I've been really busy with work and whatnot over the last couple of months, plus with taxes, I haven't had any time to relax. Fortunately, there has been some progress over the last couple of months, so I guess we will do it in chronological order.

First off, my begging for the interior firewall insulation piece finally paid off. ldsbeaker spent considerable time and effort salvaging this piece from an E28 he's been working on and it's close enough to work well in the E12. It had remained a piece that was virtually unobtanium and an off-handed remark during a text conversation resulted in this - delivered, even!

It fit in the space well and only needed minor modification around the steering column/pedal bracket and the heater outlet. Everything else works well and it's actually in pretty good shape, too.

Of course, the month of February totally sucks for me and it remained in that spot until the end of March when I accidentally had a couple of hours to see how everything would work together.

February 19th, I found out that of the 11 pistons I gave the machine shop, only two were considered "usable." I've got two more M90 motors, but if I totally disassembled two M90s, could I get a full set? Then I'd have torn down motors everywhere and I'd still need rings. At that point, we decided to call JE. Many times. Leaving many messages. Yielding zero response. It has to be me. It just does. Maybe I should read between the lines. That's where everyone else seems to be.

February 22nd, I decided to drop by the wood refinisher to see what had been going on since I hadn't heard anything. They had told me two weeks when I dropped the stuff off but I let it go quite a while. I had dealt with the owner of the shop and it really seemed like we were in sync on what needed to be done and more than anything, I was looking for something to make me feel good as at this point, nearly every other aspect - actually every other aspect of the job - was giving me bad news. While the boss wasn't there, one of the guys was and I talked to him. He showed me what they had done and I had a very hard time not going ballistic. It looked nothing like it was supposed to and in stripping the veneer, they even broke chunks off in places. I was devastated. The one thing I was hoping would just come out totally tits came out totally, uh... AIDS? I don't know. It was terrible. I couldn't even talk so I left. Chunks of veneer missing and they put some varnish or whatever right over the top of it. I don't know how many times I said restoration project and, "it needs to look just like this. Can you do this?" I had total faith in them, but I guess they must have realized I was restoring an E12 and, of course, no one appreciates those.

I did the only thing I could think of and drove home, looked up the business card and got on the talking horn to the owner. He was smart and said he "couldn't comment intelligently" since he didn't have the stuff in front of him, but he'd call me back. I did tell him that I had two perfect pieces in there that I'd have never had refinished but it all had to match. It did all match. It looked like shit. It all looked like shit together, but that's not what I was paying for. I could do this myself and I probably couldn't even do this bad of a job. I respect wood too much. He did call me back as promised and he assured me they would fix it. He had said that what I wanted was something totally different than he was talking about (so much for me reading that conversation of "it needs to look exactly like these two pieces," answered by, "Yes.") So, I decided to give them the benefit of the doubt since it couldn't possibly get any worse and see what else would blow up in my face. After a while, you really start wondering if everyone out there is useless or if you're the problem.

I checked in with Alex to see if there was any progress getting a hold of JE. None. Never got a call back. We tried a couple of other piston manufacturers and they didn't have any interest in my pistons. Finally, I decided to call JE myself and somehow, I got right through to Jeremy in the Import/Exotic department and we talked for a while about every non-M90 motor BMW made that I didn't need pistons for and then finally he came up with the fact they had actually done M90 pistons before with a 9.3:1 CR and all the other stuff copied from an actual piston. So, I was thinking I was making progress and he tells me to fill out the order form and email it to him. I needed to get the bore size from the machine shop. Alex called the machinist and told him we needed the bore size so I could order the pistons. We waited.

I talked to a few other upholsterers. Two didn't want to touch the job at all and the other one seemed promising but after going over everything with them, it was clear we were going to have a bad time.

March 14, I got a call from the wood refinishers. He explained everything they did and had he known it is what I had wanted, he'd have charged me probably three to four times as much. I didn't really push the issue aside from just reiterating that we seemed to be on the same page as to what I was looking for and how he had described the materials they were going to use, etc. He wanted me to come look at it before they did the other three pieces (shifter knob and two center console storage partition bases) that I had brought in a couple days after dropping off the initial pieces. I told him pretty much exactly when I was going to come by and he said he'd be there.

He wasn't. The wood was, though.

I was satisfied. The other three pieces are going to cost me a bunch of money to have done properly, so even though he honored the price we had agreed upon on this job, it all evens out in the end. At this point, I just want something that doesn't look like a kid refinished it. They told me they could do it and from the photos, it looks like they had. I couldn't even find the spots where they ruined the veneer and I'm glad I didn't take photos of the screw up.

The St. Paddy's Day event in San Diego was coming up the following weekend, so I had had made arrangements with a couple of members to help me out with transporting some things I needed worked on. The bell housing and all of the aluminum parts for the engine sans the throttle body and the upper timing cover (at masheen shop with the head) would be refinished and the dash delivered to Just Dashes in Van Nuys, CA. I spent a considerable amount of time removing all of the gaskets and trying to pre-clean the aluminum pieces as much as possible on the day before departure (I had about two hours between jobs). I neglected to get photos of the parts ready to go, but I did get one of the intake manifold during the frustration of the cleaning process:

I was kinda surprised the window broke, but I was pretty mad.

Got all of that loaded up, but I realized at 4:40am when we were in Yuma that I had forgotten the dash, so I'd have to ship that.

I had ordered a couple of windshields from Ivo, but they didn't pan out due to shipping damage. I had also made a deal with another friend who had a NOS E28 windshield he wasn't going to use, so I got to bring that home. Well, not really. There was no way it was going to fit in an E28 safely, so thankfully, geordi offered to bring it to Phoenix, since he and Ramona were heading through there anyway. He even went to get a bicycle box to put it in. It made the trip safely and is now in my living room.

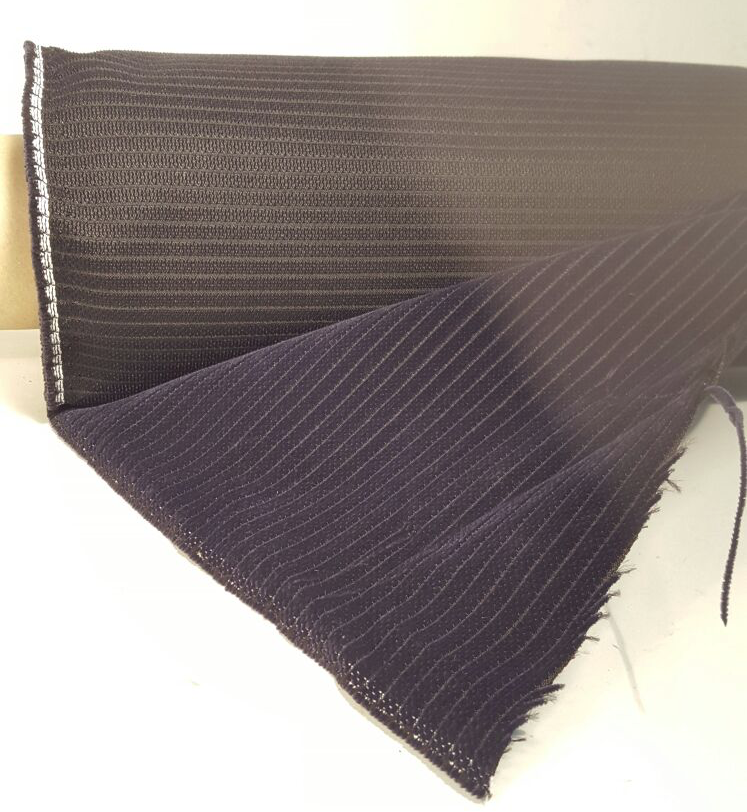

Ivo did have my cloth, though.

When I had inquired with him, it was perfect timing. I had purchased 5 meters the first time and had just enough. Perhaps enough extra to replace a bolster if necessary. Ivo came back and said that BMW had 7 meters left. I bought it all. It was over twice as much as the last batch was per meter, but the fact I could get it made all the difference. Also, with the material being NLA now and the cost, it makes it clear that it's worth it to make sure it's done the right way. I can't take any chances. It's like an insurance policy to make sure my stuff isn't ruined.

The head was done, so I picked that up.

Crack was repaired, some valves replaced, three angle valve job, etc. Came out nice. I haven't taken it out of the bag. It's safer in the bag.

After picking it up, I walked over to the yard next door and talked to the guys, one of which has known my parents since before I was born. They have a Polaris/Navy cloth '81 528i that's been sitting there for the better part of 10 years. I asked about the rear seat, sharing my predicament. They let me pull this gorgeous rear seat out of that car.

A little bit of Oxyclean on the rough spots and it's good to go.

So, with that sorted, I heard from the machinist a few days later that we needed a minimum bore size of 3.680" due to some minor taper in the cylinders. I filled out my form and emailed it to Jeremy at JE. A few days went by with no response, so I called on April and he was out to lunch. Left a message. No dice. Called back around 4 pm and he processed my order over the phone. Should have the pistons by May 1. Great.

I shipped the dash out to Just Dashes. Took two days to get there and according to their website, from receipt, I should hear from them after 1 week. I called them this past Friday since I hadn't heard from them. Here we go again.

The next day, I called the shop that I decided was the best local option to redo my interior. I brought them the redone interior, the award winning rear seat, the Recaro seat back that has some use and some other various pieces to do the seats. We went over everything again and it was decided they would start with the rear seat and I shouldn't worry about hearing from them for at least a month.

In the meantime, I've been busy with work and tax preparation and other stuff, but I've been forcing myself to work on my engine wiring harness. It was loaded with grease and grime. Totally black. On the whole, it was actually in pretty decent shape, but there were three fuel injector connectors that needed replacing and a couple of the rubber boots on other injectors needed work. I had inherited a collection of various L-Jet harnesses and started cutting out what I needed. I worked with some damaged connectors to practice taking the pins out, then once I felt good enough, I moved on to the salvage connectors to remove everything from them. Success. I worked a little bit at a time, thoroughly cleaning as I went along.

I did spend some time getting a feel for what it was going to take to fit the insulation piece Adam brought me. I put it in, along with the other parts and the carpet. It will take a bit of fettling to get everything to fit right, especially the carpet as it has never actually been in a car before. I decided that once I was satisfied with it, I'd leave it for a bit. A few days or so. I did that.

Friday, I get a notification that my pistons shipped from Ohio and were due on Thursday the 14th.

This last weekend, I removed the carpet and insulation and put it back in the house. I wanted to get all of the in-car wiring squared away. I needed to find my fuel pump wiring, figure out how to route the dome light wiring and get the door switches and unfinished bits taken care of. I took several photos when I took all of this apart in November, 2010 but I took all of the wrong photos. This has been a definite learning experience and I've added a huge hurdle in getting this back together. I've got wiring that's been sitting in a bin for years. Fortunately, I remember some of it pretty well, and with the help of the wiring diagrams in the Blue binder and the haynes manual (more helpful actually), I made a lot of progress. It's not done, but I think that it's at the point the carpet could actually go in if I wanted.

My pistons made it to Phoenix Monday night, but since they weren't scheduled for delivery until Thursday, UPS held onto them. They did show up Thursday, though. I was expecting to have to sign for a $1200 package.

Everything was there (pistons, rings, pins) and I must say, they look okay.

I took them over to the machinist on Friday and I guess I should have a block sometime this coming week.

Today, after work, I spent some time on the injection harness and I am reasonably satisfied with it. I just have one connector to replace for the coolant temp sensor. None of the other harnesses had a good one.

The ignition harness is on deck:

I got started on it and have decided that I'm going to be on the lookout for another one. Fortunately, it was used in US 528i cars, too, so it shouldn't be the end of the world to find one. I'm sure I can get this one looking and working fine, but I would like to see what's out there.

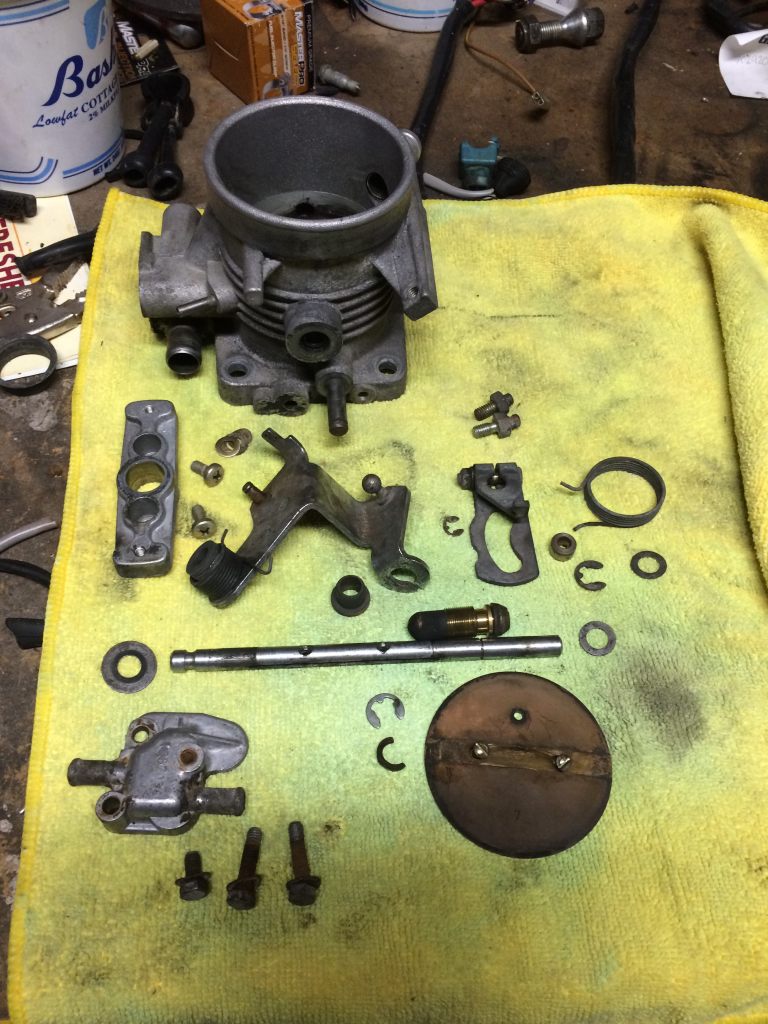

I had also been putting off looking at my throttle body and I was concerned about the complexity of getting it refinished. I then decided that I will only live once and I really shouldn't waste my life not stressing out over springs and e-clips and weird bearing seals and shims that RealOEM says it should have but doesn't so I took it apart:

The three aluminum pieces will be refinished, the other hardware plated and maybe it will work when it all goes back together.

So, at this point, I've got a dash out there, interior at the upholsterer, should have a block soon and there's still a ton to do. I'm going to have to get on the gearbox. I keep forgetting about it.