Fortunately for me, the car has spent much of it's life in the salt-free state of Colorado, preventing any serious rust from forming. Everything around the back of the transmission is covered in transmission oil, thanks to a leaky selector shaft.

But onto the problem:

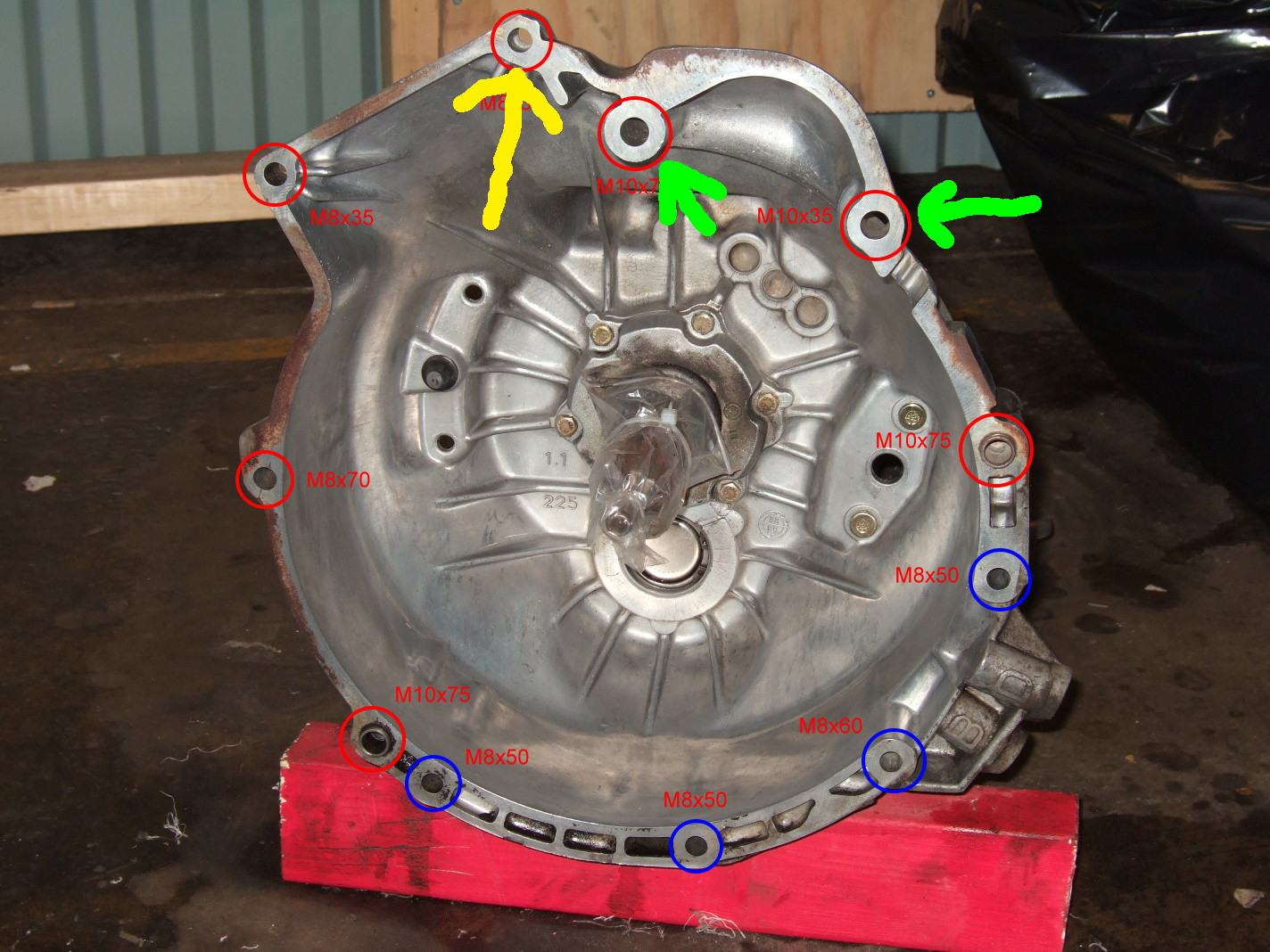

I decided to remove the hardest screws first on the transmission (good idea), and have successfully removed two from the car thus far. (Green arrows indicate removed bolts, yellow indicates stripped bolt)

The first half of those threads were rounded too much for an E10 socket to fit on, so I tried to fit an E12 on, which promptly slipped and slightly further damaged the bolt. A trip to Harbor Freight to get an E11 (clearly the correct size) did even more damage, and was unable to completely seat on the bolt. After some searching online, I tried to fit a hex socket (8mm) onto the bolt, which grabbed tightly, but ended up rounding out the bolt even more. I have an old set of Craftsman Bolt-Outs, but the smallest one is unable to adequately grab the head of the screw. There's plenty of stuff left to bite onto, just not enough for any of the tools I have. Any advice from you guys? I don't want to throw a bunch of tools here if you have a recommended solution ready.

--

Thanks,

TheYoungSir