Page 3 of 16

Posted: Mar 12, 2011 11:31 AM

by derrith

Murfinator wrote:New upper and lower control arms: Moosehead spherical bearings in the Lemforder UCA's and Grunts in the LCA E34 aluminum sports. If I don't like them I can always press in the originals.

Any reason you went with urethane for the lcabs over installing e31 monoball lowers?

Posted: Mar 12, 2011 9:09 PM

by Murfinator

derrith wrote:

Any reason you went with urethane for the lcabs over installing e31 monoball lowers?

Like these? :

http://cgi.ebay.com/ebaymotors/ws/eBayI ... K:MEWAX:IT

I've had the Grunts sitting in a box for a few years after having purchased them on eBay for $35 shipped. Had them posted here in a FS thread for a month with no interest. If they fall apart I'll go with spherical bearings in the LCA's.

Posted: Mar 20, 2011 3:59 PM

by Murfinator

paul burke wrote:Murfinator wrote:T_C_D wrote:Major update. I have some explaining to do. As it turns out my freshly built JE piston engine only lasted 500 miles. The machine shop didn't bore the cylinders large enough so the pistons almost seized. The rings were frozen. The pistons were galled. The cyl walls were trashed.

That's terrible! It would be my worse nightmare to get a major build completed only to have the motor fail in <500 miles.

Mike, from the pictures it looks like they did a good job on yours, restrictors appear to be correct size (.109 and change). If you want to purchase a cheap dial bore gauge and a 3 to 4 micrometer I will walk you through the measuring process.

Paul

...continued from Todd's thread regarding issues with his freshly built motor at less than 500 miles likely caused by improperly bored cylinders:

Would the cheap measuring tools at Harbor Freight work? Looked around at the local auto parts store and didn't find anything that seemed like it would be any more accurate than my Blue Point digital calipers. I measured the bore diameter and came up with

92.35 mm. The spec sheet with the pistons calls for

92.5 mm. I'll be taking the motor back to the machine shop for balancing of the rotating assembly. Should I have the bores opened some more? Note I only measured the bores at the tops and not throughout the bore. eBay perhaps?

Posted: Mar 20, 2011 4:03 PM

by mooseheadm5

Calipers are not the right tool for the job. You should grab the bore gauge as suggested.

Posted: Apr 10, 2011 4:40 PM

by Murfinator

Motor painted BMW Motorsport Warm Red:

Posted: Apr 11, 2011 6:52 AM

by Black Steel

Cool colour.

My block is painted red.

Posted: Apr 11, 2011 10:52 PM

by Corner Carver

I like it!

Actually, I am surprised how much I

do like it

The red really brings out the nuances of the block, much more than black does

Thanks Mike...... now there is a red block in my future

Posted: Jun 01, 2011 1:16 PM

by Cooperman

Bump for update

Posted: Jun 01, 2011 2:30 PM

by fries_man

Murfinator, I like that red block!

Which paint did you use on it?

Posted: Jun 01, 2011 3:25 PM

by Murfinator

fries_man wrote:Murfinator, I like that red block!

Which paint did you use on it?

I did some research into the Pantone/RAL colors which correspond most closely with the BMW Motorsport colors. Warm Red is the Pantone color which is the closest match. My local finishing shop has my notes with the actual numbers. I purchased two pint cans of Rennsport ROT (stock # 107409) by Uno. Since they mixed it for me I cannot return the second pint can that I have no need for. The local machine shop who frequently paint engine blocks recommended this brand for its excellent heat and oil resistance. I mixed it with the recommended proportions of reducer and hardener and sprayed it through an air gun. Two medium coats provided excellent coverage with only a couple sags due to the uneven surface. Overall I'm pleased with the result.

If you're interested in the extra pint of paint let me know.

Posted: Jun 01, 2011 4:01 PM

by Murfinator

Cooperman wrote:Bump for update

Dynaliner installed to replace the crumbling sound deadening material on the firewall.

Heater valve rebuilt

Dogleg 'Sport' transmission resealed, surface corrosion removed, filled with Redline MTL, hardware replaced, new crossmember powdercoated, IE urethane mount and AutoSolutions SSK installed

E34 M5 3.8 guibo and new/longer hardware (search Duke's old posts for reasoning)

BMP brass clutch pivot pin installed

New reverse switch

UUC steel braided slave to master cylinder hose

New direction with the intake: no more restrictive B35 cork. Paul B. sourced a nice S38B36 throttle assembly and made some adapter plates for mounting to the B35 head he's putting the finishing touches on (all new valvetrain, custom cam, etc).

Picked up an S38B35 air accumulator to use as a mock up for a custom aluminum air accumulator to more efficiently plumb in the output from the TCD S3 water-air intercooler

Ceramic coating on all heat shields (+ NOS Hartge passenger shock pillar to firewall brake line heat shield), exhaust (3" TCD) and oil pan

TIG'd an AN -10 bung on the oil pan for turbo oil return line

Landed an authentic Hartge handbrake handle

Received a black suede shift boot with Motorsport stitching from Shift Style to match the seats and steering wheel

New trunk gasket

Removed one-piece hood liner and foam

Installed BMP 3-piece hood liner

Sold the M-Systems wheels to a good home in SD

Deal fell through on the BBS 16's

Went with a nice set of Hartge Design C 17" wheels found here on the board (since first seeing them August 2009 in Monterey on RonP's stunning H5S which took first to my second in the concours, I've been in love with them. The decision was a no-brainer since the car was already sporting Hartge plasticware: airdam, side skirts and rear valance)..in the process of being refinished.

There's probably more, but rest assured I haven't lost interest in the project. Thanks for the interest. Pics soon...

Posted: Jun 02, 2011 3:53 AM

by banelba

Very interesting. I was looking into doing almost the same to my 86 528e but using the block of a 98 528i paired to the 88 heads before boosting it. I'll post pictures of my car which already went through several upgrades from M5 kit,suspensions, swaybars, brakes. It just need to go fast

Posted: Jun 02, 2011 11:21 AM

by skip535i

Murf,

You know how visually stimulated us guys are...how about some damn pictures?!

Posted: Jun 02, 2011 4:35 PM

by Nebraska_e28

skip535i wrote:Murf,

You know how visually stimulated us guys are...how about some damn pictures?!

Posted: Jun 29, 2011 3:45 PM

by EuroShark

I'm aching for an update!

Posted: Jul 02, 2011 4:05 PM

by Murfinator

Haven't taken many pics lately but they are forthcoming. Paul still has the head and throttle assembly. Every time we speak he describes more work he's done tinkering to make it perform better. If he keeps it another year I'll be able to launch the space shuttle with that sucker.

Debating whether to sell the 17" Hartge Design C wheels I've begun refinishing and replacing them with the 18" Design C's Luke is selling on the board. I'm actually liking the look of the 18's less and for the cost of shipping from Poland it may not be worth the trouble.

I've been in contract with Jon A. regarding brake setups. I'll be removing and selling the 750 calipers, vented rotors and stainless lines. Replacing them will be Alcon calipers and 12# motorsport rotors mounted to his custom aluminum rotor hats. The entire setup will be about half the weight of my current setup with great performance. Looking forward to diving deeper into those corners.

I've assembled the oil level sensor (new) and replaced all the hardware with new.

New hardware for the block: bolts, studs, gaskets, water pump and the aforementioned items such as MM oil pump.

I've been laying sod as well as building and shooting a couple of custom rifles lately so the bulk of my time has been spent in other endeavors. However, progress is being made and I am enjoying the journey.

Posted: Jul 13, 2011 1:35 PM

by Murfinator

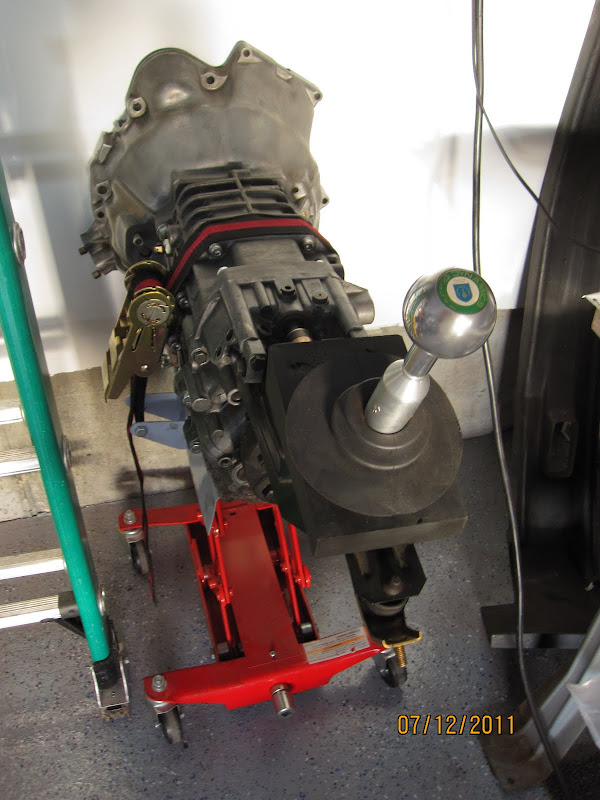

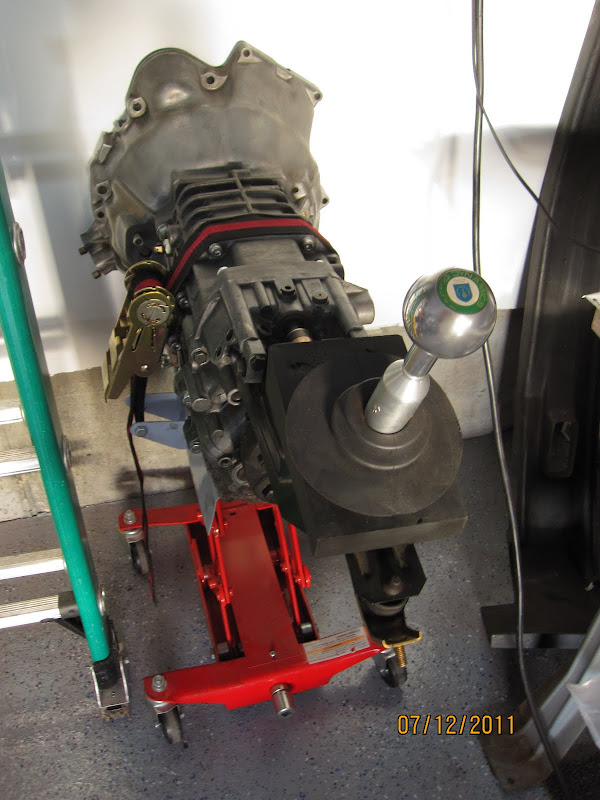

Dogleg: cleaned, fresh fluids, new hardware, AutoSolutions SSK, new sheetmetal console and rubber, new E34 M5 guibo and hardware, Racing Dynamics shift knob to go with the pedals.

Started smoothing out a few dings on the oil pan and ended up with this: new oil level sensor and hardware, magnetic drain plug, TIG'd -10 AN fitting for turbo oil return and ceramic coating (same as exhaust and heat shields). Capped the M106 drain on the block and opted for a lower entry point. It's angled back for a straighter shot from the turbo.

Current status of the car:

My wife is refinishing some antique chairs.

Where there is a Dremel there is a way: good-bye stock airbox and coil bracket.

Posted: Jul 13, 2011 4:15 PM

by wkohler

I'm going to miss the stock airbox and coil bracket.

Posted: Jul 17, 2011 6:04 PM

by itsbrokeagain

Very nice! I may have to take that pint off your hands when I redo my engine...

Posted: Jul 17, 2011 8:59 PM

by Murfinator

wkohler wrote:I'm going to miss the stock airbox and coil bracket.

Not me, but I can ship them to you FedEx Ground.

I don't care for most of what came stock.

itsbrokeagain: The remaining pint of engine paint sold a while ago.

Posted: Jul 22, 2011 11:46 PM

by paul burke

Sneak Peek of what Mike has been patiently waiting for.

Paul

Posted: Jul 23, 2011 7:39 AM

by cvillebimmer

Bling bling! I'm sure it'll be well worth the wait.

Posted: Jul 23, 2011 9:13 AM

by M. Holtmeier

Wow! That is cool.

How much work goes into the intake ports?

Posted: Jul 23, 2011 9:24 AM

by T_C_D

Murfinator wrote:Dogleg: cleaned, fresh fluids, new hardware, AutoSolutions SSK

TIG'd -10 AN fitting for turbo oil return and ceramic coating (same as exhaust and heat shields). Capped the M106 drain on the block and opted for a lower entry point. It's angled back for a straighter shot from the turbo.

The dogleg is pretty weak. You will kill the layshaft bearing in short order.

The oil return fitting should be 90 degrees.

Posted: Jul 23, 2011 10:37 AM

by Murfinator

T_C_D wrote:Murfinator wrote:Dogleg: cleaned, fresh fluids, new hardware, AutoSolutions SSK

TIG'd -10 AN fitting for turbo oil return and ceramic coating (same as exhaust and heat shields). Capped the M106 drain on the block and opted for a lower entry point. It's angled back for a straighter shot from the turbo.

The dogleg is pretty weak. You will kill the layshaft bearing in short order.

The oil return fitting should be 90 degrees.

Why, so it has a sharper bend to make on its way back into the oil pan? The dogleg is weak because if I drop the clutch at 6k from a stop then I could twist the input shaft off (if I can find a clutch that will hold and be tractable)?

Please back up your statements. I'm open to suggestions. Thanks