535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Injectors will fire even below 10v. They're a little sluggish but MS has a correction factor for it. This is not something that needs tuning.

What jumps out from the first datalog is the RPM signal. Seems like it may be having trouble picking up the pattern. I'll have to download that log and take a look. You can see the difference though if you compare to the second datalog where it picks up and reads a steady 200ish RPM during cranking until it starts.

For me that's the prime suspect at this point.

What jumps out from the first datalog is the RPM signal. Seems like it may be having trouble picking up the pattern. I'll have to download that log and take a look. You can see the difference though if you compare to the second datalog where it picks up and reads a steady 200ish RPM during cranking until it starts.

For me that's the prime suspect at this point.

-

Nebraska_e28

- Beamter

- Posts: 9056

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Looking good!

Did I miss it, are you running 10:1 pistons on this boosted setup?

Did I miss it, are you running 10:1 pistons on this boosted setup?

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Just stock B35 9:1 ratio.

But maybe this week I will try again and see if a tune from a few weeks back makes any difference with a datalog. Been doing some family outings and things while I am out of work and have a few interviews that I have a hunch I may be working soon here.

I will share soon here along with some photos of my oil pressure sensor and gauge in the car. I also may try to mock up an oil cooler in the nose and might switch the filter housing at the first oil change.

But maybe this week I will try again and see if a tune from a few weeks back makes any difference with a datalog. Been doing some family outings and things while I am out of work and have a few interviews that I have a hunch I may be working soon here.

I will share soon here along with some photos of my oil pressure sensor and gauge in the car. I also may try to mock up an oil cooler in the nose and might switch the filter housing at the first oil change.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

So I had a chance to play with the car since no start. I went back to an old tune and found that the car would actually run.

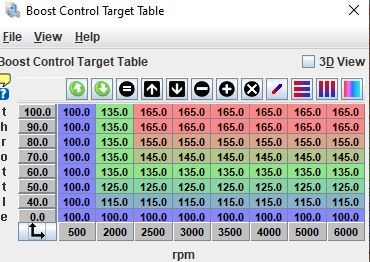

As I looked more closely, I found some different settings. Nothing seemed like it could cause a problem until I checked and found a setting for boost limiting and overboost. The 'boost tolerance' was set to ON and began limiting the the fuel and spark. I guess I had activated this and inadvertently not realized that apparently the exact same boost table as before was causing the problem. With the boost tolerance ON of 40kpa and with a reference table of 0kpa at low rpm, it was seeing that I was exceeding the tolerance of 40kpa (0+40) that trips it. So shutting that off resolved the problem. The real solution is change the low side of the boost target table so that it will never 'overboost' via the tolerance setting during cranking. This is 100kpa and won't get tripped in the future (my table has a bottom row of 100kpa at low rpm's, instead of 0kpa).

I got the car started and then was inspecting the car when I smelled a little fuel and realized my fuel supply line from tank to pump was leaking. So I have a new m12x18 hose on the way to replace and resolve the leak. The line appears to be the original braided fabric hose but I have some standard size hose in case it is the return line to the tank with the problem.

Since the car hasn't started this way for weeks, it was pleasing the hear the engine jump start into a nice smooth idle, no more slight sound of misfire or slight hunting at idle like before!

In the mean time, here is the temp sender, new oil pressure sender and the adapter on the back of the head.

You can see the gauge here where the defroster button would normally go. It isn't on here, but the gauge is red and easy to read. I have seen oil temps of about 165-180F though haven't measured it since doing real boost runs or much hard driving yet.

I was looking into the oil cooler and decided to get a 745i cooler and filter housing and filter head. Here is where I am thinking of putting it in the nose of my car (where the horns usually are). I think it just might fit here but I have to modify the lines a little bit to route to this location. I think I can make it work since it won't be significantly different than the lines that i have on hand.

To make it work, I will be adding the M5/745i/M30 oil cooler housing which is the exact same size but just has the provisions for the oil cooler. Thanks Mike A!

I will be using a small elbow fitting to tap into the oem port on the side for oil supply. The major upside here is that apparently it will allow the coolest oil coming from the oil cooler to reach the turbo. I haven't had oil temp problems and do run 15W50, but cooler oil can't hurt the turbo. Obviously it has to be thermostat activated, so it really will be for when the engine is pushed hard.

Lastly, in the back corner by the engine harness penetration and ECU, you can see a mann-hummel provent 200 that I just installed. Hoping this helps PCV while keeping any oil out of the turbo and intercooler piping. It just fits there but will definitely flow better than the small separator I had tried to install.

More tuning and updates to come. Gotta get the fuel line replaced first before I do any driving.

As I looked more closely, I found some different settings. Nothing seemed like it could cause a problem until I checked and found a setting for boost limiting and overboost. The 'boost tolerance' was set to ON and began limiting the the fuel and spark. I guess I had activated this and inadvertently not realized that apparently the exact same boost table as before was causing the problem. With the boost tolerance ON of 40kpa and with a reference table of 0kpa at low rpm, it was seeing that I was exceeding the tolerance of 40kpa (0+40) that trips it. So shutting that off resolved the problem. The real solution is change the low side of the boost target table so that it will never 'overboost' via the tolerance setting during cranking. This is 100kpa and won't get tripped in the future (my table has a bottom row of 100kpa at low rpm's, instead of 0kpa).

I got the car started and then was inspecting the car when I smelled a little fuel and realized my fuel supply line from tank to pump was leaking. So I have a new m12x18 hose on the way to replace and resolve the leak. The line appears to be the original braided fabric hose but I have some standard size hose in case it is the return line to the tank with the problem.

Since the car hasn't started this way for weeks, it was pleasing the hear the engine jump start into a nice smooth idle, no more slight sound of misfire or slight hunting at idle like before!

In the mean time, here is the temp sender, new oil pressure sender and the adapter on the back of the head.

You can see the gauge here where the defroster button would normally go. It isn't on here, but the gauge is red and easy to read. I have seen oil temps of about 165-180F though haven't measured it since doing real boost runs or much hard driving yet.

I was looking into the oil cooler and decided to get a 745i cooler and filter housing and filter head. Here is where I am thinking of putting it in the nose of my car (where the horns usually are). I think it just might fit here but I have to modify the lines a little bit to route to this location. I think I can make it work since it won't be significantly different than the lines that i have on hand.

To make it work, I will be adding the M5/745i/M30 oil cooler housing which is the exact same size but just has the provisions for the oil cooler. Thanks Mike A!

I will be using a small elbow fitting to tap into the oem port on the side for oil supply. The major upside here is that apparently it will allow the coolest oil coming from the oil cooler to reach the turbo. I haven't had oil temp problems and do run 15W50, but cooler oil can't hurt the turbo. Obviously it has to be thermostat activated, so it really will be for when the engine is pushed hard.

Lastly, in the back corner by the engine harness penetration and ECU, you can see a mann-hummel provent 200 that I just installed. Hoping this helps PCV while keeping any oil out of the turbo and intercooler piping. It just fits there but will definitely flow better than the small separator I had tried to install.

More tuning and updates to come. Gotta get the fuel line replaced first before I do any driving.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

I got the fuel line replaced and car is drivable. I have been distracted with some family/personal items that prevented me from working on this car much this last month. But I got a chance to do a few test drives since my last update.

I mounted the oil cooler in the nose but haven't run the lines yet or replaced the oil cooler housing. It is sitting there in the nose and ready to hook up when I am. Waiting to get more mileage since the rebuild. I am seeing oil temps of 165F or less but only have about 30 miles on the car since last month. Here's how it looks in use:

Also wanted to mention fuel econometer does work and OBC fuel estimate works but they are over double the fuel mileage of actual since I have larger injectors. Still gives an estimate of fuel mileage but I have to divide by 2.5.

The car runs well and I am running at about 7 psi and half throttle working on the fueling map. It seems I am able to drive the car reliably at this point, I am just working on boost region. I found a light throttle and then stab would cause an boost cut. I had to change the boost delta from 14kpa (2psi) and am trying 28kpa (4psi) to hopefully not kick in a boost cut but still allow a cut if boost control ends up way above my target for some reason.

I have made a map that ramps boost with throttle so if there is a little wheelspin, letting off or holding the throttle still will normalize boost instead of continuing to build boost and power. This is to keep the car drivable and predictable on the road course. This will also allow the same boost at higher elevations since the target remains the same even as the local air pressure decreases (and the normal wastegate reference drops lower and lower). I will continue to play with this and adjust if needed.

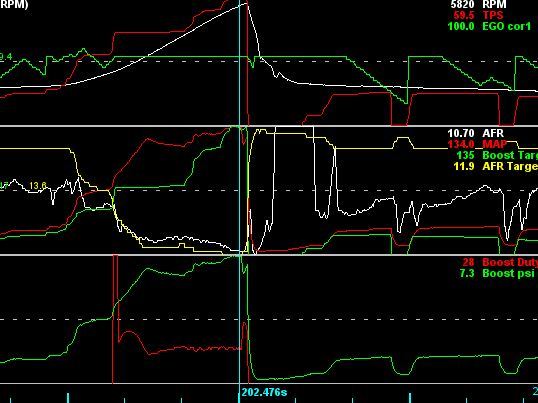

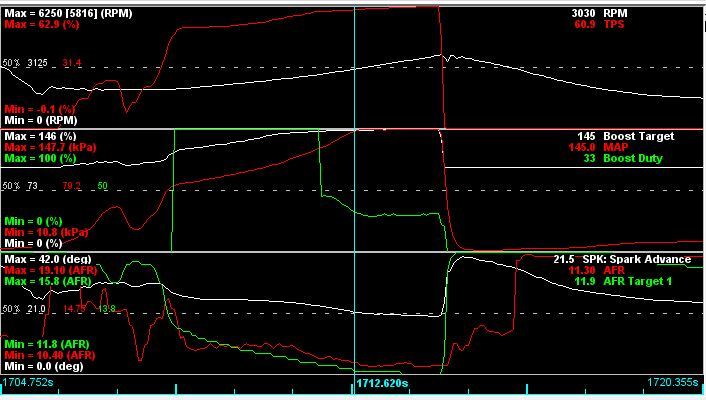

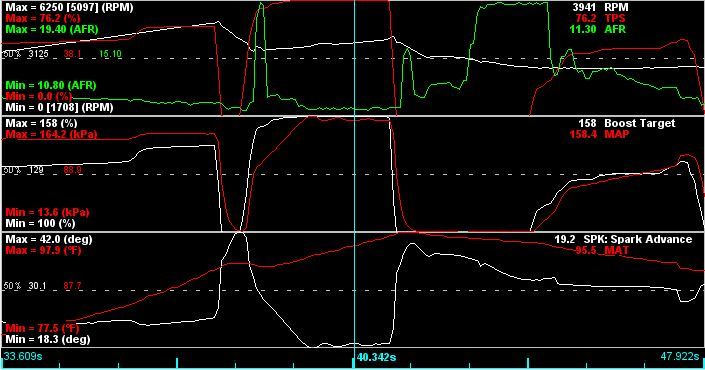

I am seeing that when the boost controller kicks in, my wideband reads slightly lean at say 13:1 instead of 12:1 in an area of the map I thought I had tuned close to my target. I think it occurs when the boost controller starts dumping pressure from the top of the wastegate because I can hear it a little bit. I am not sure yet if this is a real problem or just some cells I need to fatten up. Looking at the logs, this may be all it is because both examples below show opposite things (one rich, one lean).

Is it just reading lean because there is less fuel matching the less boost pressure? I was assuming it could remain close to the target with a .2AFR change instead of a full point. I guess it could be a small area in my map I just need to tune. I have tried to shut off ego control over 100kpa.

I have some minor things to work on at some point.

-I need to replace the rear axle boot and I have rebuilt oem axles.

-I need to swap the front lower control arm bushings, just need to remove the arms and press into place and reinstall.

-Small power steering leak. Tightening the hose to the power steering pump didn't stop the leak, but that is the location of a slow drip

-Battery drain. I think it is the power lock control unit as when i remove the fuse, the drain seems to go away

I mounted the oil cooler in the nose but haven't run the lines yet or replaced the oil cooler housing. It is sitting there in the nose and ready to hook up when I am. Waiting to get more mileage since the rebuild. I am seeing oil temps of 165F or less but only have about 30 miles on the car since last month. Here's how it looks in use:

Also wanted to mention fuel econometer does work and OBC fuel estimate works but they are over double the fuel mileage of actual since I have larger injectors. Still gives an estimate of fuel mileage but I have to divide by 2.5.

The car runs well and I am running at about 7 psi and half throttle working on the fueling map. It seems I am able to drive the car reliably at this point, I am just working on boost region. I found a light throttle and then stab would cause an boost cut. I had to change the boost delta from 14kpa (2psi) and am trying 28kpa (4psi) to hopefully not kick in a boost cut but still allow a cut if boost control ends up way above my target for some reason.

I have made a map that ramps boost with throttle so if there is a little wheelspin, letting off or holding the throttle still will normalize boost instead of continuing to build boost and power. This is to keep the car drivable and predictable on the road course. This will also allow the same boost at higher elevations since the target remains the same even as the local air pressure decreases (and the normal wastegate reference drops lower and lower). I will continue to play with this and adjust if needed.

I am seeing that when the boost controller kicks in, my wideband reads slightly lean at say 13:1 instead of 12:1 in an area of the map I thought I had tuned close to my target. I think it occurs when the boost controller starts dumping pressure from the top of the wastegate because I can hear it a little bit. I am not sure yet if this is a real problem or just some cells I need to fatten up. Looking at the logs, this may be all it is because both examples below show opposite things (one rich, one lean).

Is it just reading lean because there is less fuel matching the less boost pressure? I was assuming it could remain close to the target with a .2AFR change instead of a full point. I guess it could be a small area in my map I just need to tune. I have tried to shut off ego control over 100kpa.

I have some minor things to work on at some point.

-I need to replace the rear axle boot and I have rebuilt oem axles.

-I need to swap the front lower control arm bushings, just need to remove the arms and press into place and reinstall.

-Small power steering leak. Tightening the hose to the power steering pump didn't stop the leak, but that is the location of a slow drip

-Battery drain. I think it is the power lock control unit as when i remove the fuse, the drain seems to go away

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

I had some time this week to continue driving the car and dial in the warm up enrichment and eliminate some warmup oscillations in the idle. This smoothed out a lot when run rich at idle around 13.2-13.4 AFR.

Here she is parked downtown in Denver. Yes, the car looks more ratty than ever with the paint but is is something I am considering for an update project in the future.

I have played with the boost controller settings and am working to try to eliminate the PID bounce in boost control. It is subtle but I think I can make it better. I also found my map was just lean in some places and rich in others. I haven't been able to test cold weather for my AT settings, but I think this map is the closest ever to correct settings for my setup.

Admittedly, I need to test outside a range of 75F-90F but so far I am not seeing huge fluctuations in that range of temperatures where it is rich n the cold and lean in the hot...

I have the boost by throttle position up to 170kpa (12psi for me in Denver). So far it seems to work well that I can run along each column on my fuel map by an estimated throttle position. IE, if 70% throttle, boost doesn't just always rise to a wastegate spring, but shoots for the prescribed target value. It also means at elevation I will build more boost depending on altitude to stay at the target boost level.

I am building up to full throttle runs, but wanted correct mixtures and boost control before giving it the beans. But it feels like I have the better throttle response I was hoping for with this engine!

I adjusted my AFR table leaner in light load cruise to leaner than 14.7:1 and it seemed like the car liked it. I am advancing the ignition there and will see if that helps even more for the light load drivability. I am also advancing the boost region by 1 degree based on a map by Nosis here who ran similar settings on the dyno just recently with leaner fuel mixtures.

More to come but there will be less progress as I started a new job and will be travelling for a while.

Here she is parked downtown in Denver. Yes, the car looks more ratty than ever with the paint but is is something I am considering for an update project in the future.

I have played with the boost controller settings and am working to try to eliminate the PID bounce in boost control. It is subtle but I think I can make it better. I also found my map was just lean in some places and rich in others. I haven't been able to test cold weather for my AT settings, but I think this map is the closest ever to correct settings for my setup.

Admittedly, I need to test outside a range of 75F-90F but so far I am not seeing huge fluctuations in that range of temperatures where it is rich n the cold and lean in the hot...

I have the boost by throttle position up to 170kpa (12psi for me in Denver). So far it seems to work well that I can run along each column on my fuel map by an estimated throttle position. IE, if 70% throttle, boost doesn't just always rise to a wastegate spring, but shoots for the prescribed target value. It also means at elevation I will build more boost depending on altitude to stay at the target boost level.

I am building up to full throttle runs, but wanted correct mixtures and boost control before giving it the beans. But it feels like I have the better throttle response I was hoping for with this engine!

I adjusted my AFR table leaner in light load cruise to leaner than 14.7:1 and it seemed like the car liked it. I am advancing the ignition there and will see if that helps even more for the light load drivability. I am also advancing the boost region by 1 degree based on a map by Nosis here who ran similar settings on the dyno just recently with leaner fuel mixtures.

More to come but there will be less progress as I started a new job and will be travelling for a while.

-

Nebraska_e28

- Beamter

- Posts: 9056

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Nice work! There are so many other folks concerned with how their car looks when photographed & zero regard to dialing in performance.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Thanks LJ!

Yes, I know the nice paint is more flashy but I have been more about functionality where possible.

Here was the car doing some errands and looking pretty col after a sunrise.

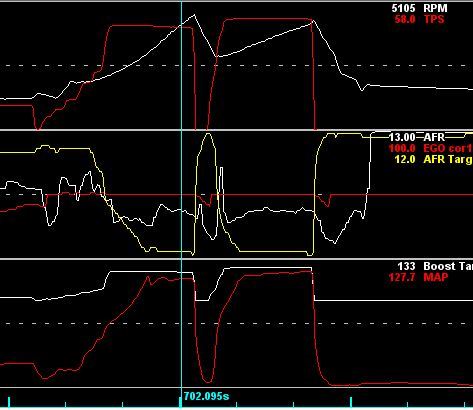

I tested up to about 70% throttle and 9psi (145kpa). I am dialing in my mixture and MAT curve to try to make sure I have consistency/ repeatability without using EGO control. I'm trying to make the response nice for changing throttle and corresponding boost control. Here's an example that at 60% throttle gives the corresponding boost target according to my table. See how the boost is nicely tracking the target without much oscillation. I am trying to tune the pid settings so that it matches, but this is difficult when rpm is high and throttle opening changes quickly (when the wastegate is partially held shut by the solenoid).

Solenoid duty starts dropping at a setting of 20kpa below the target to hopefully allow for enough time to control the boost spikes. Note I do not allow ego control over atmospheric pressure.

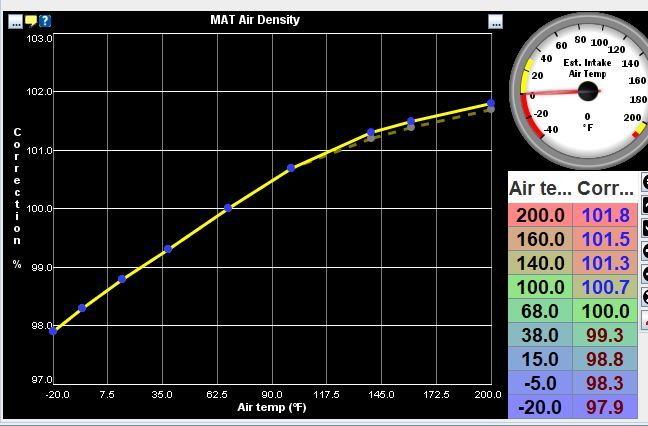

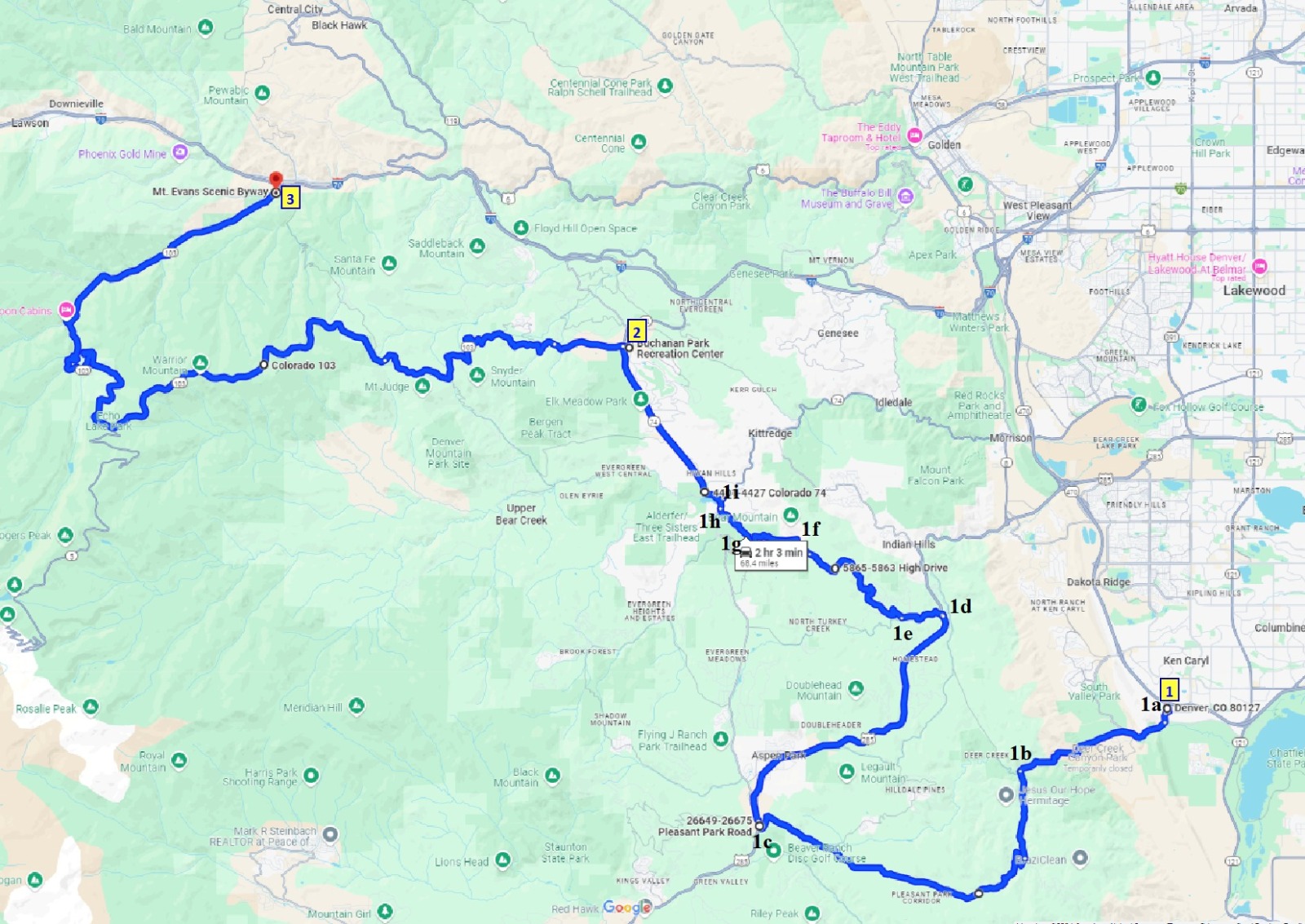

I tested a hot restart after letting the car sit for a couple minutes. I am adjusting the MAT temp correction and am hoping to be close to a nice reliable curve that doesn't change afr mixtures with temperature change. I think my ego limit is like 10%. You can see the car started at 15-F MAT and then in a minute was dropping temperature but the fuel mixture was leaning out slightly as it registered lower air temps. So my curve was off slightly here.

After idling like that I found the oil temps were at 185 and coolant at 195F. I think this is a good example to show why an oil cooler is useful. It will also take some load off the cooling system if the oil temps would otherwise be above the coolant temps. I need to plumb the lines and filter head housing when I do the next oil change. But I haven't seen these temps in normal driving, though this was idling in 75F weather and then a little bit of boost before shutting of for a couple minutes. With the cooler, there would be more cooling capacity with the additional oil provided by the cooler and the lines that it would be silly not to add at this point.

I need to drive it more and keep tuning. But overall, it feels really nice at the 6-9psi range and I am feeling like the head and piston upgrades were worth it! Can't wait to do a full WOT boost run to redline but I am simply creeping up on it making sure all is good with my tune.

Yes, I know the nice paint is more flashy but I have been more about functionality where possible.

Here was the car doing some errands and looking pretty col after a sunrise.

I tested up to about 70% throttle and 9psi (145kpa). I am dialing in my mixture and MAT curve to try to make sure I have consistency/ repeatability without using EGO control. I'm trying to make the response nice for changing throttle and corresponding boost control. Here's an example that at 60% throttle gives the corresponding boost target according to my table. See how the boost is nicely tracking the target without much oscillation. I am trying to tune the pid settings so that it matches, but this is difficult when rpm is high and throttle opening changes quickly (when the wastegate is partially held shut by the solenoid).

Solenoid duty starts dropping at a setting of 20kpa below the target to hopefully allow for enough time to control the boost spikes. Note I do not allow ego control over atmospheric pressure.

I tested a hot restart after letting the car sit for a couple minutes. I am adjusting the MAT temp correction and am hoping to be close to a nice reliable curve that doesn't change afr mixtures with temperature change. I think my ego limit is like 10%. You can see the car started at 15-F MAT and then in a minute was dropping temperature but the fuel mixture was leaning out slightly as it registered lower air temps. So my curve was off slightly here.

After idling like that I found the oil temps were at 185 and coolant at 195F. I think this is a good example to show why an oil cooler is useful. It will also take some load off the cooling system if the oil temps would otherwise be above the coolant temps. I need to plumb the lines and filter head housing when I do the next oil change. But I haven't seen these temps in normal driving, though this was idling in 75F weather and then a little bit of boost before shutting of for a couple minutes. With the cooler, there would be more cooling capacity with the additional oil provided by the cooler and the lines that it would be silly not to add at this point.

I need to drive it more and keep tuning. But overall, it feels really nice at the 6-9psi range and I am feeling like the head and piston upgrades were worth it! Can't wait to do a full WOT boost run to redline but I am simply creeping up on it making sure all is good with my tune.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

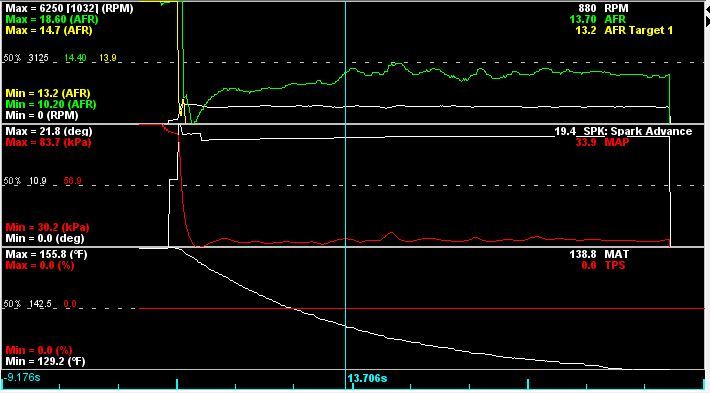

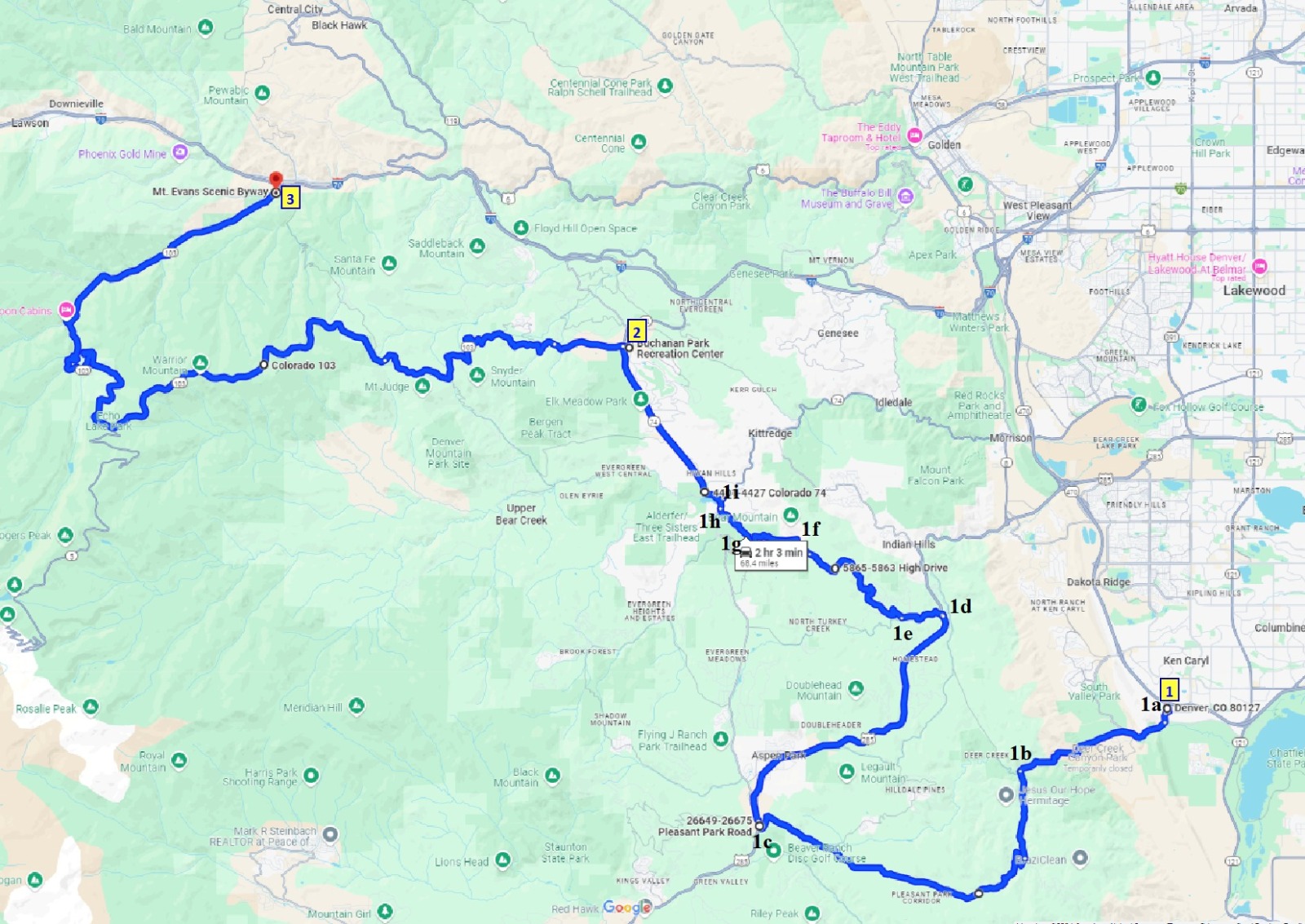

BMW mountain drive today! I organized some friends and coordinated a shake down run for Burt.

In preparation, I reinstalled the Rial mesh wheels which haven't been on the car for ~4 years. The look great IMO, expecially with the slim euro bumpers.

About 15 cars showed up though some weren't joining for the drive

'Nosis' was able to join with his TCD/B35 engined car.

We took a route I haven't driven, with a regroup and bathroom stop in the middle

Where we got some photos of the two turbo e28s as well as Franklin (my wife's 535iA).

Overall the car made good power and was a great choice for these roads! I am still not confident to run foot to the floor at 170kpa all the way to the top of the revs, but it was not critical for this route as the midrange with boost is a nice place to be when climbing hills and powering out of corners! The S3.46 is a great ratio, and I don't think there is much need to go with the 3.25 that I was considering swapping in.

I have a slight driveline vibration I'd like to resolve which I didn't really notice on the twisty roads, only on the highway and pulling from stoplights. Something to look at in depth.

Overall, my barometric and MAT corrections were working well with corrections of about 3% which was better than I was expecting going from 84kpa down to 72 or lower absolute pressures. The time I had started with was a bit rich at high boost, but I figured this would be safer for pushing it hard up mountain climbs. Oil temps were about 150-160F only reaching 170F after hard climbing under boost. Ambient was probably 60-65F at this point. So even if I had plumbed the oil cooler, I am not sure the thermostat would have even opened... But having the extra capacity is still something I think that is useful and I will add at the next oil change.

Part way down the mountain, we stopped and my brother got a cool photo. Yes, my two boys were joining for the ride and were being hauled around at 9000 ft

This was the first real test and I made it home no problems! Great feeling on an engine you disassembled entirely yourself and put back together.

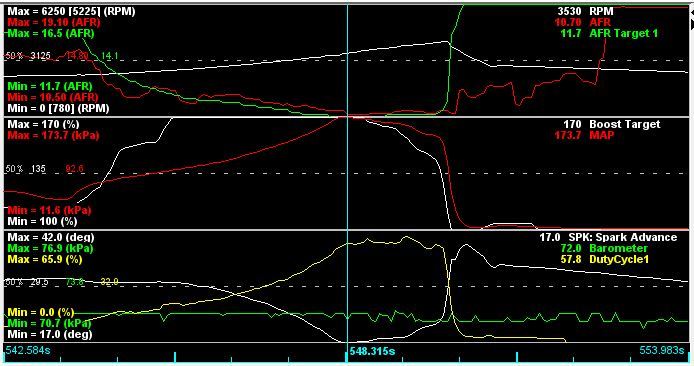

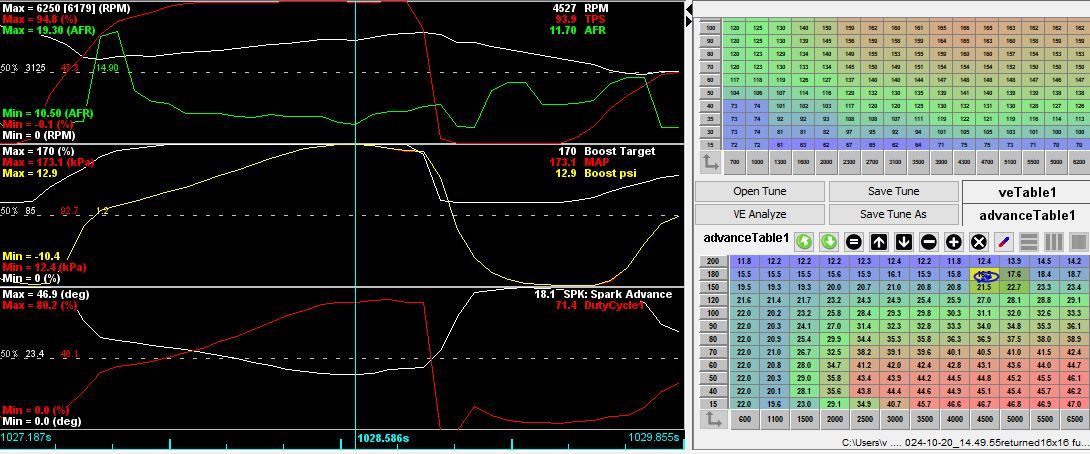

Here are a few datalogs showing maximum boost at 173kpa (target of 170) at 8500ft elevation. I'd like to dial out the oscillation on boost target, or at least minimize it from fluctuating and bouncing.

Also, you can see 155kpa and partial boost target with ~70% tps. This functionality worked great and I never had unwanted wheelspin since boost was always being moderated nicely. Coming otu a turn you push more throttle for a bit of oversteer, or slightly let off and the rear comes back in line easily.

More tuning to come.

In other news, i have a line on another B35 engine.... Not sure what I will do with it, but I need to make some space and get rid of the another engine to make room. I have too many engines, I think.

In preparation, I reinstalled the Rial mesh wheels which haven't been on the car for ~4 years. The look great IMO, expecially with the slim euro bumpers.

About 15 cars showed up though some weren't joining for the drive

'Nosis' was able to join with his TCD/B35 engined car.

We took a route I haven't driven, with a regroup and bathroom stop in the middle

Where we got some photos of the two turbo e28s as well as Franklin (my wife's 535iA).

Overall the car made good power and was a great choice for these roads! I am still not confident to run foot to the floor at 170kpa all the way to the top of the revs, but it was not critical for this route as the midrange with boost is a nice place to be when climbing hills and powering out of corners! The S3.46 is a great ratio, and I don't think there is much need to go with the 3.25 that I was considering swapping in.

I have a slight driveline vibration I'd like to resolve which I didn't really notice on the twisty roads, only on the highway and pulling from stoplights. Something to look at in depth.

Overall, my barometric and MAT corrections were working well with corrections of about 3% which was better than I was expecting going from 84kpa down to 72 or lower absolute pressures. The time I had started with was a bit rich at high boost, but I figured this would be safer for pushing it hard up mountain climbs. Oil temps were about 150-160F only reaching 170F after hard climbing under boost. Ambient was probably 60-65F at this point. So even if I had plumbed the oil cooler, I am not sure the thermostat would have even opened... But having the extra capacity is still something I think that is useful and I will add at the next oil change.

Part way down the mountain, we stopped and my brother got a cool photo. Yes, my two boys were joining for the ride and were being hauled around at 9000 ft

This was the first real test and I made it home no problems! Great feeling on an engine you disassembled entirely yourself and put back together.

Here are a few datalogs showing maximum boost at 173kpa (target of 170) at 8500ft elevation. I'd like to dial out the oscillation on boost target, or at least minimize it from fluctuating and bouncing.

Also, you can see 155kpa and partial boost target with ~70% tps. This functionality worked great and I never had unwanted wheelspin since boost was always being moderated nicely. Coming otu a turn you push more throttle for a bit of oversteer, or slightly let off and the rear comes back in line easily.

More tuning to come.

In other news, i have a line on another B35 engine.... Not sure what I will do with it, but I need to make some space and get rid of the another engine to make room. I have too many engines, I think.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Hi, do you mind sharing how did you run the economy gauge?

Thanks

Thanks

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

All I did was connect the glovebox econometer g103 I thunk to megaquirt injector 1s output.

With over double the injector size my fuel rate currently shows over double the mpg, but it works both the needle and the obc reading.

With over double the injector size my fuel rate currently shows over double the mpg, but it works both the needle and the obc reading.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Thanks mate , let me also try the same .

I have 210cc Bosch injectors, it should be close to original values.

*****

I did what you said, working perfectly.

Thanks again

I have 210cc Bosch injectors, it should be close to original values.

*****

I did what you said, working perfectly.

Thanks again

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

I drove the car today after advancing a bit more of the ignition table. This is more advance that I have ever run and all is working well, though I have now confirmed my timing with the light so I am dead on with the values.

I did datalog a little bit and have the following log of up to 170kpa and boost tracking my target within about 1/2 second of oscillation and less than 5kpa.This chart also shows the ignition map I am using as I continue to creep up on WOT throttle runs to redline at full boost. I have been going up to 8psi mostly, but here you see basically my maximum 13psi which is limited by my injectors at maximum rpm. Here is a reasonable 70% injector duty cycle.

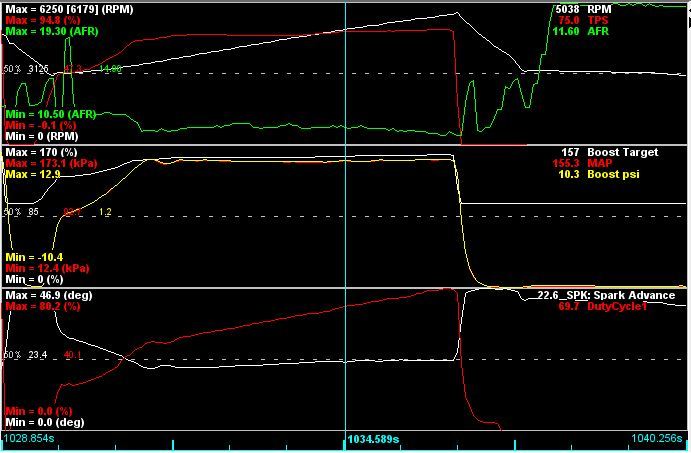

Here is 75% throttle for 155kpa (10psi boost) but at higher rpm where you see dutycycle up at a maximum 80% at ~5800rpm. I think at full boost this may be about 90% but I need to measure it to know for sure. If necessary, I will limit or reduce boost above 5800rpm with my boost controller as a safety feature.

You can see the boost level is regulated pretty well by the boost controller, even though there is a small oscillation of ~3-5kpa.

After, I played with idle a little bit and will see if the setting changes help to improve the consistency of idling. I had felt that there was a slight misfire feel during my idle, an audible noise so I decided to play with it in the driveway today. Some good detail from turbodan in PM about methods for improving idle and the possibility for using an advance curve instead of a closed loop idle valve to control the idle speed is something I may try out:

More updates to come as I continue with cold starts. I tried removing WUE to save some fuel on cold start, but the engine was running too lean. Continuing to dial it in and will report back.

I did datalog a little bit and have the following log of up to 170kpa and boost tracking my target within about 1/2 second of oscillation and less than 5kpa.This chart also shows the ignition map I am using as I continue to creep up on WOT throttle runs to redline at full boost. I have been going up to 8psi mostly, but here you see basically my maximum 13psi which is limited by my injectors at maximum rpm. Here is a reasonable 70% injector duty cycle.

Here is 75% throttle for 155kpa (10psi boost) but at higher rpm where you see dutycycle up at a maximum 80% at ~5800rpm. I think at full boost this may be about 90% but I need to measure it to know for sure. If necessary, I will limit or reduce boost above 5800rpm with my boost controller as a safety feature.

You can see the boost level is regulated pretty well by the boost controller, even though there is a small oscillation of ~3-5kpa.

After, I played with idle a little bit and will see if the setting changes help to improve the consistency of idling. I had felt that there was a slight misfire feel during my idle, an audible noise so I decided to play with it in the driveway today. Some good detail from turbodan in PM about methods for improving idle and the possibility for using an advance curve instead of a closed loop idle valve to control the idle speed is something I may try out:

My tuning previously had identified that MAP lowered as the timing was advanced, so I had been set at 22 degrees with about 30-32kpa idle. But at 15 degrees, the idle feels smoother and is able to be idling a bit leaner, although PW is about the same.All you have available to stabilize idle is timing and the ICV. I have always had better results with a fixed ICV setting and using advance to stay on top of things. It responds quicker than the ICV can, almost instantaneously.

What they did with early EFI systems for idle was to pull the timing way back and maintain idle at a relatively high manifold pressure. Too much vacuum increases emissions as combustion is less efficient at low kPa. I'm splitting the difference, I still run mid 30s vacuum at idle but I am also running relatively little timing. Usually it runs in the 14-18 degree range, though this depends on the amount of air supplied by the ICV. Decrease the ICV duty cycle and it will idle slightly lower with more advance. More air moves idle higher, into the lower advance part of the curve.

In either situation, it pulls timing back if RPM tries to climb and feeds it back in if it drops. Works pretty well. I am always looking for a smoother idle but it's not bad as is. I could give it more air and pull the timing back further but this would be less economical in terms of fuel consumption.

More updates to come as I continue with cold starts. I tried removing WUE to save some fuel on cold start, but the engine was running too lean. Continuing to dial it in and will report back.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Looking at your MAT Air Density correction, that curve may be doing the opposite of what is desired. Air density is has an inverse relationship with temperature. Should be adding fuel at low temps and pulling some back as IAT climbs.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

I have been fighting too rich in cold weather and too lean in hot since I have had megasquirt and I suspect it is related to the real time baro measurement. I have slowly changed the MAT curve to my current since 2020 and this post:

https://www.mye28.com/viewtopic.php?t=1 ... 0#p1487528

I have been aiming for 5% ego control and believe my current baro corrections are accurate. The MAT curve is a result of empirical testing and I think it is finally getting close. I never liked the mix being more lean as temperatures increased!

Maybe those without realtime baro don't have the same problems as me, or they just rely on ego control to make the adjustments.

https://www.mye28.com/viewtopic.php?t=1 ... 0#p1487528

I have been aiming for 5% ego control and believe my current baro corrections are accurate. The MAT curve is a result of empirical testing and I think it is finally getting close. I never liked the mix being more lean as temperatures increased!

Maybe those without realtime baro don't have the same problems as me, or they just rely on ego control to make the adjustments.

Re: 535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

If it works it works.

5% is all I give authority I give to the EGO control, and I really don't like seeing any correction greater than 3%.

5% is all I give authority I give to the EGO control, and I really don't like seeing any correction greater than 3%.