My e28 story started in the fall of 2011, but it doesn't start with a quest for an old BMW. I was 18, starting my mechanic's apprenticeship at a shop I had been working at part time since I was 12. In that time I had restored a 1972 Austin Mini for myself, and had it on the road in spring 2011. I had not done the metal work and exterior paint on the car, but did all the other mechanical and interior restoration on the car. Heres a quick photo of it last summer, for reference.

EA25EB0B-3781-495F-AAFD-C86ADD670FF6 by Warren Tomlinson, on Flickr

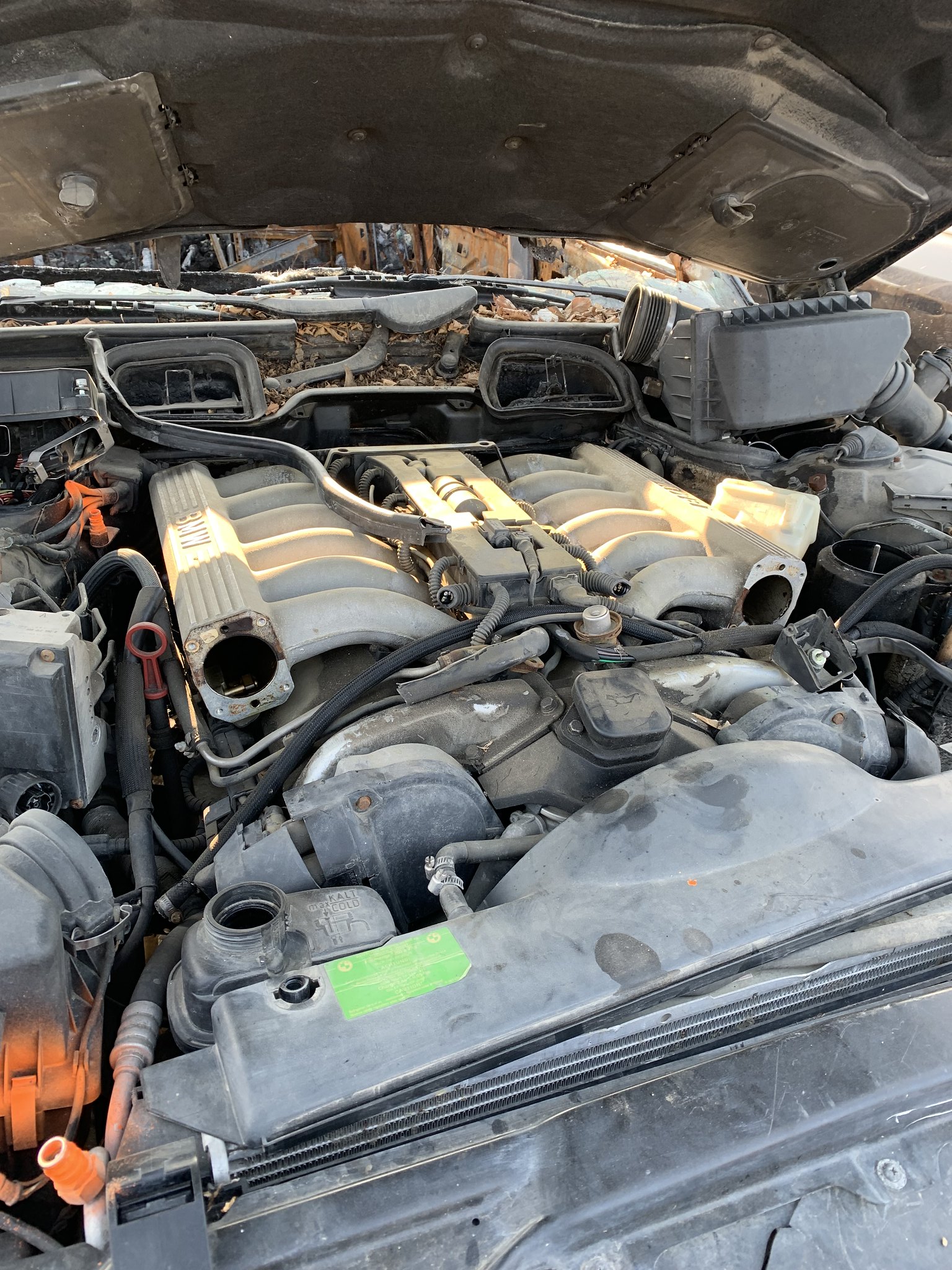

EA25EB0B-3781-495F-AAFD-C86ADD670FF6 by Warren Tomlinson, on FlickrI mention this car, as I had sold my daily driver 1993 Nissan 240sx in my last year of high school, to get that last bit of cash to finish up the Mini. That was great, but as winter approached, I needed to get a winter car. As luck would have it, my boss informed me that a customer was selling his BMWs. Up until then I hadn't had any interest or awareness of e28s, or old BMWs in general. But, the cars were both running and driving well, relatively rust free, and only $2500 CDN, for BOTH. One 1984, one 1986, both blue manual 528e sedans. I didnt need both, but they were a package deal and the price was right. I sold one to my Dad, who is not a car guy at all, for $1000 as his '91 Nissan Micra had finally bitten the dust. I came to really enjoy the driving dynamics of the e28, and with an LSD, it sure was fun in the snow! Unfortunately, that car met an untimely end at the hands of an impaired driver, while my brother was driving. He was okay, but the car was totaled. I had a picture of it, but cannot find it. After this, I had a turbocharged 1991 Mazda Miata, which was much faster, but I missed the character of the e28. I sold the Miata, and the search was on again for an e28. In fall 2012, I found my 1987 Smaragdgrun Green Metallic 535i. It was in a city that was a 3 hour drive away, my brother and I went down to collect it. It had an intermittent starting issue, but that was eventually tracked down to a corroded main relay. From then on, that car was my daily driver. Winter, summer, that car took me everywhere. I bought some Bavauto long tube headers off the forum, did the steering box and clutch pedal reinforcements, rebuilt the leaky brake booster, got some Sachs dampers and H and R lowering springs, and generally kept up with the maintenance. As I got more familiar with the car, I realized it was an auto car, manual swapped with a Getrag 260/6, the brakes had been upgraded to the larger vented 750il units front and rear, and it had a 3.46 LSD. I found some matching pearl beige sport seats and installed those, and kept on driving.

The extended winter use was hard on the car, and the small nibbles of rust it had when I bought it, had bloomed into a fairly unsightly mess. I liked the car, but wasn't sure I wanted to undertake a serious revival of it. It's future was uncertain. At 440k KM, it had served me well. At some point in 2019 or 2020 I had a chance encounter with a fellow in a parking lot. His uncle used to own my car, he recognized the colour, the aftermarket speakers on the parcel shelf, and the one door that was duller than the rest. I got in touch with the previous owner, and had many lengthy exchanges, where he told me about him doing the manual swap, the audio upgrade, a timing chain refresh and painting the intake manifold. He wasn't sure if he was interested in purchasing the car, as he didn't have the facilities for the amount of work it would need. For reference, here's some photos he shared with me of his ownership, looking better than it ever did while I owned it. This would have been circa 2002.

971CF8ED-230A-4C5C-9CEC-5E7D866067E4 by Warren Tomlinson, on Flickr

971CF8ED-230A-4C5C-9CEC-5E7D866067E4 by Warren Tomlinson, on Flickr B7CBC38F-5A40-412C-A485-2BAC5C486FB3 by Warren Tomlinson, on Flickr

B7CBC38F-5A40-412C-A485-2BAC5C486FB3 by Warren Tomlinson, on FlickrIn 2018 I had purchased a 1995 Jaguar XJ12. It was a nice car, and relegated the e28 to mostly winter duties. In summer of 2021, my fiance and I were getting married. We eloped to British Columbia, the venue was a 10 hour drive away. I was excited to take the Jaguar, and to see it in the wedding photos, and had gotten it all serviced and ready to go. The night before we were to leave for the trip, disaster struck. The radiator, likely original, had a catastrophic failure. A plastic hose connection completely separated from the end tank, depositing a large quantity of it's coolant in the parking lot I was in.

C1A2344C-16E7-455E-A3EE-4824C3362565 by Warren Tomlinson, on Flickr

C1A2344C-16E7-455E-A3EE-4824C3362565 by Warren Tomlinson, on Flickr 3431B8EB-31A2-4473-A8B4-BA7E0DD2E612 by Warren Tomlinson, on Flickr

3431B8EB-31A2-4473-A8B4-BA7E0DD2E612 by Warren Tomlinson, on Flickr 29535D93-1BDD-4EA4-9B05-403B417A5664 by Warren Tomlinson, on Flickr

29535D93-1BDD-4EA4-9B05-403B417A5664 by Warren Tomlinson, on FlickrThis is a part of the story, because with no preparation beyond a hurried check of tire pressures and fluid levels, my rusty old e28 performed flawlessly, carting us to our wedding near Penticton, and to our honeymoon on Vancouver Island.

Karlee & Warren - Previews by Warren Tomlinson, on Flickr

Karlee & Warren - Previews by Warren Tomlinson, on Flickr EC7F3E69-7314-4F3F-90DF-87BEDFCEC28A by Warren Tomlinson, on Flickr

EC7F3E69-7314-4F3F-90DF-87BEDFCEC28A by Warren Tomlinson, on Flickr D9A6618C-D710-434D-AB55-ECE4986EB587 by Warren Tomlinson, on Flickr

D9A6618C-D710-434D-AB55-ECE4986EB587 by Warren Tomlinson, on FlickrThis changed a lot for me. I already had trouble thinking of my garage without this green machine, and now it had proved itself to me, just like it always had as a daily driver, always dependable and reliable, like an old friend. I repaired the Jaguar with a nice new all aluminium radiator, but eventually sold it in the fall of 2022. I purchased a second e28, a mostly stripped shell, to chop up for donor metal.

1B1B74DF-2188-4BDA-9295-38836C466FB8 by Warren Tomlinson, on Flickr

1B1B74DF-2188-4BDA-9295-38836C466FB8 by Warren Tomlinson, on Flickr 4EEDB222-1A97-4512-B809-015A745E3F91 by Warren Tomlinson, on Flickr

4EEDB222-1A97-4512-B809-015A745E3F91 by Warren Tomlinson, on Flickr D93CF98F-16ED-4BEB-B052-1672E0BF9FAD by Warren Tomlinson, on Flickr

D93CF98F-16ED-4BEB-B052-1672E0BF9FAD by Warren Tomlinson, on Flickr F50A53D2-F8D0-40B9-B43D-4342A62EB0E8 by Warren Tomlinson, on Flickr

F50A53D2-F8D0-40B9-B43D-4342A62EB0E8 by Warren Tomlinson, on FlickrMany people would find it easier to have fixed the Bronzit car, it had some accident damage, it had been gutted inside, no drivetrain, and the wiring was a mess, but all of my parts could probably have been swapped over. However, it wouldn't be "my car", and that was most of the point of this. I cut up the car over the Christmas break, and a couple weeks ago, I got my car into the shop, to start seeing what I was up against. I've gotten the carpet out, and chiseled off the sound deadening from the floor, to see the extent of the rust there. My plan is to take it a bit at a time, starting with the floors, then the sills, and then move to the rust at the rear, and finally to the quarter panels and other external areas. I plan on fitting used, rust free doors and fenders, to limit the amount of work on those pieces. It will likely take far longer than I hope, but I'm feeling eager so far. Here is a photo dump of the car as it sits.

3FCC8DC6-C3AE-44E4-82E6-C346F95C95D2 by Warren Tomlinson, on Flickr

3FCC8DC6-C3AE-44E4-82E6-C346F95C95D2 by Warren Tomlinson, on Flickr 664BD40A-BA70-488F-8438-D63945629855 by Warren Tomlinson, on Flickr

664BD40A-BA70-488F-8438-D63945629855 by Warren Tomlinson, on Flickr CC45750E-358A-474D-9F96-9FF23A41A9F2 by Warren Tomlinson, on Flickr

CC45750E-358A-474D-9F96-9FF23A41A9F2 by Warren Tomlinson, on Flickr 0FF4A1B9-54A3-4382-8812-4CAD26BA1F86 by Warren Tomlinson, on Flickr

0FF4A1B9-54A3-4382-8812-4CAD26BA1F86 by Warren Tomlinson, on Flickr 5CB0D49D-97E2-452A-9ABE-F1699E4990F0 by Warren Tomlinson, on Flickr

5CB0D49D-97E2-452A-9ABE-F1699E4990F0 by Warren Tomlinson, on Flickr 57DDB330-E114-4D9F-9139-F242DB497D44 by Warren Tomlinson, on Flickr

57DDB330-E114-4D9F-9139-F242DB497D44 by Warren Tomlinson, on Flickr 1C54470C-317A-4FA0-B667-C4D5F663A082 by Warren Tomlinson, on Flickr

1C54470C-317A-4FA0-B667-C4D5F663A082 by Warren Tomlinson, on Flickr 10BE7D6A-B33C-4BDC-8FD7-0421773EC279 by Warren Tomlinson, on Flickr

10BE7D6A-B33C-4BDC-8FD7-0421773EC279 by Warren Tomlinson, on Flickr EFEEF793-240B-4859-B229-4D97FDDD2D24 by Warren Tomlinson, on Flickr

EFEEF793-240B-4859-B229-4D97FDDD2D24 by Warren Tomlinson, on Flickr 7C6B308B-5C61-468C-86AF-681796D54065 by Warren Tomlinson, on Flickr

7C6B308B-5C61-468C-86AF-681796D54065 by Warren Tomlinson, on FlickrIf you've made it down to here, thanks for reading my immense first post of the project. The updates going forward will be far more brief!