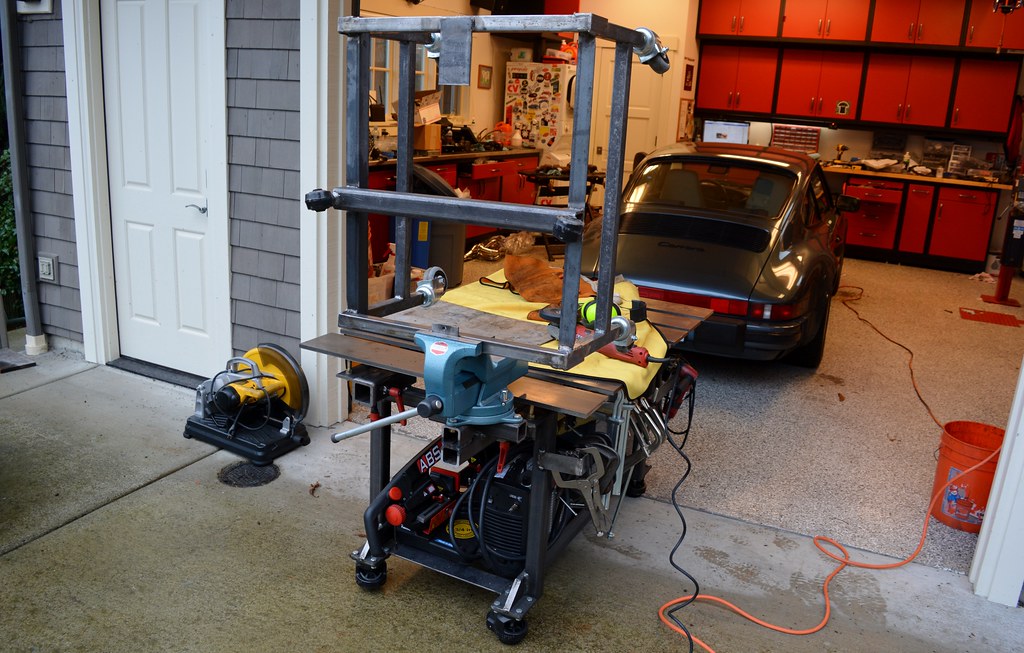

Last time I did this, I assembled the strut lower plates and control arms with the control arms attached to the car. That was dumb. This was much easier:

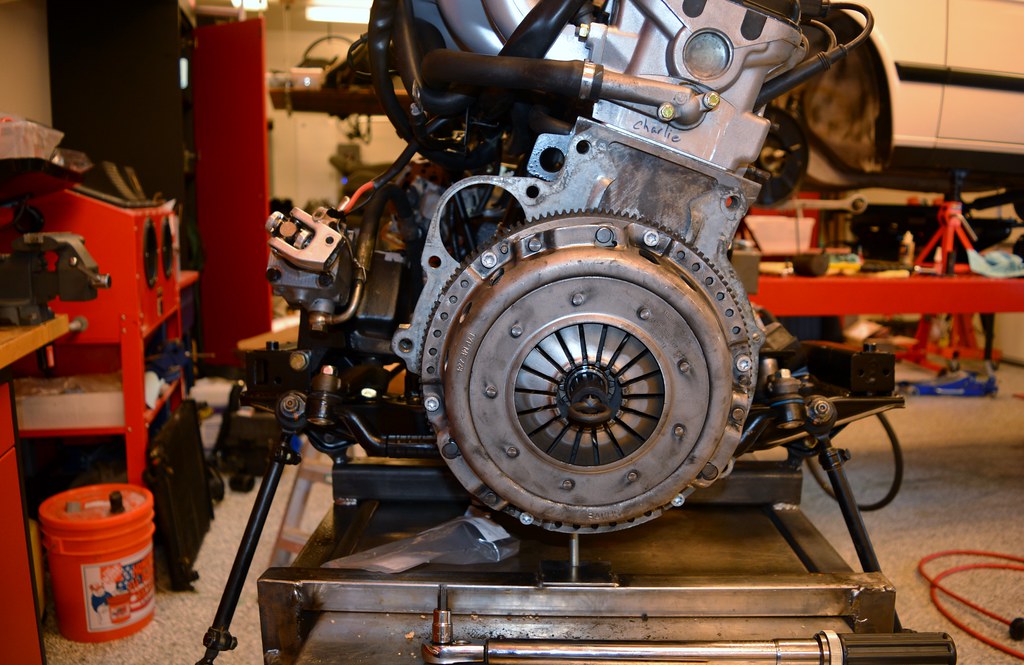

As you can see I had the shocks way too low:

It's pretty easy adjusting these things once on the car. Just undo the 3 nuts holding the struts to the strut tower brace, letting the assembly settle onto a jackstand. Then just spin the top part of the strut counter clockwise to make it longer. I added about 3.8cm of length for my second try to decided it's close enough. When I get it aligned I'll have them dial it in perfectly.

Ta-da:

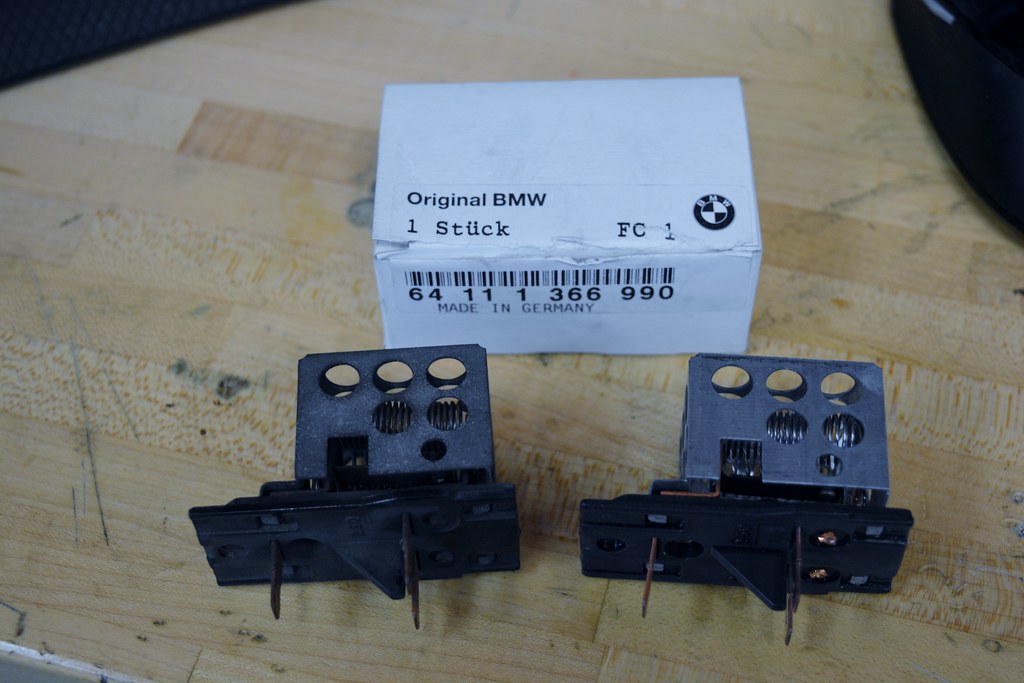

Then I tried my hand at the string-alignment technique. It was already pretty close to tits, but I was able to get it even closer. I didn't measure it, but the camber looks almost 0. The BC Racing coil overs have tons of camber adjustment.

Went for a spirited shakedown drive in the rain/dark/wind. Felt fine. Tracked straight, turned left and right as expected, stopped, and even went over some bumps. Nothing fell off (I checked when I got it back on the lift).

I had to use the freeway to get to my indoor soccer game and it felt a little squirlley. I think its a combination of both the front & rear not being aligned (I clearly have some (-) toe in the rear), the rear being about 1.27cm higher than the front (relatively), and the squishy sidewalls of the Nokian Hakkapeliitta snow tires. Ride feels great.

Hope to get it in to be aligned on tues or weds.