Sure enough, it fired right up, idled, and I was able to drive it around his property. The body was straighter and the interior nicer than I expected. Definitely problems with the brakes. For another $100, the guy delivered it to my driveway.

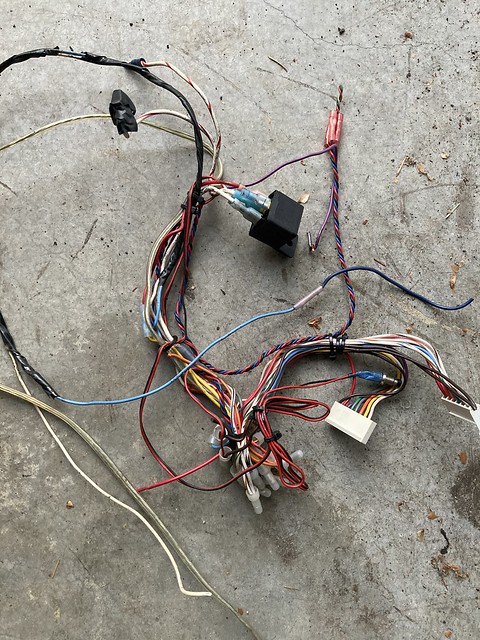

A close inspection showed that in addition to the brakes, none of the indicator lights worked, the rear muffler was falling off, there was a major oil leak, and several other common problems needed attention.

Good news was that everything was there, the car had never been hacked on, and it had an lsd.

Here she is last summer not long after delivery. She didn't come like this. TRX wheels and tires were replaced with the spoked 16x8 set and new Bridgstones and new fog lenses added.

[/url]

[/url] [/url]

[/url]First, the brakes.

The calipers were seized and rotors were deeply grooved. Never seen rotors so bad. Someone forced (pounded) the wrong calipers on the rotors. So first major repair was all new brake hardware with the big brakes upfront. Not fun but necessary and very gratifying now that I could actually drive it.

Test drive revealed some suspension clunking, of course. Typical e28 issues. First replaced the subframe bushings, pittman arms, endlinks and sway bushings. Helped tremendously, especially in the rear end and overall NVH reduction. Still a clunking in the front which turned out to be a control arm.

I love the way it drives. Even though it was an auto, it was still fun, especially with the sport mode. At this point I knew I was all in and I would do right by the car.

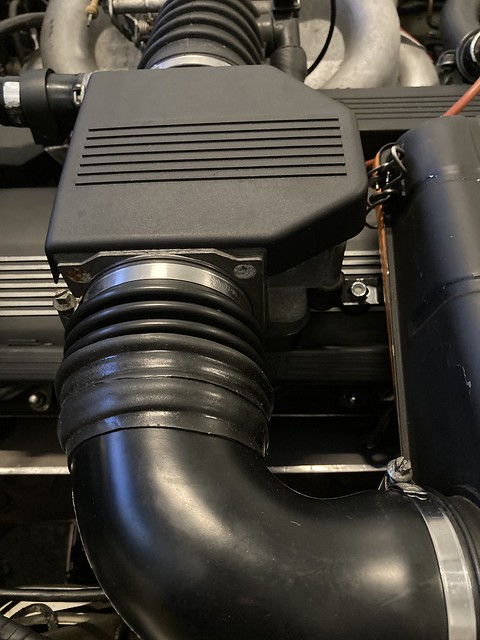

Next up was a basic tune-up. Cap and rotor were baked and crumbled to pieces. Original? Not sure how it even ran. Plug color indicated good combustion and was consistent across all 6. Still had a stumbly idle at start-up afterwards.

After a tank or so of fuel, it was apparent the fuel pump was going. I replaced with and Airtek unit and threw in a new fuel filter at the same time. I'll rehab the old unit with a good pump later on. The new pump and filter seemed to help start-up and acceleration and of course the fuel starvation issue.

Decided next step was a trip to Seattle on a hot summer day. Opted for adventure over caution. Stuck in Tacoma traffic and started seeing coolant vapor billowing from underhood. Oh boy. Kind folks let me off the highway.Turns out the system was almost dry and my trips around town never got it hot enough to show. A few gallons of coolant later and all was good to get there and home. After some testing, found the fan was shot. I believe this is likely the reason why the original owner sold the car. After replacing the fan and thermostat and all new coolant, I ended up driving the car all over with no overheating issues for almost a year.

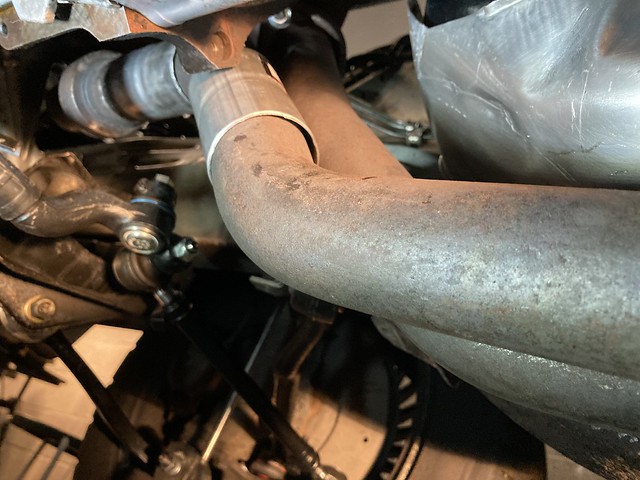

There was still the dreaded oil leak. I tried to tighten up the pan bolts and even resealed the upper timing cover but it continued to sling oil. It was running great but I can't tolerate major oil leaks.

Along the way, I met a local enthusiast who just happened to have an e32 with a b35 and 260/6 that had seen better days. Engine and drivetrain was original but had some body and interior damage. After hearing it run and driving it a bit, you guessed it.

[/url]

[/url] [/url]

[/url]More to come later.

[/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url]

[/url][url=

[/url][url=

[/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url]