E12 M535i Project - 08-21-19 Update

Re: E12 M535i Project - 01-24-16 Update

"Huge progress" indeed.

-

Mark 88/M5 Houston

- Posts: 8548

- Joined: Feb 12, 2006 12:00 PM

- Location: Far North Houston

Re: E12 M535i Project - 01-24-16 Update

Congrats on the progress Chris! Looks great!

Re: E12 M535i Project - 01-24-16 Update

Dude...

DUDE!

Very well done, it's good to see the actual results of your OCD.

Can't wait to see it...someday.

DUDE!

Very well done, it's good to see the actual results of your OCD.

Can't wait to see it...someday.

Re: E12 M535i Project - 01-24-16 Update

Way better than when it was delivered new!

Re: E12 M535i Project - 02-03-16 Update

Thanks. I appreciate the comments.

I picked up a set of the rotor retaining screws and put them in. Also did brake pads front and rear as well. At this point, all the brakes should need to work is fluid. Fingers crossed on that.

The reinforcements came in for the axles, so I got them installed. I can torque the bolts when I put the drivetrain in or something.

I needed a set of wheels for it. I didn't want to buy tires for the car yet in case it ends up sitting for a few more years, so I tried to think of what I had in storage. The wheel fort has been greatly depleated since most of the battlements have been sent to the front lines and the budget (and desire for that matter) for procurement has been all but eliminated. I did have the stock wheels from the '75 530i and while I really just don't like them, they'll work. I brought them home, cleaned them up and put them on the car.

I decided that I better turn my attention to the fuel tank while the car was still on jack stands. I had a fuel tank powder-coated. I disassembled and cleaned the original sending unit, used a new o-ring and measured out new fuel line for the return and feed lines and got that installed. It was a little trickier than anticipated, but it worked well nonetheless. The tank also has a new heat shield for the rear muffler and I also had a rear muffler hanger powder-coated, too, so that's all installed with the new bolts I purchased from BMW. Unfortunately, I wasn't able to get good photos of this stuff, so I will try another day.

I moved to the front, put the pins in all of the steering linkage castle nuts. I wasn't going to do that but I decided I no longer cared and didn't want to forget.

I temporarily installed the steering column and next thing you know, the car was on the ground.

The panel gaps changed slightly - in a good way. Still a couple of adjustments, but none will be made until this thing has the drivetrain in it.

I worked a bit on trying to get the wiring situated at the left side of the firewall inside, but it's a long and tedious process of trying to remember where half of this crap goes. Definitely a lesson there. I took lots of photos when I initially took the car apart, but I didn't take the right photos. Some of the harnesses have essentially fallen into place, but some areas aren't quite like that.

I looked at what needed to be done now that the car is on the ground. I have lots of interior stuff to do yet, but I still don't have insulation for the firewall. I also cannot reach the guy who put the headliner in the B7. I have left a few messages and even went by the shop he works out of and no luck, so I guess I have to look for someone that can make and install the headliner in addition to redoing my seats again. I did pick up a second floor carpet to cut up to hopefully make all of the rest of the pieces I need, but we will see on that as well. Not really looking forward to that process since I'm back to trying to find someone and you never know how that will work out. I'm at the point now where even if I did get a hold of the guy, it doesn't sound like he wants to take on my project and if he did, would I ever hear from him again?

There was something I could do though. I had everything I needed to rebuild my heater. This is very important since I have never actually used a heater in any BMW I've ever owned.

I moved on to the heater. When I removed it from the car, I simply left the heater control panel attached to it and it's been moved around for years. I had acquired a very nice heater panel a few years back and it's been in a closet waiting for something to happen. I figured the bigger pieces I could leave things in, the better time I'd have trying to put them back together. I had a new heater blower and recently purchased a new heater core, new heater valve and anything else I thought I would need for this, the heater that I will never use.

I split the halves (which was pretty interesting):

Not as bad as I thought. Once I got the old core out and removed all of the compost, I started thoroughly cleaning the halves. What I had seen was just how poor the foam was on the flaps. I could remove it all, but it's supposed to be there, so what could I replace it with? I found a suitable replacement and removed the old foam. I thoroughly cleaned all of the parts and was left with this:

One of the floor flaps:

I couldn't remove the fresh air flaps, so I replaced their foam in situ, but used the floor flaps for a template. I had to slightly trim it to size, but it worked well.

New core installed - Made in 2002:

O-rings replaced, halves mated, the 1997-build heater valve (specific to non-AC cars) installed and new heater blower in position:

I've made arrangements to disassemble the engine on Friday. Work is really picking up starting this weekend, so I'm hoping that we can get that knocked out Friday. I should hopefully have a good idea of what I'm in for on the motor then. At this point, I'm kinda stuck with everything else, I guess.

I picked up a set of the rotor retaining screws and put them in. Also did brake pads front and rear as well. At this point, all the brakes should need to work is fluid. Fingers crossed on that.

The reinforcements came in for the axles, so I got them installed. I can torque the bolts when I put the drivetrain in or something.

I needed a set of wheels for it. I didn't want to buy tires for the car yet in case it ends up sitting for a few more years, so I tried to think of what I had in storage. The wheel fort has been greatly depleated since most of the battlements have been sent to the front lines and the budget (and desire for that matter) for procurement has been all but eliminated. I did have the stock wheels from the '75 530i and while I really just don't like them, they'll work. I brought them home, cleaned them up and put them on the car.

I decided that I better turn my attention to the fuel tank while the car was still on jack stands. I had a fuel tank powder-coated. I disassembled and cleaned the original sending unit, used a new o-ring and measured out new fuel line for the return and feed lines and got that installed. It was a little trickier than anticipated, but it worked well nonetheless. The tank also has a new heat shield for the rear muffler and I also had a rear muffler hanger powder-coated, too, so that's all installed with the new bolts I purchased from BMW. Unfortunately, I wasn't able to get good photos of this stuff, so I will try another day.

I moved to the front, put the pins in all of the steering linkage castle nuts. I wasn't going to do that but I decided I no longer cared and didn't want to forget.

I temporarily installed the steering column and next thing you know, the car was on the ground.

The panel gaps changed slightly - in a good way. Still a couple of adjustments, but none will be made until this thing has the drivetrain in it.

I worked a bit on trying to get the wiring situated at the left side of the firewall inside, but it's a long and tedious process of trying to remember where half of this crap goes. Definitely a lesson there. I took lots of photos when I initially took the car apart, but I didn't take the right photos. Some of the harnesses have essentially fallen into place, but some areas aren't quite like that.

I looked at what needed to be done now that the car is on the ground. I have lots of interior stuff to do yet, but I still don't have insulation for the firewall. I also cannot reach the guy who put the headliner in the B7. I have left a few messages and even went by the shop he works out of and no luck, so I guess I have to look for someone that can make and install the headliner in addition to redoing my seats again. I did pick up a second floor carpet to cut up to hopefully make all of the rest of the pieces I need, but we will see on that as well. Not really looking forward to that process since I'm back to trying to find someone and you never know how that will work out. I'm at the point now where even if I did get a hold of the guy, it doesn't sound like he wants to take on my project and if he did, would I ever hear from him again?

There was something I could do though. I had everything I needed to rebuild my heater. This is very important since I have never actually used a heater in any BMW I've ever owned.

I moved on to the heater. When I removed it from the car, I simply left the heater control panel attached to it and it's been moved around for years. I had acquired a very nice heater panel a few years back and it's been in a closet waiting for something to happen. I figured the bigger pieces I could leave things in, the better time I'd have trying to put them back together. I had a new heater blower and recently purchased a new heater core, new heater valve and anything else I thought I would need for this, the heater that I will never use.

I split the halves (which was pretty interesting):

Not as bad as I thought. Once I got the old core out and removed all of the compost, I started thoroughly cleaning the halves. What I had seen was just how poor the foam was on the flaps. I could remove it all, but it's supposed to be there, so what could I replace it with? I found a suitable replacement and removed the old foam. I thoroughly cleaned all of the parts and was left with this:

One of the floor flaps:

I couldn't remove the fresh air flaps, so I replaced their foam in situ, but used the floor flaps for a template. I had to slightly trim it to size, but it worked well.

New core installed - Made in 2002:

O-rings replaced, halves mated, the 1997-build heater valve (specific to non-AC cars) installed and new heater blower in position:

I've made arrangements to disassemble the engine on Friday. Work is really picking up starting this weekend, so I'm hoping that we can get that knocked out Friday. I should hopefully have a good idea of what I'm in for on the motor then. At this point, I'm kinda stuck with everything else, I guess.

Re: E12 M535i Project - 02-03-16 Update

The new wheels look particularly handsome.

Re: E12 M535i Project - 02-03-16 Update

I find it particularly satisfying to rebuild heater boxes.

Re: E12 M535i Project - 02-03-16 Update

I think it looks great. I have a question, what did you use for the heater foam? I'm doing this very shortly.

Re: E12 M535i Project - 02-03-16 Update

For the love of God, man, get that car OUT OF YOUR DRIVEWAY!

Looks good, Chris.

Looks good, Chris.

Re: E12 M535i Project - 02-03-16 Update

That's funny Vince. Of course the car is in the garage. It was just outside for photos. First time it was outside since it came back from the body shop. I am getting tired of looking at it though. Too much to do yet.

-

Adam W in MN

- Posts: 5053

- Joined: Feb 12, 2006 12:00 PM

- Location: Don't waste my motherf***in' time!

- Contact:

Re: E12 M535i Project - 02-03-16 Update

I'll be hitting you up for advice on that heater core work. Isn't there some o-ring that leaks that the firstfives guys have complained about? I'd like to make sure I take care of that before putting mine back in.

x2 on the foam question, what did you use?

x2 on the foam question, what did you use?

Re: E12 M535i Project - 02-03-16 Update

There are two o-rings where the heater valve attaches. One for the brass pipe and the other for the core. One of the recent complaints I had seen is that replacement valves are leaking. My old valve was leak free as was the core but I decided to take no chances. This is also a valve for a non-AC car which is different than what they have here.

Anyway, the o-rings are odd sizes so they have to come from the dealer.

Anyway, the o-rings are odd sizes so they have to come from the dealer.

-

Adam W in MN

- Posts: 5053

- Joined: Feb 12, 2006 12:00 PM

- Location: Don't waste my motherf***in' time!

- Contact:

Re: E12 M535i Project - 02-03-16 Update

Dayuuum -- lookin' good!

Re: E12 M535i Project - 02-12-16 Update

Thanks. I've been really busy over the last couple of weeks, but before it all got out of control, I scheduled time with my mechanic to disassemble the engine. I have learned just about everything I know from watching him over the years and he had no issue with me assisting him on the motor. I've never done much other than valve adjustments or pulling the junk head off of the 745i parts car, so time to learn more.

Just a refresher:

He picked it up from me and took it over to the shop a couple weeks ago. I made sure that before I pulled the balancer and other parts, I set the motor at TDC.

Everything went pretty smoothly removing the head:

A keen eye will see this on #5:

I put maybe 300 miles on this car before it was hit. I don't know how long the head has been like that.

It is a pretty common crack and can easily be repaired, I understand. It's the original head to the car so I'd like to keep it. We will see what the machinist says. He's fixed much worse with great success.

Everything looked pretty okay with the bottom end:

Until I looked at #5:

I have a feeling that whatever happened to that piston is probably related to the crack. Supposedly the PO did a head gasket on the car shortly after he got it according to sleuthing I have done on the M535i Yahoo! group but given how thorough he was with everything else replacing it one at a time, I'm not sure what exactly that entailed. It does not look like the head was resurfaced judging by the dimples.

The good news is that I thought ahead a few years ago and picked up a full set of M90 pistons. The other good news is that they are all in good shape and they also take the same rings as these (1.5mm, 2.5mm, 4mm instead of the 1.5mm, 2.5mm, 3.5mm).

Here are the rod bearings:

#3 has a shiny spot but you cannot feel it. What it looks like is that the oil holes on the crank weren't chamfered well, so that will be done by the machinist.

The main bearings were all in great shape. I didn't get a photo of those because my hands were full of oil, but here's a shot of the crank:

The timing chain, oil pump chain and sprockets are all in nice shape, but will, of course be replaced. The plastic guide rail looks pretty good too for the age and mileage:

Here's the block ready to go to the machinist. It will be magnafluxed and the bores measured, etc. The cross-hatching is still evident on all of the cylinders so we will see what it needs. Once we know that, I'll decide on the route I want to go with the rings.

Those are TSMacNeil's legs there. He happened to swing by as we were getting started and pretty much spent the whole day with us.

The head came apart easily. No trouble with the rocker shafts and putting a straight edge on it, it isn't warped, so that's a good sign. Once it's back, the head will get all new rockers, shafts, eccentrics, etc. The cam is in great shape. Here's the bare head:

I don't have any photos of the process because my hands were covered in oil and then I had to run and pick up a couple of parts for a car they had on the lift. By the time I got back, the cam was out.

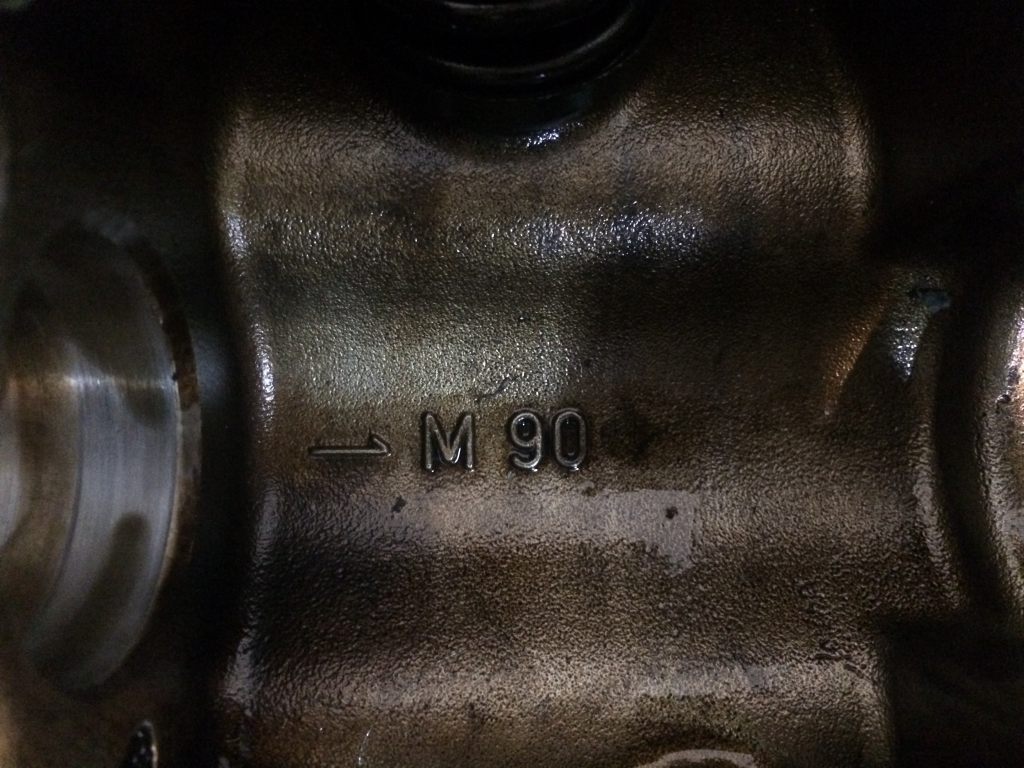

This had been discussed before on here but I don't think anyone ever posted photos. The "M90" heads have "M90" in two places on the head. First, under the cam by #6:

and lastly at the front of the head behind the timing cover:

I was a bit surprised about #5, but I was prepared for it not knowing what I was going to be in for with the motor. I'm glad that the issues are minor. It's going to get a lot of new parts so I'm wondering what I'll be in for on this, but in seeing what was going on, I'm obviously glad we took it apart - not to say I was going to leave it alone, since I was sure it needed valve guide seals at a minimum.

In other news...

I have spent pretty much the last three weeks trying to get a hold of the guy who put the headliner in my B7 Turbo. He apparently has developed a phone allergy and it's very frustrating. I've gone by his shop three separate times and cannot get a hold of him. He is affiliated with a restoration shop, so I called them. Besides being told "to read between the lines" and "all I can tell you is that he's really busy," I've made no progress. He does excellent work from what I've seen and unfortunately, I cannot get him to even talk to me to even have a look at my project.

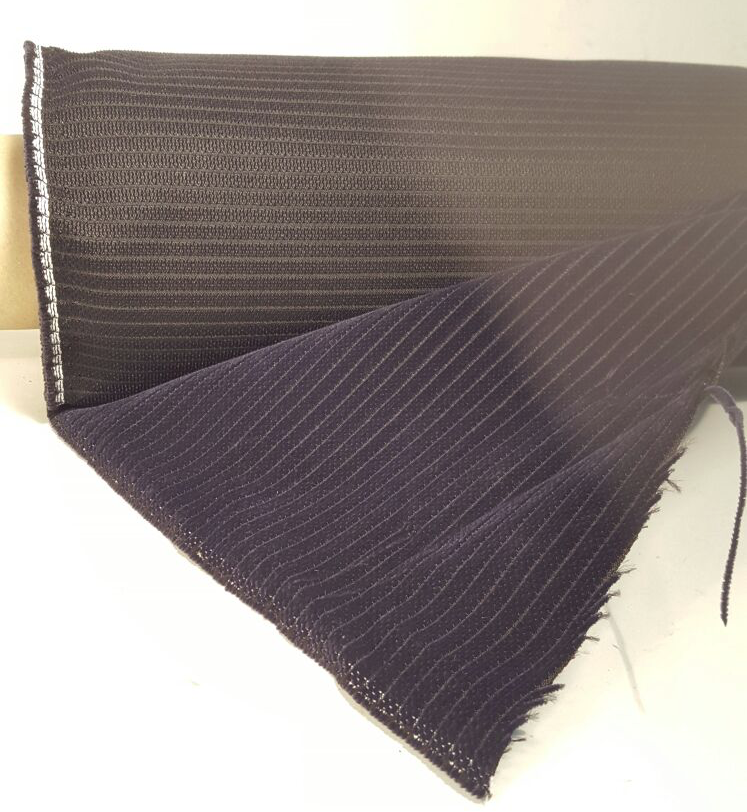

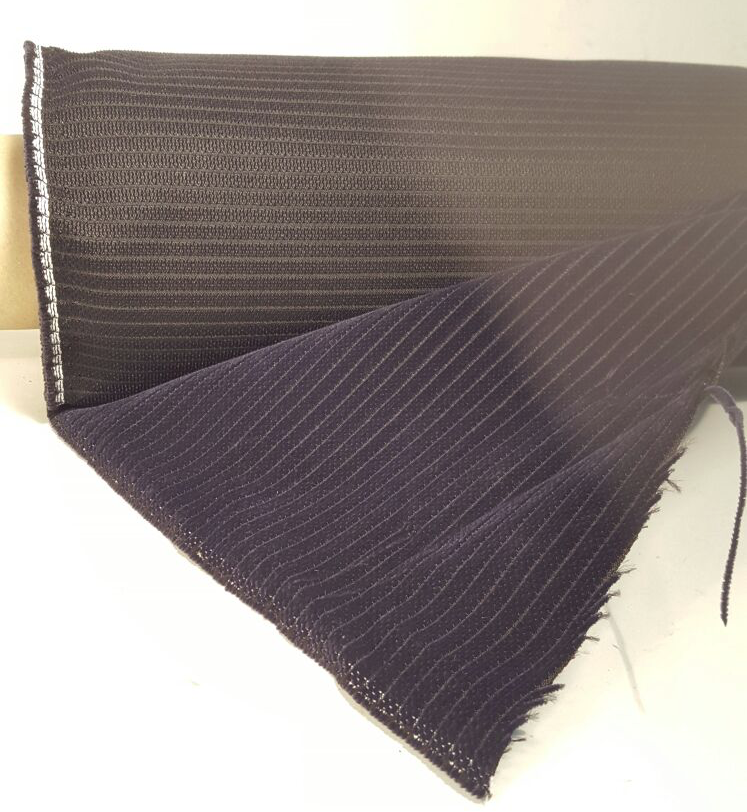

I ordered headliner fabric from BMW. A member on firstfives ordered some for his car and apparently had enough to redo his entire headliner. I ordered qty 2 of the same part number he did figuring I would have this car and the Golf E12 someday needing a headliner and found that I only had enough to cover the main section of it. The dealer ordered 1 more and it was about half was much material. Turns out it is sold by the meter, so I don't know how he got a headliner out of it. Either way, having three meters, it turns out is just enough. I can use the 2m section for the main headliner section and then make the c-pillars out of the other. Unfortunately, it also means I paid about 3x more than I should have for the material.

I picked up another Marineblau-grau carpet from jodystevens and I'm going to use that to make the carpet pieces for the front kick panels and the rear deck carpeting. It is apparently the only way to get new Marineblau carpeting.

I also have to redo my seats again. In July, 2010, I had my seats recovered by Jim's Auto Upholstery using the cloth I sourced through a German enthusiast. Unfortunately, the vinyl that was used to recover the seats was totally wrong. It's closer in color to my recycling bin than what belongs on the seats. Another case of "how much extra do I have to pay to get what I've already paid for?" I was assured by the shop that they could just replace the vinyl with the correct stuff, which I purchased from Global Upholstery. It's an exact match and for all I know, it's the same stuff. I've had a roll of it in my closet since July, 2010. I decided to start looking for other shops who could help me with the seats. I was unhappy with some aspects of the work too. I went by a shop that I've seen some pretty interesting cars at. I brought one of the Recaros and my headliner. They gave me a pretty reasonable price to sew up the headliner using my old one as a pattern. Unfortunately, their installation price was quite steep, though they would come to my house to do it on a weekend, so it might be worth considering. I showed them the seat and that's when I was informed that they did such a shitty job sewing and matching up the corduroy pattern that the cloth could not be reused. He figured there were a few places they could cheat it where it wouldn't be seen but they'd need the little bit I had left to replace a couple of panels entirely. I had never really looked closely at the seats because the vinyl made me sick and I knew they were to be redone. Studying some of the stitch-work on the seats really showed just how poor of a job it was.

I felt like I had been punched in the stomach. I had been budgeting what was needed to finish the car and I thought I had a pretty good handle on things. This is now getting more expensive than I had anticipated. I checked to see what was available on the cloth front. I had ordered 5m last time and it was just enough to do the seats. I got with Ivo and found that the price of the cloth more than doubled since I last purchased it. I don't know why I expected any differently since everything else has doubled, too. Anyway, I was able to order what looks to be the last of it available, so hopefully that will go as planned. I went by a couple more shops in Phoenix based upon what I had seen over the years and also some reviews I've found and I got a couple of quotes of over $3k to redo the seats and $800 to do the headliner (with installation, but they need the car in their shop). That's all just labor. I'm providing the materials. The biggest issue is that with the seats having basically been ruined by idiots, there are no patterns to go off of. I do have a seat back and headrest from the original driver seat that can be used as a pattern and I think I can come up with a rear seat from a yard which would help since the rear seat is not even close to what I gave them. It looks like it belongs in a Corsica.

With the dash restoration, wood restoration, headliner, cloth, vinyl and carpet costs on top of the seats, I'm looking at about $10k just in interior for the car and it will be blue when it's finished. It will also be an E12, too. At this point, I'm still trying to figure out how big of a bullet I want to bite. There's someone that I'm reasonably certain could do a perfect job on the seats, but he has quoted more money than the other quotes I have received. It would be basically a sure thing while I don't have any direct experience with the other shops I've talked to. Upholstery really is as bad as paint and I think you obviously get what you pay for as well. It's depressing.

Oh, and I still have to figure out what I'm going to do for the transmission.

Just a refresher:

He picked it up from me and took it over to the shop a couple weeks ago. I made sure that before I pulled the balancer and other parts, I set the motor at TDC.

Everything went pretty smoothly removing the head:

A keen eye will see this on #5:

I put maybe 300 miles on this car before it was hit. I don't know how long the head has been like that.

It is a pretty common crack and can easily be repaired, I understand. It's the original head to the car so I'd like to keep it. We will see what the machinist says. He's fixed much worse with great success.

Everything looked pretty okay with the bottom end:

Until I looked at #5:

I have a feeling that whatever happened to that piston is probably related to the crack. Supposedly the PO did a head gasket on the car shortly after he got it according to sleuthing I have done on the M535i Yahoo! group but given how thorough he was with everything else replacing it one at a time, I'm not sure what exactly that entailed. It does not look like the head was resurfaced judging by the dimples.

The good news is that I thought ahead a few years ago and picked up a full set of M90 pistons. The other good news is that they are all in good shape and they also take the same rings as these (1.5mm, 2.5mm, 4mm instead of the 1.5mm, 2.5mm, 3.5mm).

Here are the rod bearings:

#3 has a shiny spot but you cannot feel it. What it looks like is that the oil holes on the crank weren't chamfered well, so that will be done by the machinist.

The main bearings were all in great shape. I didn't get a photo of those because my hands were full of oil, but here's a shot of the crank:

The timing chain, oil pump chain and sprockets are all in nice shape, but will, of course be replaced. The plastic guide rail looks pretty good too for the age and mileage:

Here's the block ready to go to the machinist. It will be magnafluxed and the bores measured, etc. The cross-hatching is still evident on all of the cylinders so we will see what it needs. Once we know that, I'll decide on the route I want to go with the rings.

Those are TSMacNeil's legs there. He happened to swing by as we were getting started and pretty much spent the whole day with us.

The head came apart easily. No trouble with the rocker shafts and putting a straight edge on it, it isn't warped, so that's a good sign. Once it's back, the head will get all new rockers, shafts, eccentrics, etc. The cam is in great shape. Here's the bare head:

I don't have any photos of the process because my hands were covered in oil and then I had to run and pick up a couple of parts for a car they had on the lift. By the time I got back, the cam was out.

This had been discussed before on here but I don't think anyone ever posted photos. The "M90" heads have "M90" in two places on the head. First, under the cam by #6:

and lastly at the front of the head behind the timing cover:

I was a bit surprised about #5, but I was prepared for it not knowing what I was going to be in for with the motor. I'm glad that the issues are minor. It's going to get a lot of new parts so I'm wondering what I'll be in for on this, but in seeing what was going on, I'm obviously glad we took it apart - not to say I was going to leave it alone, since I was sure it needed valve guide seals at a minimum.

In other news...

I have spent pretty much the last three weeks trying to get a hold of the guy who put the headliner in my B7 Turbo. He apparently has developed a phone allergy and it's very frustrating. I've gone by his shop three separate times and cannot get a hold of him. He is affiliated with a restoration shop, so I called them. Besides being told "to read between the lines" and "all I can tell you is that he's really busy," I've made no progress. He does excellent work from what I've seen and unfortunately, I cannot get him to even talk to me to even have a look at my project.

I ordered headliner fabric from BMW. A member on firstfives ordered some for his car and apparently had enough to redo his entire headliner. I ordered qty 2 of the same part number he did figuring I would have this car and the Golf E12 someday needing a headliner and found that I only had enough to cover the main section of it. The dealer ordered 1 more and it was about half was much material. Turns out it is sold by the meter, so I don't know how he got a headliner out of it. Either way, having three meters, it turns out is just enough. I can use the 2m section for the main headliner section and then make the c-pillars out of the other. Unfortunately, it also means I paid about 3x more than I should have for the material.

I picked up another Marineblau-grau carpet from jodystevens and I'm going to use that to make the carpet pieces for the front kick panels and the rear deck carpeting. It is apparently the only way to get new Marineblau carpeting.

I also have to redo my seats again. In July, 2010, I had my seats recovered by Jim's Auto Upholstery using the cloth I sourced through a German enthusiast. Unfortunately, the vinyl that was used to recover the seats was totally wrong. It's closer in color to my recycling bin than what belongs on the seats. Another case of "how much extra do I have to pay to get what I've already paid for?" I was assured by the shop that they could just replace the vinyl with the correct stuff, which I purchased from Global Upholstery. It's an exact match and for all I know, it's the same stuff. I've had a roll of it in my closet since July, 2010. I decided to start looking for other shops who could help me with the seats. I was unhappy with some aspects of the work too. I went by a shop that I've seen some pretty interesting cars at. I brought one of the Recaros and my headliner. They gave me a pretty reasonable price to sew up the headliner using my old one as a pattern. Unfortunately, their installation price was quite steep, though they would come to my house to do it on a weekend, so it might be worth considering. I showed them the seat and that's when I was informed that they did such a shitty job sewing and matching up the corduroy pattern that the cloth could not be reused. He figured there were a few places they could cheat it where it wouldn't be seen but they'd need the little bit I had left to replace a couple of panels entirely. I had never really looked closely at the seats because the vinyl made me sick and I knew they were to be redone. Studying some of the stitch-work on the seats really showed just how poor of a job it was.

I felt like I had been punched in the stomach. I had been budgeting what was needed to finish the car and I thought I had a pretty good handle on things. This is now getting more expensive than I had anticipated. I checked to see what was available on the cloth front. I had ordered 5m last time and it was just enough to do the seats. I got with Ivo and found that the price of the cloth more than doubled since I last purchased it. I don't know why I expected any differently since everything else has doubled, too. Anyway, I was able to order what looks to be the last of it available, so hopefully that will go as planned. I went by a couple more shops in Phoenix based upon what I had seen over the years and also some reviews I've found and I got a couple of quotes of over $3k to redo the seats and $800 to do the headliner (with installation, but they need the car in their shop). That's all just labor. I'm providing the materials. The biggest issue is that with the seats having basically been ruined by idiots, there are no patterns to go off of. I do have a seat back and headrest from the original driver seat that can be used as a pattern and I think I can come up with a rear seat from a yard which would help since the rear seat is not even close to what I gave them. It looks like it belongs in a Corsica.

With the dash restoration, wood restoration, headliner, cloth, vinyl and carpet costs on top of the seats, I'm looking at about $10k just in interior for the car and it will be blue when it's finished. It will also be an E12, too. At this point, I'm still trying to figure out how big of a bullet I want to bite. There's someone that I'm reasonably certain could do a perfect job on the seats, but he has quoted more money than the other quotes I have received. It would be basically a sure thing while I don't have any direct experience with the other shops I've talked to. Upholstery really is as bad as paint and I think you obviously get what you pay for as well. It's depressing.

Oh, and I still have to figure out what I'm going to do for the transmission.

-

Adam W in MN

- Posts: 5053

- Joined: Feb 12, 2006 12:00 PM

- Location: Don't waste my motherf***in' time!

- Contact:

Re: E12 M535i Project - 02-12-16 Update

Wow, adds up fast. I'm probably not helping, but seeing those pictures of the seats all together.... yes Chevy Corsica comes to mind (nice analogy, can't get that out of my head now). Unfortunate that it's so off and used up valuable raw materials for your build.

That's some nice forward thinking about the Mahle pistons for the M90 many years ago! I'm assuming you've perused my very old M90 engine build details, are you going to do similar bottom end "while we're in there" things like balancing, etc, with the clutch, flywheel, and reciprocating mass?

That's some nice forward thinking about the Mahle pistons for the M90 many years ago! I'm assuming you've perused my very old M90 engine build details, are you going to do similar bottom end "while we're in there" things like balancing, etc, with the clutch, flywheel, and reciprocating mass?

Re: E12 M535i Project - 02-12-16 Update

That's why the seats have been sitting in my office since 2010. I can't stand to look at them and I probably should have gotten on this sooner, but I was thinking, "sure, just replace the vinyl. No big deal." I never realized how they totally did the rear seat completely wrong. I brought up the point of the missing piping with them and they said they'd fix it when they replace the vinyl but the pattern is totally wrong, so what am I to do about that? The rear headrests are absolutely atrocious, too.

The machinist has the flywheel, crank, balancer, etc. That will all be balanced, flywheel resurfaced, etc. I had followed your engine build pretty closely but have decided to keep my motor as stock as possible, too, sticking with the stock pistons and what not. The oil pump will get all new internals, too.

I'd love to be doing the motor and the interior at the same time, but I don't know what this will all end up costing.

The machinist has the flywheel, crank, balancer, etc. That will all be balanced, flywheel resurfaced, etc. I had followed your engine build pretty closely but have decided to keep my motor as stock as possible, too, sticking with the stock pistons and what not. The oil pump will get all new internals, too.

I'd love to be doing the motor and the interior at the same time, but I don't know what this will all end up costing.

-

white chocolate

- Posts: 428

- Joined: Sep 21, 2011 9:44 PM

- Location: Canton, Ohio

Re: E12 M535i Project - 02-12-16 Update

Love reading these updates. That is a huge punch in the face with the interior, what a crappy situation. Here's to hoping it works out well, I'm sure it will look great when it is all said and done!

Re: E12 M535i Project - 02-12-16 Update

Visiting London maybe?wkohler wrote:I have spent pretty much the last three weeks trying to get a hold of the guy who put the headliner in my B7 Turbo. He apparently has developed a phone allergy and it's very frustrating. I've gone by his shop three separate times and cannot get a hold of him. He is affiliated with a restoration shop, so I called them. Besides being told "to read between the lines"

I've officially given up on Jim's Upholstery, they just don't seem to give a shit anymore.

Re: E12 M535i Project - 02-12-16 Update

Cars are expensive to build, the good news is the nicest cars make the best parts cars.

Re: E12 M535i Project - 02-12-16 Update

I'm glad you will be putting those pistons to use!

Re: E12 M535i Project - 02-12-16 Update

They did a great job on my seats 6 years ago and a good job on a different set 8 years ago but the I sent them a simple repair job last year and it was very expensive comparatively and a recent quote was very high. I guess I should not recommending them.wkohler wrote:

I've officially given up on Jim's Upholstery, they just don't seem to give a shit anymore.

-

Kyle in NO

- Posts: 17638

- Joined: Feb 12, 2006 12:00 PM

- Location: Nasty Orleans------> Batten-Rooehjch------>More Souther LA

Re: E12 M535i Project - 02-12-16 Update

ICE must have paid them a visit.

Re: E12 M535i Project - 02-12-16 Update

Well, here's the thing. They can do decent work on stuff, but they don't really care. You can show them a seam that clearly isn't right and they say they don't see anything wrong with it. Fine. I think for what you pay, they do fine work. Also, a leather interior is a bit more forgiving, but there details like the tiebacks in the E28 sport seats that they don't do. Still, doing an entire interior with rear headrests in leather including materials for about $1500 in less than a day is something.

Unfortunately, when I had them do this work (July, 2010), I didn't realize all of the nuances to a good upholstery job.

They did a nice job on my 535is interior, with the exception of omitting the tiebacks and whatnot, but I think the problem here was twofold:

I was told they could get the same vinyl and I actually selected a swatch of it that matched, but the vinyl they got was clearly lighter. Also, dealing with a cloth with a distinct pattern, like the corduroy, requires extra care and attention to ensure that everything lines up as it should. Unfortunately, that didn't happen. They also didn't follow the pattern for the rear seat or put the piping on. Brenda told me it would be no trouble to replace the vinyl (but I'd, of course, have to pay again). Sure, they could replace the vinyl, but I'd end up with something as bad or worse (from a quality perspective) as what I have now. So, the frustrating part is the waste of the cloth. The money I paid to Jim's sucks, but I put that out of my mind years ago. It's all sunk cost (and boy is there a lot of that on this turd).

Either way, my cloth has been secured, so, that's great. I'm not sure what the next step is. I have so much work to do now that I'm having a hard time staying focused on it because this snafu is on the forefront of my thoughts. I'm easily distracted to begin with.

Unfortunately, when I had them do this work (July, 2010), I didn't realize all of the nuances to a good upholstery job.

They did a nice job on my 535is interior, with the exception of omitting the tiebacks and whatnot, but I think the problem here was twofold:

I was told they could get the same vinyl and I actually selected a swatch of it that matched, but the vinyl they got was clearly lighter. Also, dealing with a cloth with a distinct pattern, like the corduroy, requires extra care and attention to ensure that everything lines up as it should. Unfortunately, that didn't happen. They also didn't follow the pattern for the rear seat or put the piping on. Brenda told me it would be no trouble to replace the vinyl (but I'd, of course, have to pay again). Sure, they could replace the vinyl, but I'd end up with something as bad or worse (from a quality perspective) as what I have now. So, the frustrating part is the waste of the cloth. The money I paid to Jim's sucks, but I put that out of my mind years ago. It's all sunk cost (and boy is there a lot of that on this turd).

Either way, my cloth has been secured, so, that's great. I'm not sure what the next step is. I have so much work to do now that I'm having a hard time staying focused on it because this snafu is on the forefront of my thoughts. I'm easily distracted to begin with.

Re: E12 M535i Project - 04-18-16 Update

I've been really busy with work and whatnot over the last couple of months, plus with taxes, I haven't had any time to relax. Fortunately, there has been some progress over the last couple of months, so I guess we will do it in chronological order.

First off, my begging for the interior firewall insulation piece finally paid off. ldsbeaker spent considerable time and effort salvaging this piece from an E28 he's been working on and it's close enough to work well in the E12. It had remained a piece that was virtually unobtanium and an off-handed remark during a text conversation resulted in this - delivered, even!

It fit in the space well and only needed minor modification around the steering column/pedal bracket and the heater outlet. Everything else works well and it's actually in pretty good shape, too.

Of course, the month of February totally sucks for me and it remained in that spot until the end of March when I accidentally had a couple of hours to see how everything would work together.

February 19th, I found out that of the 11 pistons I gave the machine shop, only two were considered "usable." I've got two more M90 motors, but if I totally disassembled two M90s, could I get a full set? Then I'd have torn down motors everywhere and I'd still need rings. At that point, we decided to call JE. Many times. Leaving many messages. Yielding zero response. It has to be me. It just does. Maybe I should read between the lines. That's where everyone else seems to be.

February 22nd, I decided to drop by the wood refinisher to see what had been going on since I hadn't heard anything. They had told me two weeks when I dropped the stuff off but I let it go quite a while. I had dealt with the owner of the shop and it really seemed like we were in sync on what needed to be done and more than anything, I was looking for something to make me feel good as at this point, nearly every other aspect - actually every other aspect of the job - was giving me bad news. While the boss wasn't there, one of the guys was and I talked to him. He showed me what they had done and I had a very hard time not going ballistic. It looked nothing like it was supposed to and in stripping the veneer, they even broke chunks off in places. I was devastated. The one thing I was hoping would just come out totally tits came out totally, uh... AIDS? I don't know. It was terrible. I couldn't even talk so I left. Chunks of veneer missing and they put some varnish or whatever right over the top of it. I don't know how many times I said restoration project and, "it needs to look just like this. Can you do this?" I had total faith in them, but I guess they must have realized I was restoring an E12 and, of course, no one appreciates those.

I did the only thing I could think of and drove home, looked up the business card and got on the talking horn to the owner. He was smart and said he "couldn't comment intelligently" since he didn't have the stuff in front of him, but he'd call me back. I did tell him that I had two perfect pieces in there that I'd have never had refinished but it all had to match. It did all match. It looked like shit. It all looked like shit together, but that's not what I was paying for. I could do this myself and I probably couldn't even do this bad of a job. I respect wood too much. He did call me back as promised and he assured me they would fix it. He had said that what I wanted was something totally different than he was talking about (so much for me reading that conversation of "it needs to look exactly like these two pieces," answered by, "Yes.") So, I decided to give them the benefit of the doubt since it couldn't possibly get any worse and see what else would blow up in my face. After a while, you really start wondering if everyone out there is useless or if you're the problem.

I checked in with Alex to see if there was any progress getting a hold of JE. None. Never got a call back. We tried a couple of other piston manufacturers and they didn't have any interest in my pistons. Finally, I decided to call JE myself and somehow, I got right through to Jeremy in the Import/Exotic department and we talked for a while about every non-M90 motor BMW made that I didn't need pistons for and then finally he came up with the fact they had actually done M90 pistons before with a 9.3:1 CR and all the other stuff copied from an actual piston. So, I was thinking I was making progress and he tells me to fill out the order form and email it to him. I needed to get the bore size from the machine shop. Alex called the machinist and told him we needed the bore size so I could order the pistons. We waited.

I talked to a few other upholsterers. Two didn't want to touch the job at all and the other one seemed promising but after going over everything with them, it was clear we were going to have a bad time.

March 14, I got a call from the wood refinishers. He explained everything they did and had he known it is what I had wanted, he'd have charged me probably three to four times as much. I didn't really push the issue aside from just reiterating that we seemed to be on the same page as to what I was looking for and how he had described the materials they were going to use, etc. He wanted me to come look at it before they did the other three pieces (shifter knob and two center console storage partition bases) that I had brought in a couple days after dropping off the initial pieces. I told him pretty much exactly when I was going to come by and he said he'd be there.

He wasn't. The wood was, though.

I was satisfied. The other three pieces are going to cost me a bunch of money to have done properly, so even though he honored the price we had agreed upon on this job, it all evens out in the end. At this point, I just want something that doesn't look like a kid refinished it. They told me they could do it and from the photos, it looks like they had. I couldn't even find the spots where they ruined the veneer and I'm glad I didn't take photos of the screw up.

The St. Paddy's Day event in San Diego was coming up the following weekend, so I had had made arrangements with a couple of members to help me out with transporting some things I needed worked on. The bell housing and all of the aluminum parts for the engine sans the throttle body and the upper timing cover (at masheen shop with the head) would be refinished and the dash delivered to Just Dashes in Van Nuys, CA. I spent a considerable amount of time removing all of the gaskets and trying to pre-clean the aluminum pieces as much as possible on the day before departure (I had about two hours between jobs). I neglected to get photos of the parts ready to go, but I did get one of the intake manifold during the frustration of the cleaning process:

I was kinda surprised the window broke, but I was pretty mad.

Got all of that loaded up, but I realized at 4:40am when we were in Yuma that I had forgotten the dash, so I'd have to ship that.

I had ordered a couple of windshields from Ivo, but they didn't pan out due to shipping damage. I had also made a deal with another friend who had a NOS E28 windshield he wasn't going to use, so I got to bring that home. Well, not really. There was no way it was going to fit in an E28 safely, so thankfully, geordi offered to bring it to Phoenix, since he and Ramona were heading through there anyway. He even went to get a bicycle box to put it in. It made the trip safely and is now in my living room.

Ivo did have my cloth, though.

When I had inquired with him, it was perfect timing. I had purchased 5 meters the first time and had just enough. Perhaps enough extra to replace a bolster if necessary. Ivo came back and said that BMW had 7 meters left. I bought it all. It was over twice as much as the last batch was per meter, but the fact I could get it made all the difference. Also, with the material being NLA now and the cost, it makes it clear that it's worth it to make sure it's done the right way. I can't take any chances. It's like an insurance policy to make sure my stuff isn't ruined.

The head was done, so I picked that up.

Crack was repaired, some valves replaced, three angle valve job, etc. Came out nice. I haven't taken it out of the bag. It's safer in the bag.

After picking it up, I walked over to the yard next door and talked to the guys, one of which has known my parents since before I was born. They have a Polaris/Navy cloth '81 528i that's been sitting there for the better part of 10 years. I asked about the rear seat, sharing my predicament. They let me pull this gorgeous rear seat out of that car.

A little bit of Oxyclean on the rough spots and it's good to go.

So, with that sorted, I heard from the machinist a few days later that we needed a minimum bore size of 3.680" due to some minor taper in the cylinders. I filled out my form and emailed it to Jeremy at JE. A few days went by with no response, so I called on April and he was out to lunch. Left a message. No dice. Called back around 4 pm and he processed my order over the phone. Should have the pistons by May 1. Great.

I shipped the dash out to Just Dashes. Took two days to get there and according to their website, from receipt, I should hear from them after 1 week. I called them this past Friday since I hadn't heard from them. Here we go again.

The next day, I called the shop that I decided was the best local option to redo my interior. I brought them the redone interior, the award winning rear seat, the Recaro seat back that has some use and some other various pieces to do the seats. We went over everything again and it was decided they would start with the rear seat and I shouldn't worry about hearing from them for at least a month.

In the meantime, I've been busy with work and tax preparation and other stuff, but I've been forcing myself to work on my engine wiring harness. It was loaded with grease and grime. Totally black. On the whole, it was actually in pretty decent shape, but there were three fuel injector connectors that needed replacing and a couple of the rubber boots on other injectors needed work. I had inherited a collection of various L-Jet harnesses and started cutting out what I needed. I worked with some damaged connectors to practice taking the pins out, then once I felt good enough, I moved on to the salvage connectors to remove everything from them. Success. I worked a little bit at a time, thoroughly cleaning as I went along.

I did spend some time getting a feel for what it was going to take to fit the insulation piece Adam brought me. I put it in, along with the other parts and the carpet. It will take a bit of fettling to get everything to fit right, especially the carpet as it has never actually been in a car before. I decided that once I was satisfied with it, I'd leave it for a bit. A few days or so. I did that.

Friday, I get a notification that my pistons shipped from Ohio and were due on Thursday the 14th.

This last weekend, I removed the carpet and insulation and put it back in the house. I wanted to get all of the in-car wiring squared away. I needed to find my fuel pump wiring, figure out how to route the dome light wiring and get the door switches and unfinished bits taken care of. I took several photos when I took all of this apart in November, 2010 but I took all of the wrong photos. This has been a definite learning experience and I've added a huge hurdle in getting this back together. I've got wiring that's been sitting in a bin for years. Fortunately, I remember some of it pretty well, and with the help of the wiring diagrams in the Blue binder and the haynes manual (more helpful actually), I made a lot of progress. It's not done, but I think that it's at the point the carpet could actually go in if I wanted.

My pistons made it to Phoenix Monday night, but since they weren't scheduled for delivery until Thursday, UPS held onto them. They did show up Thursday, though. I was expecting to have to sign for a $1200 package.

Everything was there (pistons, rings, pins) and I must say, they look okay.

I took them over to the machinist on Friday and I guess I should have a block sometime this coming week.

Today, after work, I spent some time on the injection harness and I am reasonably satisfied with it. I just have one connector to replace for the coolant temp sensor. None of the other harnesses had a good one.

The ignition harness is on deck:

I got started on it and have decided that I'm going to be on the lookout for another one. Fortunately, it was used in US 528i cars, too, so it shouldn't be the end of the world to find one. I'm sure I can get this one looking and working fine, but I would like to see what's out there.

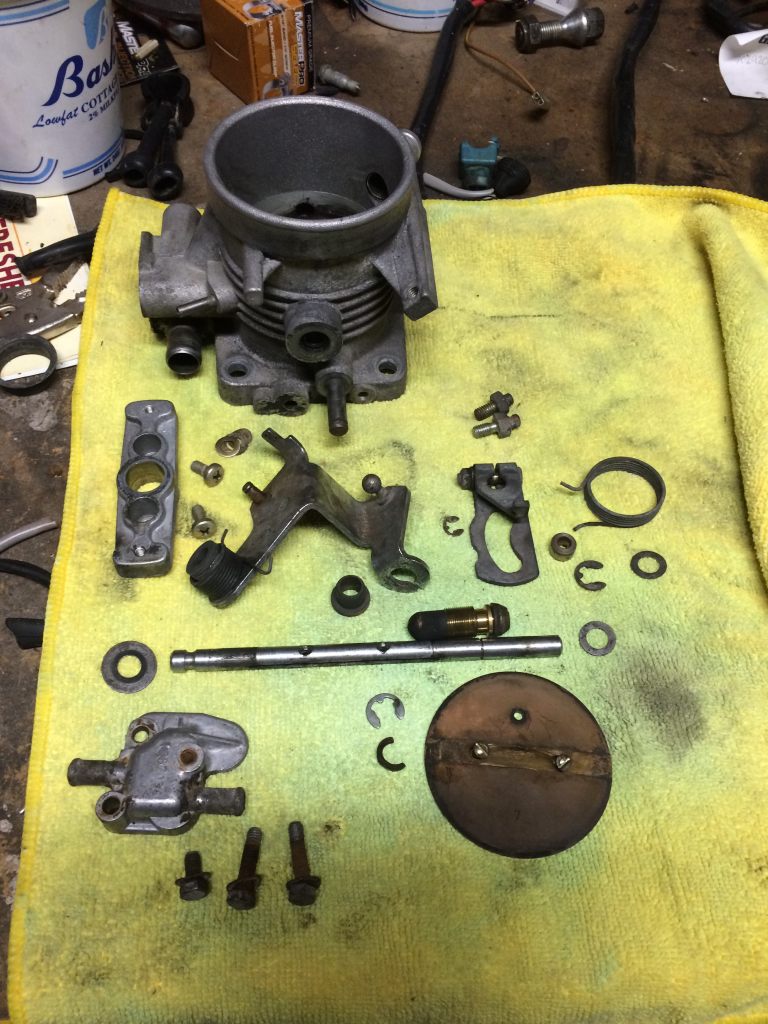

I had also been putting off looking at my throttle body and I was concerned about the complexity of getting it refinished. I then decided that I will only live once and I really shouldn't waste my life not stressing out over springs and e-clips and weird bearing seals and shims that RealOEM says it should have but doesn't so I took it apart:

The three aluminum pieces will be refinished, the other hardware plated and maybe it will work when it all goes back together.

So, at this point, I've got a dash out there, interior at the upholsterer, should have a block soon and there's still a ton to do. I'm going to have to get on the gearbox. I keep forgetting about it.

First off, my begging for the interior firewall insulation piece finally paid off. ldsbeaker spent considerable time and effort salvaging this piece from an E28 he's been working on and it's close enough to work well in the E12. It had remained a piece that was virtually unobtanium and an off-handed remark during a text conversation resulted in this - delivered, even!

It fit in the space well and only needed minor modification around the steering column/pedal bracket and the heater outlet. Everything else works well and it's actually in pretty good shape, too.

Of course, the month of February totally sucks for me and it remained in that spot until the end of March when I accidentally had a couple of hours to see how everything would work together.

February 19th, I found out that of the 11 pistons I gave the machine shop, only two were considered "usable." I've got two more M90 motors, but if I totally disassembled two M90s, could I get a full set? Then I'd have torn down motors everywhere and I'd still need rings. At that point, we decided to call JE. Many times. Leaving many messages. Yielding zero response. It has to be me. It just does. Maybe I should read between the lines. That's where everyone else seems to be.

February 22nd, I decided to drop by the wood refinisher to see what had been going on since I hadn't heard anything. They had told me two weeks when I dropped the stuff off but I let it go quite a while. I had dealt with the owner of the shop and it really seemed like we were in sync on what needed to be done and more than anything, I was looking for something to make me feel good as at this point, nearly every other aspect - actually every other aspect of the job - was giving me bad news. While the boss wasn't there, one of the guys was and I talked to him. He showed me what they had done and I had a very hard time not going ballistic. It looked nothing like it was supposed to and in stripping the veneer, they even broke chunks off in places. I was devastated. The one thing I was hoping would just come out totally tits came out totally, uh... AIDS? I don't know. It was terrible. I couldn't even talk so I left. Chunks of veneer missing and they put some varnish or whatever right over the top of it. I don't know how many times I said restoration project and, "it needs to look just like this. Can you do this?" I had total faith in them, but I guess they must have realized I was restoring an E12 and, of course, no one appreciates those.

I did the only thing I could think of and drove home, looked up the business card and got on the talking horn to the owner. He was smart and said he "couldn't comment intelligently" since he didn't have the stuff in front of him, but he'd call me back. I did tell him that I had two perfect pieces in there that I'd have never had refinished but it all had to match. It did all match. It looked like shit. It all looked like shit together, but that's not what I was paying for. I could do this myself and I probably couldn't even do this bad of a job. I respect wood too much. He did call me back as promised and he assured me they would fix it. He had said that what I wanted was something totally different than he was talking about (so much for me reading that conversation of "it needs to look exactly like these two pieces," answered by, "Yes.") So, I decided to give them the benefit of the doubt since it couldn't possibly get any worse and see what else would blow up in my face. After a while, you really start wondering if everyone out there is useless or if you're the problem.

I checked in with Alex to see if there was any progress getting a hold of JE. None. Never got a call back. We tried a couple of other piston manufacturers and they didn't have any interest in my pistons. Finally, I decided to call JE myself and somehow, I got right through to Jeremy in the Import/Exotic department and we talked for a while about every non-M90 motor BMW made that I didn't need pistons for and then finally he came up with the fact they had actually done M90 pistons before with a 9.3:1 CR and all the other stuff copied from an actual piston. So, I was thinking I was making progress and he tells me to fill out the order form and email it to him. I needed to get the bore size from the machine shop. Alex called the machinist and told him we needed the bore size so I could order the pistons. We waited.

I talked to a few other upholsterers. Two didn't want to touch the job at all and the other one seemed promising but after going over everything with them, it was clear we were going to have a bad time.

March 14, I got a call from the wood refinishers. He explained everything they did and had he known it is what I had wanted, he'd have charged me probably three to four times as much. I didn't really push the issue aside from just reiterating that we seemed to be on the same page as to what I was looking for and how he had described the materials they were going to use, etc. He wanted me to come look at it before they did the other three pieces (shifter knob and two center console storage partition bases) that I had brought in a couple days after dropping off the initial pieces. I told him pretty much exactly when I was going to come by and he said he'd be there.

He wasn't. The wood was, though.

I was satisfied. The other three pieces are going to cost me a bunch of money to have done properly, so even though he honored the price we had agreed upon on this job, it all evens out in the end. At this point, I just want something that doesn't look like a kid refinished it. They told me they could do it and from the photos, it looks like they had. I couldn't even find the spots where they ruined the veneer and I'm glad I didn't take photos of the screw up.

The St. Paddy's Day event in San Diego was coming up the following weekend, so I had had made arrangements with a couple of members to help me out with transporting some things I needed worked on. The bell housing and all of the aluminum parts for the engine sans the throttle body and the upper timing cover (at masheen shop with the head) would be refinished and the dash delivered to Just Dashes in Van Nuys, CA. I spent a considerable amount of time removing all of the gaskets and trying to pre-clean the aluminum pieces as much as possible on the day before departure (I had about two hours between jobs). I neglected to get photos of the parts ready to go, but I did get one of the intake manifold during the frustration of the cleaning process:

I was kinda surprised the window broke, but I was pretty mad.

Got all of that loaded up, but I realized at 4:40am when we were in Yuma that I had forgotten the dash, so I'd have to ship that.

I had ordered a couple of windshields from Ivo, but they didn't pan out due to shipping damage. I had also made a deal with another friend who had a NOS E28 windshield he wasn't going to use, so I got to bring that home. Well, not really. There was no way it was going to fit in an E28 safely, so thankfully, geordi offered to bring it to Phoenix, since he and Ramona were heading through there anyway. He even went to get a bicycle box to put it in. It made the trip safely and is now in my living room.

Ivo did have my cloth, though.

When I had inquired with him, it was perfect timing. I had purchased 5 meters the first time and had just enough. Perhaps enough extra to replace a bolster if necessary. Ivo came back and said that BMW had 7 meters left. I bought it all. It was over twice as much as the last batch was per meter, but the fact I could get it made all the difference. Also, with the material being NLA now and the cost, it makes it clear that it's worth it to make sure it's done the right way. I can't take any chances. It's like an insurance policy to make sure my stuff isn't ruined.

The head was done, so I picked that up.

Crack was repaired, some valves replaced, three angle valve job, etc. Came out nice. I haven't taken it out of the bag. It's safer in the bag.

After picking it up, I walked over to the yard next door and talked to the guys, one of which has known my parents since before I was born. They have a Polaris/Navy cloth '81 528i that's been sitting there for the better part of 10 years. I asked about the rear seat, sharing my predicament. They let me pull this gorgeous rear seat out of that car.

A little bit of Oxyclean on the rough spots and it's good to go.

So, with that sorted, I heard from the machinist a few days later that we needed a minimum bore size of 3.680" due to some minor taper in the cylinders. I filled out my form and emailed it to Jeremy at JE. A few days went by with no response, so I called on April and he was out to lunch. Left a message. No dice. Called back around 4 pm and he processed my order over the phone. Should have the pistons by May 1. Great.

I shipped the dash out to Just Dashes. Took two days to get there and according to their website, from receipt, I should hear from them after 1 week. I called them this past Friday since I hadn't heard from them. Here we go again.

The next day, I called the shop that I decided was the best local option to redo my interior. I brought them the redone interior, the award winning rear seat, the Recaro seat back that has some use and some other various pieces to do the seats. We went over everything again and it was decided they would start with the rear seat and I shouldn't worry about hearing from them for at least a month.

In the meantime, I've been busy with work and tax preparation and other stuff, but I've been forcing myself to work on my engine wiring harness. It was loaded with grease and grime. Totally black. On the whole, it was actually in pretty decent shape, but there were three fuel injector connectors that needed replacing and a couple of the rubber boots on other injectors needed work. I had inherited a collection of various L-Jet harnesses and started cutting out what I needed. I worked with some damaged connectors to practice taking the pins out, then once I felt good enough, I moved on to the salvage connectors to remove everything from them. Success. I worked a little bit at a time, thoroughly cleaning as I went along.

I did spend some time getting a feel for what it was going to take to fit the insulation piece Adam brought me. I put it in, along with the other parts and the carpet. It will take a bit of fettling to get everything to fit right, especially the carpet as it has never actually been in a car before. I decided that once I was satisfied with it, I'd leave it for a bit. A few days or so. I did that.

Friday, I get a notification that my pistons shipped from Ohio and were due on Thursday the 14th.

This last weekend, I removed the carpet and insulation and put it back in the house. I wanted to get all of the in-car wiring squared away. I needed to find my fuel pump wiring, figure out how to route the dome light wiring and get the door switches and unfinished bits taken care of. I took several photos when I took all of this apart in November, 2010 but I took all of the wrong photos. This has been a definite learning experience and I've added a huge hurdle in getting this back together. I've got wiring that's been sitting in a bin for years. Fortunately, I remember some of it pretty well, and with the help of the wiring diagrams in the Blue binder and the haynes manual (more helpful actually), I made a lot of progress. It's not done, but I think that it's at the point the carpet could actually go in if I wanted.

My pistons made it to Phoenix Monday night, but since they weren't scheduled for delivery until Thursday, UPS held onto them. They did show up Thursday, though. I was expecting to have to sign for a $1200 package.

Everything was there (pistons, rings, pins) and I must say, they look okay.

I took them over to the machinist on Friday and I guess I should have a block sometime this coming week.

Today, after work, I spent some time on the injection harness and I am reasonably satisfied with it. I just have one connector to replace for the coolant temp sensor. None of the other harnesses had a good one.

The ignition harness is on deck:

I got started on it and have decided that I'm going to be on the lookout for another one. Fortunately, it was used in US 528i cars, too, so it shouldn't be the end of the world to find one. I'm sure I can get this one looking and working fine, but I would like to see what's out there.

I had also been putting off looking at my throttle body and I was concerned about the complexity of getting it refinished. I then decided that I will only live once and I really shouldn't waste my life not stressing out over springs and e-clips and weird bearing seals and shims that RealOEM says it should have but doesn't so I took it apart:

The three aluminum pieces will be refinished, the other hardware plated and maybe it will work when it all goes back together.

So, at this point, I've got a dash out there, interior at the upholsterer, should have a block soon and there's still a ton to do. I'm going to have to get on the gearbox. I keep forgetting about it.

-

Kyle in NO

- Posts: 17638

- Joined: Feb 12, 2006 12:00 PM

- Location: Nasty Orleans------> Batten-Rooehjch------>More Souther LA

Re: E12 M535i Project - 04-18-16 Update

That's it?

-

Adam W in MN

- Posts: 5053

- Joined: Feb 12, 2006 12:00 PM

- Location: Don't waste my motherf***in' time!

- Contact:

Re: E12 M535i Project - 04-18-16 Update

Lol Kyle.

Nice update, I knew some of those were in process but it's always a pleasure to read the entire backstory and see the other things you've been working on. It is pretty amazing.

The shop with my M535i has had it for several weeks and there really isn't any progress to report. I'm hoping for updates significant enough to bump my thread one day, and actually end up with a completed car before I either a) run out of money or b) lose interest.

actually end up with a completed car before I either a) run out of money or b) lose interest.

Nice update, I knew some of those were in process but it's always a pleasure to read the entire backstory and see the other things you've been working on. It is pretty amazing.

The shop with my M535i has had it for several weeks and there really isn't any progress to report. I'm hoping for updates significant enough to bump my thread one day, and

-

harrypalmer

- Posts: 669

- Joined: Jul 25, 2012 12:10 AM

- Location: Denver, Colorado

Re: E12 M535i Project - 04-18-16 Update

Just like your past Alpina thread, this one I enjoy very much as it is always entertaining, useful and inspiring. Good luck!