Today I started teaching myself how to weld. I've been reading a welding book and about 4 years ago my son I took a half day class. I started by just trying things with some 3/16" steel I had lying around and some E6013 1/16" electrodes.

Then I got serious and watched some youtube videos. I also discovered that I hadn't removed the protective plastic sticker on the inside of my auto-mask. Turns out it's a lot easier to weld if you can see.

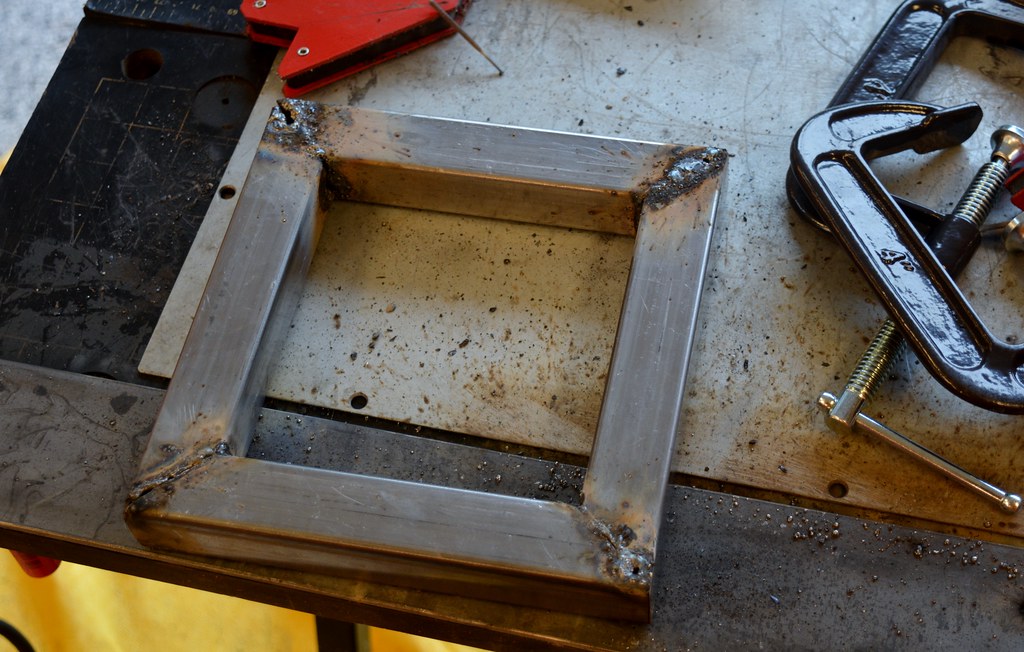

Starting to get the hang of it. I have a long way to go, but I've now drawn enough beads that I can actually control things.

Fun, fun, fun.