Another restoration - 83' 528i

Re: Another restoration - 83' 528i

I was wondering about panel and body alignment/fitment with all that cutting and re-welding; looks like you're on top of it.

Re: Another restoration - 83' 528i

I do weld in temporary supports to keep eveything lined up whenever I cut out a larger section or when it might move otherwise.vinceg101 wrote: Sep 17, 2020 11:22 AM I was wondering about panel and body alignment/fitment with all that cutting and re-welding; looks like you're on top of it.

Late August 2020

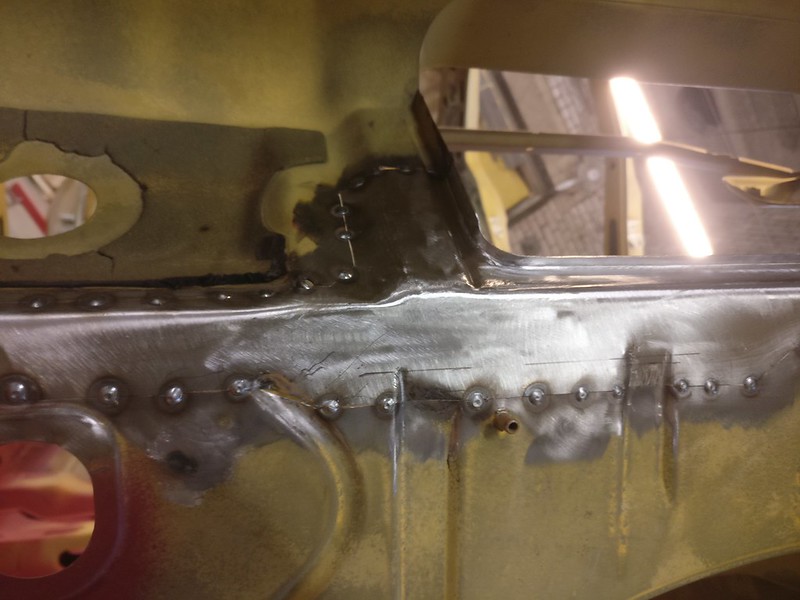

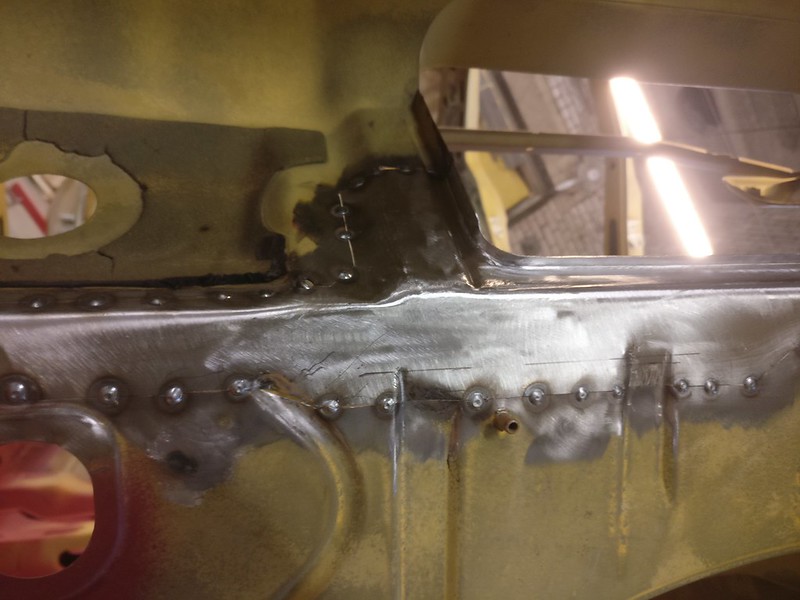

To get the driver’s side rocker done I had to first finish up this rear section

I had a few days before my buddy could come over to assist with the rocker so I decided to begin work on that ugliness in engine compartment. Notice how the firewall has actually bulged from the previous repair or whatever you call it.

View from the front wheel housing

A small piece tacked in

Welded up and finished

And then the hole in the firewall got filled in

Doors fitted. As I mentioned before, the remains of the rocker panel were of little help aligning the doors.

Then removed the rocker and as I suspected there was a bit too much sandwich rust to my liking here.

After this, new side sill panel was fitted and welded in. Interestingly, the front of the driver’s side panel had much better fitment out of the box than the other side. E.g the front line where it meets the wing was straight.

And finished off. Could have used some more work on the inner side where it meets the front and rear pillars but it will do.

Today, a courier came by and dropped me off a large box. I now have two large boxes (and a nice cow hide carpet).

Re: Another restoration - 83' 528i

First half of September 2020

To move on with passenger side front strut tower I first wanted to finish up other side so if necessary I could see how everything goes together there. This meant fixing the front wing support flange and installing new support plate.

This was removed

And a replacement made

Brand new OEM support panels for both sides. Those were quite cheap and would have been a pain to replicate.

Sits there like that

Some prepping, drilling (for plug welds) and welding later it was installed.

On with the passenger side then. This is what I had to begin with.

Before cutting it open and sandblasting the strut tower I began working on the replacement. Cut out a piece of sheet metal and bent it more or less into shape.

Later on (a bit too late), I realized that I should’ve made the panel bigger and included the whole front wing flange. This could’ve saved some time on welding/grinding and I’d usually prefer a single larger repair to multiple smaller ones.

Anyway, strut tower was in a similar condition to the other side.

This time I didn’t forget to take any photos of the results of sandblasting. Just to be on the safe side, I treated it with rust-converter as well.

I also sandblasted a small (about 15mm diameter) rust spot on windshield frame. And of course I didn’t take any pics of that. There was no way I was going to do any cutting and welding in a spot like that and I wasn’t too confident with just filling it with bondo. So, after consulting with my buddy (the car restorer) we decided to apply some lead over that spot. As always, he was happy to help.

After the area was thoroughly cleaned, tinning butter was applied followed by some lead.

Then excess lead was filed down

After the treatment with rust-converter, firewall got patched up on the other side

And then work continued on the wheel housing panel. Not well visible on this pic but a couple of nails were welded to the panel to replicate the fixings for the clips.

Some adjustments to the shape and all the drains and holes for plug welds done.

It fit like a glove, really happy about it.

That was it for the first half of September. Stay tuned for finished product!

To move on with passenger side front strut tower I first wanted to finish up other side so if necessary I could see how everything goes together there. This meant fixing the front wing support flange and installing new support plate.

This was removed

And a replacement made

Brand new OEM support panels for both sides. Those were quite cheap and would have been a pain to replicate.

Sits there like that

Some prepping, drilling (for plug welds) and welding later it was installed.

On with the passenger side then. This is what I had to begin with.

Before cutting it open and sandblasting the strut tower I began working on the replacement. Cut out a piece of sheet metal and bent it more or less into shape.

Later on (a bit too late), I realized that I should’ve made the panel bigger and included the whole front wing flange. This could’ve saved some time on welding/grinding and I’d usually prefer a single larger repair to multiple smaller ones.

Anyway, strut tower was in a similar condition to the other side.

This time I didn’t forget to take any photos of the results of sandblasting. Just to be on the safe side, I treated it with rust-converter as well.

I also sandblasted a small (about 15mm diameter) rust spot on windshield frame. And of course I didn’t take any pics of that. There was no way I was going to do any cutting and welding in a spot like that and I wasn’t too confident with just filling it with bondo. So, after consulting with my buddy (the car restorer) we decided to apply some lead over that spot. As always, he was happy to help.

After the area was thoroughly cleaned, tinning butter was applied followed by some lead.

Then excess lead was filed down

After the treatment with rust-converter, firewall got patched up on the other side

And then work continued on the wheel housing panel. Not well visible on this pic but a couple of nails were welded to the panel to replicate the fixings for the clips.

Some adjustments to the shape and all the drains and holes for plug welds done.

It fit like a glove, really happy about it.

That was it for the first half of September. Stay tuned for finished product!

Re: Another restoration - 83' 528i

Second half of September 2020

Tacks and plug welds done on wheel housing repair

Fully welded

And cleaned up

Then work continued on the firewall. I do not have a fresh “before” photo so this one will have to do.

I had saved a section of firewall from the other car. That included the bottom panel of the fan area. Unfortunately, I didn’t cut it off in full length and this bottom panel is NLA.

I didn’t like the idea of welding it in as is and it looked like I can’t separate the two panels (firewall from fan bottom panel) without destroying one of them. They had quite some seam sealer/glue in addition to plug welds in between them. So I decided to make a repair for firewall and use the fan bottom panel from the other car. Latter still needed to be extended to the passenger corner.

I happen to have a full series of photos of how the firewall piece was made, so here they are.

First cut out a suitable piece of sheet metal and mark down everything

Then bent the corner using my bending assistant. This is not a very tight bend thus pushing it over by hand gave me exactly the correct radius. Usually I use an appriopriately sized metal rod or similar to make those radiused bends.

After those two bends were done I had something like this

Next, made two bends here. Used some repurposed and dulled chisels to help me out there.

After that, made the small step by just hitting it with the chisel while the piece was attached to my tool

Needs a little bit dressing here and then it will do fine

Finally, added the lip for heater box. The corner needs quite a stretch and I actually messed up the first repair panel here. On the first try, I was just bending over the corner without stretching it against a dolly and that twisted the whole top part. As it was quite quick to remake I didn’t bother to fix it and redid the previous bends on a fresh piece of sheet metal

Rust removed and repair tacked in

I did the top parts of the beads after tacking it in to avoid any twisting of the repair panel. Didn’t realize before it was too late that the beads get wider in the ends not go straight as I did them. Compare the top and bottom end of that short bead on the following photo. But as all that gets covered up by a thick layer of insulation I didn’t bother with it much.

And firewall is whole again

I didn’t take any pictures of the process but the passenger corner piece of fan area got reinstalled and bottom fan panel extended and put back where it belongs. Those are made out of 0.6mm (24 gauge) sheet metal so need a bit more extra care welding but, on the plus side, less bead to grind off.

This was finished off only few hours ago so we have caught up with the progress now.

Tacks and plug welds done on wheel housing repair

Fully welded

And cleaned up

Then work continued on the firewall. I do not have a fresh “before” photo so this one will have to do.

I had saved a section of firewall from the other car. That included the bottom panel of the fan area. Unfortunately, I didn’t cut it off in full length and this bottom panel is NLA.

I didn’t like the idea of welding it in as is and it looked like I can’t separate the two panels (firewall from fan bottom panel) without destroying one of them. They had quite some seam sealer/glue in addition to plug welds in between them. So I decided to make a repair for firewall and use the fan bottom panel from the other car. Latter still needed to be extended to the passenger corner.

I happen to have a full series of photos of how the firewall piece was made, so here they are.

First cut out a suitable piece of sheet metal and mark down everything

Then bent the corner using my bending assistant. This is not a very tight bend thus pushing it over by hand gave me exactly the correct radius. Usually I use an appriopriately sized metal rod or similar to make those radiused bends.

After those two bends were done I had something like this

Next, made two bends here. Used some repurposed and dulled chisels to help me out there.

After that, made the small step by just hitting it with the chisel while the piece was attached to my tool

Needs a little bit dressing here and then it will do fine

Finally, added the lip for heater box. The corner needs quite a stretch and I actually messed up the first repair panel here. On the first try, I was just bending over the corner without stretching it against a dolly and that twisted the whole top part. As it was quite quick to remake I didn’t bother to fix it and redid the previous bends on a fresh piece of sheet metal

Rust removed and repair tacked in

I did the top parts of the beads after tacking it in to avoid any twisting of the repair panel. Didn’t realize before it was too late that the beads get wider in the ends not go straight as I did them. Compare the top and bottom end of that short bead on the following photo. But as all that gets covered up by a thick layer of insulation I didn’t bother with it much.

And firewall is whole again

I didn’t take any pictures of the process but the passenger corner piece of fan area got reinstalled and bottom fan panel extended and put back where it belongs. Those are made out of 0.6mm (24 gauge) sheet metal so need a bit more extra care welding but, on the plus side, less bead to grind off.

This was finished off only few hours ago so we have caught up with the progress now.

-

Bonsaibacker

- Posts: 966

- Joined: Oct 26, 2017 3:36 PM

- Location: Fleming Island FL

Re: Another restoration - 83' 528i

That firewall patch is pure craftsmanship!

Re: Another restoration - 83' 528i

Fantastic work bud. I've been down this road before myself, and I really appreciate the skill you are applying to your work (which far exceed my results back in the day). Very, very. well done indeed!

Re: Another restoration - 83' 528i

Thank you guys!

First, I think I figured out most of my sway bar stuff. Thanks to JohnH who posted about this amazing site (https://bmw-grouparchiv.de/) under tech talk I stumbled across an old parts catalogue. Turns out they did use 16mm front sway bar on 525i up to build date 09/82. My front sway bar came from a 81 525i. However, realoem has no knowledge of such sway bar, therefore my earlier confusion.

I crawled under my friend’s late E28 and realized there’s no way I could get away with late rear sway bar. It sits too tight around the diff mount to clear the old style mount/cover. This is actually quite clearly visible from vinceg photos he shared in this thread. My only hope was that maybe the newer sway bar sits further back than the old one but that doesn’t seem to be the case.

For the sake of knowledge I paired up the photo of Vlad with one of my chassis. I hope you don’t mind, cek.

The longitudinal beam that’s between fuel tank and spare wheel housing is actually a difference between US and Euro cars not early/late cars. All the late euro cars I’ve seen share the same beam with my chassis.

Floor pan sheet metal seems to be identical for late and early cars.

Late cars have wider crossbeam with different sway bar and diff mounts. Longitudinal beam between wheels is a bit different but has the same width.

My initial though was that rear sway bar on late cars is mounted further back because the arms of the sway bar are longer and mounts face the rear end. Comparing the two photos, I find they sit almost in the same position. Late sway bar might be a little bit further back but not much.

Unfortunately, I didn’t do any measuring on my friend’s car as it was clear to me that no matter what I do with the mounts I'd have to use the old style sway bar to clear the differential.

However, I finally found a 16mm aftermarket sway bar that, at least according to the pictures, should fit my older chassis. So at least I have some options.

In conclusion, I’ll most likely reinforce my rear mounts and fabricate some custom mounts for front.

So on with the progress on chassis repairs.

1 - 7 Oct 2020

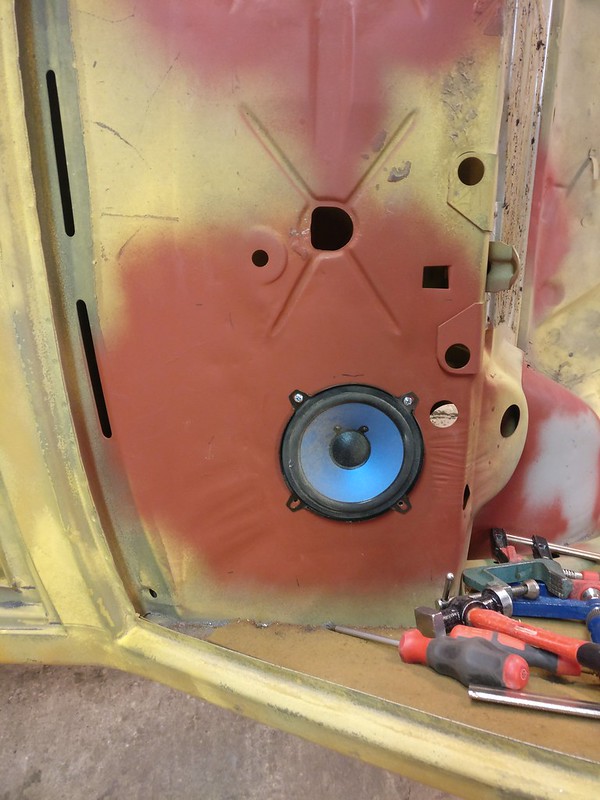

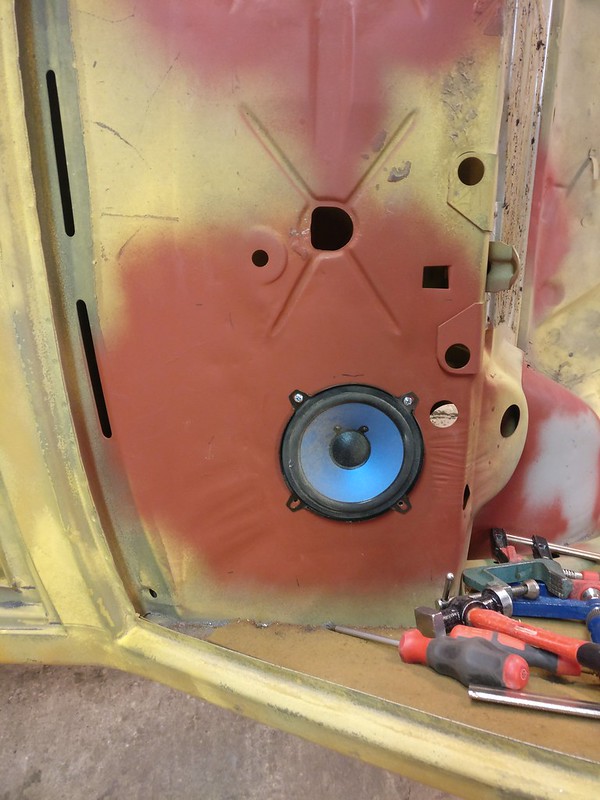

I have changed my mind about speakers on the rear parcel shelf. I have a quite decent set of 6 ½ inch component speakers lying around and I’d like to use them on this car. I guess some car audio enthusiasts would hate me for running such setup but I’ve been thinking about mounting the midwoofers from that set on my rear parcel, probably run them through some LPF. I’d use tweeters and filters from that set for front end and source a nice quality 4 inch midrange speakers to go into A-pillars. Also, I have a 4-channel amp I could use to run this setup.

Now, I know that there’s no way 6 ½ half speakers fit there without hacking everything up but I already have some plans for a custom parcel shelf cover that wouldn’t look too out of place on an E28. If that doesn’t pan out I’ll most likely ditch those speakers for a cleaner look.

Anyway, I now need some holes there for speakers.

I began with cutting some rough holes in my recently repaired parcel shelf

Did a little bit grinding and filing to tidy them up

Cut out some molds out of plywood. The holes in the corners helped to align the bottom and top piece. Used some C-clamps to tighten them up and started hammering.

A little bit later I had something like this

These holes were made for 5 ¼ inch speakers as this is the largest you could mount flush without going into the lower panel. I went through multiple datasheets for different speakers to look up the dimensions beforehand so most of the 5 ¼ inch speakers should fit there nicely. Some speakers might hit the fuel expansion tank but I am not concerned about that right now.

Here’s a random speaker mounted.

After both sides were done, I trimmed the flare and enlarged the small holes so they could be used to attach the speaker. I could’ve done mounting points for the sheet metal nuts, something like BMW did for A-pillar speakers. This would’ve made mounting the speakers easier (no need to hold the nut from the trunk) but then I would’ve lost some rigidity of the panel by removing the lip in the corners.

I am happy with these. Nothing like the crap that was there before.

Then I went on and cleaned up any remaining sound insulation and glue residue on C-pillars and parcel shelf. This time I used heat gun and scraper. To be honest, I can't say it was worse than freezing the insulation panels. Xylene was used to remove glue residue.

One of the license place light openings was rather badly rusted so I cut it out and made a piece to fix it.

The other side has a little bit of rust pits. It was blasted clean and no rust has creeped through the etching primer since then. Haven’t decided yet if I want to replace it or leave it be.

I know I had two small pit holes where the panel seen on the next photo was attached to the fuel filler neck housing in the trunk. I though I’ll just weld them up and be done with it. But on a closer look there was more like 20 small holes hidden behind that panel. So it had to come out. And I am glad it did, as it turned out the bottom flange of this piece was also quite rusted.

OEM panel is still available and doesn’t cost much. But then I’d have to wait for it to arrive and besides where’s the fun in that. So I decided to replicate this myself.

I began with the toughest part - return bend on top. I still haven’t figured out an easy way to do those tight return bends without a bead roller. My methods give some results but I usually need to tidy it up later.

Cut out a suitable piece of sheet metal and tacked it to a metal bar so it wouldn’t move while I work on the bend.

I clamped an additional bar on the top part to keep the bend tight and used a blunt chisel to hit it on the bottom line. That gave me this

Then cut some holes

And used the same method I used for speaker holes to form the flares

Next, did the bottom flange. Messed up the smaller hole a bit during bending but it can be saved with some hammering.

Trimmed to size

Finally, drilled the small holes, did the harness attachment clips and made it shine.

I wonder if anyone knows what those clips are for? I first though the central locking harness for fuel door runs past there but my old photos tell me otherwise. I can’t think of anything else electrical there.

Today, I came home to this parcel

In there was a brand new front bumper

Got it at a very decent price from a German gentleman. Sad thing about it is that my rear bumper was actually in worse state than the front (front I could've run as is) and there’s no way I can get that lucky twice.

First, I think I figured out most of my sway bar stuff. Thanks to JohnH who posted about this amazing site (https://bmw-grouparchiv.de/) under tech talk I stumbled across an old parts catalogue. Turns out they did use 16mm front sway bar on 525i up to build date 09/82. My front sway bar came from a 81 525i. However, realoem has no knowledge of such sway bar, therefore my earlier confusion.

I crawled under my friend’s late E28 and realized there’s no way I could get away with late rear sway bar. It sits too tight around the diff mount to clear the old style mount/cover. This is actually quite clearly visible from vinceg photos he shared in this thread. My only hope was that maybe the newer sway bar sits further back than the old one but that doesn’t seem to be the case.

For the sake of knowledge I paired up the photo of Vlad with one of my chassis. I hope you don’t mind, cek.

The longitudinal beam that’s between fuel tank and spare wheel housing is actually a difference between US and Euro cars not early/late cars. All the late euro cars I’ve seen share the same beam with my chassis.

Floor pan sheet metal seems to be identical for late and early cars.

Late cars have wider crossbeam with different sway bar and diff mounts. Longitudinal beam between wheels is a bit different but has the same width.

My initial though was that rear sway bar on late cars is mounted further back because the arms of the sway bar are longer and mounts face the rear end. Comparing the two photos, I find they sit almost in the same position. Late sway bar might be a little bit further back but not much.

Unfortunately, I didn’t do any measuring on my friend’s car as it was clear to me that no matter what I do with the mounts I'd have to use the old style sway bar to clear the differential.

However, I finally found a 16mm aftermarket sway bar that, at least according to the pictures, should fit my older chassis. So at least I have some options.

In conclusion, I’ll most likely reinforce my rear mounts and fabricate some custom mounts for front.

So on with the progress on chassis repairs.

1 - 7 Oct 2020

I have changed my mind about speakers on the rear parcel shelf. I have a quite decent set of 6 ½ inch component speakers lying around and I’d like to use them on this car. I guess some car audio enthusiasts would hate me for running such setup but I’ve been thinking about mounting the midwoofers from that set on my rear parcel, probably run them through some LPF. I’d use tweeters and filters from that set for front end and source a nice quality 4 inch midrange speakers to go into A-pillars. Also, I have a 4-channel amp I could use to run this setup.

Now, I know that there’s no way 6 ½ half speakers fit there without hacking everything up but I already have some plans for a custom parcel shelf cover that wouldn’t look too out of place on an E28. If that doesn’t pan out I’ll most likely ditch those speakers for a cleaner look.

Anyway, I now need some holes there for speakers.

I began with cutting some rough holes in my recently repaired parcel shelf

Did a little bit grinding and filing to tidy them up

Cut out some molds out of plywood. The holes in the corners helped to align the bottom and top piece. Used some C-clamps to tighten them up and started hammering.

A little bit later I had something like this

These holes were made for 5 ¼ inch speakers as this is the largest you could mount flush without going into the lower panel. I went through multiple datasheets for different speakers to look up the dimensions beforehand so most of the 5 ¼ inch speakers should fit there nicely. Some speakers might hit the fuel expansion tank but I am not concerned about that right now.

Here’s a random speaker mounted.

After both sides were done, I trimmed the flare and enlarged the small holes so they could be used to attach the speaker. I could’ve done mounting points for the sheet metal nuts, something like BMW did for A-pillar speakers. This would’ve made mounting the speakers easier (no need to hold the nut from the trunk) but then I would’ve lost some rigidity of the panel by removing the lip in the corners.

I am happy with these. Nothing like the crap that was there before.

Then I went on and cleaned up any remaining sound insulation and glue residue on C-pillars and parcel shelf. This time I used heat gun and scraper. To be honest, I can't say it was worse than freezing the insulation panels. Xylene was used to remove glue residue.

One of the license place light openings was rather badly rusted so I cut it out and made a piece to fix it.

The other side has a little bit of rust pits. It was blasted clean and no rust has creeped through the etching primer since then. Haven’t decided yet if I want to replace it or leave it be.

I know I had two small pit holes where the panel seen on the next photo was attached to the fuel filler neck housing in the trunk. I though I’ll just weld them up and be done with it. But on a closer look there was more like 20 small holes hidden behind that panel. So it had to come out. And I am glad it did, as it turned out the bottom flange of this piece was also quite rusted.

OEM panel is still available and doesn’t cost much. But then I’d have to wait for it to arrive and besides where’s the fun in that. So I decided to replicate this myself.

I began with the toughest part - return bend on top. I still haven’t figured out an easy way to do those tight return bends without a bead roller. My methods give some results but I usually need to tidy it up later.

Cut out a suitable piece of sheet metal and tacked it to a metal bar so it wouldn’t move while I work on the bend.

I clamped an additional bar on the top part to keep the bend tight and used a blunt chisel to hit it on the bottom line. That gave me this

Then cut some holes

And used the same method I used for speaker holes to form the flares

Next, did the bottom flange. Messed up the smaller hole a bit during bending but it can be saved with some hammering.

Trimmed to size

Finally, drilled the small holes, did the harness attachment clips and made it shine.

I wonder if anyone knows what those clips are for? I first though the central locking harness for fuel door runs past there but my old photos tell me otherwise. I can’t think of anything else electrical there.

Today, I came home to this parcel

In there was a brand new front bumper

Got it at a very decent price from a German gentleman. Sad thing about it is that my rear bumper was actually in worse state than the front (front I could've run as is) and there’s no way I can get that lucky twice.

Last edited by taavipa on Oct 18, 2020 5:31 PM, edited 1 time in total.

Re: Another restoration - 83' 528i

Inspirational. I think your work is superb. Well done.

A question. What tools are you using to cut the bodywork and repair pieces, especially those around the strut towers. I'm looking to do the same task on mine and have been using a dremel with its 38mm cutting wheel which works quite well in the restricted spaces around the tower.

A question. What tools are you using to cut the bodywork and repair pieces, especially those around the strut towers. I'm looking to do the same task on mine and have been using a dremel with its 38mm cutting wheel which works quite well in the restricted spaces around the tower.

Re: Another restoration - 83' 528i

Thanks!JohnH wrote: Oct 08, 2020 9:45 PM Inspirational. I think your work is superb. Well done.

A question. What tools are you using to cut the bodywork and repair pieces, especially those around the strut towers. I'm looking to do the same task on mine and have been using a dremel with its 38mm cutting wheel which works quite well in the restricted spaces around the tower.

Most of my cutting gets done by an air cut off tool/grinder. I use 75mm (~3 inch) x 1mm discs on that. I keep the worn out discs to get into tight places.

I've also used Dremel and those 38mm discs are quite nice. Although, from the last batch I had almost every disc had a premature failure in the middle where the EZ SpeedClick shaft gets attached. I haven't bought any more of these after that. I also use those tiny and narrow cutting discs (0.5mm) for Dremel that sometimes come in handy (e.g those cuts I made for the rocker drains). If the cutting tools don't fit, I grind away excess metal with either rolocs or with my belt sander/powerfile, sometimes you can even make cuts with snips where power tools don't fit.

For new repair panels I usually use cutting discs only for cutting the initial piece out of sheet metal. I haven't yet invested into an air or electric snipping tool or nibbler, otherwise I'd use that. Trimming gets mostly done with aviation snips. If I'd like to get a cleaner edge, I grind the last millimeter or two. For a very tight panel fitment you can't beat hand filing the very last part.

I guess it would be a perfect place to also list some of the tools I use for grinding the welds and finishing.

Nothing beats my 90 degree angled air die grinder equipped with roloc discs. Whenever possible I try to plan the repairs so that I have good access to the welds with this tool. For grinding I use 50mm (~2 in) 3M red Cubitron discs. They also have a purple series of Cubitron discs but in my experience they wear out quicker and have too stiff backing. I start with 60+ grit discs and sometimes, on more visible areas, I use 80+ grit for the last bit. When fresh, these roloc discs cut through welds like a knife through butter. Some discs also have soft backing and those are useful to remove welds from the inner corner of the bends. I bought a big bag of Chinese made roloc discs off eBay that have really soft backing. They don't last for long but help me out sometimes. I don't have one but I imagine a 45 degree angled die grinder would also come in handy for tighter areas.

To smooth everything out after the grinding I use coarse (brown) Scotch Brite roloc discs on the same tool. Mostly 75mm (3in), sometimes 50mm (2in).

Second best tool I have for grinding the welds is the air powered belt sander/powerfile. I use 10x330mm 3M Cubitron belts on that. For the belt sander I do like the purple belts more than the red ones. Not sure why, but the red ones tend to snap in two from the joint more easily. 60+ grit and 80+ grit. The tip of this tool can get into quite tight spots. But it is much harder to achieve a nice flat finish with this and it is much more agressive than rolocs so care must be taken when grinding. They also do offer Scotch Brite belts but I haven't had a chance to try one yet.

For both of these I prefer the "original" accessories made by 3M. The replicas aren't that much cheaper, wear out quicker and perform worse. As the grinding is definitely the most appalling part of the work, I see no reason to use them.

For really tight spots I have a tiny 3mm carbide bit for Dremel. Its hard to get a smooth finish with that but it helps to at least take the tops off the welds.

For the inner corners of bends the edge of a cutting disc works to remove the majority of the weld.

When the weld doesn't get ground off, like if there was a seam weld there from the factory or in some hidden place where no tool would fit, I run a wire wheel over the weld and the surrounding area to clean it up. Not doing so results in primer/paint not adhering properly.

Re: Another restoration - 83' 528i

Great reply. I'm still digesting it. 3M roloc takes a bit of beating as does most 3M stuff. Iv'e still got my old Speedglas, which is a great bit of kit.

Re: Another restoration - 83' 528i

Fantastic work.

You are right as those clips hold nothing on the passenger side. Those clips for the similar piece on the drivers side hold the taillight and central locking wire harness.

Here’s mine

You are right as those clips hold nothing on the passenger side. Those clips for the similar piece on the drivers side hold the taillight and central locking wire harness.

Here’s mine

Re: Another restoration - 83' 528i

8 - 18 Oct 2020

Continued the work on the trunk. I did a crappy patch (no pictures) on the fuel filler neck housing and got it all warped. Well, it was already warped a bit from the sandblasting. Anyway, I couldn’t leave it like that so I removed it and made a replacement.

I decided to leave the top section from the original panel and butt weld the new bottom part. I have neither tools nor skills to make a full replacement and this is not the time I’d like to try out new things. The bend on top should make it stiff enough to get good results joining it there.

I also discovered some rust between this and trunk panel so I'm glad I removed it.

Fortunately, I realized at the very last moment I had forgotten to add an important detail to this piece. Would have been next to impossible to do it after the installation. Can you spot what's missing on the previous pictures?

Here it’s partially welded.

The bottom joint to the trunk panel had two seam welds and then the gap in between was stuffed with seam sealer. I decided to use 1K panel glue (Teroson MS 9220) I have used as seam sealer in the past and skip the welding. To make the seam welds I couldn’t use any sealer there before and I didn’t see how I could get the gap fully sealed after the panel is in place. Masking tape is there so I wouldn’t have tons of metal shavings in the sealer later.

Weld cleaned

And done

Decided to fix the metal surrounding the other license plate light. I didn’t feel comfortable with the pitting there as the moisture sure does get trapped between the gasket and the panel. As this side was in better shape than the other I made a smaller patch and actually had better results.

Both finished

Installed the side panel from the previous post

And punched out the hole for central locking

If I remember correctly this chassis came with an LSD and ABS but was missing many other common options, like central locking. Unfortunately, none of the VIN decoders I have tried is able to list the options for this car any more. I am pretty sure they were working a while back but I didn't save the list then. If anyone knows a VIN decoder that can list the options, please let me know.

I noticed this hole in driver’s side rear wheel well quite some time ago.

This is the result of a crappy job in the factory. This is on the other side where trunk separator/parcel shelf panel is attached to the wheel well in the cabin.

I’ve found three porous factory welds in total on this chassis. Plus a weld that classifies as just crappy. I guess it is too late for a warranty chassis replacement?

I did what any sane person would do and ground it out. Had to do a longer weld there, as some of the remaining metal just melted away. But I prefer this to the porous weld that was there before.

Discovered that my trunk floor is oil-canning. I guess the sandblaster went too hard on it. While I don’t need my trunk floor to be perfectly straight, I do mind it clunking every time I drop a bag in the trunk. To fix it I tried something new to me - heat shrinking.

I don’t have an oxy-acetylene torch which is usually used for that purpose so I did it with regular torch using some gas mixture that by specifications should burn a bit hotter than propane. Turns out it worked quite well and I achieved exactly what I wanted.

Took two shrinks to get it done. Actually, the oil-canning was gone after the first shrink but I still had a high spot so I went for another.

And today, I started the work on the rear wheel arches.

I’ll probably put the wheel arches on hold for a bit. But more about this in the next post.

Continued the work on the trunk. I did a crappy patch (no pictures) on the fuel filler neck housing and got it all warped. Well, it was already warped a bit from the sandblasting. Anyway, I couldn’t leave it like that so I removed it and made a replacement.

I decided to leave the top section from the original panel and butt weld the new bottom part. I have neither tools nor skills to make a full replacement and this is not the time I’d like to try out new things. The bend on top should make it stiff enough to get good results joining it there.

I also discovered some rust between this and trunk panel so I'm glad I removed it.

Fortunately, I realized at the very last moment I had forgotten to add an important detail to this piece. Would have been next to impossible to do it after the installation. Can you spot what's missing on the previous pictures?

Here it’s partially welded.

The bottom joint to the trunk panel had two seam welds and then the gap in between was stuffed with seam sealer. I decided to use 1K panel glue (Teroson MS 9220) I have used as seam sealer in the past and skip the welding. To make the seam welds I couldn’t use any sealer there before and I didn’t see how I could get the gap fully sealed after the panel is in place. Masking tape is there so I wouldn’t have tons of metal shavings in the sealer later.

Weld cleaned

And done

Decided to fix the metal surrounding the other license plate light. I didn’t feel comfortable with the pitting there as the moisture sure does get trapped between the gasket and the panel. As this side was in better shape than the other I made a smaller patch and actually had better results.

Both finished

Installed the side panel from the previous post

And punched out the hole for central locking

If I remember correctly this chassis came with an LSD and ABS but was missing many other common options, like central locking. Unfortunately, none of the VIN decoders I have tried is able to list the options for this car any more. I am pretty sure they were working a while back but I didn't save the list then. If anyone knows a VIN decoder that can list the options, please let me know.

I noticed this hole in driver’s side rear wheel well quite some time ago.

This is the result of a crappy job in the factory. This is on the other side where trunk separator/parcel shelf panel is attached to the wheel well in the cabin.

I’ve found three porous factory welds in total on this chassis. Plus a weld that classifies as just crappy. I guess it is too late for a warranty chassis replacement?

I did what any sane person would do and ground it out. Had to do a longer weld there, as some of the remaining metal just melted away. But I prefer this to the porous weld that was there before.

Discovered that my trunk floor is oil-canning. I guess the sandblaster went too hard on it. While I don’t need my trunk floor to be perfectly straight, I do mind it clunking every time I drop a bag in the trunk. To fix it I tried something new to me - heat shrinking.

I don’t have an oxy-acetylene torch which is usually used for that purpose so I did it with regular torch using some gas mixture that by specifications should burn a bit hotter than propane. Turns out it worked quite well and I achieved exactly what I wanted.

Took two shrinks to get it done. Actually, the oil-canning was gone after the first shrink but I still had a high spot so I went for another.

And today, I started the work on the rear wheel arches.

I’ll probably put the wheel arches on hold for a bit. But more about this in the next post.

Re: Another restoration - 83' 528i

So, today I was cleaning off the spray glue from the inside of my roof when I discovered the sunroof frame was loose from the roof panel at the back.

I stepped over to my buddy's E28 and gently pressed on the roof in the same area - it has the same issue.

Edit: This is actually how they came from the factory, see the next post.

I made a quick video to demonstrate the problem:

https://youtu.be/4LqZNOqHKJY

And a photo for those who doesn't bother to watch the video

It would be 30 cm forward from the rear window. About here

The roof panel looks completely straight and fine. I guess the adhesive has shrunk and/or there was too little adhesive there to begin with. It's secure in the rear corners and everywhere else. I'll probably try to remove some of the old adhesive as it's all stuck to the sunroof frame and then squeeze some fresh panel glue in between the panels.

I guess the only consequence of this would be some possible noise issues.

I was wondering if any of your cars suffer from it. But be careful not to dent your roofs!

I stepped over to my buddy's E28 and gently pressed on the roof in the same area - it has the same issue.

Edit: This is actually how they came from the factory, see the next post.

I made a quick video to demonstrate the problem:

https://youtu.be/4LqZNOqHKJY

And a photo for those who doesn't bother to watch the video

It would be 30 cm forward from the rear window. About here

The roof panel looks completely straight and fine. I guess the adhesive has shrunk and/or there was too little adhesive there to begin with. It's secure in the rear corners and everywhere else. I'll probably try to remove some of the old adhesive as it's all stuck to the sunroof frame and then squeeze some fresh panel glue in between the panels.

I guess the only consequence of this would be some possible noise issues.

I was wondering if any of your cars suffer from it. But be careful not to dent your roofs!

Last edited by taavipa on Oct 25, 2020 7:48 PM, edited 1 time in total.

Re: Another restoration - 83' 528i

19 - 25 Oct 2020

First of all, the roof panel issue from the last post was a false alarm. Kinda. I could swear I saw some adhesive between the panels there but on closer inspection there was actually none. I guess they didn’t glue the panels together in the back.

I still don’t like this and I’m going to squeeze something between them. I found a tiny bit of surface rust on the roof right where the sunroof panel touches it. Due to this issue the primer has been scraped off there and given way to rust.

Some weeks ago I was cleaning the sunroof drain pipes as they had some rust and pitting on them. Rears were in a good shape, fronts a bit worse. Discovered a hole in driver’s side front drain pipe right next to the brazed joint. So no way to weld it shut there and I had to replace it.

Here’s one of the front drains.

Luckily, my buddy was happy to TIG weld two pipes to a piece of sheet metal for me so I could shape the piece and replace the damaged drains. He also skimmed a bit off on lathe to make a better fit as I was able to only source 16mm pipe (1.5mm wall). The original drains are 15mm (1mm wall).

New drain installed

Exterior view

It was a PITA to grind the weld there and I wasn’t able to get it all perfectly flush (without digging into the surrounding metal which I’d prefer to avoid in spot like that). I am going to add a skim of 2K panel adhesive on top of those later. This adhesive is perfectly sandable so once it’s dry I can smooth everything out and make sure there are no low spots remaining where water could get trapped.

A few more details to cabin area were still undone.

Remaining holes for rivet nuts to mount my brake and fuel pipes using OEM clips. As was mentioned in one of the previous posts, the replacement floor panels I bought won’t allow me to run both sets of pipes between frame rail and that rectangular thingy as they were from the factory. After playing around with the clips I concluded there’s no issue running them like this.

Then there were these pins under the car.

Some of you might be familiar with these, they are used to mount the rear heat shield. On older cars they are also used to mount the soft firewall heat shield. Later these were replaced by some studs and plastic clips but rears were kept as is. I don’t have strong feelings for these pins because they feel like a single use item. I went on and replaced as many as I could with M6 studs so I wouldn’t have so much trouble with these braking off in the future.

Discovered a nice way to MIG weld the studs. First, you’d run a smaller hole through sheet metal, then tap it for your stud. This way the stud stays put while welding and it is also easy to tune the length of it. You’d still have to be careful not to melt the whole area at once as the stud could possibly move or fall off.

Two new studs on firewall

Seven new studs here

Also did some shrinking on the tunnel (damn sandblasting).

Had to keep the two middle pins in the back as I don’t have good access to the other side.

Got all that done by yesterday’s evening. Then went on sanding the cabin which took pretty much the whole night. No pictures of that, nothing I’d like to remember.

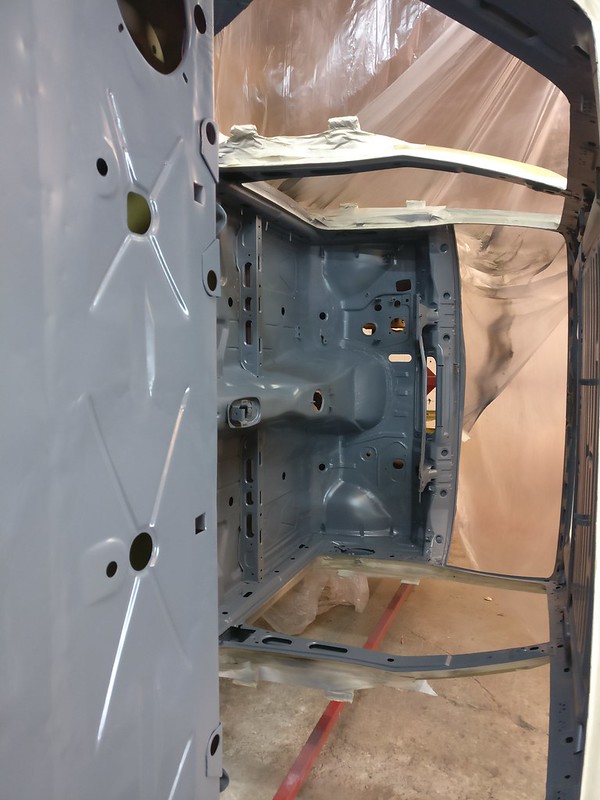

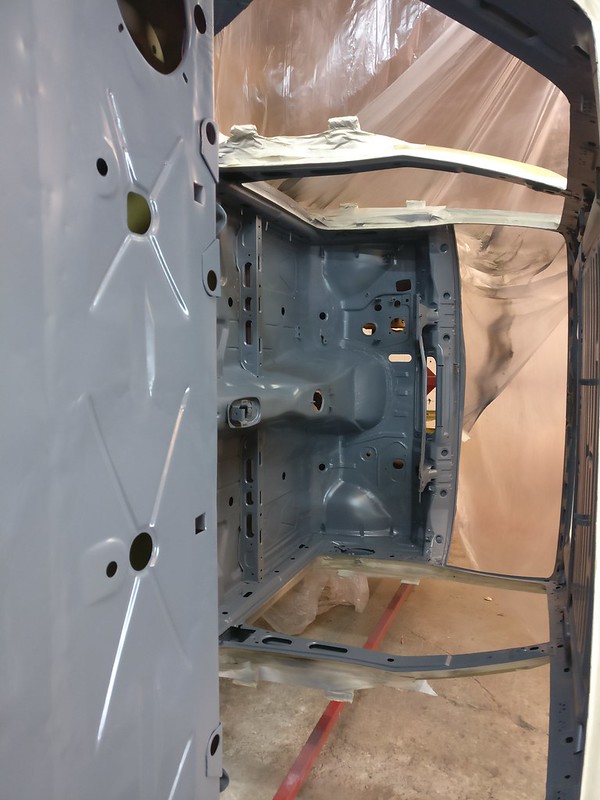

All that so I could do this today

Best one I have with roof visible

This time I wanted to give it a go myself. Got some runs where I tried to get the primer on some mounts or into a nook but otherwise looks good. I can sand down the runs later (oh joy). I’ll probably let my friend do the final coat of paint though.

Some insight why I was in a hurry with this.

I had bought the primer when I did the inside of the sills and rear valance. Not enough for the whole lot but still plenty. Back then the plan was to get the chassis ready by this fall. Well, this didn’t happen.

Plan B was to get the rear end up to the firewall done by now so I could use the primer on cabin and trunk. I still have rear wheel arches to do before I could prime the trunk. Now, it’s starts getting colder around here and the rooms we have aren’t warm enough I’d feel comfortable doing any paint work during winter months.

On with the plan C - do the cabin and some other panels.

Also, it looks awesome and helps to stay motivated.

First of all, the roof panel issue from the last post was a false alarm. Kinda. I could swear I saw some adhesive between the panels there but on closer inspection there was actually none. I guess they didn’t glue the panels together in the back.

I still don’t like this and I’m going to squeeze something between them. I found a tiny bit of surface rust on the roof right where the sunroof panel touches it. Due to this issue the primer has been scraped off there and given way to rust.

Some weeks ago I was cleaning the sunroof drain pipes as they had some rust and pitting on them. Rears were in a good shape, fronts a bit worse. Discovered a hole in driver’s side front drain pipe right next to the brazed joint. So no way to weld it shut there and I had to replace it.

Here’s one of the front drains.

Luckily, my buddy was happy to TIG weld two pipes to a piece of sheet metal for me so I could shape the piece and replace the damaged drains. He also skimmed a bit off on lathe to make a better fit as I was able to only source 16mm pipe (1.5mm wall). The original drains are 15mm (1mm wall).

New drain installed

Exterior view

It was a PITA to grind the weld there and I wasn’t able to get it all perfectly flush (without digging into the surrounding metal which I’d prefer to avoid in spot like that). I am going to add a skim of 2K panel adhesive on top of those later. This adhesive is perfectly sandable so once it’s dry I can smooth everything out and make sure there are no low spots remaining where water could get trapped.

A few more details to cabin area were still undone.

Remaining holes for rivet nuts to mount my brake and fuel pipes using OEM clips. As was mentioned in one of the previous posts, the replacement floor panels I bought won’t allow me to run both sets of pipes between frame rail and that rectangular thingy as they were from the factory. After playing around with the clips I concluded there’s no issue running them like this.

Then there were these pins under the car.

Some of you might be familiar with these, they are used to mount the rear heat shield. On older cars they are also used to mount the soft firewall heat shield. Later these were replaced by some studs and plastic clips but rears were kept as is. I don’t have strong feelings for these pins because they feel like a single use item. I went on and replaced as many as I could with M6 studs so I wouldn’t have so much trouble with these braking off in the future.

Discovered a nice way to MIG weld the studs. First, you’d run a smaller hole through sheet metal, then tap it for your stud. This way the stud stays put while welding and it is also easy to tune the length of it. You’d still have to be careful not to melt the whole area at once as the stud could possibly move or fall off.

Two new studs on firewall

Seven new studs here

Also did some shrinking on the tunnel (damn sandblasting).

Had to keep the two middle pins in the back as I don’t have good access to the other side.

Got all that done by yesterday’s evening. Then went on sanding the cabin which took pretty much the whole night. No pictures of that, nothing I’d like to remember.

All that so I could do this today

Best one I have with roof visible

This time I wanted to give it a go myself. Got some runs where I tried to get the primer on some mounts or into a nook but otherwise looks good. I can sand down the runs later (oh joy). I’ll probably let my friend do the final coat of paint though.

Some insight why I was in a hurry with this.

I had bought the primer when I did the inside of the sills and rear valance. Not enough for the whole lot but still plenty. Back then the plan was to get the chassis ready by this fall. Well, this didn’t happen.

Plan B was to get the rear end up to the firewall done by now so I could use the primer on cabin and trunk. I still have rear wheel arches to do before I could prime the trunk. Now, it’s starts getting colder around here and the rooms we have aren’t warm enough I’d feel comfortable doing any paint work during winter months.

On with the plan C - do the cabin and some other panels.

Also, it looks awesome and helps to stay motivated.

-

Bonsaibacker

- Posts: 966

- Joined: Oct 26, 2017 3:36 PM

- Location: Fleming Island FL

Re: Another restoration - 83' 528i

It does look awesome- stay motivated!

If the rest of your build is this detailed and complete, you will need the patience of Job. Keep going.

If the rest of your build is this detailed and complete, you will need the patience of Job. Keep going.

Re: Another restoration - 83' 528i

Love this project, its process and your documentary style. But more than anything else, I am amazed by your skill and patience.

Don't rush it.

Don't rush it.

Re: Another restoration - 83' 528i

Thanks, folks! I'll do my best.

26 Oct - 04 Nov 2020

Not much work done on the chassis. Spent some days cleaning the workshop and building some additional shelves for tools and other stuff.

This large storage shelf we have in our shop turned out to be a workbench. Go figure.

A new large shelf for E28 stuff only. Still can’t fit everything there, though.

While I had all parts I’ve taken off the car bagged, labelled and boxed the old shelf was too crowded and it still took quite some time to find anything. This time I tried to do a better job organizing the boxes and also marked down on which shelf something is. Should be able to find what I need in matter of minutes now.

I’ve also grabbed all the parts lists and diagrams for my car from realoem so I could make a spreadsheet that helps me track what I’m still missing, where everything is and what should be done next to existing parts.

One thing that’s really annoying about sandblasting. It’s been two months since blasting the strut tower. During this time the car has been probably rolled over tens of times in the rotisserie, cabin’s been frequently vacuumed, everything thoroughly cleaned before priming and you still get this:

Guess I’m lucky I decided not to turn the car over during the priming.

One of the large boxes I had stored away contained this - a brand new nose frame.

Although the existing nose frame isn’t too bad and it’s fixable I decided my car deserves better. Removing the frame also let’s me take better care of the hackjob that was done there before. I’ll probably fix the old nose frame up in the future and sell it.

In the second box was a new front valance

Couldn’t resist fitting them together

Both parts were prepped for priming. Nose frame would be difficult enough to prime off car so it’s better to take care of it before installing. Front valance will be primed only on the backside at this moment.

So, to get it done, I went to shop on Sunday only to discover I didn’t seal the can with hardener well enough a week back and it was all solidified. Luckily, I was able to get some today and regardless of the delay it’s now finished. This time I watched my buddy do the job to avoid all the paint runs I’d make on that nose frame.

Also primed the cover lid for the trunk.

Then ran a small bead of panel adhesive between roof and sunroof panel. This should eliminate any rubbing between these panels.

Now, I don't think I have any more excuses not to work on those rear wheel arches...

26 Oct - 04 Nov 2020

Not much work done on the chassis. Spent some days cleaning the workshop and building some additional shelves for tools and other stuff.

This large storage shelf we have in our shop turned out to be a workbench. Go figure.

A new large shelf for E28 stuff only. Still can’t fit everything there, though.

While I had all parts I’ve taken off the car bagged, labelled and boxed the old shelf was too crowded and it still took quite some time to find anything. This time I tried to do a better job organizing the boxes and also marked down on which shelf something is. Should be able to find what I need in matter of minutes now.

I’ve also grabbed all the parts lists and diagrams for my car from realoem so I could make a spreadsheet that helps me track what I’m still missing, where everything is and what should be done next to existing parts.

One thing that’s really annoying about sandblasting. It’s been two months since blasting the strut tower. During this time the car has been probably rolled over tens of times in the rotisserie, cabin’s been frequently vacuumed, everything thoroughly cleaned before priming and you still get this:

Guess I’m lucky I decided not to turn the car over during the priming.

One of the large boxes I had stored away contained this - a brand new nose frame.

Although the existing nose frame isn’t too bad and it’s fixable I decided my car deserves better. Removing the frame also let’s me take better care of the hackjob that was done there before. I’ll probably fix the old nose frame up in the future and sell it.

In the second box was a new front valance

Couldn’t resist fitting them together

Both parts were prepped for priming. Nose frame would be difficult enough to prime off car so it’s better to take care of it before installing. Front valance will be primed only on the backside at this moment.

So, to get it done, I went to shop on Sunday only to discover I didn’t seal the can with hardener well enough a week back and it was all solidified. Luckily, I was able to get some today and regardless of the delay it’s now finished. This time I watched my buddy do the job to avoid all the paint runs I’d make on that nose frame.

Also primed the cover lid for the trunk.

Then ran a small bead of panel adhesive between roof and sunroof panel. This should eliminate any rubbing between these panels.

Now, I don't think I have any more excuses not to work on those rear wheel arches...

Re: Another restoration - 83' 528i

Sexy stuff!

What color will this car be?

Don't forget to do this:

I forgot on Minerva...

What color will this car be?

Don't forget to do this:

I forgot on Minerva...

Re: Another restoration - 83' 528i

I have pretty much (to leave me some wiggle room) decided on Burgundy Red. I also do fancy Calypso Red and I'd go for it but it has already been done on an E28. I'd prefer a non-original paint color to be a one-off.

Thanks for the tip! I would have missed that.

How much does it actually bother you standing next to the car? On the photos of Minerva I wouldn't notice it unless I look for it. Just that I'm not too fond of that color transition in this spot either.

By the way, something similar was done on the parcel shelf. The very rear section where the vent openings are was black on my car (also on my mate's). It wasn't regular paint though but some thicker and softer stuff that scraped off. At least with the flat Euro parcel cover, this area is not fully covered.

It's already removed here, but you can spot the line where the yellow acid primer ends and OEM primer begins.

Re: Another restoration - 83' 528i

If you like those reds, consider a dark burnt orange!

I doubt anyone would notice those grill supports being body color other than me.

I doubt anyone would notice those grill supports being body color other than me.

Re: Another restoration - 83' 528i

That's a nice one. I do dig this and some other orange colors on newer BMWs but I am not sure about it on E28. I'd say it would definitely benefit from shadowline trim.

When I started with this project I was determined to use an original color, thus the Burgundy. Meanwhile, I've reconsidered and should probably do a thorough research on other options.

I already found this: S03 Ruby Red II.

Re: Another restoration - 83' 528i

I have always though that the older pre E28 colours were the best. An Inka (dark orange) E28 appeals to me. I do miss my Inka 02.

Re: Another restoration - 83' 528i

That's one of my favourites on 02's!JohnH wrote: Nov 05, 2020 6:47 AM I have always though that the older pre E28 colours were the best. An Inka (dark orange) E28 appeals to me. I do miss my Inka 02.

I'm starting to like this color (which I believe is B50 Sakhir Orange) more and more and I'm definitely considering this. So thanks for the suggestion!

On the contrary, the Ruby Red looks kinda dull on some photos.

I've also found some other options, once the list is done, I'll share it. Then I'll probably choose 1-3 colors and try to get some samples to aid with the final decision.

Re: Another restoration - 83' 528i

4 - 15 Nov 2020

Work on the driver’s side rear wheel well continued.

This was pretty much the starting point, I actually had the flange for trunk floor already made and tacked in before priming the cabin.

Then there was this huge blob of sealant right where I needed to weld the repairs. This photo is taken from the trunk, quarter panel on top, rear end of wheel well in the bottom.

Leaving it there for welding is a big no-no. It splatters like crazy, contamination and porosity is guaranteed. I am pretty sure they make fireworks out of the same stuff.

Due to almost non-existent access removing it was a long and hideous work.

Considering the amount of rust right beneath that sealant I wonder if it ever did any good there...

From the beginning, the plan for rear wheel arches was as follows:

Back to repairs. Sealant removed and everything cleaned up I started making repairs to the inner wheel arch. I decided to give myself some slack and build it up in three sections.

All done

Only spot it had rust further from the flange was around the rear bumper mount point.

This is the repair panel I had bought. Made by Klokkerholm. I must say, although the bends aren’t as sharp and nice as on OEM panels, it’s a pretty decent repair panel. Unlike their sill replacement the fitment is spot on and all the lines line up nicely. Well, the rocker section is crap but who would use it anyway. I also dig the galvanizing they used instead of some cheapish primer. It’s been sitting on the shelf for three years without any signs of corrosion.

Line marked for cutting

Trimmed and fitted over existing panel to get an idea where to remove old arch.

Old arch removed. Gives a better view of the inner arch replacement. Needs a little bit more tweaking at the joints.

New panel fitted. This took quite some hours of trimming and refitting and adjusting to get a perfect alignment.

Removed the inner panel and fully tacked in the outer

At this point I did some hammering so everything would be perfectly straight and edges flush before welding.

I must apologize for the crappy photos, I had some dust stuck on my camera lens yesterday and didn’t realize it before looking at the photos today. I’ll try to grab some better ones of the finished arch in the upcoming days.

Fully welded

Cleaned up

Done

Edit: got some better shots

Now, need to repeat it on the other side and get the inner panels installed.

Work on the driver’s side rear wheel well continued.

This was pretty much the starting point, I actually had the flange for trunk floor already made and tacked in before priming the cabin.

Next in line was this section of the inner wheel housing. I made and scrapped three patches before I was happy with it. Piece had to be shrunk quite a lot where the bead is making the turn outwards. You can still see a gap there on the final patch, worked it out after tacking the piece in.

Then there was this huge blob of sealant right where I needed to weld the repairs. This photo is taken from the trunk, quarter panel on top, rear end of wheel well in the bottom.

Leaving it there for welding is a big no-no. It splatters like crazy, contamination and porosity is guaranteed. I am pretty sure they make fireworks out of the same stuff.

Due to almost non-existent access removing it was a long and hideous work.

Considering the amount of rust right beneath that sealant I wonder if it ever did any good there...

From the beginning, the plan for rear wheel arches was as follows:

- Cut out and replace inner arch, only tacking it in

- Cut out outer arch and fit repair panel, tack it in

- Remove inner arch to give access to the backside of outer panel

- Weld and finish the outer panel

- Reinstall inner panel using panel adhesive for the flange instead plug welds

Back to repairs. Sealant removed and everything cleaned up I started making repairs to the inner wheel arch. I decided to give myself some slack and build it up in three sections.

All done

Only spot it had rust further from the flange was around the rear bumper mount point.

This is the repair panel I had bought. Made by Klokkerholm. I must say, although the bends aren’t as sharp and nice as on OEM panels, it’s a pretty decent repair panel. Unlike their sill replacement the fitment is spot on and all the lines line up nicely. Well, the rocker section is crap but who would use it anyway. I also dig the galvanizing they used instead of some cheapish primer. It’s been sitting on the shelf for three years without any signs of corrosion.

Line marked for cutting

Trimmed and fitted over existing panel to get an idea where to remove old arch.

Old arch removed. Gives a better view of the inner arch replacement. Needs a little bit more tweaking at the joints.

New panel fitted. This took quite some hours of trimming and refitting and adjusting to get a perfect alignment.

Removed the inner panel and fully tacked in the outer

At this point I did some hammering so everything would be perfectly straight and edges flush before welding.

I must apologize for the crappy photos, I had some dust stuck on my camera lens yesterday and didn’t realize it before looking at the photos today. I’ll try to grab some better ones of the finished arch in the upcoming days.

Fully welded

Cleaned up

Done

Edit: got some better shots

Now, need to repeat it on the other side and get the inner panels installed.

Re: Another restoration - 83' 528i

Got better shots of the wheel arch today, replaced some of the foggy ones in the last post.

Also, took an inventory of sunroof parts today and figured I might be missing some parts. If anyone could weigh in, I'd be most grateful.

See: viewtopic.php?f=3&p=1493765#p1493765

Also, took an inventory of sunroof parts today and figured I might be missing some parts. If anyone could weigh in, I'd be most grateful.

See: viewtopic.php?f=3&p=1493765#p1493765