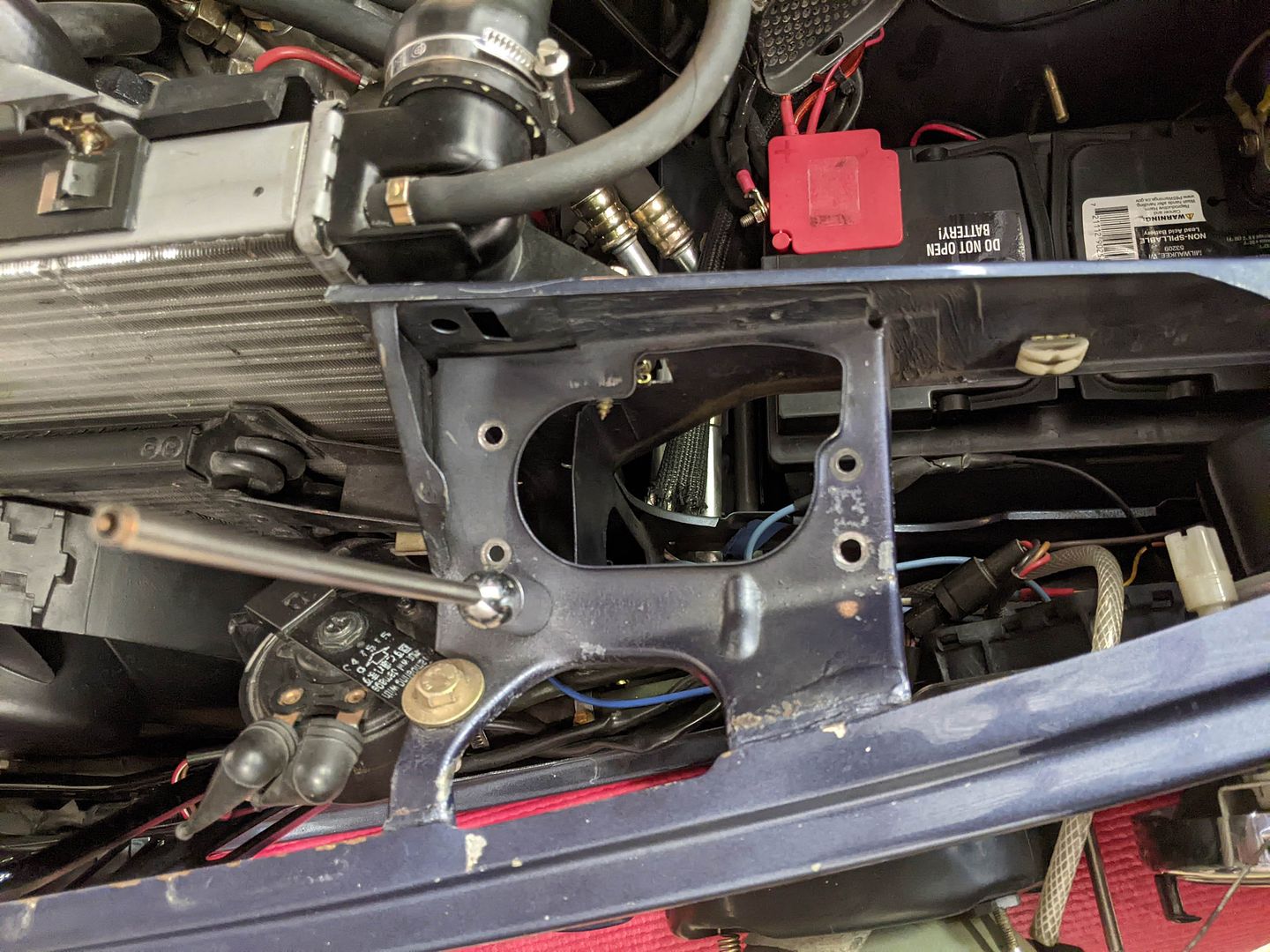

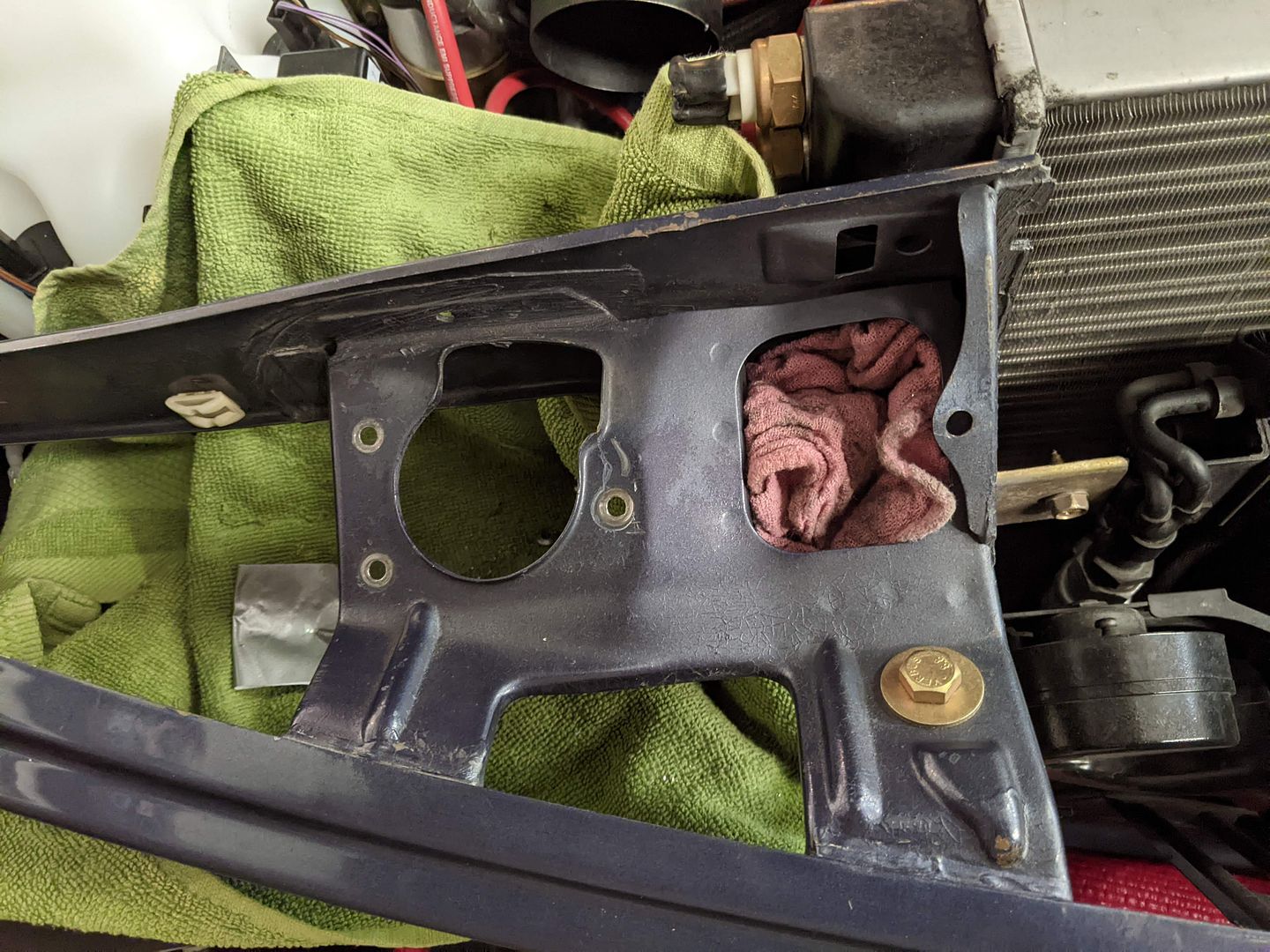

-First I had to remove the previous yellow zinc versions which means I had to drill out the four pop-rivets holding the base receptors onto the front nose. Be sure to put down copious amounts of towels or cardboard to catch all the metal filings and the spent rivets (they go everywhere). In fact magnets would help a lot.

-Installation: Feed the release cable through the driver’s side and then across the top of the radiator shroud/nose over the passenger’s side. It doesn’t really matter which side you start to install first, just be sure you need to feed the release cable through the driver’s side receiver catch first.

-Be sure you pick up or borrow a good quality HD rivet gun since the BMW rivets are steel not aluminum. Steel is needed since these are under a fair amount of force and tension. If you’re using a hand-powered version get ready for a workout. You might also have to grind off or file off any messy cut tabs (in theory you shouldn’t have to with a quality tool as it should snap off the legs cleanly; mine didn’t). You want to be careful if you do grind/file them off so as not to scuff the rivet heads too much as they are very visible (if that matters to you).

-Make the final release cable connections into the receiver latches and install with the proper yellow zinc M6 set bolt. Test the cabin release lever then tighten the bolts down. (There should be a visible indentation on the cable from where the connection was before, so start there.)

-Next install the upper catches on the hood itself. Again, there should be marks on the hood where the old catches were so start here. The holes are cut with a slight oval for adjustments particularly the driver’s side with the release handle. You should also note the amount of threads on the bolt under the springs are showing on the old ones since this is you starting point for the hood seating. Adjustments are straight-forward: loosen the locking nut at the base, use large regular screwdriver to rotate the bolt and spring up/down or in/out. If you’re doing this from scratch, it will take some back and forth (opening/closing of the hood) to find the right position for these. Same for the horizontal positions of the latches on the hood. Slightly tedious but should be okay if you’re starting at the old positions. I believe this process is spelled out in the Bentley's. You can get the official BMW bolts with integrated washers or you can pick up correct yellow zinc hardware somewhere for the four bolts holding both sides to the hood.

-That’s it. Clean up, make one final check for latching and safety catching and hood seating. Be sure to apply any additional grease in the receivers catches (they come with some from the factory but you may need more). There are two plastic cover caps that slide onto the bottom of the receivers on the nose; be sure to install these before the headlights as it's easier access. Close it all up and you’re done.

[I know, one of these days I may have the whole radiator support/nose repainted. It's original and wasn't repainted with the rest of the car back in 1990/91. It's looking a bit tattered.]

Hood Latches:

This was to correct a mistake/misstep I did back in 2016 wherein I re-plated them in yellow zinc. They are supposed to be a form of Green Cad, a finish that is very hard for modern platers to match (at least the ones I know around here). At the time (early 2022) all four components were still available from BMW, so that’s what I did.

-First I had to remove the previous yellow zinc versions which means I had to drill out the four pop-rivets holding the base receptors onto the front nose. Be sure to put down copious amounts of towels or cardboard to catch all the metal filings and the spent rivets (they go everywhere). In fact magnets would help a lot.

-Installation: Feed the release cable through the driver’s side and then across the top of the radiator shroud/nose over the passenger’s side. It doesn’t really matter which side you start to install first, just be sure you need to feed the release cable through the driver’s side receiver catch first.

-Be sure you pick up or borrow a good quality HD rivet gun since the BMW rivets are steel not aluminum. Steel is needed since these are under a fair amount of force and tension. If you’re using a hand-powered version get ready for a workout. You might also have to grind off or file off any messy cut tabs (in theory you shouldn’t have to with a quality tool as it should snap off the legs cleanly; mine didn’t). You want to be careful if you do grind/file them off so as not to scuff the rivet heads too much as they are very visible (if that matters to you).

-Make the final release cable connections into the receiver latches and install with the proper yellow zinc M6 set bolt. Test the cabin release lever then tighten the bolts down. (There should be a visible indentation on the cable from where the connection was before, so start there.)

-Next install the upper catches on the hood itself. Again, there should be marks on the hood where the old catches were so start here. The holes are cut with a slight oval for adjustments particularly the driver’s side with the release handle. You should also note the amount of threads on the bolt under the springs are showing on the old ones since this is you starting point for the hood seating. Adjustments are straight-forward: loosen the locking nut at the base, use large regular screwdriver to rotate the bolt and spring up/down or in/out. If you’re doing this from scratch, it will take some back and forth (opening/closing of the hood) to find the right position for these. Same for the horizontal positions of the latches on the hood. Slightly tedious but should be okay if you’re starting at the old positions. I believe this process is spelled out in the Bentley's. You can get the official BMW bolts with integrated washers or you can pick up correct yellow zinc hardware somewhere for the four bolts holding both sides to the hood.

-That’s it. Clean up, make one final check for latching and safety catching and hood seating. Be sure to apply any additional grease in the receivers catches (they come with some from the factory but you may need more). There are two plastic cover caps that slide onto the bottom of the receivers on the nose; be sure to install these before the headlights as it's easier access. Close it all up and you’re done.

[I know, one of these days I may have the whole radiator support/nose repainted. It's original and wasn't repainted with the rest of the car back in 1990/91. It's looking a bit tattered.]

Last edited by vinceg101 on Mar 27, 2023 9:12 PM, edited 1 time in total.

Re: 1985 Arktisblau M535i Renovation - Progression

I love this car.

Re: 1985 Arktisblau M535i Renovation - Progression

UPDATE

Wow, has it really been almost a year since my last update? Yikes, apologies for not keeping up. I went back and realized that I had drafted one to follow last March's but I never completed it and posted it.

Not much happened during 2023 but for some small projects, both troubleshooting/repairs and some upgrades. The first part of the below list took place back in 2022 with the remainder up until just recently. I have to promise myself to make this more of a regular thing since waiting a year or so to update is daunting and time consuming (I'm just as soon to skip updating altogether, but I said to myself I wouldn't do that).

Okay so here we go:

2022:

BBS Wheel Refinishing:

This was one of those items that should have been a low priority items since my BBS RS211’s were still in relatively good condition. There were some blemishes that I couldn’t get out and the wheel bolts were corroded or at least were losing their sharpness. So, I set out on what I thought would and should have been a straightforward task. I had done this exercise for my spare wheel the previous summer, so it should have been simple. On the spare wheel it was a combined effort between the wheel refinishing shop and the plating shop for the bolts.

Through a bit of bad luck on timing & schedules between the two shops and my own, sourcing a replacement set of BBS wheel rim bolts and the wheel refinisher going out of business in the middle of the whole thing, the task turned complicated and took waaay longer than anticipated. A mistake by the first wheel refinisher (the wrong center color and not finding out until the day they closed their doors) forced me to find another shop and more or less start all over again. The only thing they really didn’t have to do was polish the lips again, but they had to do everything else which included dismantling the three piece BBS system, remove the glue, strip the paint on the centers, find the matching paint (a sort of bronze/pewter), then reassemble them all. So, in the end I paid a lot of money to effectively have my lips polished. Add in a new set of Continental’s since the old set was aging out (certainly not by tread wear) and this turned into a major investment, more than I was anticipating for something that was more or less optional.

On and on it went from there. But in the end, they came out good looking much better than they were before.

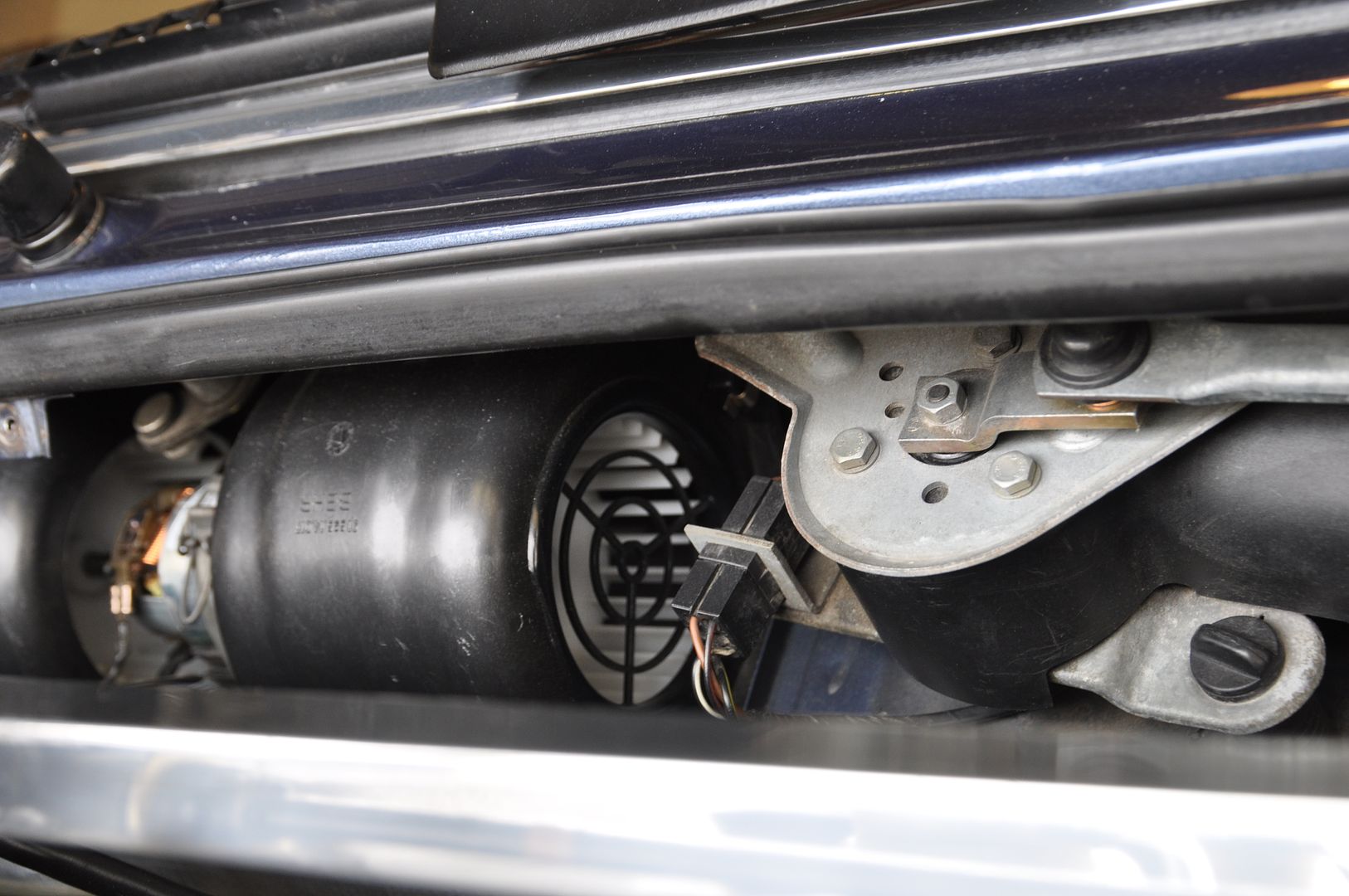

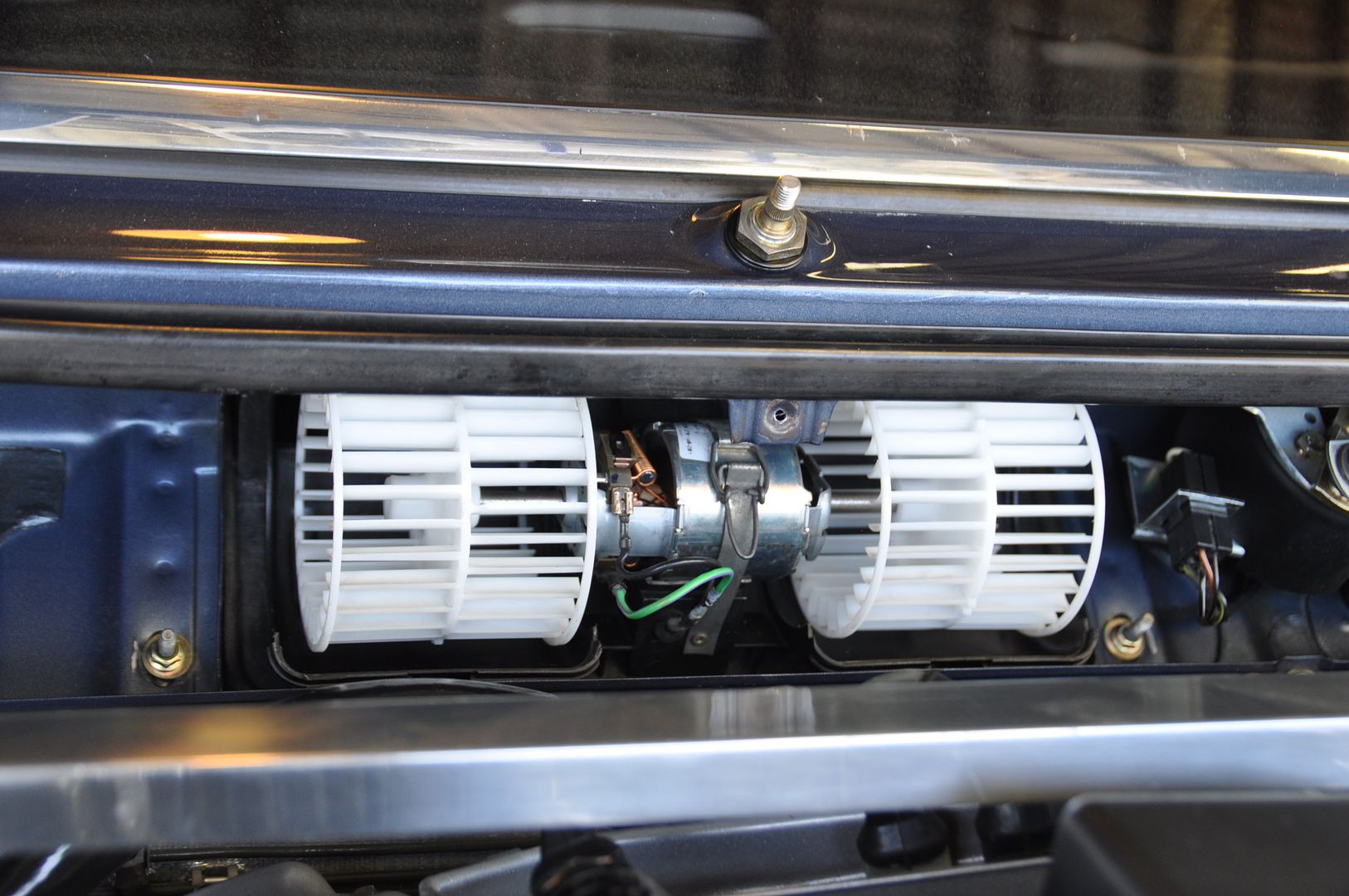

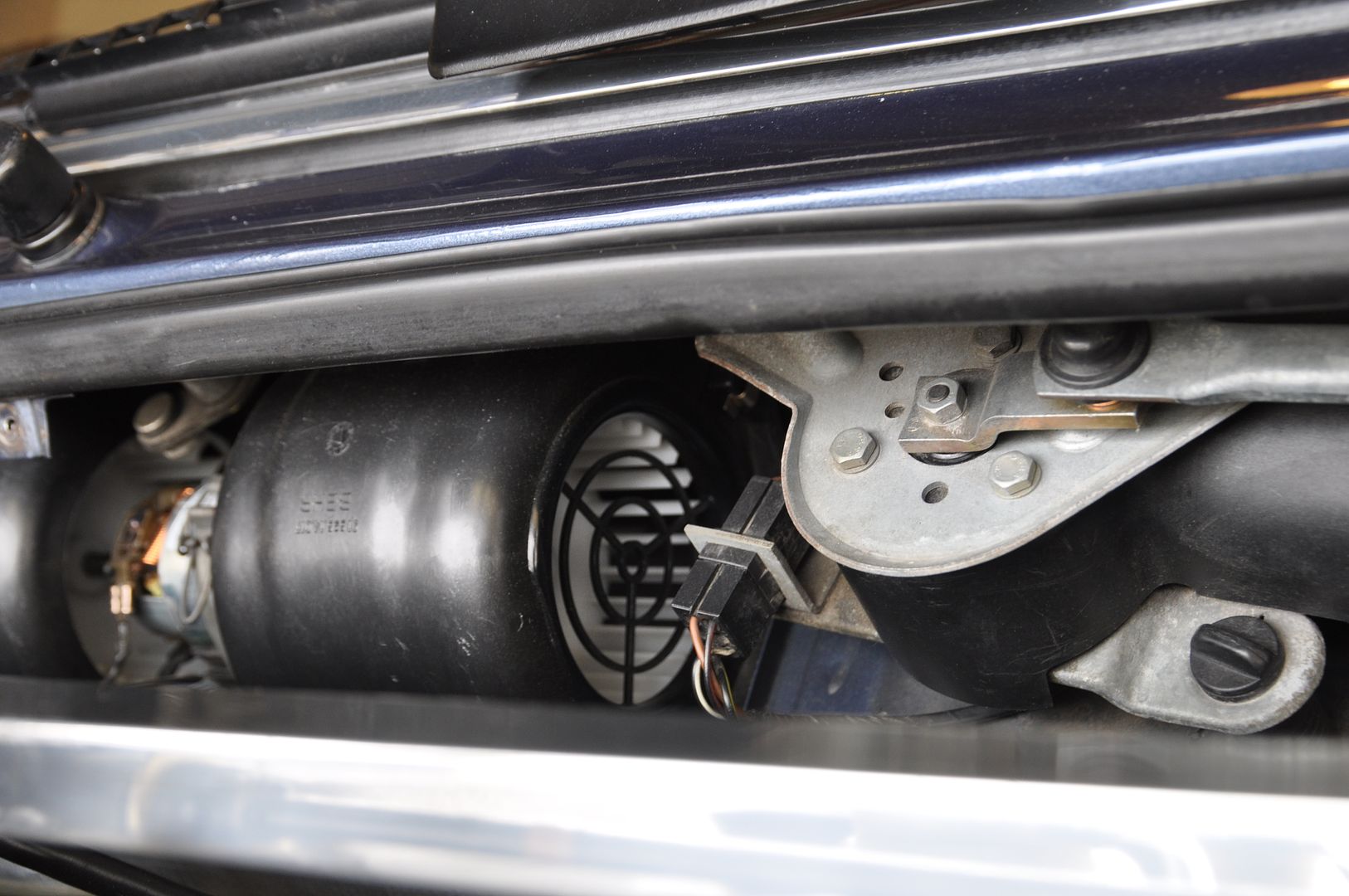

Windshield Wiper System:

My wiper motor has been progressively slowing down for years now and all the stuff under the cowling was showing its’ age (not that I ever drive this car in the rain, but hey, it’s about the principle, right?) This was a splurge and maybe in getting older I made an executive decision to use the hardest working tool in my toolbox: my credit card. I opted to buy all new parts rather than trying to refinish/rebuild the motor and other parts since it was all still available (except a few hardware pieces). Given BMW’s penchant to discontinue parts at will, there was no telling if they would be available in the near/far future. So, an order was placed and I waiting for the Norwegian express to deliver a box.

First up: Removal:

1) Remove the firewall panel in the engine bay to access the system

2) Next, remove the Wiper Arms but first pulling up the plastic covering cap on the Wiper Arm

3) Then pull up the plastic covering over to expose the Retaining Nut

4) Next unbolt the thin Retaining Nuts & washers. Important to note here: these two Retaining Nuts actually secure the whole Wiper Arm and motor to the body. There is a small rubber adjuster ‘foot’ behind the motor that braces it to the inner well firewall, but otherwise, that’s it.

5) The rubber gasket ring that goes around the hole in the outer body cowling has likely decomposed over time (mine had) so you may have to carefully pick and pull it out of the hole. Clean up with some cleaner (Goof-Off or a little lacquer thinner) to get the residue off.

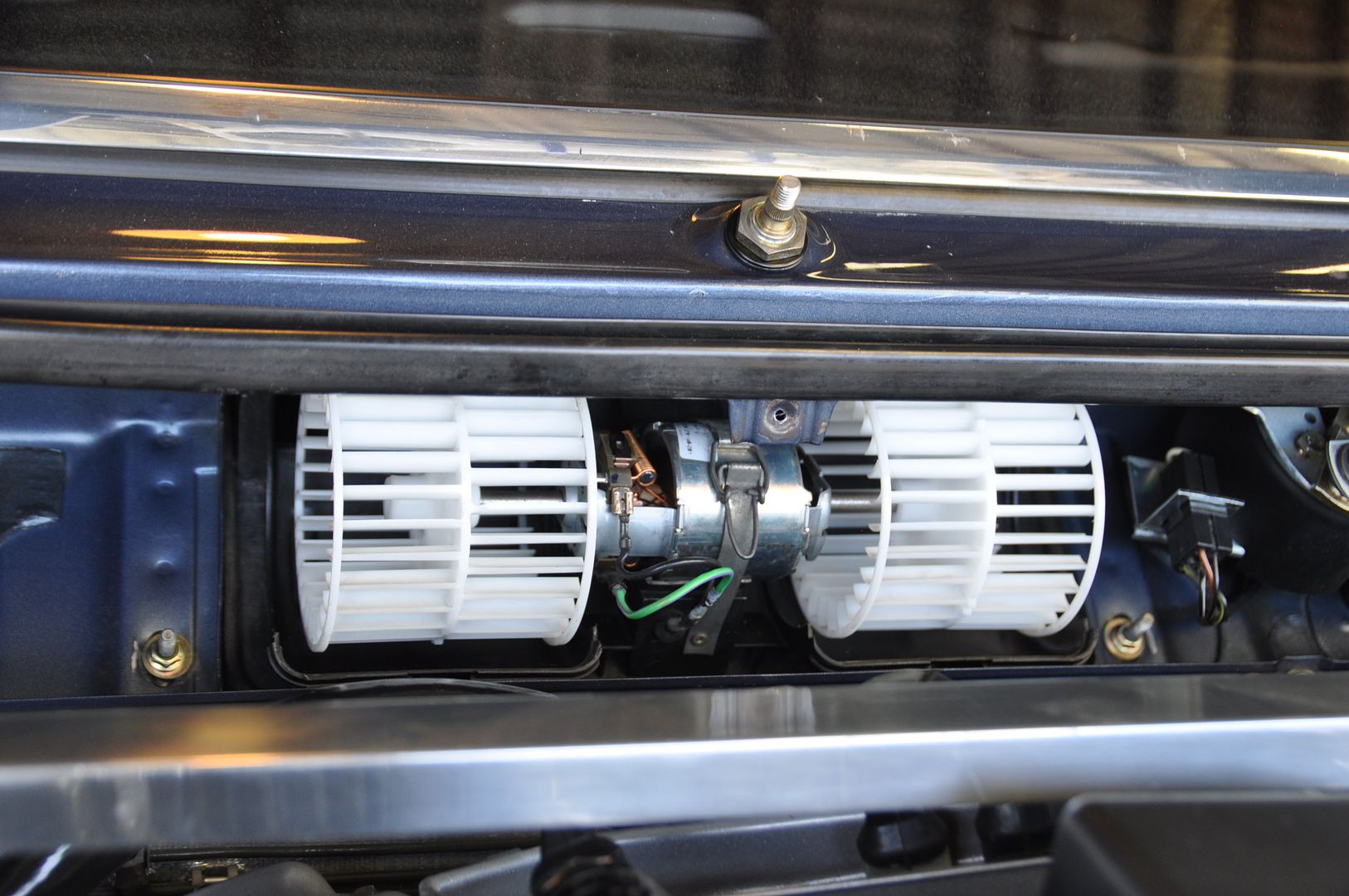

6) Remove the Fresh Air Blower Fan Covers and Fan itself (now’s the time to replace it if it needs it)

7) Disconnect the Wiper Motor power plug

8) Unbolt & remove the Wiper Motor from the Wiper Arm: there are three smaller nuts holding the Motor to the underside of the Arm and the one nut that connects the Motor to the rotating Arm joint in the center

9) Now comes the tricky part: Pull the Motor out from below while keeping the Arm secure in place (it might help to reinstall the two Retaining Nuts to hold it to the cowling). With the Motor out of the way, you can drop the Wiper Arm down into the well as the Wiper Arm connections drop through the cowling holes. From there, you have to rotate the armature flat to clear the firewall well. Don’t mar your paint.

Now is a great time to clean the whole well thoroughly. Vacuum, wash, dry. Clean out the drain holes and inspect for any rust. If all is good, liberally apply some wax and treat the Fresh Air Fan holder and cover as well as the Wipe Motor plastic cover.

Next: Prep & Install the New Parts:

1) Sort out the mounting hardware. The one item that is NLA is the thin Retaining Nut that holds the Wiper Arm securely to the cowling; keep your existing and/or source some new (I found what I thought was a thin replacement nut, but it was too thick and that matters since you can’t fit the covers back on. So, stick with the original part)

2) I opted to spray the Wiper Arm assembly with a clear spray lacquer to help keep the aluminum looking fresh and from oxidizing

3) Install the new rubber gasket/grommets in the cowling holes

Installation is the reverse of disassembly. Careful to slide the New Wiper Motor into the well first, then install the Wiper Arm. It’s best to secure the Wiper Arm up into the cowling holes first before trying to mount the Wiper Motor; this way one of the items is stable. With them in place, adjust the rubber leveling ‘foot’ so it makes contact with the back of the firewall. Secure the Retaining Nuts to the cowling, reconnect the power plug and you’re ready to move onto Wiper Arms. Remember to reinstall the Fresh Air Fan and its’ cover.

This is where most everyone will just reinstall the arms and covers, but not me. Not willing to let well enough alone, I just had to address the next two components to serve my anal nature.

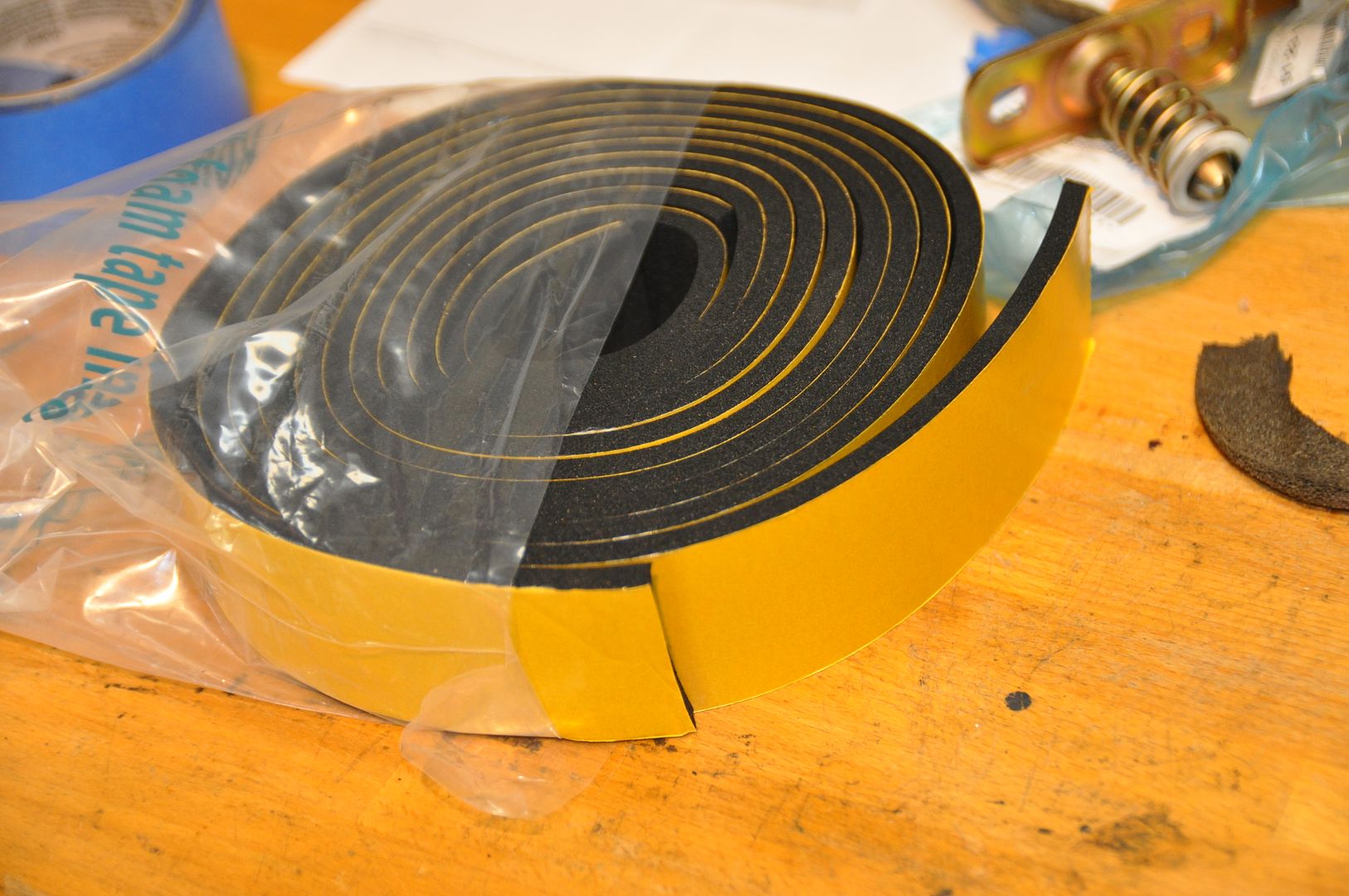

Firewall Cover Panel:

Mine was in remarkably good condition for being original, and seeing as how these are also NLA, I had to work with what I had. The engine side rubber/neoprene coating was mostly intact so there wasn’t much to do to that side except treat it thoroughly with a rubber preservative. What did need addressing was new foam gasketing on the backside facing the Wiper Arm well.

1) Remove the old existing deteriorating gasket, scrape off the residue, and clean

2) When done, the whole back side needed repainting, so I sanded it all down and prepped for new paint

3) Applied a few coats of Rustoleum Satin Black (since there was some surface rust and didn’t want that coming back)

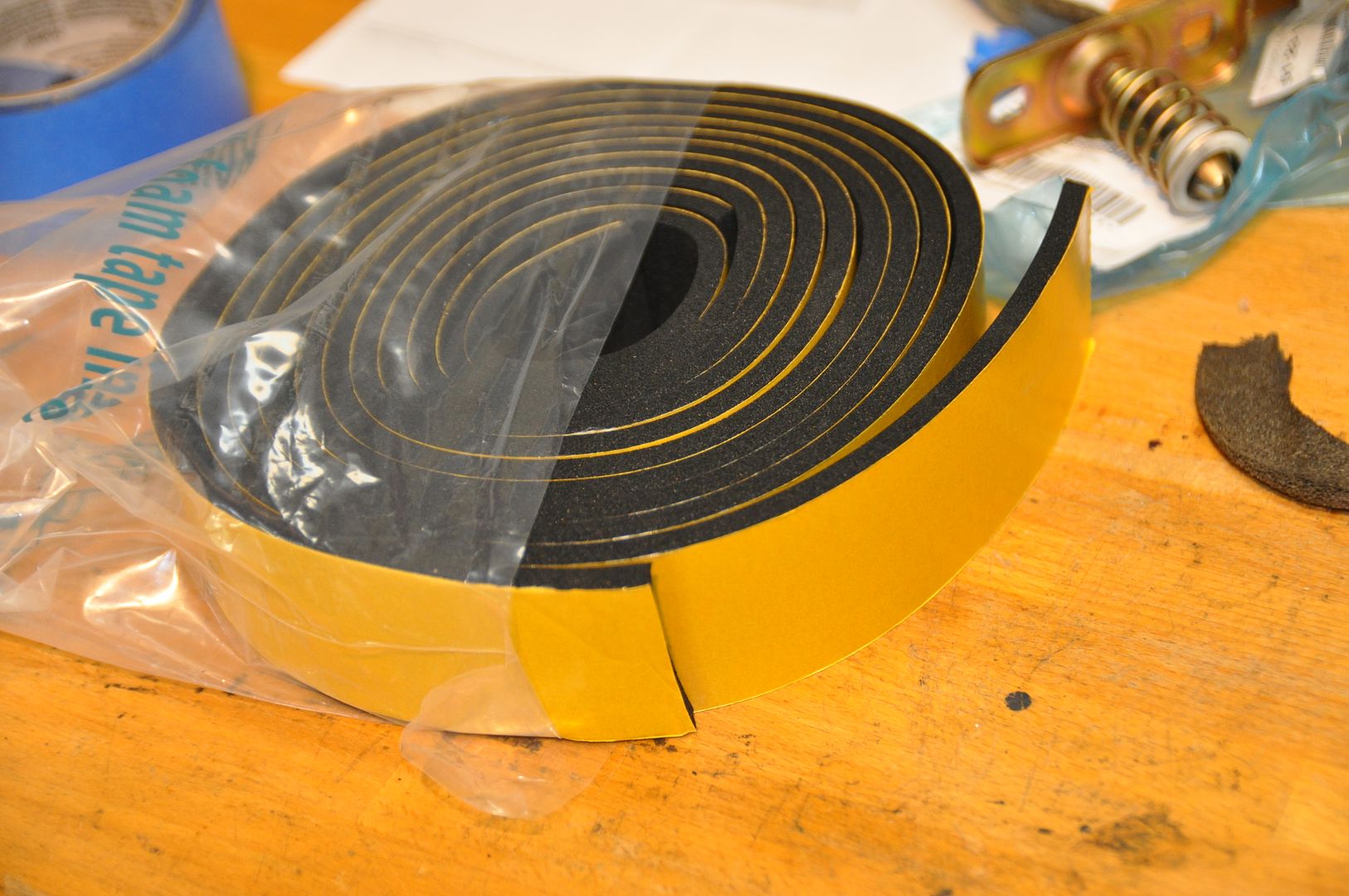

4) I sourced some replacement foam gasket tape in the right thickness and width and set out to template the pieces. This is closed-cell vs. the open cell foam BMW used. I prefer the closed-cell for its' compressiblity and its' ability to seal better

5) Installed the new foam gasketing. Final fitting and re-installation (after testing and final Wiper Arms adjustments)

Wiper Arms:

Here again E28 Wiper Arms are now all NLA, so we all have to work with what we’ve got. Finding replacements (the correct ones) in decent condition is very hard these days. I was lucky in that I had one NIB US E28 (late) Passenger Arm in a box, but I had to refinish my Driver’s side with the high-speed wing (I think it is actually either an E24 or E32 version, but I don’t know). What’s worse is repainting old ones is actually hard (especially if you’re relying on spray can paints); I imagine if you’re using a spray gun it might yield better results. I did several spare arms at the same time. First up:

Prep & Paint:

The old ones were pitted and scratched from road wear with a little bit of rust. So I bench wire-wheeled them all down to as much bare metal as possible. Then I sanded these as smooth as I could.

2) I applied a few coats of self-leveling automotive primer to even out the surface as much as possible; wait for this to thoroughly set up and dry (like a week if possible)

3) Start applying fine,light coats of SEM Black Trim paint (although that doesn’t completely match the finish of the original Wiper Arms as they are glossier). Be careful with the paint and make it go on evenly; I kept having to go back and remove paint and re-apply as it kept splattering or running (here a paint sprayer would have helped). Again, set them up to thoroughly cure and dry (a week)

4) To address the finish issues, I applied a very light coat of clear spray lacquer to both try to match the OEM finish as well give them some protection. And again, let them cure completely (yes, another week)

Wiper Arm Installation:

Install your favorite flavor of blades and mount them to Wiper Arm bolts with the small nuts & washers. Pretty straight-forward but follow instincts and the Bentley manual for aligning & adjusting. Once you have them set, lock in the top nuts, install the covers and close everything up.

Wow, has it really been almost a year since my last update? Yikes, apologies for not keeping up. I went back and realized that I had drafted one to follow last March's but I never completed it and posted it.

Not much happened during 2023 but for some small projects, both troubleshooting/repairs and some upgrades. The first part of the below list took place back in 2022 with the remainder up until just recently. I have to promise myself to make this more of a regular thing since waiting a year or so to update is daunting and time consuming (I'm just as soon to skip updating altogether, but I said to myself I wouldn't do that).

Okay so here we go:

2022:

BBS Wheel Refinishing:

This was one of those items that should have been a low priority items since my BBS RS211’s were still in relatively good condition. There were some blemishes that I couldn’t get out and the wheel bolts were corroded or at least were losing their sharpness. So, I set out on what I thought would and should have been a straightforward task. I had done this exercise for my spare wheel the previous summer, so it should have been simple. On the spare wheel it was a combined effort between the wheel refinishing shop and the plating shop for the bolts.

Through a bit of bad luck on timing & schedules between the two shops and my own, sourcing a replacement set of BBS wheel rim bolts and the wheel refinisher going out of business in the middle of the whole thing, the task turned complicated and took waaay longer than anticipated. A mistake by the first wheel refinisher (the wrong center color and not finding out until the day they closed their doors) forced me to find another shop and more or less start all over again. The only thing they really didn’t have to do was polish the lips again, but they had to do everything else which included dismantling the three piece BBS system, remove the glue, strip the paint on the centers, find the matching paint (a sort of bronze/pewter), then reassemble them all. So, in the end I paid a lot of money to effectively have my lips polished. Add in a new set of Continental’s since the old set was aging out (certainly not by tread wear) and this turned into a major investment, more than I was anticipating for something that was more or less optional.

On and on it went from there. But in the end, they came out good looking much better than they were before.

Windshield Wiper System:

My wiper motor has been progressively slowing down for years now and all the stuff under the cowling was showing its’ age (not that I ever drive this car in the rain, but hey, it’s about the principle, right?) This was a splurge and maybe in getting older I made an executive decision to use the hardest working tool in my toolbox: my credit card. I opted to buy all new parts rather than trying to refinish/rebuild the motor and other parts since it was all still available (except a few hardware pieces). Given BMW’s penchant to discontinue parts at will, there was no telling if they would be available in the near/far future. So, an order was placed and I waiting for the Norwegian express to deliver a box.

First up: Removal:

1) Remove the firewall panel in the engine bay to access the system

2) Next, remove the Wiper Arms but first pulling up the plastic covering cap on the Wiper Arm

3) Then pull up the plastic covering over to expose the Retaining Nut

4) Next unbolt the thin Retaining Nuts & washers. Important to note here: these two Retaining Nuts actually secure the whole Wiper Arm and motor to the body. There is a small rubber adjuster ‘foot’ behind the motor that braces it to the inner well firewall, but otherwise, that’s it.

5) The rubber gasket ring that goes around the hole in the outer body cowling has likely decomposed over time (mine had) so you may have to carefully pick and pull it out of the hole. Clean up with some cleaner (Goof-Off or a little lacquer thinner) to get the residue off.

6) Remove the Fresh Air Blower Fan Covers and Fan itself (now’s the time to replace it if it needs it)

7) Disconnect the Wiper Motor power plug

8) Unbolt & remove the Wiper Motor from the Wiper Arm: there are three smaller nuts holding the Motor to the underside of the Arm and the one nut that connects the Motor to the rotating Arm joint in the center

9) Now comes the tricky part: Pull the Motor out from below while keeping the Arm secure in place (it might help to reinstall the two Retaining Nuts to hold it to the cowling). With the Motor out of the way, you can drop the Wiper Arm down into the well as the Wiper Arm connections drop through the cowling holes. From there, you have to rotate the armature flat to clear the firewall well. Don’t mar your paint.

Now is a great time to clean the whole well thoroughly. Vacuum, wash, dry. Clean out the drain holes and inspect for any rust. If all is good, liberally apply some wax and treat the Fresh Air Fan holder and cover as well as the Wipe Motor plastic cover.

Next: Prep & Install the New Parts:

1) Sort out the mounting hardware. The one item that is NLA is the thin Retaining Nut that holds the Wiper Arm securely to the cowling; keep your existing and/or source some new (I found what I thought was a thin replacement nut, but it was too thick and that matters since you can’t fit the covers back on. So, stick with the original part)

2) I opted to spray the Wiper Arm assembly with a clear spray lacquer to help keep the aluminum looking fresh and from oxidizing

3) Install the new rubber gasket/grommets in the cowling holes

Installation is the reverse of disassembly. Careful to slide the New Wiper Motor into the well first, then install the Wiper Arm. It’s best to secure the Wiper Arm up into the cowling holes first before trying to mount the Wiper Motor; this way one of the items is stable. With them in place, adjust the rubber leveling ‘foot’ so it makes contact with the back of the firewall. Secure the Retaining Nuts to the cowling, reconnect the power plug and you’re ready to move onto Wiper Arms. Remember to reinstall the Fresh Air Fan and its’ cover.

This is where most everyone will just reinstall the arms and covers, but not me. Not willing to let well enough alone, I just had to address the next two components to serve my anal nature.

Firewall Cover Panel:

Mine was in remarkably good condition for being original, and seeing as how these are also NLA, I had to work with what I had. The engine side rubber/neoprene coating was mostly intact so there wasn’t much to do to that side except treat it thoroughly with a rubber preservative. What did need addressing was new foam gasketing on the backside facing the Wiper Arm well.

1) Remove the old existing deteriorating gasket, scrape off the residue, and clean

2) When done, the whole back side needed repainting, so I sanded it all down and prepped for new paint

3) Applied a few coats of Rustoleum Satin Black (since there was some surface rust and didn’t want that coming back)

4) I sourced some replacement foam gasket tape in the right thickness and width and set out to template the pieces. This is closed-cell vs. the open cell foam BMW used. I prefer the closed-cell for its' compressiblity and its' ability to seal better

5) Installed the new foam gasketing. Final fitting and re-installation (after testing and final Wiper Arms adjustments)

Wiper Arms:

Here again E28 Wiper Arms are now all NLA, so we all have to work with what we’ve got. Finding replacements (the correct ones) in decent condition is very hard these days. I was lucky in that I had one NIB US E28 (late) Passenger Arm in a box, but I had to refinish my Driver’s side with the high-speed wing (I think it is actually either an E24 or E32 version, but I don’t know). What’s worse is repainting old ones is actually hard (especially if you’re relying on spray can paints); I imagine if you’re using a spray gun it might yield better results. I did several spare arms at the same time. First up:

Prep & Paint:

The old ones were pitted and scratched from road wear with a little bit of rust. So I bench wire-wheeled them all down to as much bare metal as possible. Then I sanded these as smooth as I could.

2) I applied a few coats of self-leveling automotive primer to even out the surface as much as possible; wait for this to thoroughly set up and dry (like a week if possible)

3) Start applying fine,light coats of SEM Black Trim paint (although that doesn’t completely match the finish of the original Wiper Arms as they are glossier). Be careful with the paint and make it go on evenly; I kept having to go back and remove paint and re-apply as it kept splattering or running (here a paint sprayer would have helped). Again, set them up to thoroughly cure and dry (a week)

4) To address the finish issues, I applied a very light coat of clear spray lacquer to both try to match the OEM finish as well give them some protection. And again, let them cure completely (yes, another week)

Wiper Arm Installation:

Install your favorite flavor of blades and mount them to Wiper Arm bolts with the small nuts & washers. Pretty straight-forward but follow instincts and the Bentley manual for aligning & adjusting. Once you have them set, lock in the top nuts, install the covers and close everything up.

Re: 1985 Arktisblau M535i Renovation - Progression

2023:

M5 Sun Visors:

I put these in kind of at the last minute during the Interiors project simply because I had forgotten I had a set of these lighted M5 Sun Visors sitting in a box for nearly a decade. I hadn’t even bothered to test them before I installed them and given how they came along late in the process, I had to get creative with the wiring for them. So, when they didn’t work part of me wasn’t surprised and I put them on the punch list. I just got around a few weeks back to addressing this issue.

1) Stated by bench testing them wherein I found out they do indeed work

2) Turns out the contacts on the receiver clips and on the visor themselves needed some attention

3)They still don’t work 100% and is dependent on what position the visor is in (the contact points on those clips is a bit 'iffy) but more than they did before, which wasn’t at all

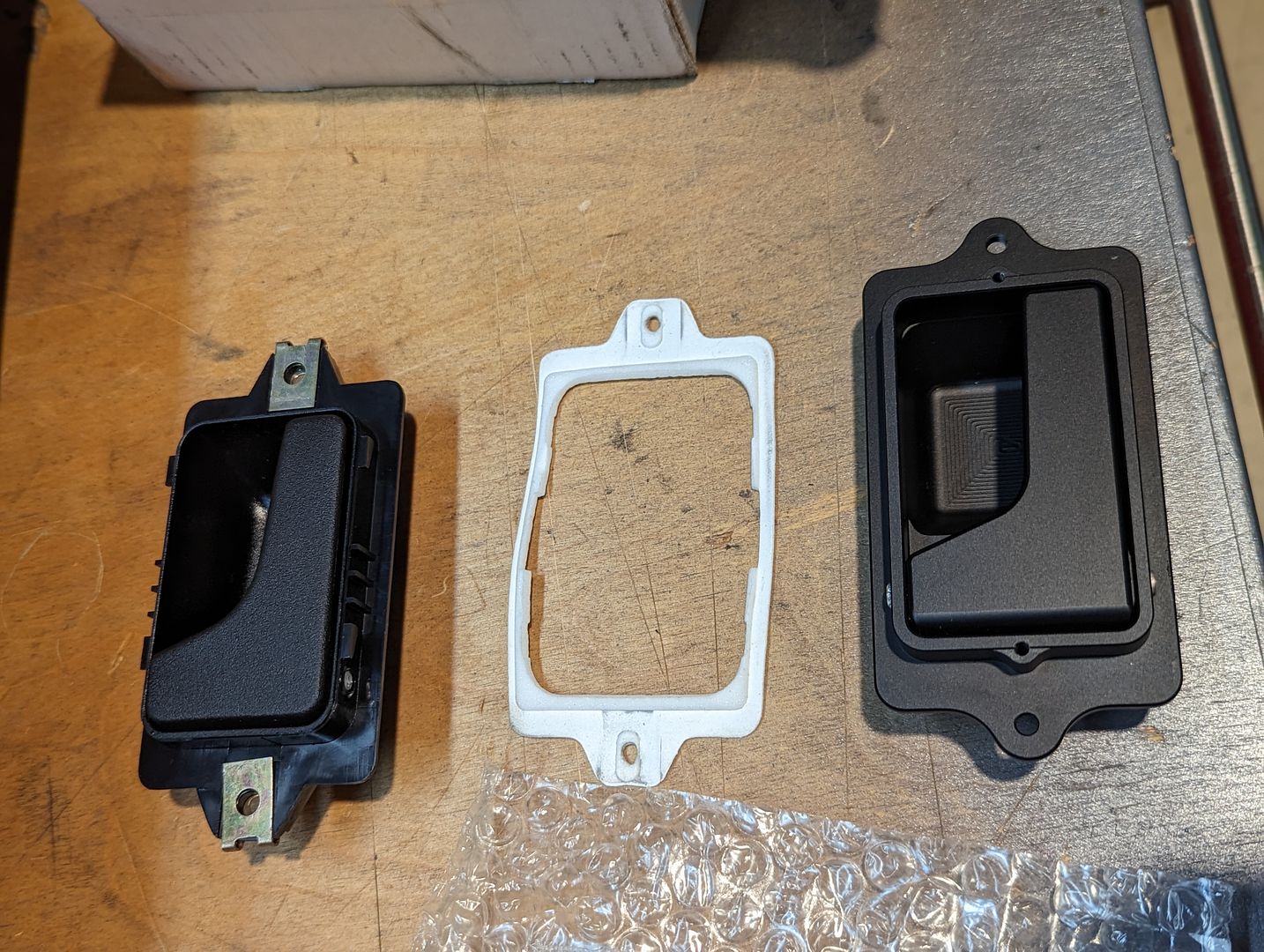

Interior Door Handles:

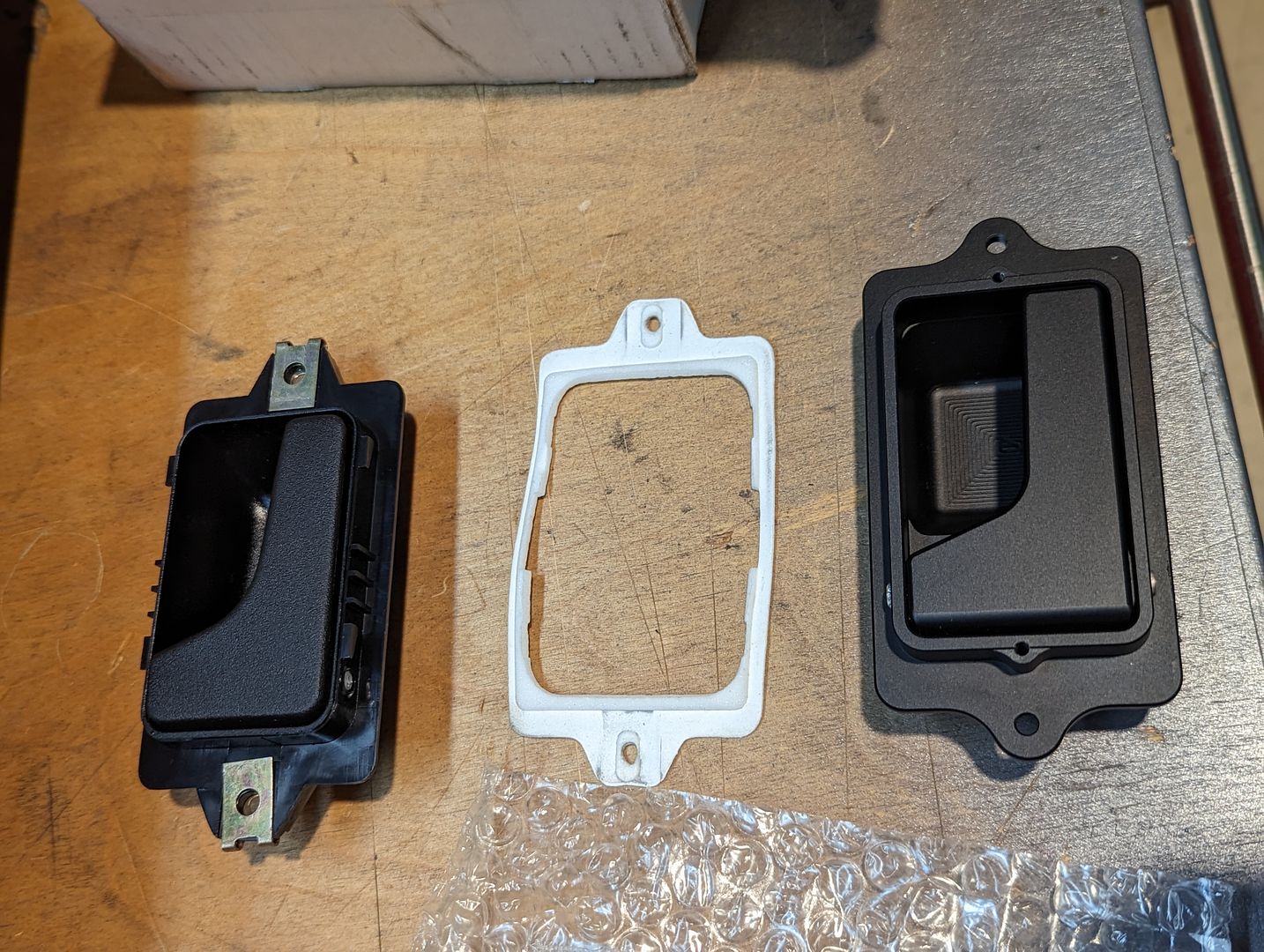

Okay, I thought the Wiper System was a splurge, this, however was a total indulgence. After I have replaced several Interior Door Latch assemblies in recent years, it is evident that the quality of these new parts is really lacking. Someone came up with solution, albeit an over the top, expensive one. Leo Grande Racing out of Long Island, NY started fabricating aluminum replacement assemblies. This included the one part that keeps breaking: the Interior Trim Ring. These are really robust pieces that will hopefully outlast my lifetime.

Here I was in a bit of quandary regarding the Trim Rings: BMW still makes replacements in a color that they claim is Taurusrot but in reality is Cardinal. All my used or old NIB Taurusrot trim rings consistently break even after I tried reinforcing them by laying down a bead of Super Glue on the back side. (You can see the 'new' Taurus rings in one of the photos below; see how light it is compared to either the original ring or vinyl cover)

The quandary was that Leo Grande only makes the Trim Rings in either black or clear anodized finishes. I could have simply accepted the black ones, but I just couldn’t, not after spending all this effort on the Taurusrot interior; it seemed a sacrilege. Since they weren’t changing their finishes, I asked for milled finish and decided to powder coat the rings in a matching color.

After going through RAL color samples at the powdercoater, I came up with one from Prismatic Powders (RAL 8016). It’s actually a brown but given the brown nature of Taurus in certain light, it works. Too bad it’s only available in a gloss finish, but I’m living with it. I may apply a satin or low luster topcoat to knock that sheen down eventually. I will also paint the trim screws either to match or just black.

Installation was easy and they go in just like the OEM versions: Remove Trim Ring, Armrest/Handle, and Door Panel. Disconnect & remove existing latch. Connect and install new latch. Re-install all the components. Screw on the finish Trim Ring with the oh-so-impossibly small torx screws they provide. You’re set.

Yeah, it is an expensive solution to a minor problem but I did it anyway.

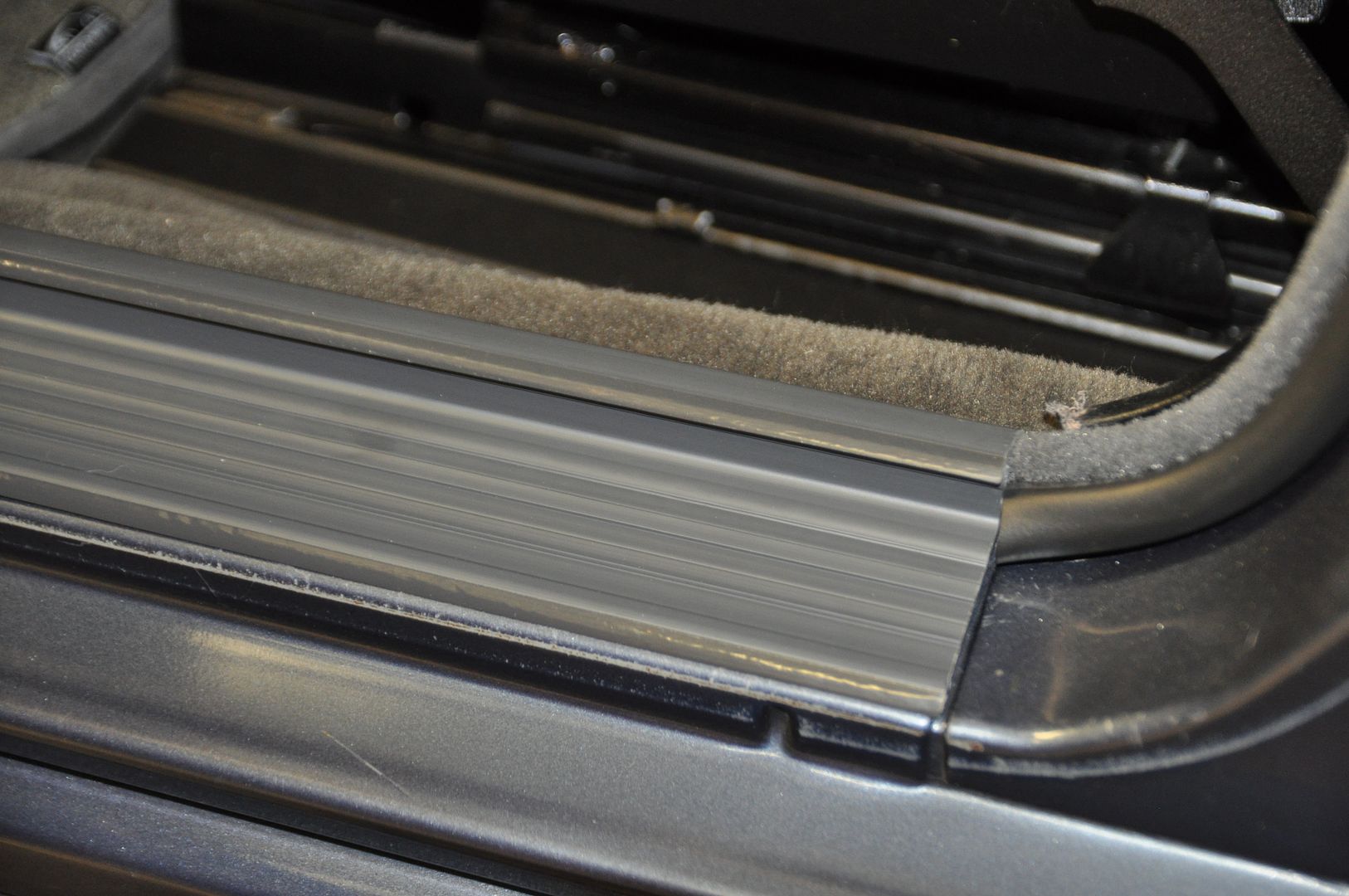

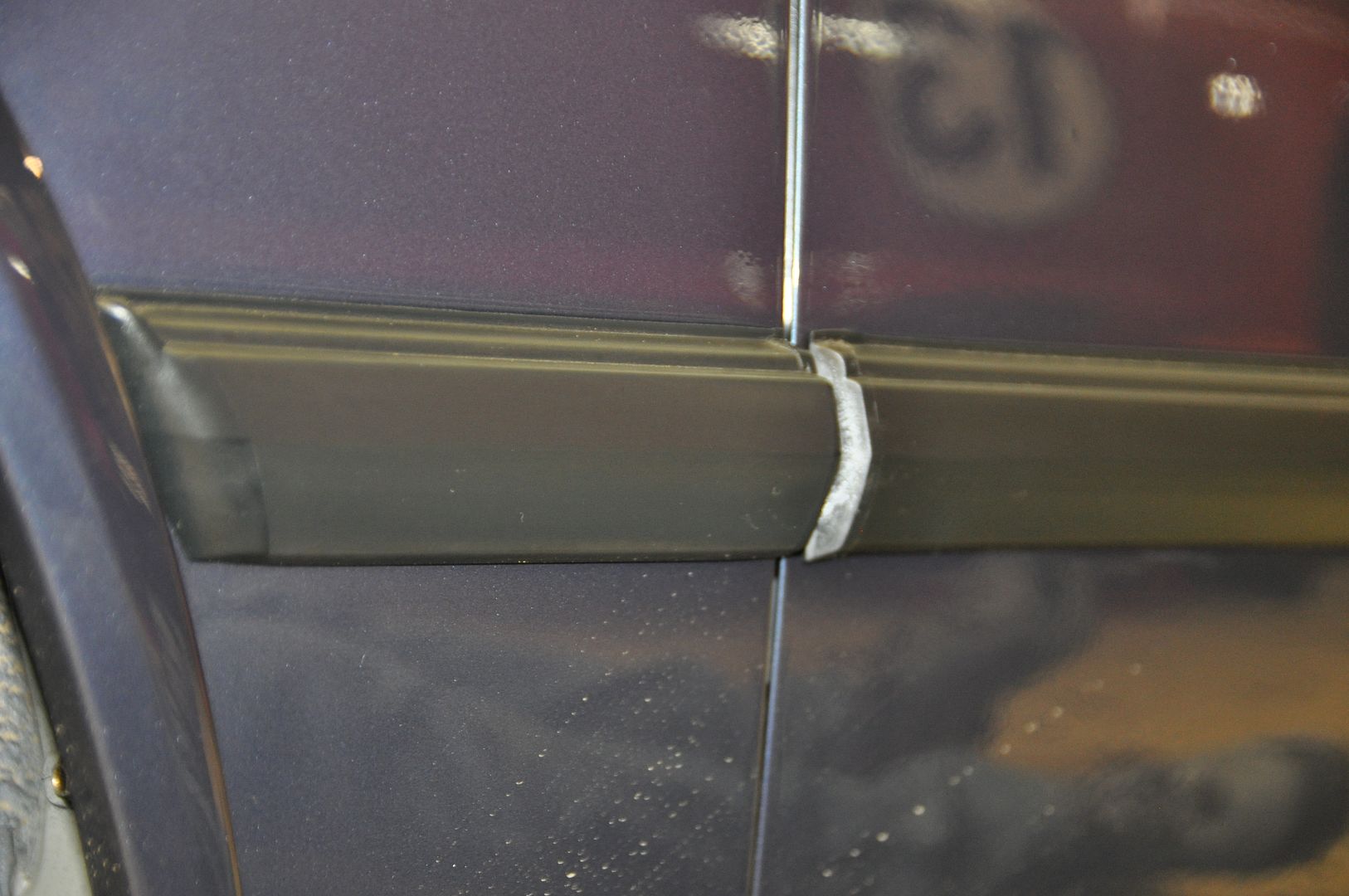

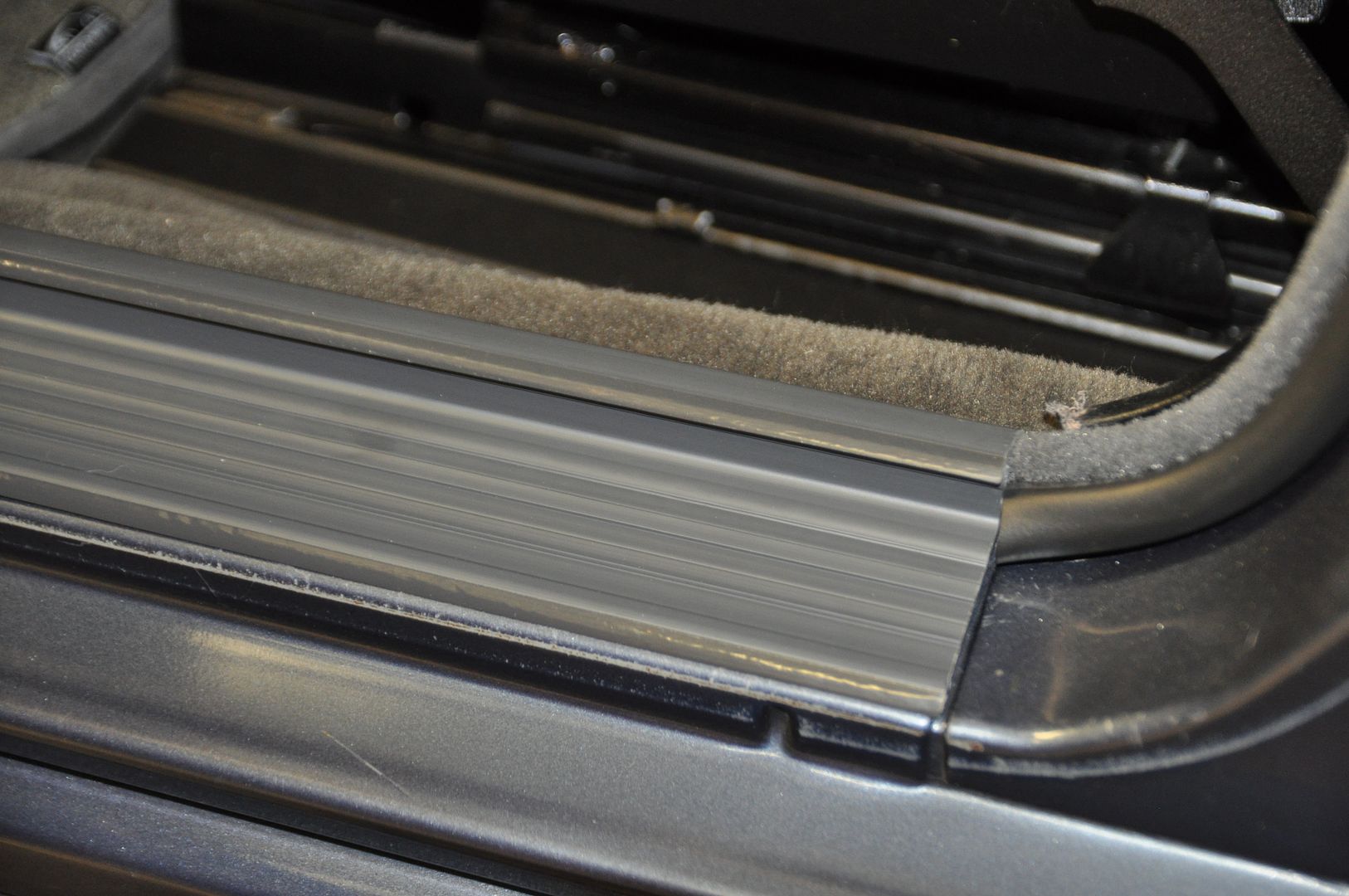

Door Weatherstripping & Door Sills:

This too is a work in progress but is getting closer to being complete. I installed my original rear sets, but due to an extreme case of brain-fartness, I ‘lost’ my original front sets. I temporarily installed a set of after-market versions sourced from a guy in Turkey via ebay. While they don’t have the requisite “Mouse Fur” of the OEM, they fit really well and offered complete door opening coverage. This is the real weak part of the E28 door seal system: the seal breaks at the Door Sills and nothing is underneath them to seal off the opening adequately (BMW offered complete opening seals in almost every other model except the E28 and E12).

I also ‘lost’ my two front Door Sills (I don’t know what happened that week in the Hangar) and of course these are NLA so I set out trying to find decent, clean replacements; a tall order. I have plans to modify the sills and add some rubber/foam profile weatherstrip to build a better mousetrap, more complete seal to the bottom of the door seal to get better acoustic control.

In the meantime, the E12 Door Sills are/were available and compared to used E28 sills, a bargain from BMW. The E12’s are also all black which I tend to like better with my interior.

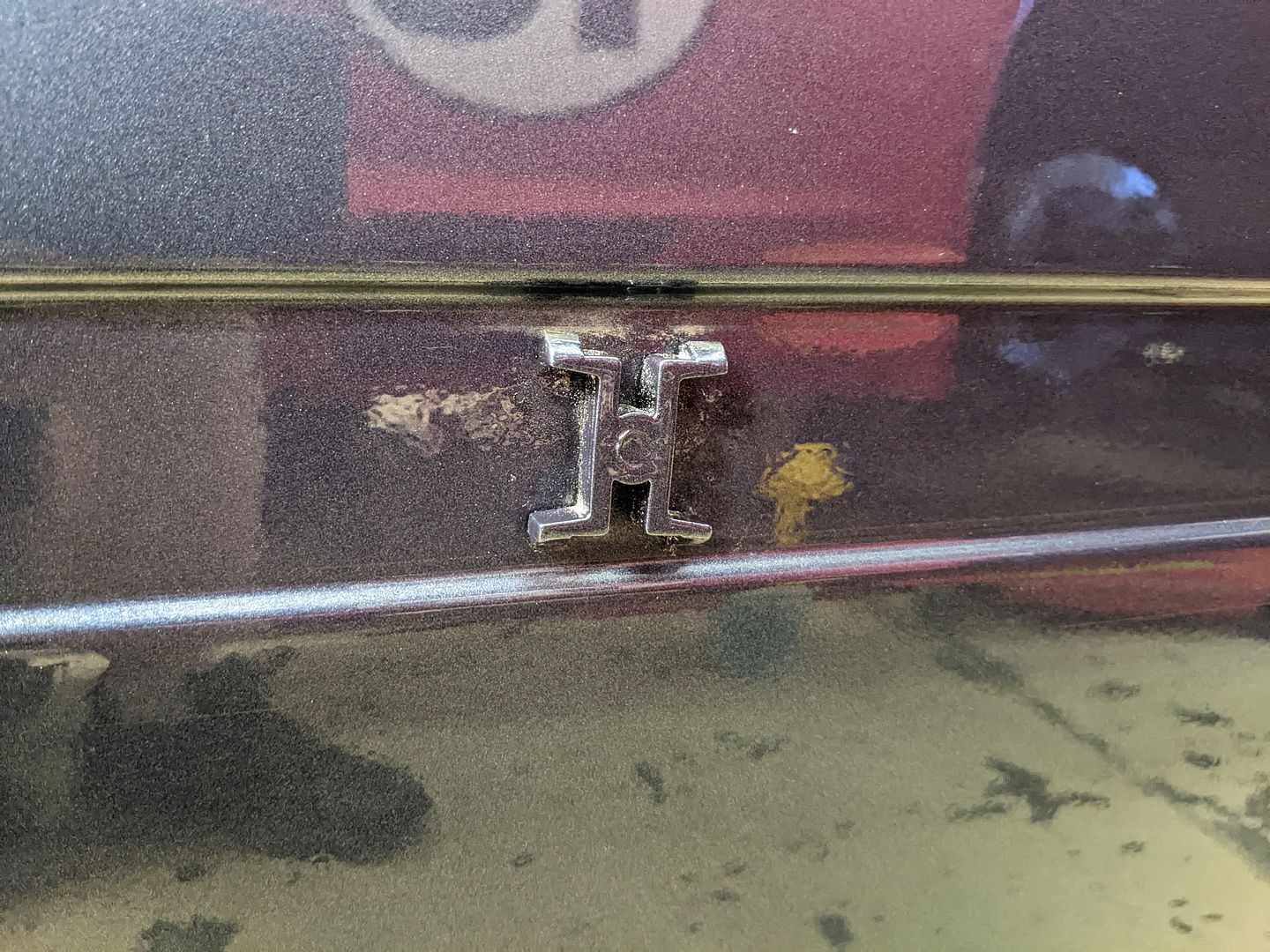

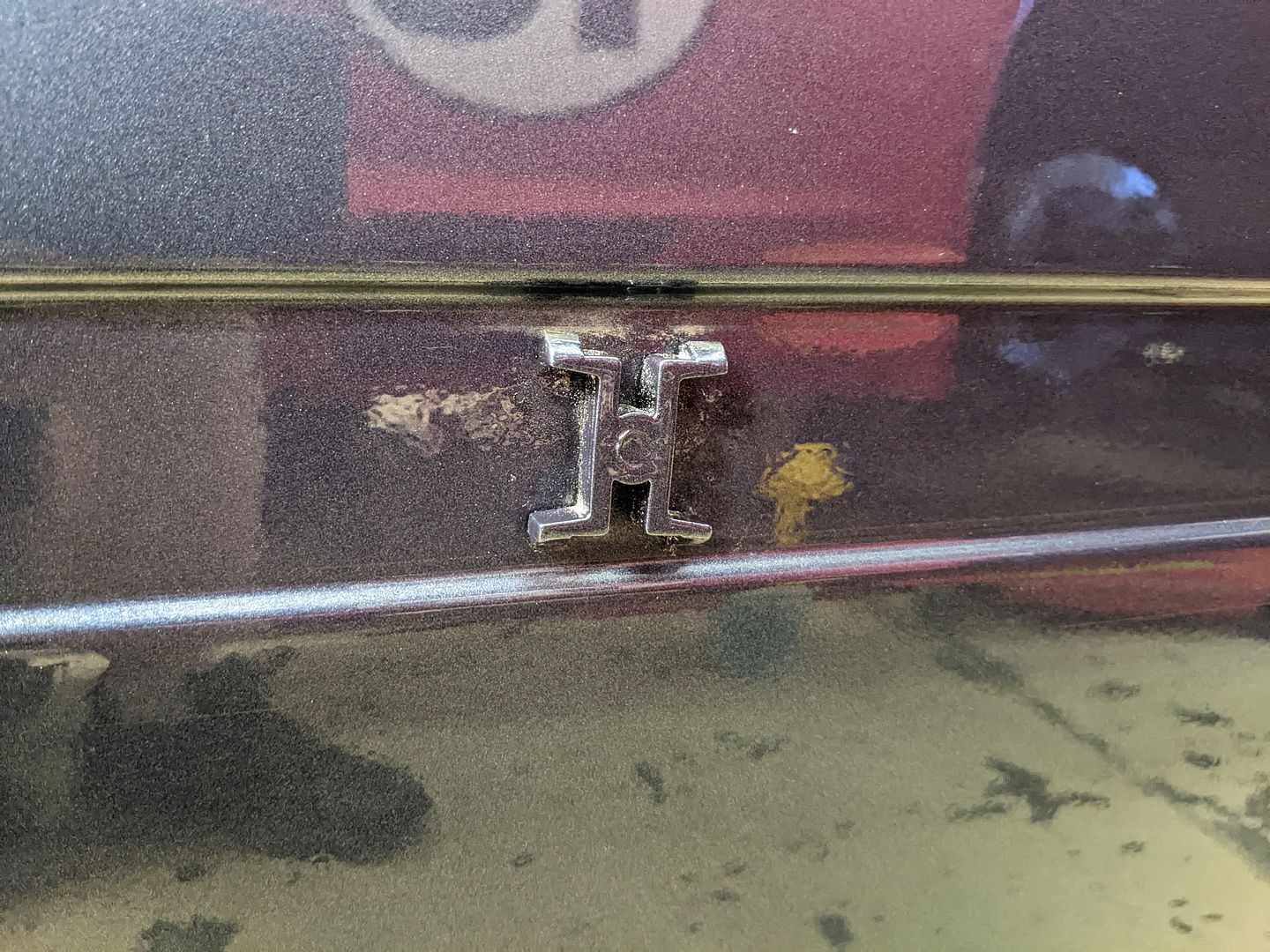

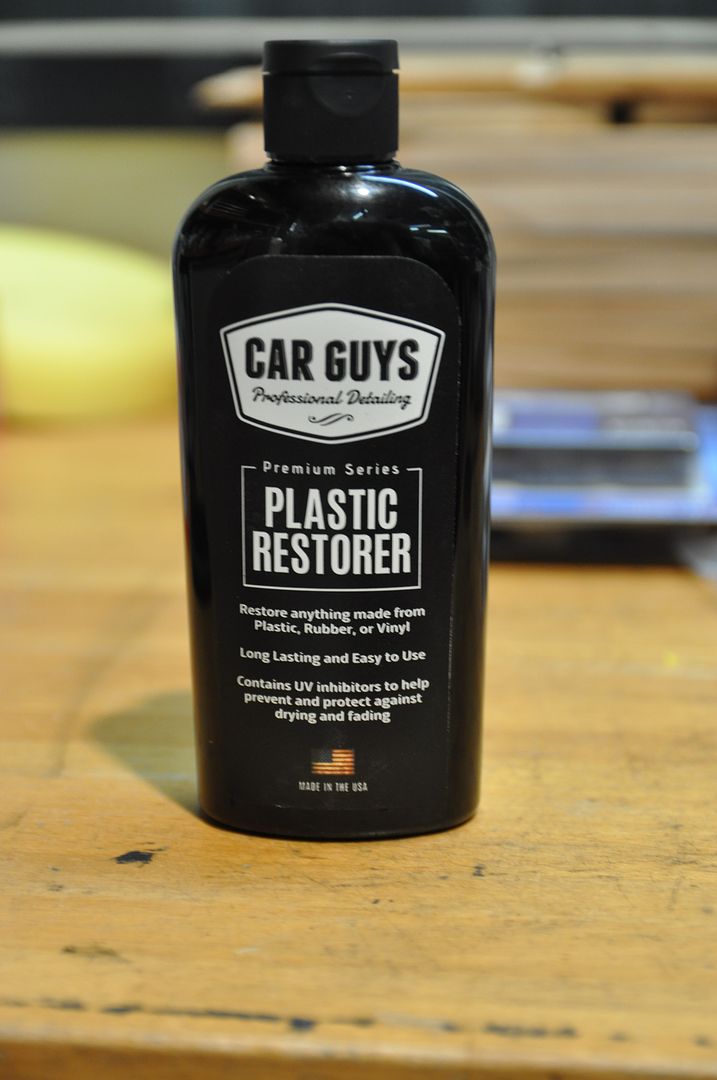

Door Lower Edge Guards:

After 32 years those rubber edge guards were starting to show their age and wear. Multiple dings, scrapes, and general fading left these kind of dull looking and a bit distracting. No matter what refinishing and/or cleaning and treatments I did, I couldn’t restore them completely. On the M535i these are Shadowline trim so finding good replacements was next to impossible. Fortunately, these are still available from BMW; but unfortunately not all of them are available: missing are the Driver’s front fender and the Passenger’s rear door.

Replacing these is very easy actually as they are held in with just one plastic capture nut and some plastic clips on the door:

1) Open door, remove the plastic capture nut on the inside of the door edge at the back

2) Gently pry off the edge guard with the correct plastic trim tools, they will pop off the clips with some concentrated effort

3) Replace any retaining clips as needed, thoroughly clean behind them and prep the replacement edge guards (it’s a good idea to pre-thread the plastic capture nuts ahead of installation) as well as treating the new rubber. Mine were obviously not removed during the car re-paint in 1990-91(these are white and still available in bulk from BMW):

4) Install the new edge guard in reverse order.

However, that left what to do about the two pieces that couldn’t be replaced with new. The two choices were to source a good used part or refinish my old ones. I was able to find a pretty nice rear door strip which was actually better than mine (no dings).

I couldn’t find that front fender one to save my life. The issue with mine were mars and discoloration which I couldn’t do anything with by simple means; it was going to require more aggressive means. One of the issues to overcome was the texture differences between the new rubber and that of a 32-year-old piece; the older ones have usually been worked smooth while the new ones have the tooth and luster of new rubber. Duplicating that finish to match the other 4 new pieces was going to take some work

Re-Finishing:

1) First step was to strip all the finish and product out of the two pieces. Scrubbing them down with degreaser and soap then soaking them in said solution to leech out as much as possible

2) Second is a firm couple passes with an acetone soaked rag. This burns in a new layer of rubber, one that has tooth

3) Third step was a light couple of passes with 220 wet sandpaper, then progressively down to 600 grit. The trick is to not to polish the rubber too much, you need to leave texture in your wake.

[URL=https://hosting.photobucket.com/images/ ... fit=bounds]

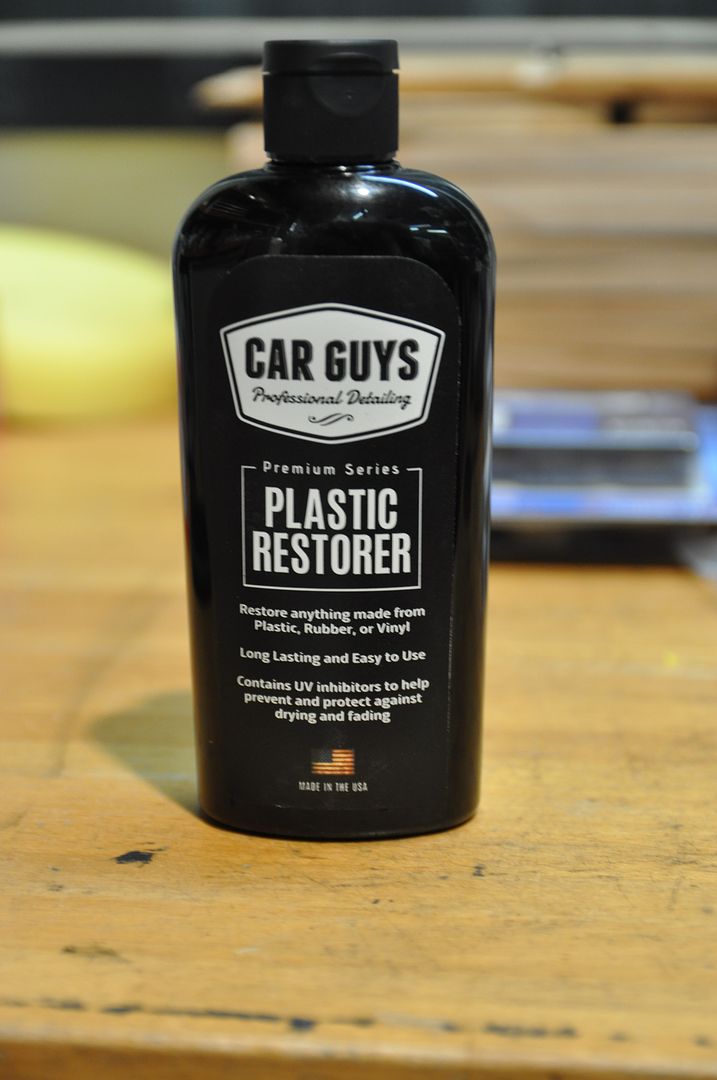

4) Next was to put back something to restore the rubber and get the color back. I tried out the myriad of the many, many different rubber treatment products in my cabinet on one of the old trim pieces. I finally settled on this one: Trim Restorer:

It was less a topical cover like Back To Black and some others; it actually soaks in while leveling out the finish and matches the luster of the new rubber. It takes some practice in application so as not to leave streaks and get even coverage. Let it soak in for as long as you can (6, 12, 24 hours or longer). Lightly buff it in one direction with a clean microfiber to remove any excess and even out the finish. It may take a few coats. If you leave streaks you have to strip it off with acetone and start over. Since I don’t wash the car down with water & soap nor does it sit out in the rain and sun, time will tell how long this finish lasts.

Coincidentally I tried a similar process on the rubber M-Tech Rear Spoiler rubber lip, that is a work in progress. (More and that soon).

M5 Sun Visors:

I put these in kind of at the last minute during the Interiors project simply because I had forgotten I had a set of these lighted M5 Sun Visors sitting in a box for nearly a decade. I hadn’t even bothered to test them before I installed them and given how they came along late in the process, I had to get creative with the wiring for them. So, when they didn’t work part of me wasn’t surprised and I put them on the punch list. I just got around a few weeks back to addressing this issue.

1) Stated by bench testing them wherein I found out they do indeed work

2) Turns out the contacts on the receiver clips and on the visor themselves needed some attention

3)They still don’t work 100% and is dependent on what position the visor is in (the contact points on those clips is a bit 'iffy) but more than they did before, which wasn’t at all

Interior Door Handles:

Okay, I thought the Wiper System was a splurge, this, however was a total indulgence. After I have replaced several Interior Door Latch assemblies in recent years, it is evident that the quality of these new parts is really lacking. Someone came up with solution, albeit an over the top, expensive one. Leo Grande Racing out of Long Island, NY started fabricating aluminum replacement assemblies. This included the one part that keeps breaking: the Interior Trim Ring. These are really robust pieces that will hopefully outlast my lifetime.

Here I was in a bit of quandary regarding the Trim Rings: BMW still makes replacements in a color that they claim is Taurusrot but in reality is Cardinal. All my used or old NIB Taurusrot trim rings consistently break even after I tried reinforcing them by laying down a bead of Super Glue on the back side. (You can see the 'new' Taurus rings in one of the photos below; see how light it is compared to either the original ring or vinyl cover)

The quandary was that Leo Grande only makes the Trim Rings in either black or clear anodized finishes. I could have simply accepted the black ones, but I just couldn’t, not after spending all this effort on the Taurusrot interior; it seemed a sacrilege. Since they weren’t changing their finishes, I asked for milled finish and decided to powder coat the rings in a matching color.

After going through RAL color samples at the powdercoater, I came up with one from Prismatic Powders (RAL 8016). It’s actually a brown but given the brown nature of Taurus in certain light, it works. Too bad it’s only available in a gloss finish, but I’m living with it. I may apply a satin or low luster topcoat to knock that sheen down eventually. I will also paint the trim screws either to match or just black.

Installation was easy and they go in just like the OEM versions: Remove Trim Ring, Armrest/Handle, and Door Panel. Disconnect & remove existing latch. Connect and install new latch. Re-install all the components. Screw on the finish Trim Ring with the oh-so-impossibly small torx screws they provide. You’re set.

Yeah, it is an expensive solution to a minor problem but I did it anyway.

Door Weatherstripping & Door Sills:

This too is a work in progress but is getting closer to being complete. I installed my original rear sets, but due to an extreme case of brain-fartness, I ‘lost’ my original front sets. I temporarily installed a set of after-market versions sourced from a guy in Turkey via ebay. While they don’t have the requisite “Mouse Fur” of the OEM, they fit really well and offered complete door opening coverage. This is the real weak part of the E28 door seal system: the seal breaks at the Door Sills and nothing is underneath them to seal off the opening adequately (BMW offered complete opening seals in almost every other model except the E28 and E12).

I also ‘lost’ my two front Door Sills (I don’t know what happened that week in the Hangar) and of course these are NLA so I set out trying to find decent, clean replacements; a tall order. I have plans to modify the sills and add some rubber/foam profile weatherstrip to build a better mousetrap, more complete seal to the bottom of the door seal to get better acoustic control.

In the meantime, the E12 Door Sills are/were available and compared to used E28 sills, a bargain from BMW. The E12’s are also all black which I tend to like better with my interior.

Door Lower Edge Guards:

After 32 years those rubber edge guards were starting to show their age and wear. Multiple dings, scrapes, and general fading left these kind of dull looking and a bit distracting. No matter what refinishing and/or cleaning and treatments I did, I couldn’t restore them completely. On the M535i these are Shadowline trim so finding good replacements was next to impossible. Fortunately, these are still available from BMW; but unfortunately not all of them are available: missing are the Driver’s front fender and the Passenger’s rear door.

Replacing these is very easy actually as they are held in with just one plastic capture nut and some plastic clips on the door:

1) Open door, remove the plastic capture nut on the inside of the door edge at the back

2) Gently pry off the edge guard with the correct plastic trim tools, they will pop off the clips with some concentrated effort

3) Replace any retaining clips as needed, thoroughly clean behind them and prep the replacement edge guards (it’s a good idea to pre-thread the plastic capture nuts ahead of installation) as well as treating the new rubber. Mine were obviously not removed during the car re-paint in 1990-91(these are white and still available in bulk from BMW):

4) Install the new edge guard in reverse order.

However, that left what to do about the two pieces that couldn’t be replaced with new. The two choices were to source a good used part or refinish my old ones. I was able to find a pretty nice rear door strip which was actually better than mine (no dings).

I couldn’t find that front fender one to save my life. The issue with mine were mars and discoloration which I couldn’t do anything with by simple means; it was going to require more aggressive means. One of the issues to overcome was the texture differences between the new rubber and that of a 32-year-old piece; the older ones have usually been worked smooth while the new ones have the tooth and luster of new rubber. Duplicating that finish to match the other 4 new pieces was going to take some work

Re-Finishing:

1) First step was to strip all the finish and product out of the two pieces. Scrubbing them down with degreaser and soap then soaking them in said solution to leech out as much as possible

2) Second is a firm couple passes with an acetone soaked rag. This burns in a new layer of rubber, one that has tooth

3) Third step was a light couple of passes with 220 wet sandpaper, then progressively down to 600 grit. The trick is to not to polish the rubber too much, you need to leave texture in your wake.

[URL=https://hosting.photobucket.com/images/ ... fit=bounds]

4) Next was to put back something to restore the rubber and get the color back. I tried out the myriad of the many, many different rubber treatment products in my cabinet on one of the old trim pieces. I finally settled on this one: Trim Restorer:

It was less a topical cover like Back To Black and some others; it actually soaks in while leveling out the finish and matches the luster of the new rubber. It takes some practice in application so as not to leave streaks and get even coverage. Let it soak in for as long as you can (6, 12, 24 hours or longer). Lightly buff it in one direction with a clean microfiber to remove any excess and even out the finish. It may take a few coats. If you leave streaks you have to strip it off with acetone and start over. Since I don’t wash the car down with water & soap nor does it sit out in the rain and sun, time will tell how long this finish lasts.

Coincidentally I tried a similar process on the rubber M-Tech Rear Spoiler rubber lip, that is a work in progress. (More and that soon).

Re: 1985 Arktisblau M535i Renovation - Progression

MORE 2023:

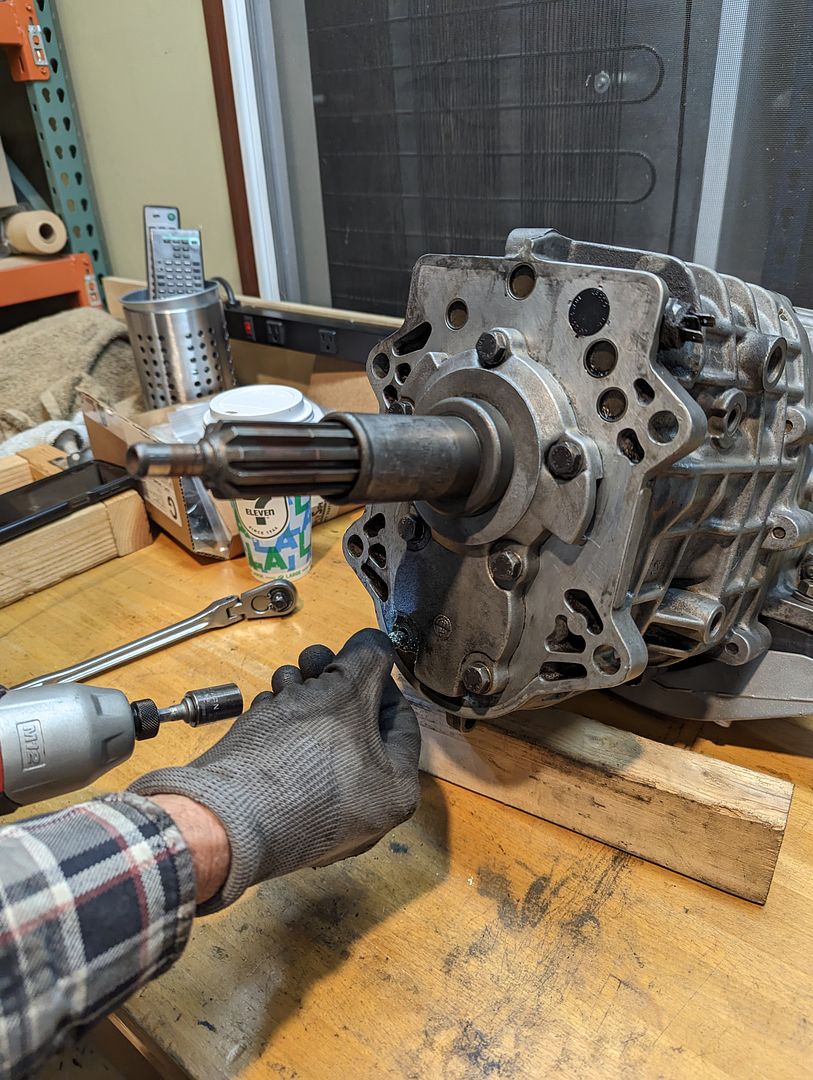

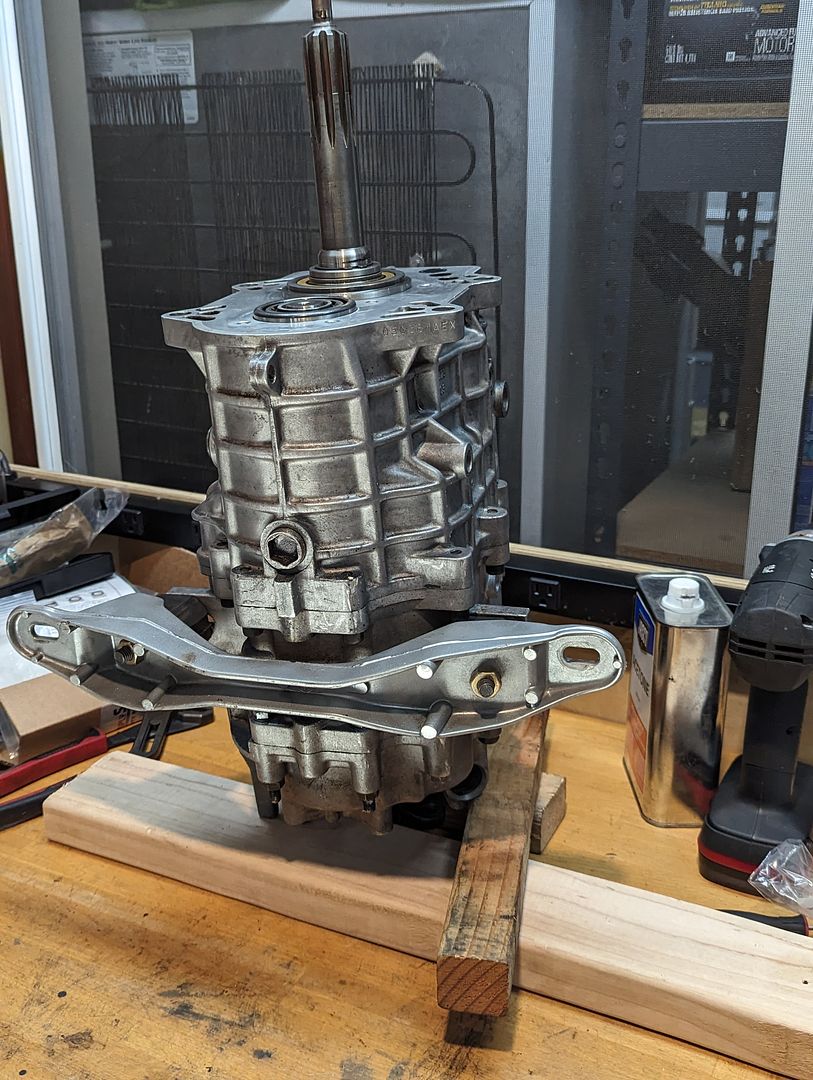

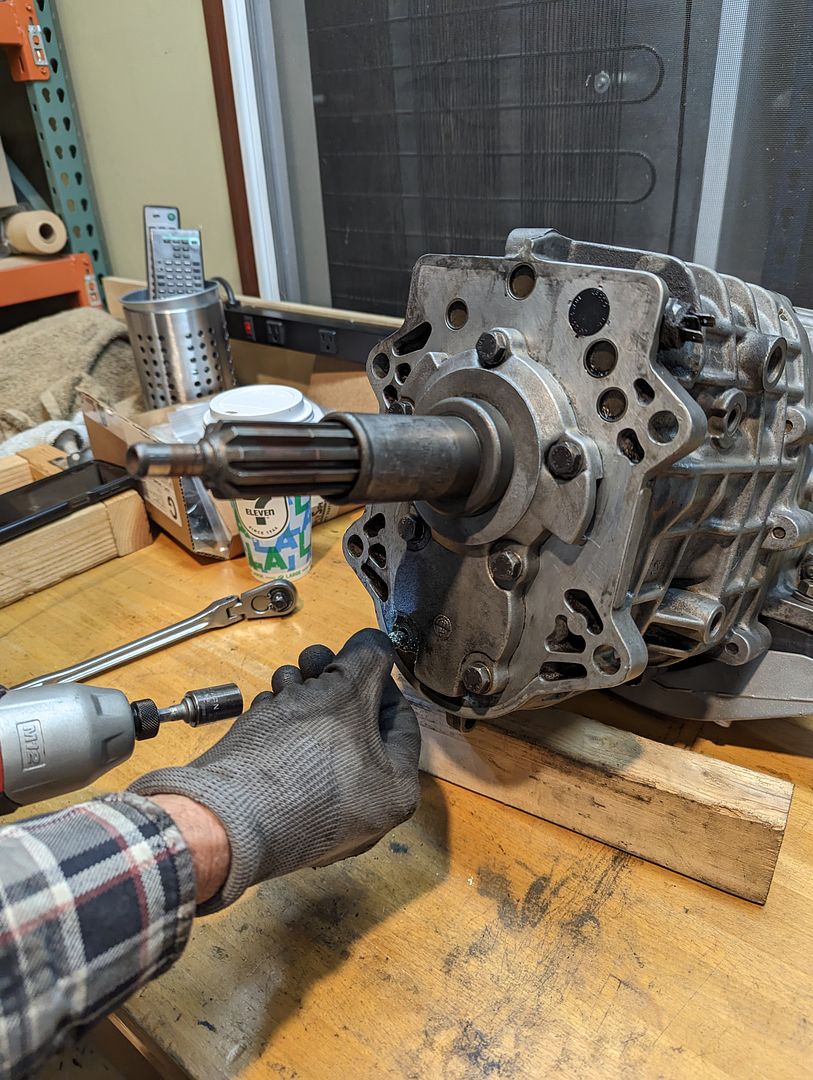

Transmission Repairs:

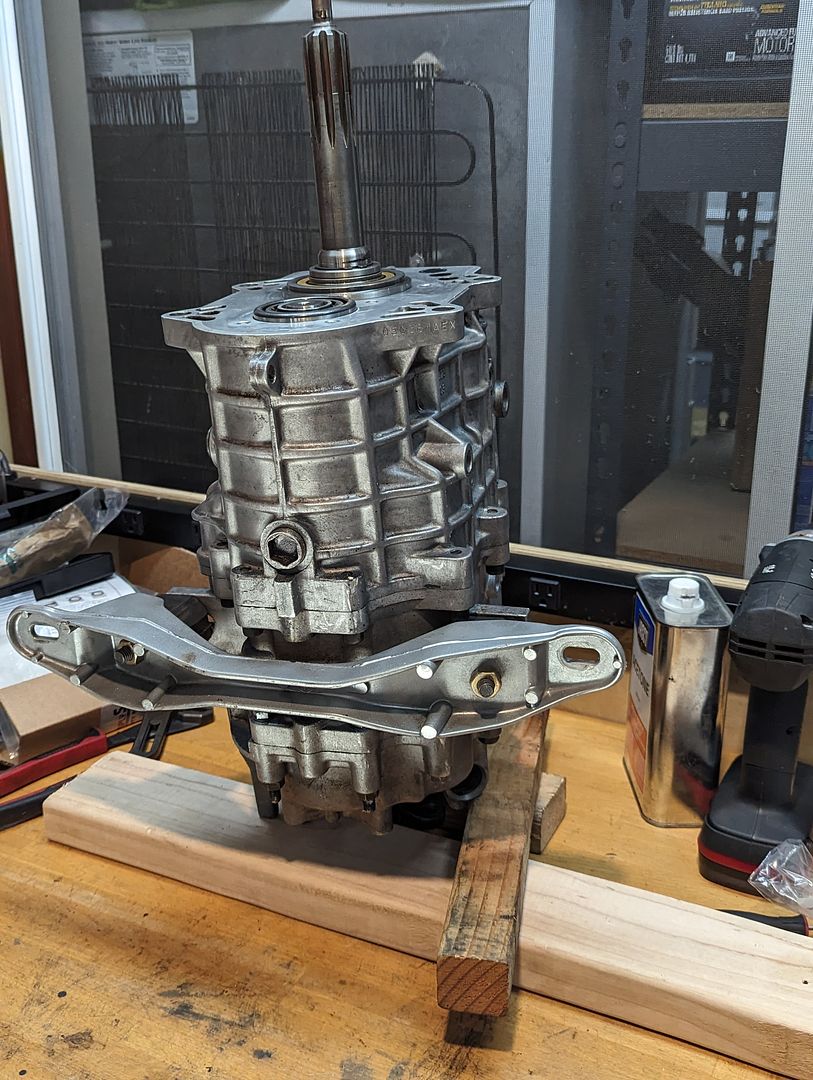

Okay that leads up to the last item I did just before the holidays: Transmission troubleshooting. This has been on the Punch List since 2016 when I did the last big mechanical work. I have a Getrag G265/6 Overdrive unit in this car (this is actually the third such unit this car as seen since it was converted to manual back in 1989/90). The big issue is the trademark signature of these older transmission: excessive internal Bearing noise. Derogatorily known as the “Death Rattle” and is most noticeable when in neutral and the clutch out. It actually doesn’t automatically mean the unit has failed as it can usually go for years in this state under normal or light driving conditions. But it does get progressively worse, as my current one is doing.

The big culprit for the G265/6 is the wearing of the Input Shaft Bearing (ISB); FAG made these for BMW and they discontinued making them decades ago. The versions for the /6 are unique to these so any old replacement is insufficient and they are next to impossible to find any NIB. There are whole threads on this issue, so I won’t go into too much of the R&D for solutions and/or sourcing, except to say that my partner-in-crime Ralph came up with a temporary fix that seems to relieve and lessen the rattle noise.

It involves replacing the shims around the Input Shaft just outside the ISB; BMW employed a set of steel shim snap rings of varying thicknesses in order to take up the play in the shaft (it’s almost as if they knew there would be a need for this in the future as the bearings wear out). Luckily all the thicknesses are still available so it would be a matter of determining which one to employ.

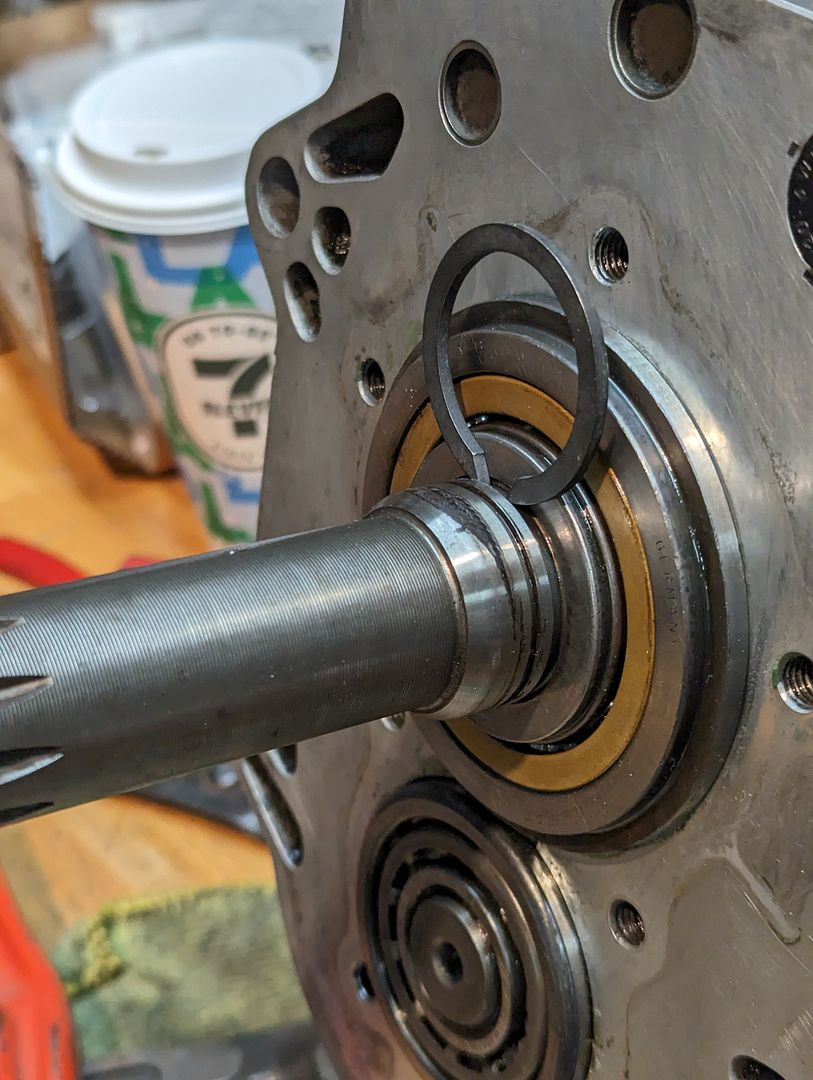

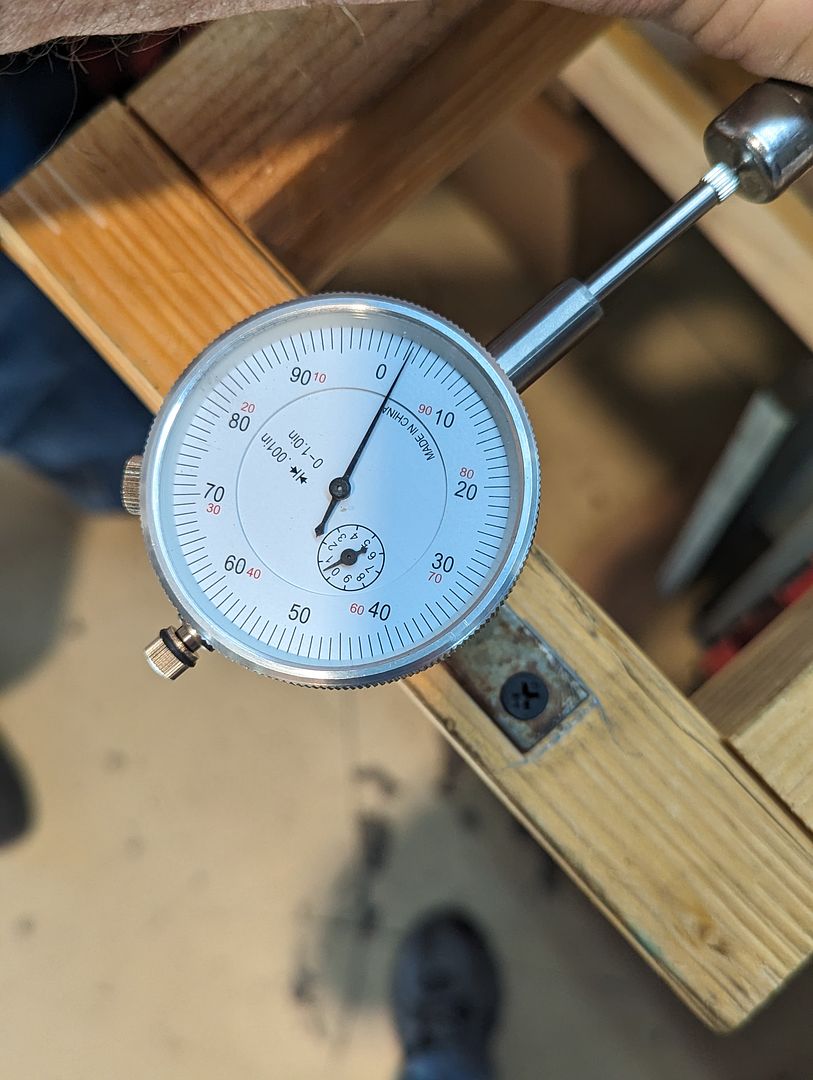

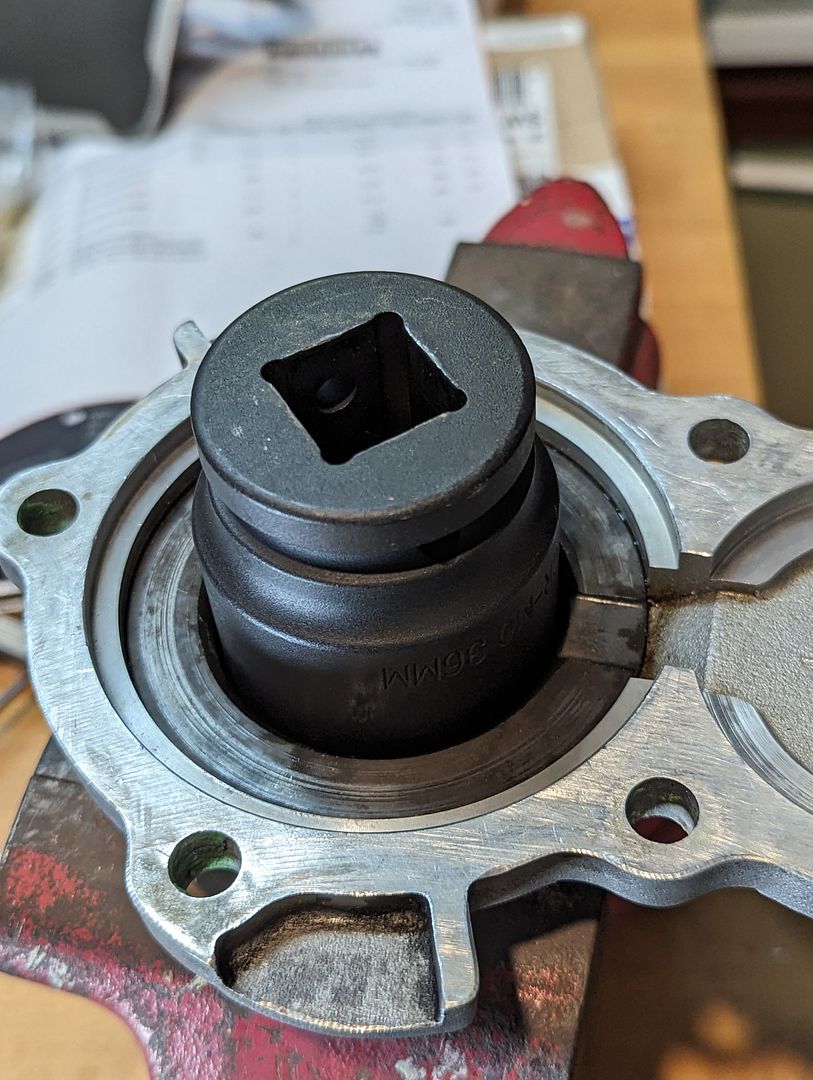

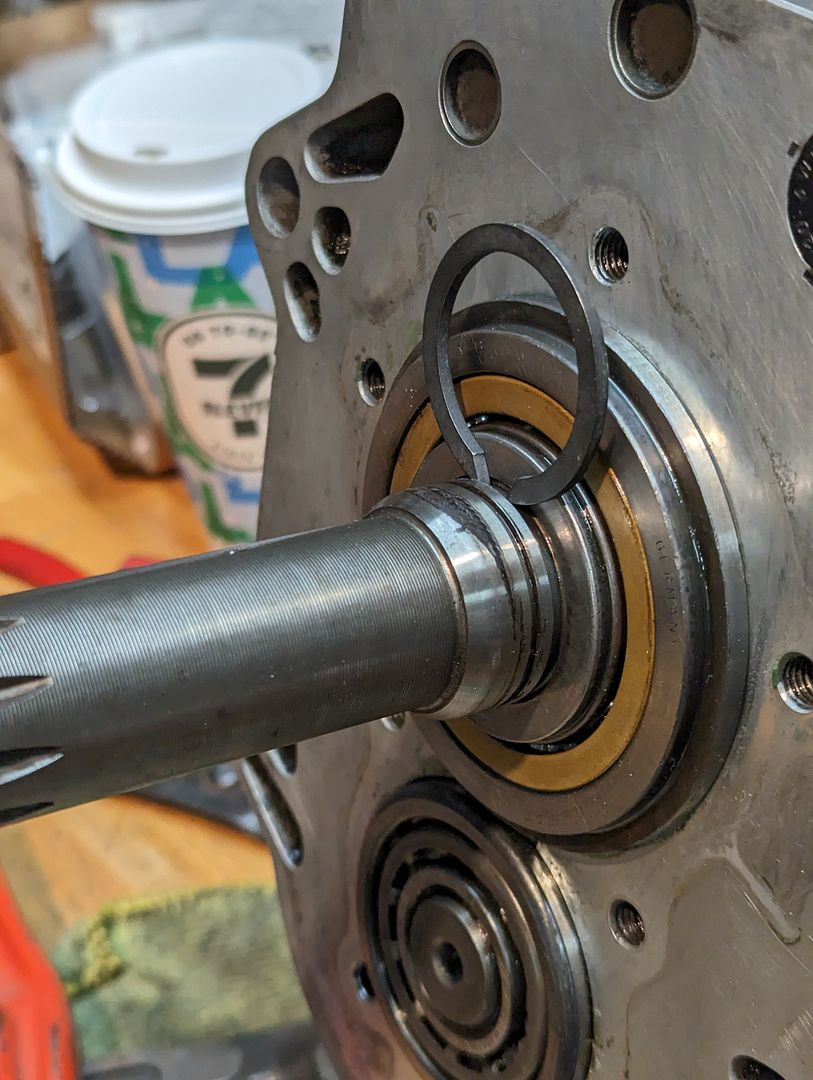

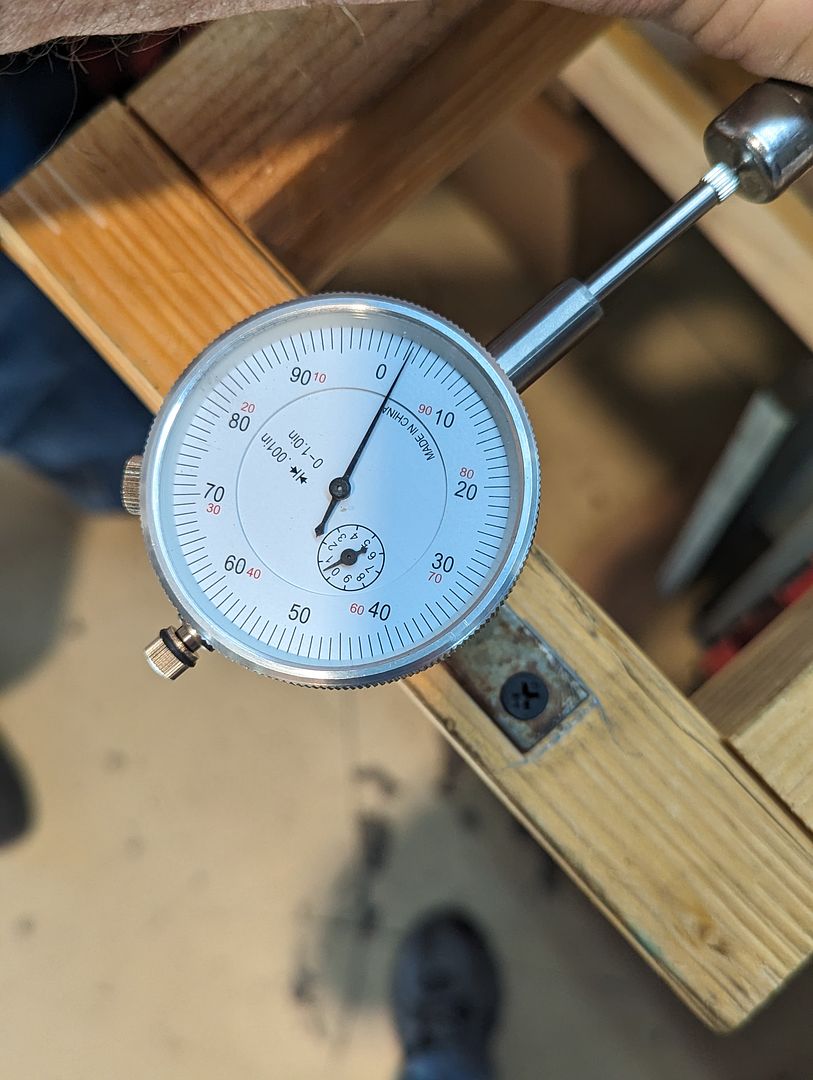

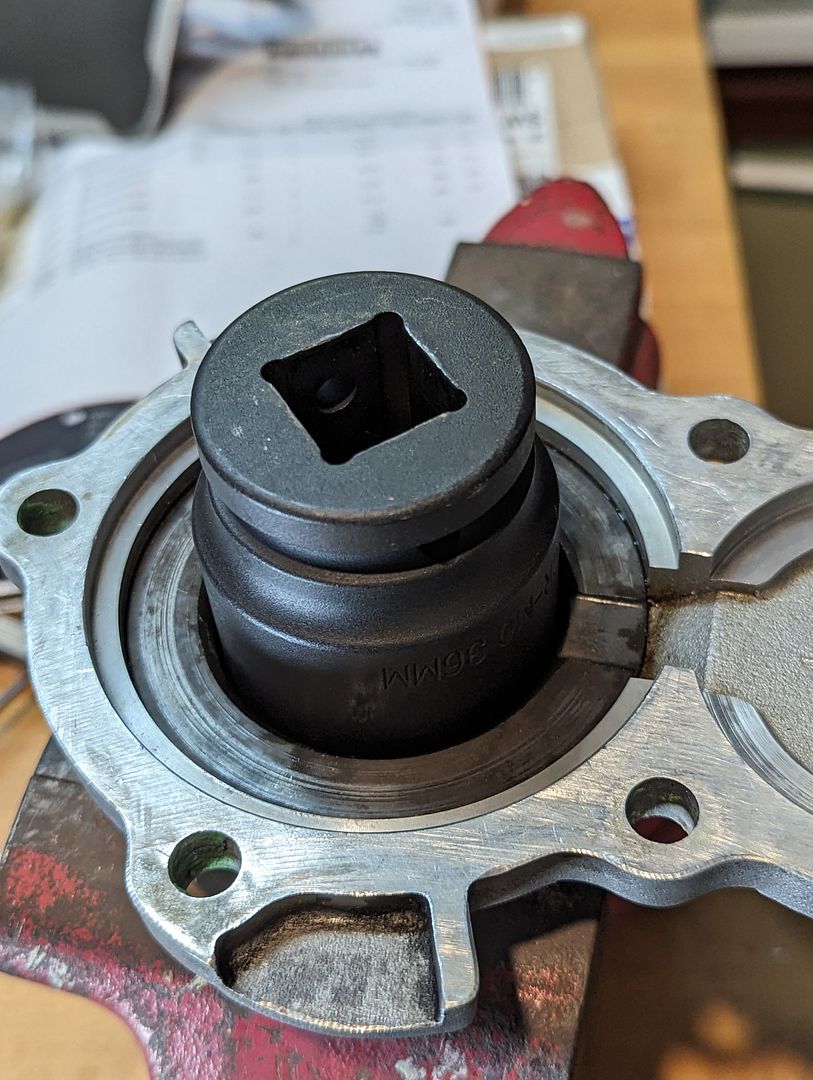

Ralph fabbed up a crude tool to measure the play (shaft in/out) and matched that to one of the shim thicknesses I picked up. As you can see when we started, there was quite a bit of play:

Replacing these shims is somewhat fairly straight-forward with the biggest PITA is the removing/re-installing the transmission itself. Having a lift makes this infinitely less of a PITA, especially for middle-aged men like Ralph & I (all that lying on a concrete floor working on our backs, oy).

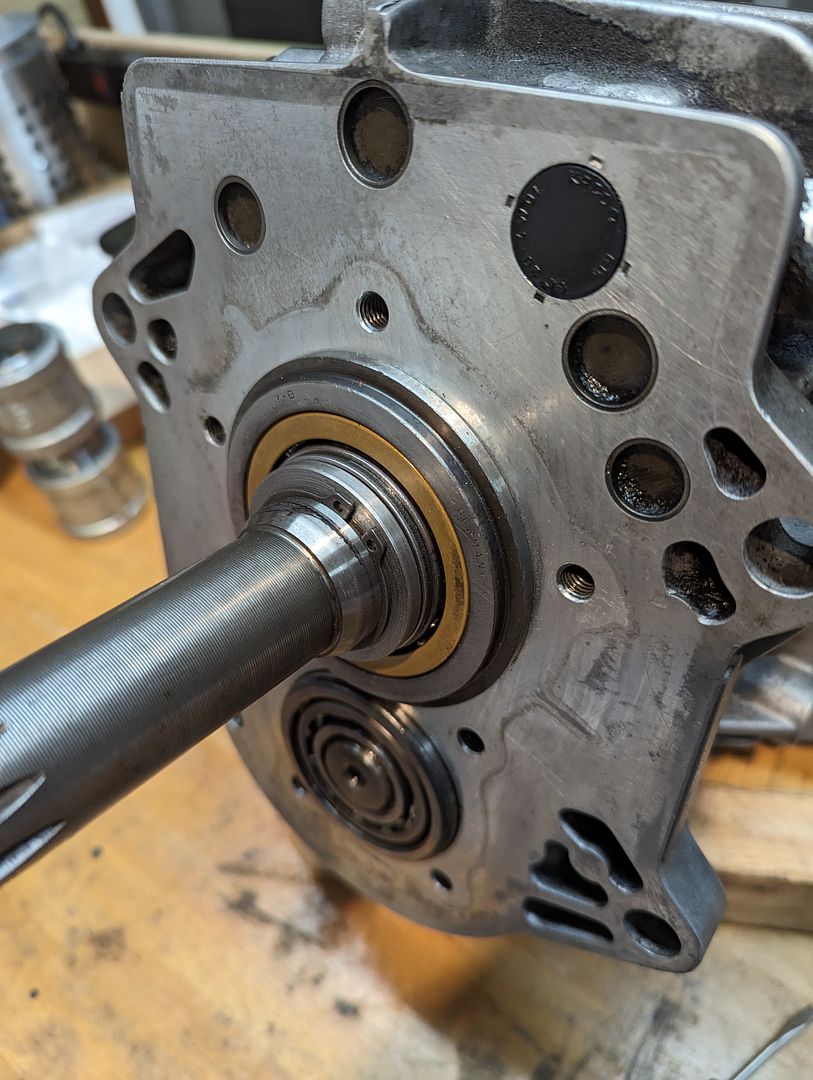

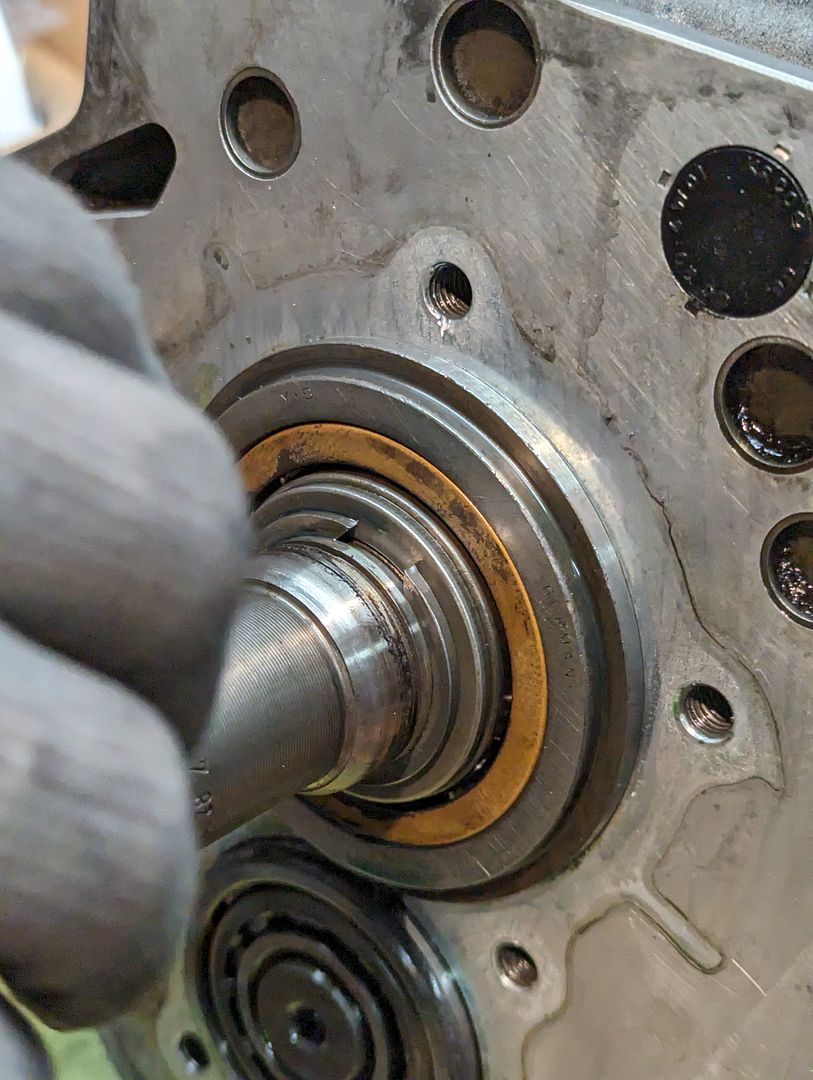

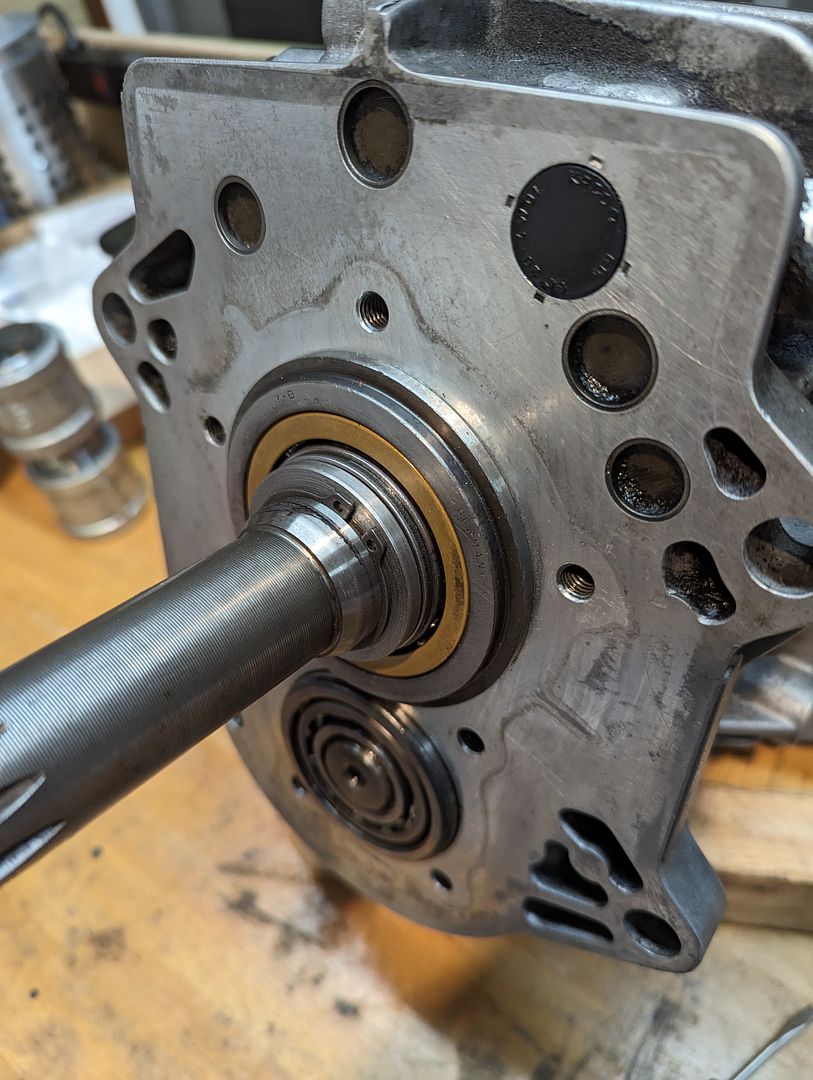

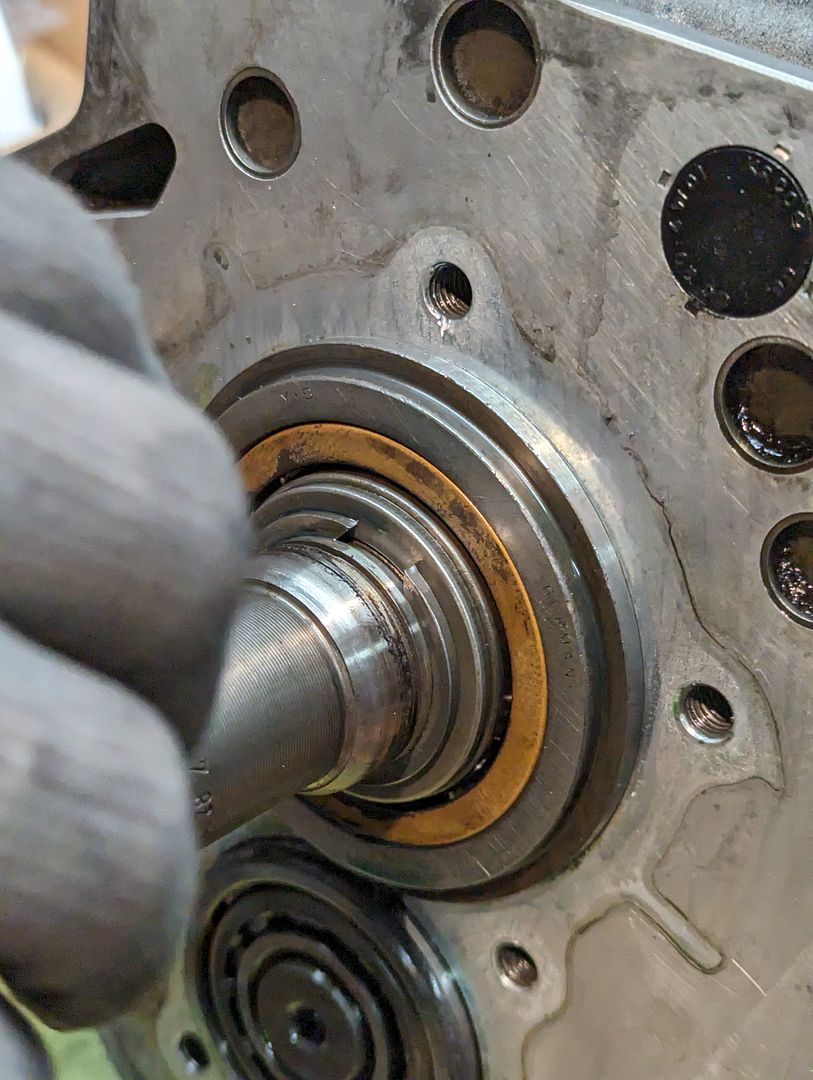

Once out and on the bench:

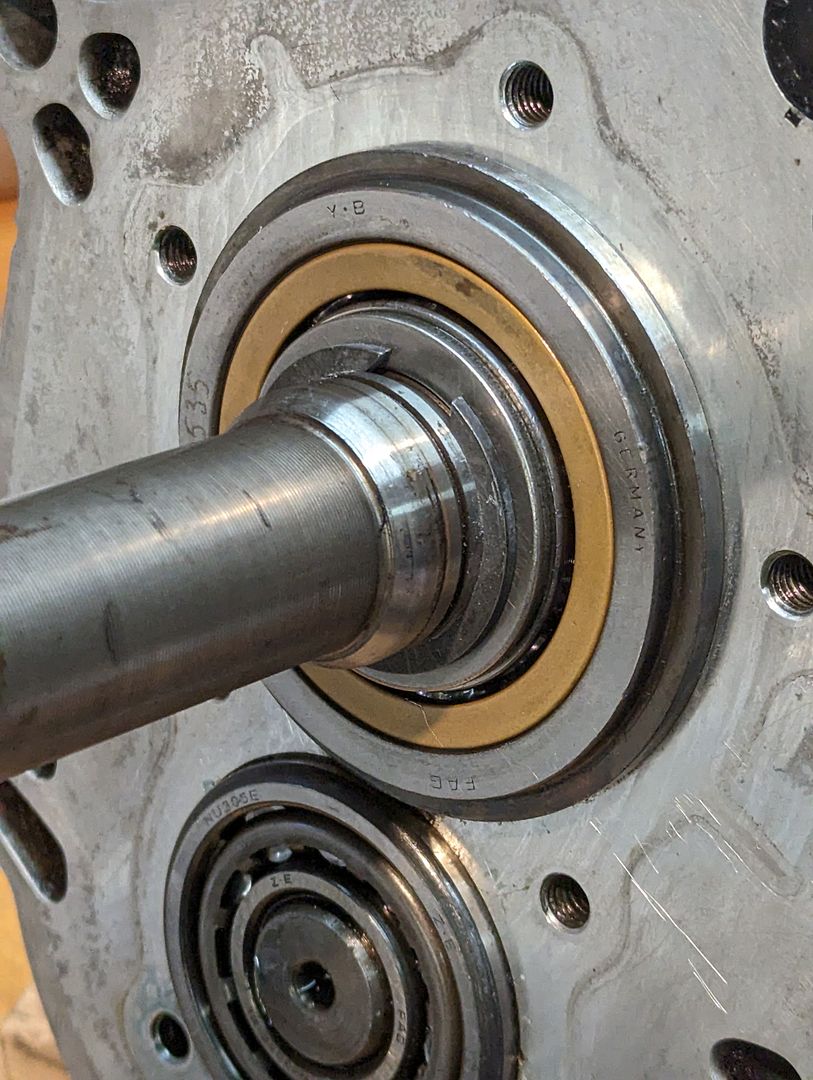

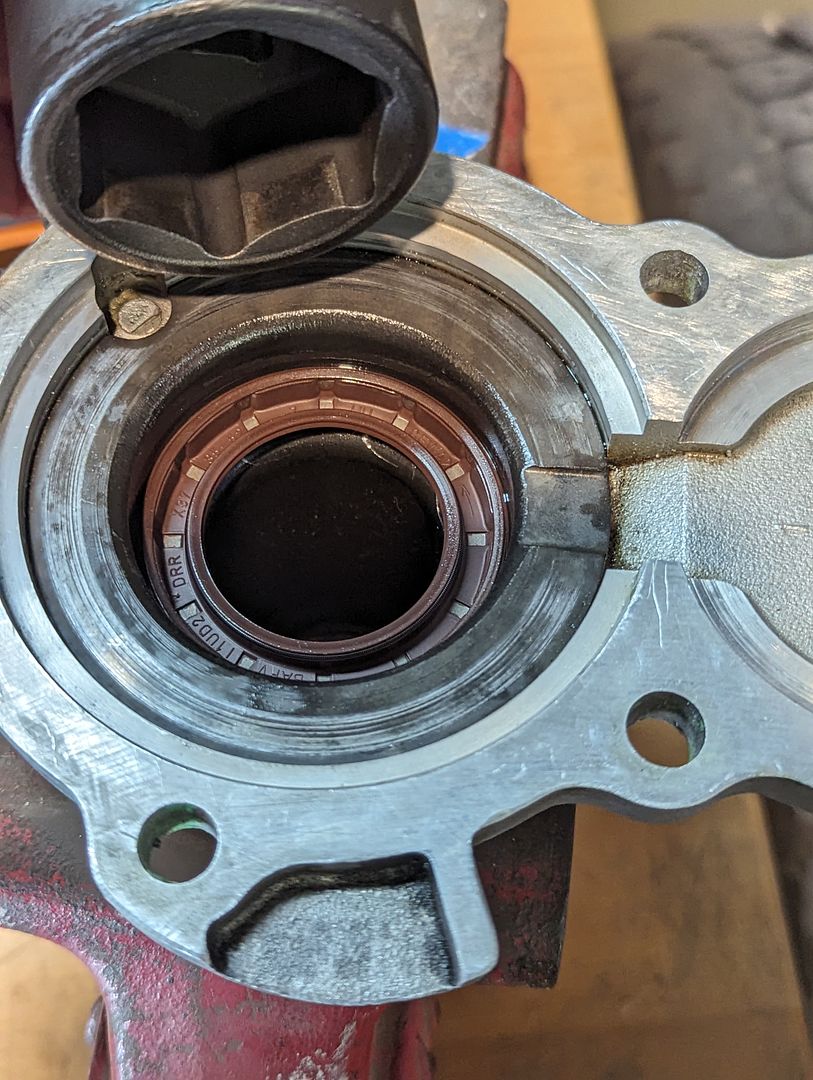

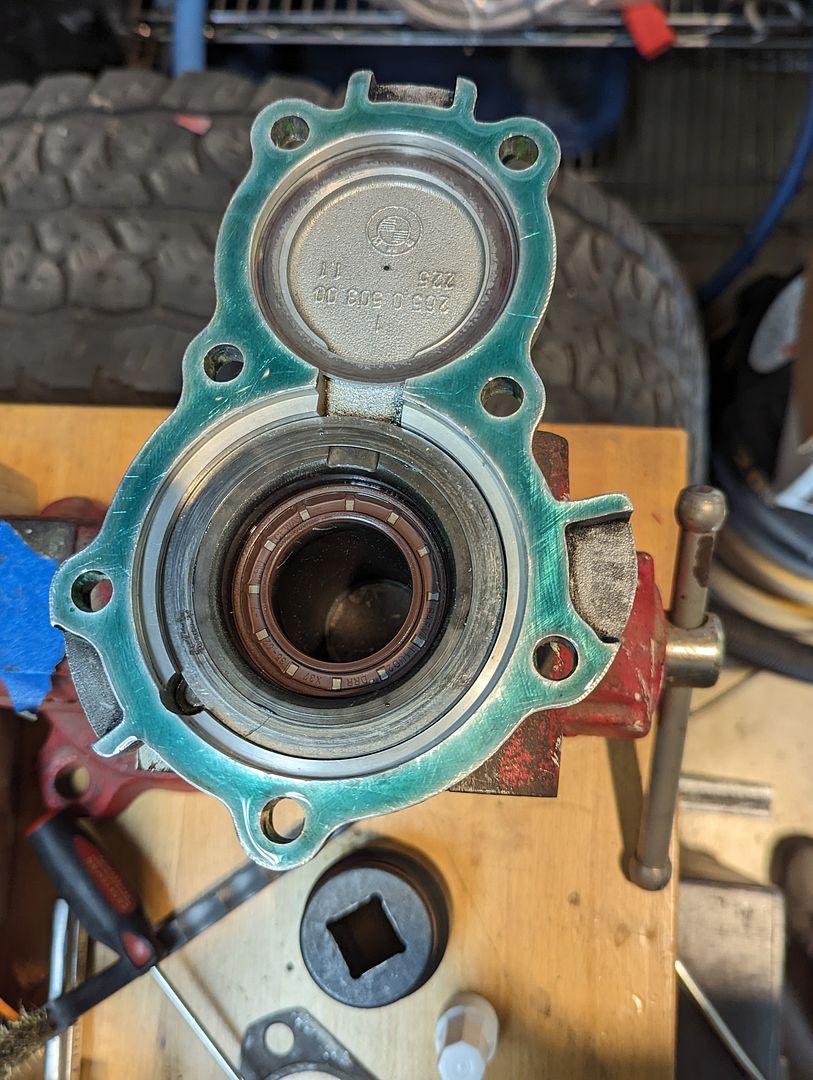

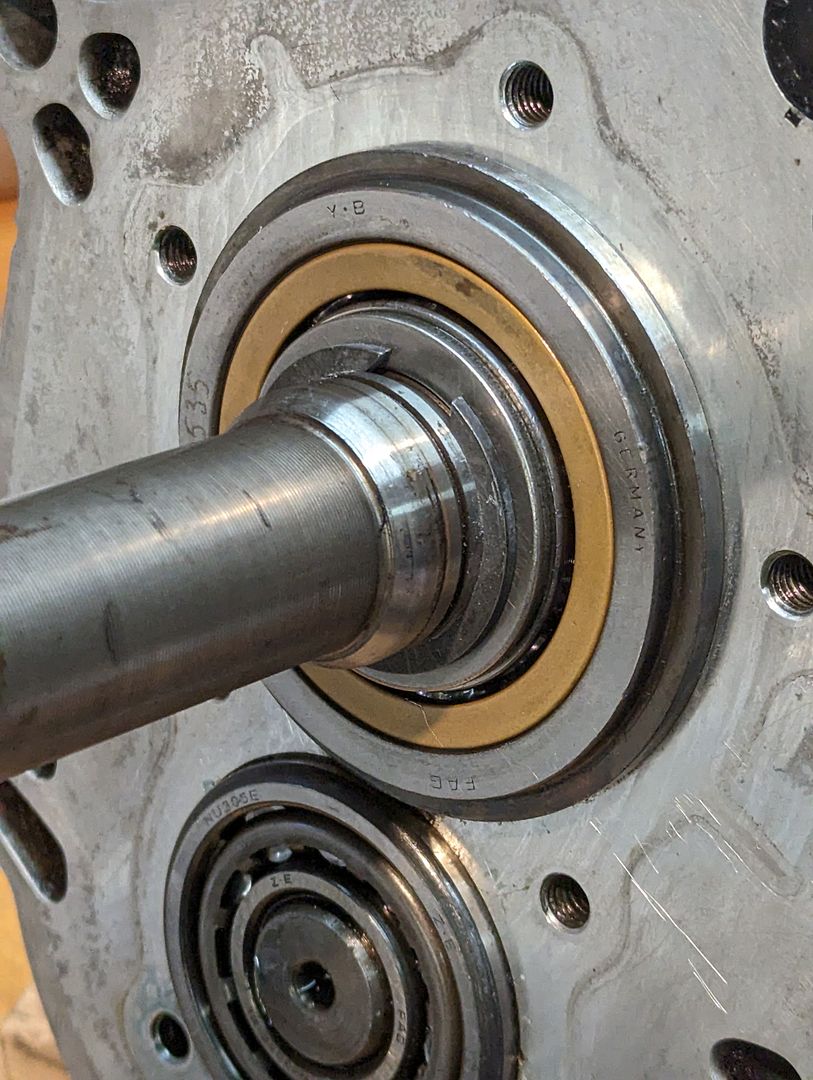

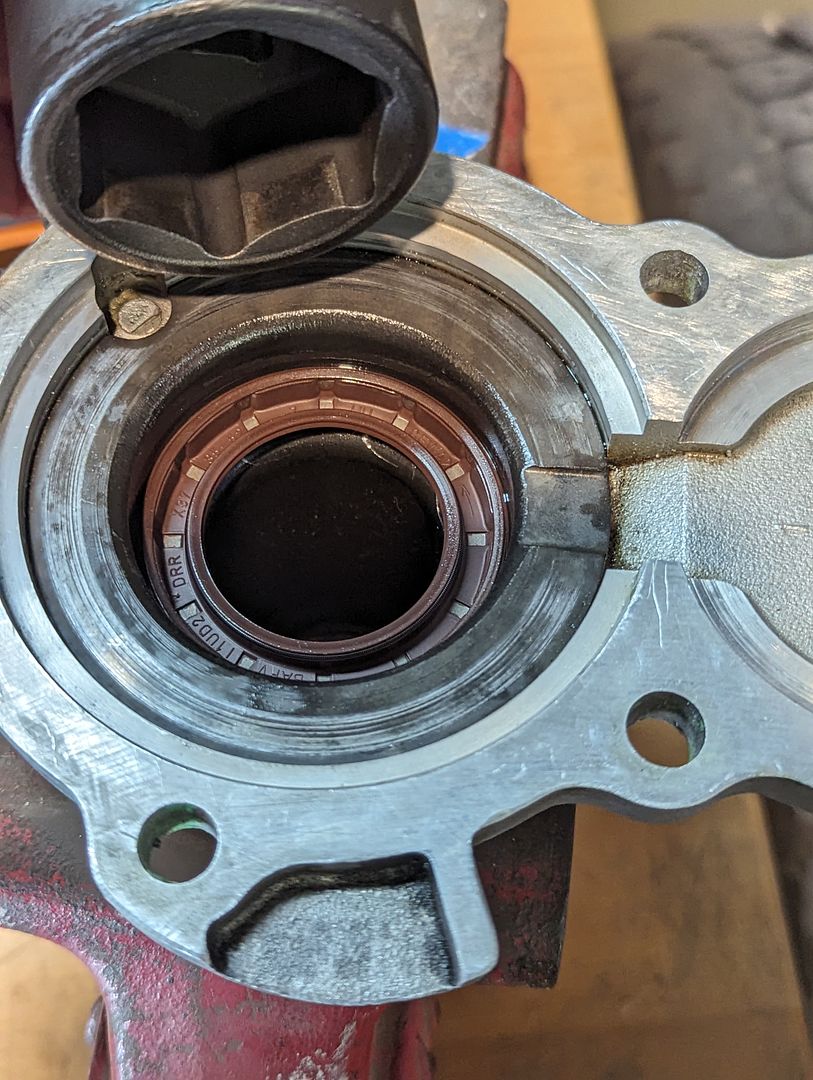

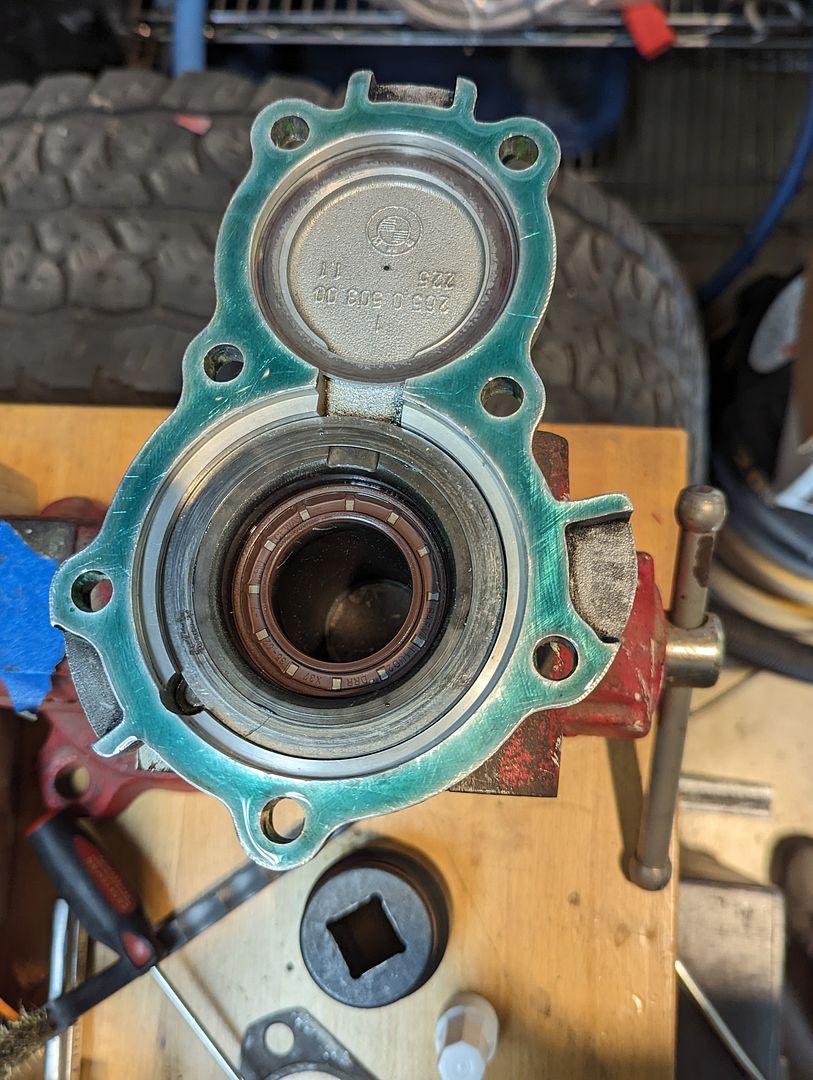

1) Remove the front cover that surrounds the Input Shaft. This exposes the shims, protection rings and the ISB itself (it’s the big thing at the back with the brass ring)

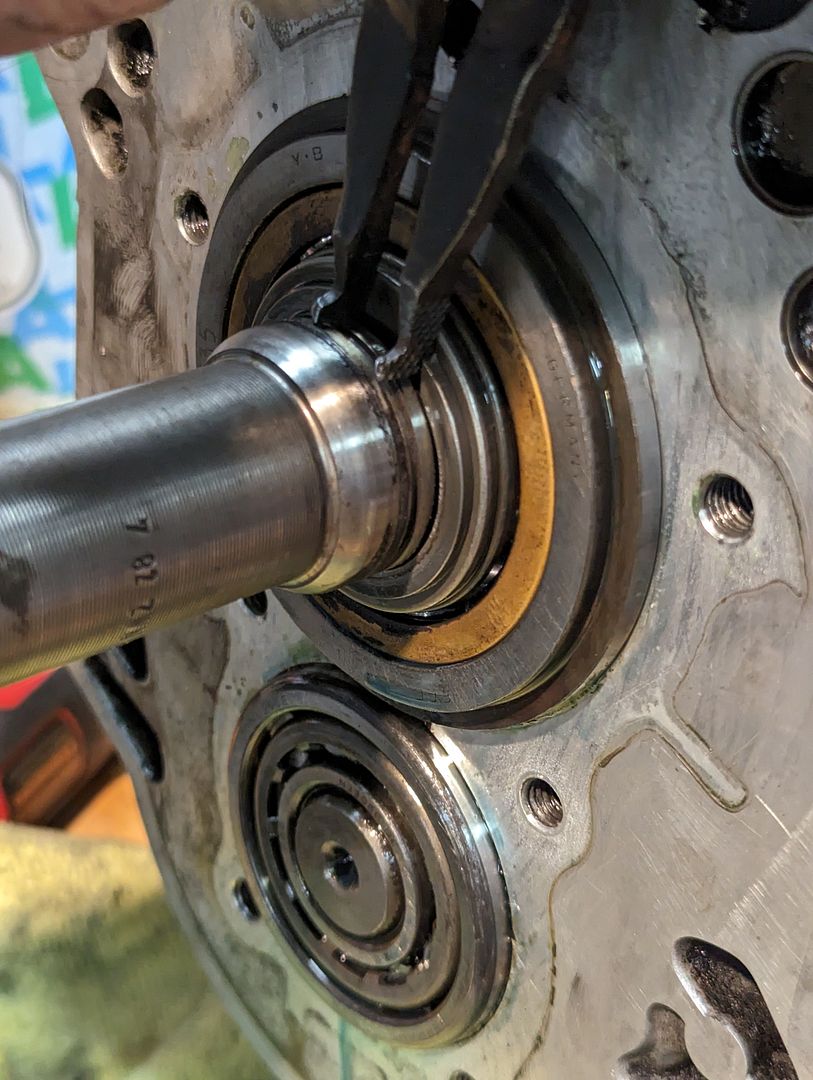

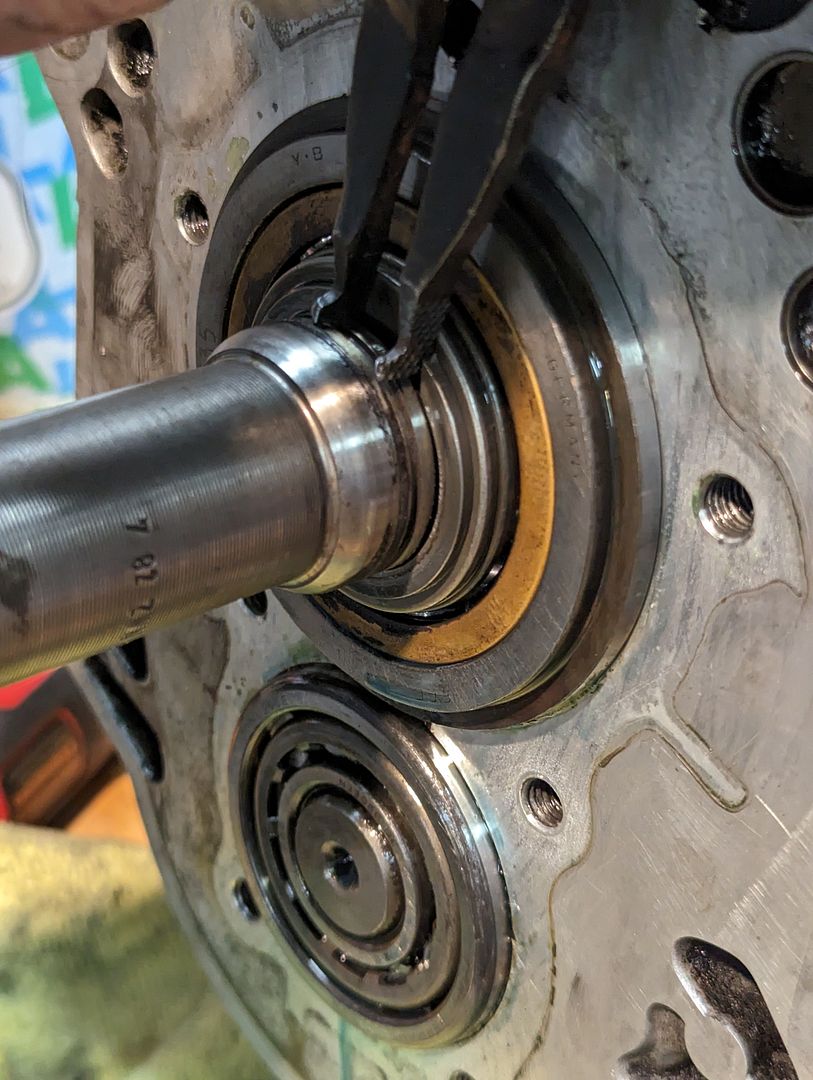

2)Now comes Ralph’s other tool: a set of simple pipe fittings to compress the shims and spacer rings back to relieve the tension and fully expose the shim ring we’re after. Without this, no snap ring plier in the world will be able to get that ring out. You’re going to maul this getting it out so don’t sweat it

3) Chose the appropriate replacement shim and begin to install it; it too will take some effort without damaging it or the surrounding components

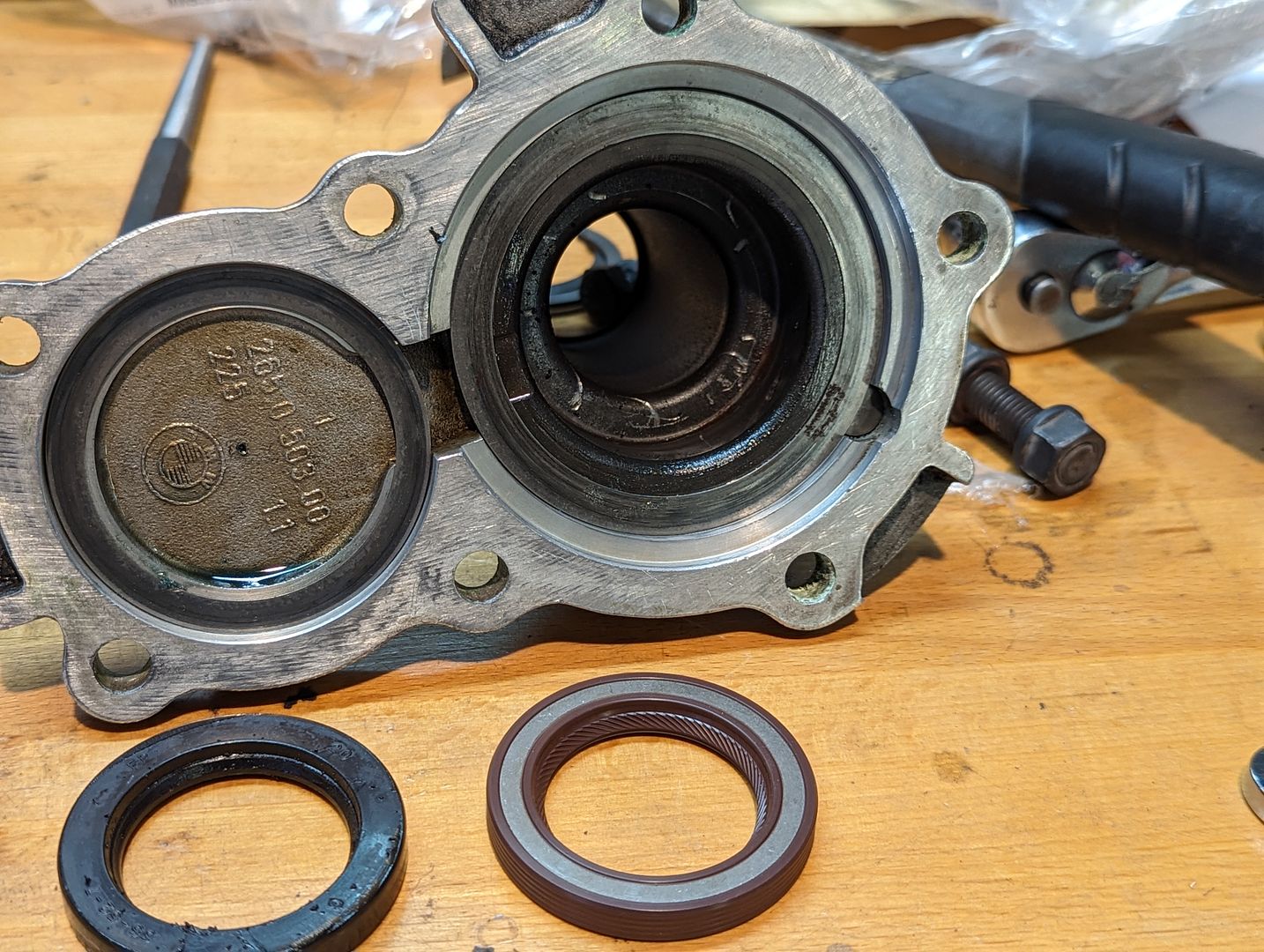

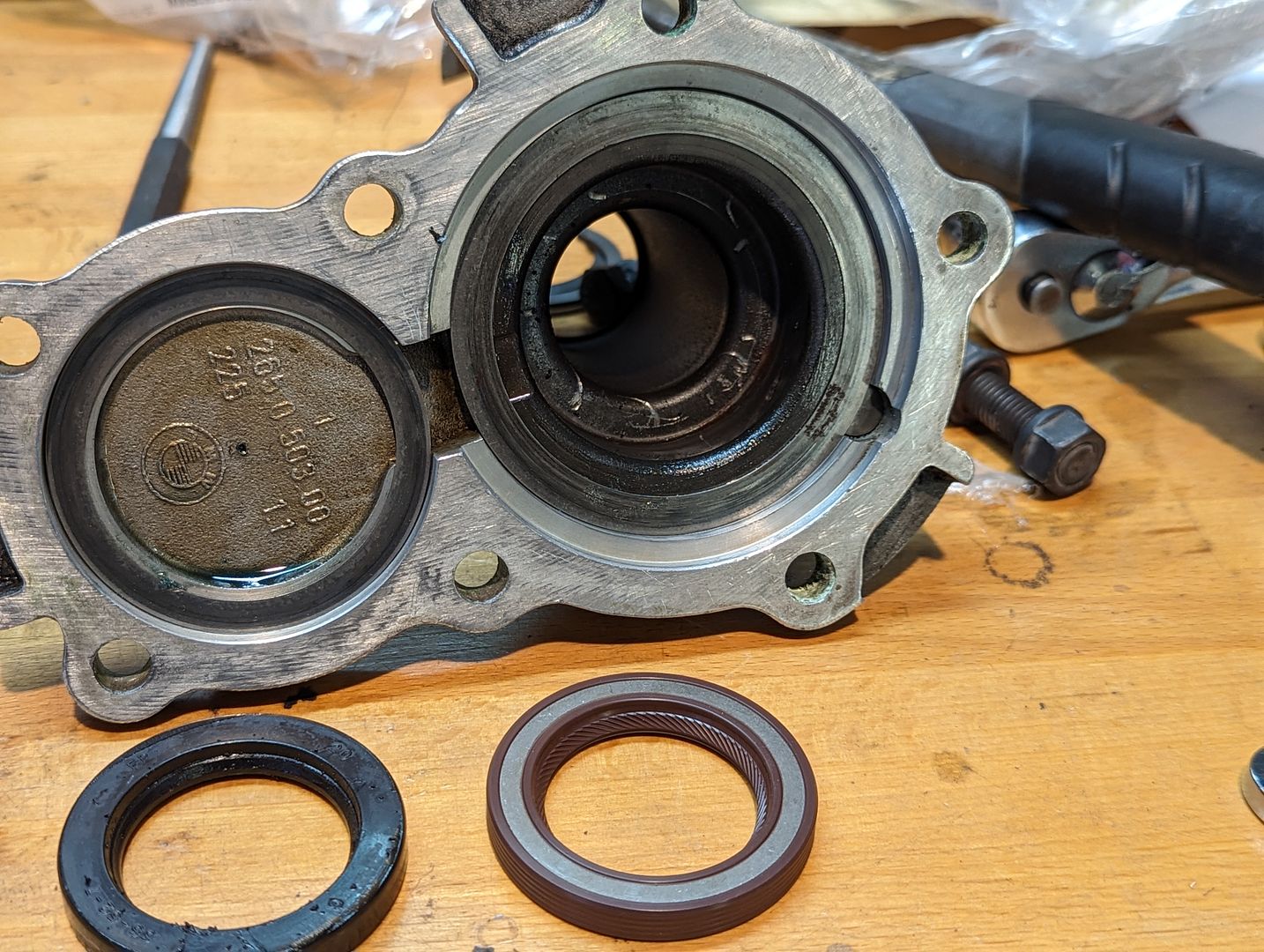

4) Re-install the old cover cap (this part is NLA so don’t damage it), a new outer snap ring and you’re done.

After shim replacement, we got the play down considerably:

Outer Cover:

Since the space behind it and around the ISB gets transmission oil into it, this cover is the source of most transmission leaks. On a /6 there is no gasket (unlike the /5 Dogleg) between the cover and case, it relies on sealant to prevent leaking. So, you need to clean off any of the old and replace the gasket/seal, making sure to properly seat it into the cover.

Liberally apply generous amount of Loctite 609 Green sealant to the Cover and re-install to the case. Torque the cover bolts, keep upright so as not to let the transmission oil into this front area until the Loctite has set up.

Next up is to reinstall the transmission (and the driveshaft, and the exhaust system, and the gear shifter, and the front sway bar). Lower the car and test drive.

The verdict?

Totally worth it, so far. The noise has been dramatically reduced; my real test however will come in two months on the long drive to San Diego and in traffic where it will get hot, that was when it was at its’ loudest. If we have some clearer days soon I will take it out for longer drives to see also.

Transmission Repairs:

Okay that leads up to the last item I did just before the holidays: Transmission troubleshooting. This has been on the Punch List since 2016 when I did the last big mechanical work. I have a Getrag G265/6 Overdrive unit in this car (this is actually the third such unit this car as seen since it was converted to manual back in 1989/90). The big issue is the trademark signature of these older transmission: excessive internal Bearing noise. Derogatorily known as the “Death Rattle” and is most noticeable when in neutral and the clutch out. It actually doesn’t automatically mean the unit has failed as it can usually go for years in this state under normal or light driving conditions. But it does get progressively worse, as my current one is doing.

The big culprit for the G265/6 is the wearing of the Input Shaft Bearing (ISB); FAG made these for BMW and they discontinued making them decades ago. The versions for the /6 are unique to these so any old replacement is insufficient and they are next to impossible to find any NIB. There are whole threads on this issue, so I won’t go into too much of the R&D for solutions and/or sourcing, except to say that my partner-in-crime Ralph came up with a temporary fix that seems to relieve and lessen the rattle noise.

It involves replacing the shims around the Input Shaft just outside the ISB; BMW employed a set of steel shim snap rings of varying thicknesses in order to take up the play in the shaft (it’s almost as if they knew there would be a need for this in the future as the bearings wear out). Luckily all the thicknesses are still available so it would be a matter of determining which one to employ.

Ralph fabbed up a crude tool to measure the play (shaft in/out) and matched that to one of the shim thicknesses I picked up. As you can see when we started, there was quite a bit of play:

Replacing these shims is somewhat fairly straight-forward with the biggest PITA is the removing/re-installing the transmission itself. Having a lift makes this infinitely less of a PITA, especially for middle-aged men like Ralph & I (all that lying on a concrete floor working on our backs, oy).

Once out and on the bench:

1) Remove the front cover that surrounds the Input Shaft. This exposes the shims, protection rings and the ISB itself (it’s the big thing at the back with the brass ring)

2)Now comes Ralph’s other tool: a set of simple pipe fittings to compress the shims and spacer rings back to relieve the tension and fully expose the shim ring we’re after. Without this, no snap ring plier in the world will be able to get that ring out. You’re going to maul this getting it out so don’t sweat it

3) Chose the appropriate replacement shim and begin to install it; it too will take some effort without damaging it or the surrounding components

4) Re-install the old cover cap (this part is NLA so don’t damage it), a new outer snap ring and you’re done.

After shim replacement, we got the play down considerably:

Outer Cover:

Since the space behind it and around the ISB gets transmission oil into it, this cover is the source of most transmission leaks. On a /6 there is no gasket (unlike the /5 Dogleg) between the cover and case, it relies on sealant to prevent leaking. So, you need to clean off any of the old and replace the gasket/seal, making sure to properly seat it into the cover.

Liberally apply generous amount of Loctite 609 Green sealant to the Cover and re-install to the case. Torque the cover bolts, keep upright so as not to let the transmission oil into this front area until the Loctite has set up.

Next up is to reinstall the transmission (and the driveshaft, and the exhaust system, and the gear shifter, and the front sway bar). Lower the car and test drive.

The verdict?

Totally worth it, so far. The noise has been dramatically reduced; my real test however will come in two months on the long drive to San Diego and in traffic where it will get hot, that was when it was at its’ loudest. If we have some clearer days soon I will take it out for longer drives to see also.

Re: 1985 Arktisblau M535i Renovation - Progression

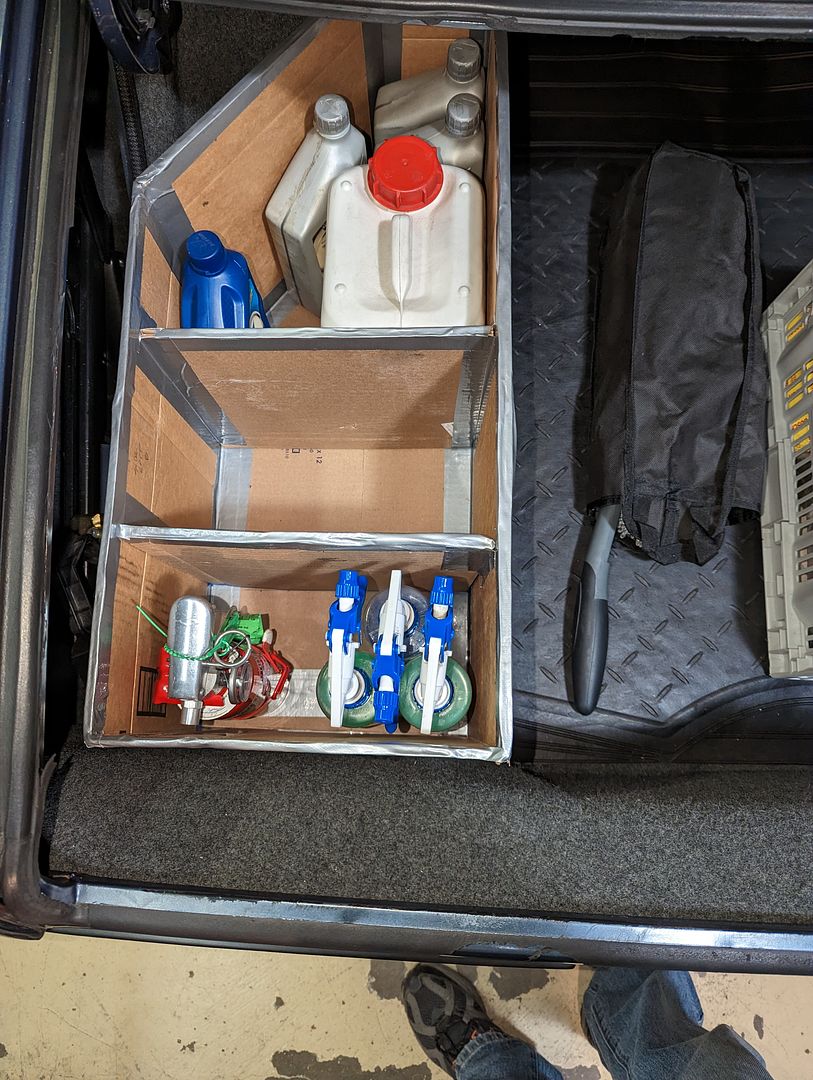

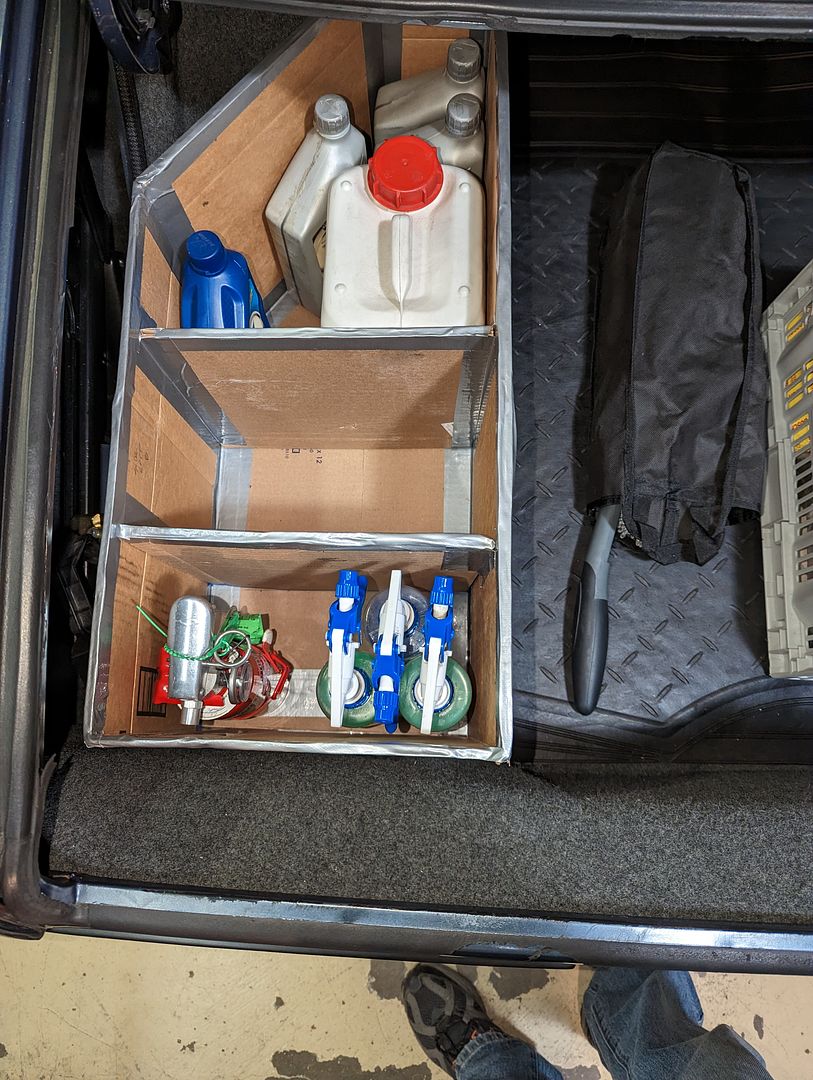

Okay, so this is only tangentially related to this car as this is something I've been kicking around since my last E28. Again, in an attempt to make a better mousetrap and not to settle with other perfectly fine solutions, I set out to design the ultimate trunk organization box.

This was inspired by a blurry image from the German language E28 Accessory catalog of something BMW called a 'Kofferaumbox' (cleverly translates as 'Trunk Box'). It was a metal box wrapped in the same trunk lining material and was a simple affair of just one open compartment; but what attracted me to it was that it was shaped to fit the driver's side of the trunk so it is specific to the E28.

I, of course, needed my version to handle a lot more program and turn it into a multi-function storage box and tool kit. This needed to hold:

-Fluids

-Fire Extinguisher

-First Aid Kit

-Flashlight/Lamp

-Tools

-Spare Parts

-Car Cleaning Supplies

-Misc items

I, like you, probably have several boxes (cardboard, milk crates, etc.) to solve this; but I am kind of tired of having those slide around in my trunk.

This meant that it needs to have multiple compartments and be tall enough to completely cover all the contents with a lid, but yet still fit inside the trunk. As a result, this new box kind of resembles the M5/6 Battery Box, albeit slightly bigger.

This cardboard mock-up is a proof of concept working model as I needed to adjust its' proportions and shape to best fit the geometry of an E28 trunk.

The middle section will have two lift-out stacking trays that hold the tools (wrenches, screwdrivers, pliers, socket set, etc.). I know, I know: BMW gave you a perfectly good tool kit in the lid of the trunk, but these tools are the 'everyday' tools one might need on a road trip.

I am trying out which Warning Triangle to mount to the lid. The BMW version is correct, but that red one is a better triangle

It will be covered inside and out with a covering that matches the BMW trunk liner material. There will be a hook or angle that holds this to sloping panel along the driver's trunk side (where the jack is stored); this will keep in place and allows it to be removed without too much fuss.

My next steps are to make a better template model for a welder since I want to make this out of thin aluminum panels to keep the weight down while giving it the most strength possible. Then finally execute this thing (it's only been about 10 years... )

)

Okay, so 2024 is bringing more opportunities for car road trips for events including possibly going to Monterey and participating at Legends of the Autobahn for the first time. This means I have to get moving on my Troubleshooting Punch List/Upgrade List, which means I will have more updates coming to this thread. See you soon.

This was inspired by a blurry image from the German language E28 Accessory catalog of something BMW called a 'Kofferaumbox' (cleverly translates as 'Trunk Box'). It was a metal box wrapped in the same trunk lining material and was a simple affair of just one open compartment; but what attracted me to it was that it was shaped to fit the driver's side of the trunk so it is specific to the E28.

I, of course, needed my version to handle a lot more program and turn it into a multi-function storage box and tool kit. This needed to hold:

-Fluids

-Fire Extinguisher

-First Aid Kit

-Flashlight/Lamp

-Tools

-Spare Parts

-Car Cleaning Supplies

-Misc items

I, like you, probably have several boxes (cardboard, milk crates, etc.) to solve this; but I am kind of tired of having those slide around in my trunk.

This meant that it needs to have multiple compartments and be tall enough to completely cover all the contents with a lid, but yet still fit inside the trunk. As a result, this new box kind of resembles the M5/6 Battery Box, albeit slightly bigger.

This cardboard mock-up is a proof of concept working model as I needed to adjust its' proportions and shape to best fit the geometry of an E28 trunk.

The middle section will have two lift-out stacking trays that hold the tools (wrenches, screwdrivers, pliers, socket set, etc.). I know, I know: BMW gave you a perfectly good tool kit in the lid of the trunk, but these tools are the 'everyday' tools one might need on a road trip.

I am trying out which Warning Triangle to mount to the lid. The BMW version is correct, but that red one is a better triangle

It will be covered inside and out with a covering that matches the BMW trunk liner material. There will be a hook or angle that holds this to sloping panel along the driver's trunk side (where the jack is stored); this will keep in place and allows it to be removed without too much fuss.

My next steps are to make a better template model for a welder since I want to make this out of thin aluminum panels to keep the weight down while giving it the most strength possible. Then finally execute this thing (it's only been about 10 years...

Okay, so 2024 is bringing more opportunities for car road trips for events including possibly going to Monterey and participating at Legends of the Autobahn for the first time. This means I have to get moving on my Troubleshooting Punch List/Upgrade List, which means I will have more updates coming to this thread. See you soon.

Re: 1985 Arktisblau M535i Renovation - Progression

Great work, Vince, and I love the detailed approach you take to these projects. Super helpful for the rest of us is the step-by-step pics and write ups you have done here (and big props for the amount of effort that takes).

This car just keeps getting better and better and better. It's come a loooong way from when I first saw it here in Colorado sometime in the early 2000's!

Jim

This car just keeps getting better and better and better. It's come a loooong way from when I first saw it here in Colorado sometime in the early 2000's!

Jim

Re: 1985 Arktisblau M535i Renovation - Progression

Impressive, as always!

Re: 1985 Arktisblau M535i Renovation - Progression

Well now, seeing as you now have all this experience.......  Hope to see it at some point!

Hope to see it at some point!

Re: 1985 Arktisblau M535i Renovation - Progression

The trunk box is a thing of corrugated beauty.

I wouldn't be afraid to make it out of sheet steel though, weight savings will be negligible vs the cost delta (and considering all the weight it is holding.)

I wouldn't be afraid to make it out of sheet steel though, weight savings will be negligible vs the cost delta (and considering all the weight it is holding.)

Re: 1985 Arktisblau M535i Renovation - Progression

It's going to be a balance between weight and strength; and you're right: it has to be strong enough to support all the stuff inside when it gets lifted out. It's the reason I'm considering thin aluminum sheet/plate; however it's a discussion to have with the welder.ElGuappo wrote: Jan 26, 2024 2:16 PM The trunk box is a thing of corrugated beauty.

I wouldn't be afraid to make it out of sheet steel though, weight savings will be negligible vs the cost delta (and considering all the weight it is holding.)

I initially tried making one out of 1/8" MDF and 3/16" Masonite Hardboard but couldn't get the joinery to work with the odd angles and thin stock. Once I get the advanced model mocked up I can then have an intelligent conversation with the welder.

Re: 1985 Arktisblau M535i Renovation - Progression

That would've been a good application for a medium size laser cutter and 1/4" plywood.

They cut finger joints for edges so well, all that surface area for glue. Also thru 'tenons' in the sides to lock partitions in place.

They cut finger joints for edges so well, all that surface area for glue. Also thru 'tenons' in the sides to lock partitions in place.

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

Re: 1985 Arktisblau M535i Renovation - Progression

My goodness that is one staggeringly beautiful E28.

-

alpinab10biturbo

- Posts: 9

- Joined: Jun 12, 2006 5:33 PM

- Location: NL

Re: 1985 Arktisblau M535i Renovation - Progression

Really informative and helpful thread - provided useful information for my own project (E28S M5 DC91)