(https://www.garagejournal.com/forum/for ... ay.php?f=7) and the other a thread which asks "What did you do in your shop today?"

(https://www.garagejournal.com/forum/sho ... p?t=126997). Some of you here are posting members over there, and while I lurk over there, I'm not terribly active. I realize this may be a sub-thread to the ever popular related threads here on this forum: "What did you do to your house today?" and "What did you to your car today" and by extension "What did you to do to your other car(s) today?", however I thought maybe it was time to create a thread dedicated to our specific work spaces, whether it be a garage, yard, storage unit, barn, or whatever regardless of its' size. It's the space we work in on our cars and this thread is about what you do in it and what you do to it.

If you've been like me, maybe you all have been spending a lot more time in your shop these past few months. I have been taking advantage of doing certain improvements to The Hangar now that there hasn't been the constant summer pressure of car events and preparation for them. All these improvements are both in support of doing future car projects and a bit of procrastination mixed in.

So let me start with what I have been doing over the last month or two to the actual space:

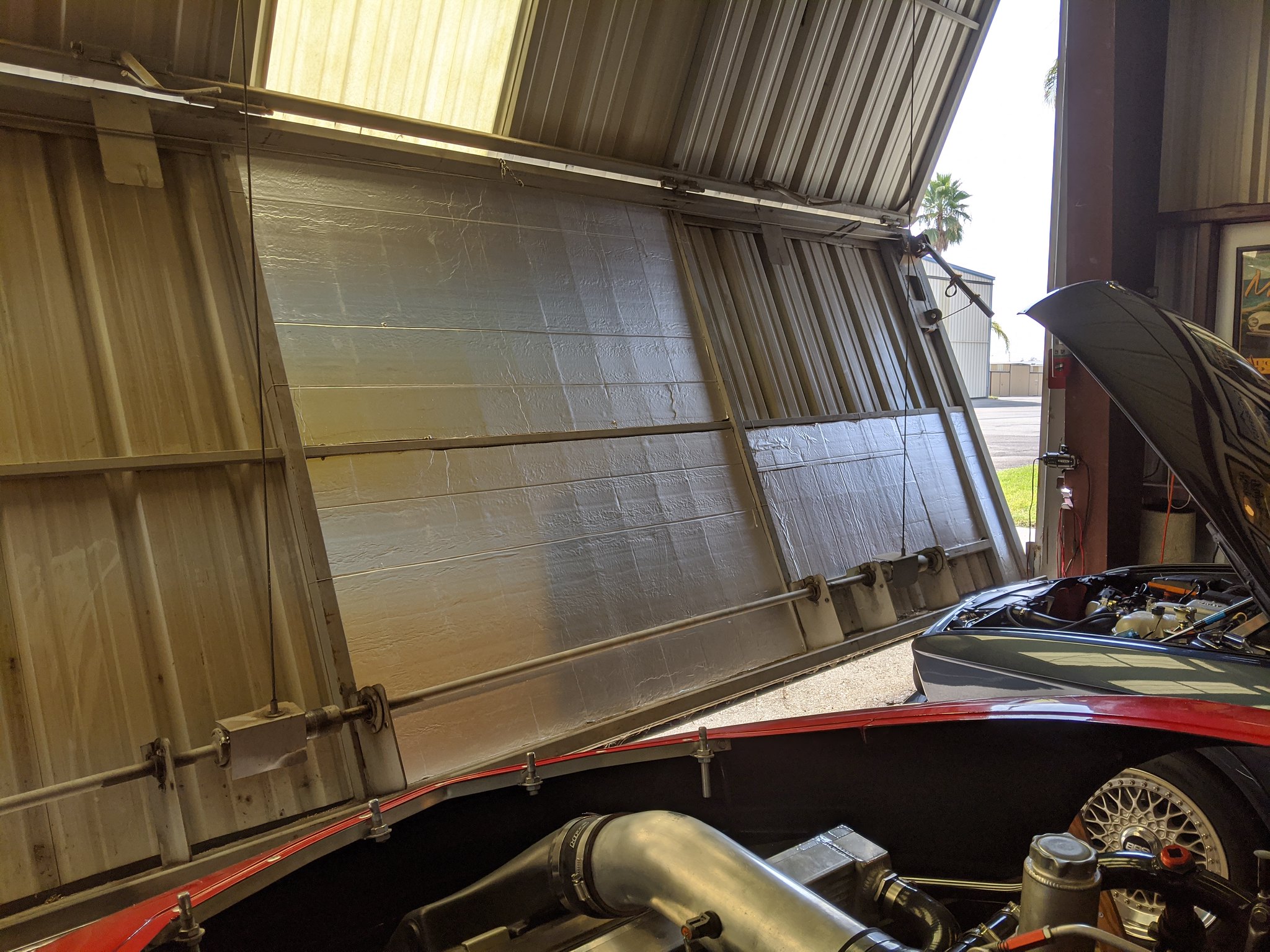

First off, as some of you are aware and some of have actually been here, The Hangar is exactly that: a 2,000 s.f. communal aircraft hangar at one of the somewhat nearby local county airports, that I share with now just two other like-minded car guys (one deep in the '02 and Coupe crowd and the other an avid American racing car driver, don't ask me to remember the class and category). We were lucky to get this space some 9 years ago and have been using it to full effect for work and storage ever since. It's doubly cool that I get this space to retreat to that is all about working on my car and that I am surrounded by other life-long fascination: airplanes. Both airplanes and helicopters are all around me taxiing, flying over, taking off, landing, etc. all day long while I'm up there.

This past Sunday I was up there working on both the M535i chasing down an electrical gremlin and starting a long delayed interior upgrade to the E39. Here they are together, it's not often that these two get to "socialize" in the same space, the race driver had his new rig, a Camaro, out for a race weekend (probably Buttonwillow):

Over the past few months doing some organization and shuffling when we went from 4 tenants to 3, I added some new heavy duty shelving (the ones on the left side of the first photo) and this slap-dash utilitarian work bench:

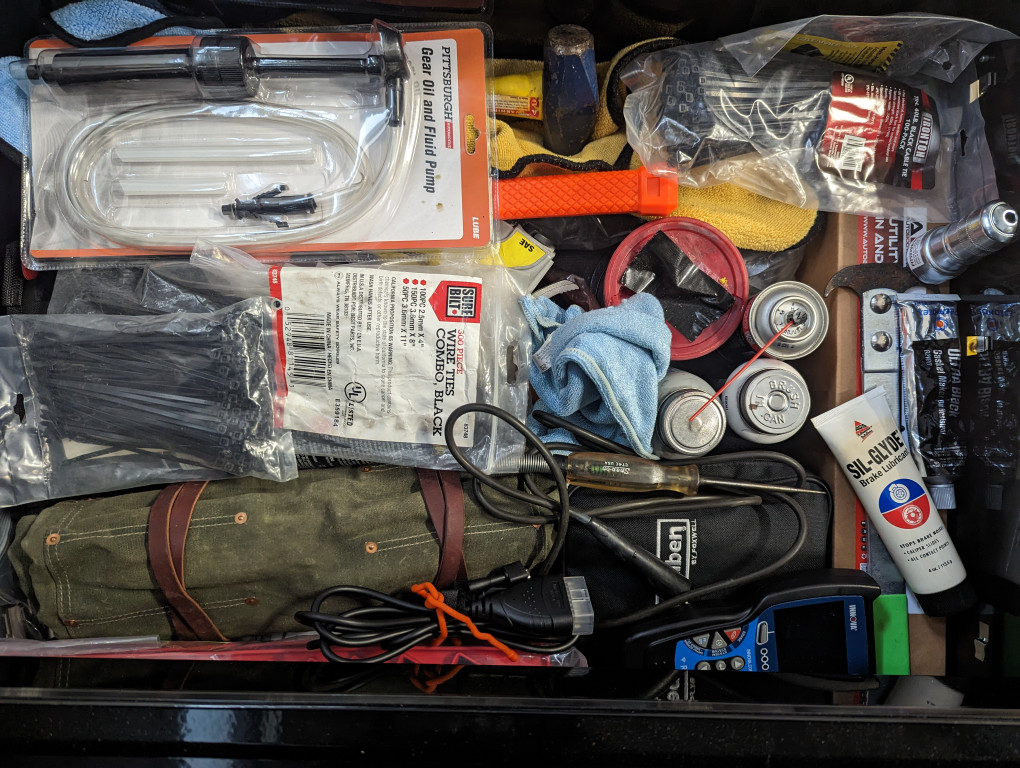

It was mostly made from left-over parts and stock; the top was an Ikea Scratch & Dent clearance item my wife and I have been schlepping around for the last two decades that was languishing in my garage at home, the back was leftover from my closet remodel, and the 2x4's were from various projects. The only thing I had to buy was one stick of 2x4, the Simpson post connectors (great things those) and the shelf brackets for the light above. I had everything else. The bench vise is my father's that I remember vividly being in his basement workshop back in New Jersey. The rolling drop-leaf drawer box underneath is my Craigslist find painted out to match the Craftsman tool chest colors; it contains all my hardware.

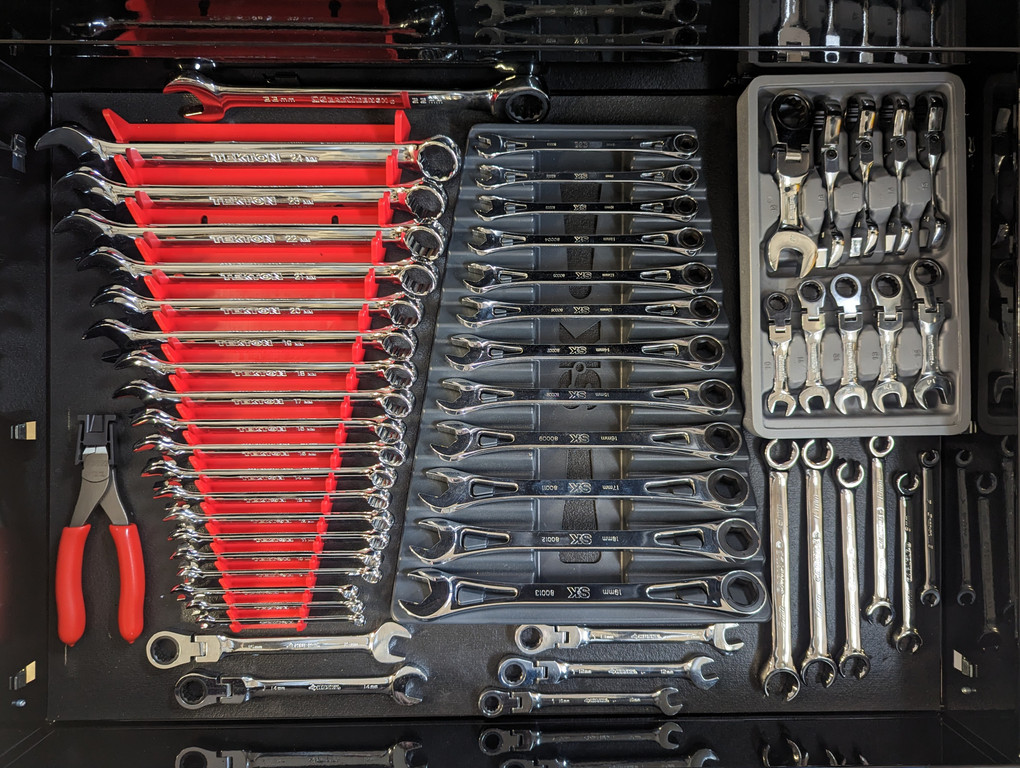

Speaking of which, I re-shuffled my collection of vintage Craftsman tool chests from the outer wall to an "island" in the middle of my bay:

These too were Craigslist finds and are in various states of refinishing. They are mostly from the late 1960's and early 1970's and are built like tanks to last a lifetime; I know once they are re-painted and lubed up they will outlast me. The one odd-ball out is the Husky Mid box in the first photo; I re-painted it to blend in with the Craftsman's. I have two other smaller 3-drawer bottom cabinets on the opposite wall that hold supplies and other tools as well. (It is my submission/response to the "Wall of Craftsman" thread over at GJ).

Also I tested out some prototype jack stand adapters for standard jack stands to fit the jack pads on the E39 body. A relatively simple design to be able to lock into the receiving "cup" to stabilize the car when on the stands. It is a steel box with a piece of bar stock on top:

(And before you ask, no: these are not part of the infamous HF recall; the pawls on these are quite substantial).

The design works so I'm going to polish up the design a bit and see if the welder I worked with will do a run of these since I KNOW there are other E39/46/38/X5 owners here that might find these useful. I am not a welder (yet, maybe?) otherwise I would do this myself. Maybe someone who does weld wants to step up and give it a go?

Anyway, I have a really long list of tasks and projects for the space. The next being a pneumatic air distribution system (a mix of copper and RapidAir Maxline) which I'm gathering parts for presently.

Someday, we may get a lift...