External links now open in a new browser tab - turn this off in your UCP - Read more here.

Head bolt question (pg. 3)

I browsed through the thread and I didn't see why you're removing the crank nut. You don't need to do that to R&R the head.

If the head is visibly cracked its garbage. Used heads are in the 150-250 dollar range. Don't spend any more than that. Resurfacing should be all thats necessary if the head is good and shouldn't cost more than about $45.

If the head is visibly cracked its garbage. Used heads are in the 150-250 dollar range. Don't spend any more than that. Resurfacing should be all thats necessary if the head is good and shouldn't cost more than about $45.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

It had a broken timing chain guide, and the front crank seal was leaking, so the hub needs to come off. So you are saying if it has cracks, they can not be repaired? Maybe I saw some casting irregularities with carbon in them. I had them check for cracks and what not.turbodan wrote:I browsed through the thread and I didn't see why you're removing the crank nut. You don't need to do that to R&R the head.

If the head is visibly cracked its garbage. Used heads are in the 150-250 dollar range. Don't spend any more than that. Resurfacing should be all thats necessary if the head is good and shouldn't cost more than about $45.

Last edited by VW+bimmer=bliss on Feb 01, 2013 1:33 PM, edited 1 time in total.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

wow, I AM A SPACE CADET.demetk wrote:Sorry to hear. That really sucks.

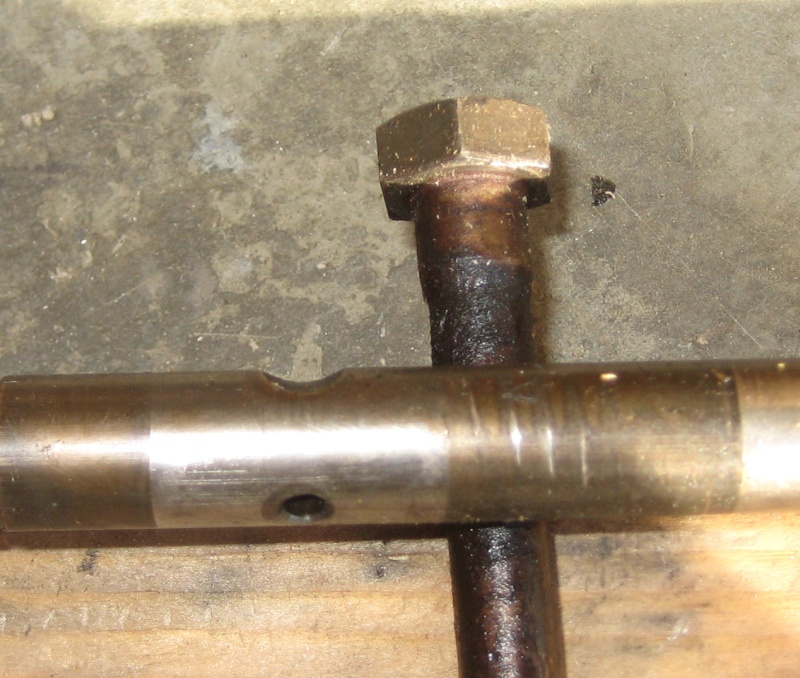

The hub with the v-belt on it? Are you talking about the vibration dampener? Once you have the front pulley off then you can just pry the dampener off the hub. Here the dampener has been removed and I'm pulling the hub off the crank.

LOL. Wish I was an actual space cadet. That would be fun.VW+bimmer=bliss wrote:wow, I AM A SPACE CADET.demetk wrote:Sorry to hear. That really sucks.

The hub with the v-belt on it? Are you talking about the vibration dampener? Once you have the front pulley off then you can just pry the dampener off the hub. Here the dampener has been removed and I'm pulling the hub off the crank.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

-

Frybrid 524td

- Posts: 2689

- Joined: May 27, 2009 11:42 AM

- Location: ...

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

They showed me, it was some kind of aluminum frame and it had a cylinder on it that would clamp to the head, each individual cylinder, and they would put water in there and pressurize it. No leaks any where, and no pressure drop when the air supply was removed....so who knows, maybe the gasket let go.Frybrid 524td wrote:How was the head tested? A visual inspection after hot-tanking isn't proof of no cracks.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

Sometimes you have to bang them with a hammer to move them a MM, other times the rocker springs will push them out of place. Push the spring out of the way, grab a channellocks and you should be able to work it back. Twist and push. No biggie.VW+bimmer=bliss wrote:And they drove the rear intake rocker shaft to far in the head, now i can not put my head on the block cause i can not put the the flippin head bolts through.

Fuck.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

I did just that, worked great! Until I noticed also about half of the eccentrics were not facing the right way. So i took the head off the block again, and went to rotate the cam to relieve sping pressure on some of the valves and BINGO the intake rear rocker shaft to slides all the way to the back of the head taking intake rockers #4,5,6 with it! I am just a little ticked now. Sorry no pics, phone was dropped into a bucket of PB gasoline and coolant.Mike W. wrote:Sometimes you have to bang them with a hammer to move them a MM, other times the rocker springs will push them out of place. Push the spring out of the way, grab a channellocks and you should be able to work it back. Twist and push. No biggie.VW+bimmer=bliss wrote:And they drove the rear intake rocker shaft to far in the head, now i can not put my head on the block cause i can not put the the flippin head bolts through.

Fuck.

Ugg. Sorry about the phone, but that may be the most toxic soup I've heard of one being dropped into. No, come to think of it one of my crew dropped one into a sewage pit and recovered it, if you want to phrase it that way, several years later. No attempt to find out if it still worked was made.VW+bimmer=bliss wrote:I did just that, worked great! Until I noticed also about half of the eccentrics were not facing the right way. So i took the head off the block again, and went to rotate the cam to relieve sping pressure on some of the valves and BINGO the intake rear rocker shaft to slides all the way to the back of the head taking intake rockers #4,5,6 with it! I am just a little ticked now. Sorry no pics, phone was dropped into a bucket of PB gasoline and coolant.Mike W. wrote:Sometimes you have to bang them with a hammer to move them a MM, other times the rocker springs will push them out of place. Push the spring out of the way, grab a channellocks and you should be able to work it back. Twist and push. No biggie.VW+bimmer=bliss wrote:And they drove the rear intake rocker shaft to far in the head, now i can not put my head on the block cause i can not put the the flippin head bolts through.

Fuck.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

I know right? The R button on my keyboard is quite stubborn now and the camera and LED refuses to work, but everything else works just fine! I was amazed, it smells as though my phone needs a headgasket now

So what you are saying is the rocker shafts will stay in place once you get the head torqued down? Because the other 4 are quite snug in their bores, the intake rear on the other hand, in can push it freely with my hand and if I remove the circlips, can easily remove it from the back of the head. Next to no resistance in the bore is felt. In the Bently is says they have to be driven out with a hammer and mandrel or the special BMW tool, so that makes me think the machine shop messed something up.

Also the bently just states to install the shafts into their original position, taking note of orientation and intake, , exhaust sides, etc, nothing about what to do if the shaft does not stay in the head.

So what you are saying is the rocker shafts will stay in place once you get the head torqued down? Because the other 4 are quite snug in their bores, the intake rear on the other hand, in can push it freely with my hand and if I remove the circlips, can easily remove it from the back of the head. Next to no resistance in the bore is felt. In the Bently is says they have to be driven out with a hammer and mandrel or the special BMW tool, so that makes me think the machine shop messed something up.

Also the bently just states to install the shafts into their original position, taking note of orientation and intake, , exhaust sides, etc, nothing about what to do if the shaft does not stay in the head.

-

Mark 88/M5 Houston

- Posts: 8548

- Joined: Feb 12, 2006 12:00 PM

- Location: Far North Houston

The rocker shafts are notched for clearance at the head bolt locations; that is why it is important that they go in the correct position. As soon as a head bolt is dropped in place the rocker shaft will not move more than a millimeter or so back and forth.VW+bimmer=bliss wrote:I know right? The R button on my keyboard is quite stubborn now and the camera and LED refuses to work, but everything else works just fine! I was amazed, it smells as though my phone needs a headgasket now

So what you are saying is the rocker shafts will stay in place once you get the head torqued down? Because the other 4 are quite snug in their bores, the intake rear on the other hand, in can push it freely with my hand and if I remove the circlips, can easily remove it from the back of the head. Next to no resistance in the bore is felt. In the Bently is says they have to be driven out with a hammer and mandrel or the special BMW tool, so that makes me think the machine shop messed something up.

Also the bently just states to install the shafts into their original position, taking note of orientation and intake, , exhaust sides, etc, nothing about what to do if the shaft does not stay in the head.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

I did put the head bolts in, and it still moves...I have all new head bolts as well, thought they might be the wrong ones so for shits and giggles i put the old ones back, to no avail, the shaft still slides freely to the back of thehead. Now I am in a predicament because my engine block is at TDC and the cylinder head is not, and I can not rotate the cam to the correct position because three rocker rams are not on their perspective lobes.Mark 88/M5 Houston wrote:The rocker shafts are notched for clearance at the head bolt locations; that is why it is important that they go in the correct position. As soon as a head bolt is dropped in place the rocker shaft will not move more than a millimeter or so back and forth.VW+bimmer=bliss wrote:I know right? The R button on my keyboard is quite stubborn now and the camera and LED refuses to work, but everything else works just fine! I was amazed, it smells as though my phone needs a headgasket now

So what you are saying is the rocker shafts will stay in place once you get the head torqued down? Because the other 4 are quite snug in their bores, the intake rear on the other hand, in can push it freely with my hand and if I remove the circlips, can easily remove it from the back of the head. Next to no resistance in the bore is felt. In the Bently is says they have to be driven out with a hammer and mandrel or the special BMW tool, so that makes me think the machine shop messed something up.

Also the bently just states to install the shafts into their original position, taking note of orientation and intake, , exhaust sides, etc, nothing about what to do if the shaft does not stay in the head.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

II put the three rearmost headbolts into the head on the intake side and the rocker shaft moves alot more than 1MM, more like 5MM. All three other shafts (IF, EF and ER) wont even budge and are in their ccorrect positions. Damnit I wash I could post a video on youtube but I have no ccomp. And my phone is on its last legs

Do you have the threads run all the way down? I don't remember how long the shoulder on the head bolt is, but it's not real long and may require more than just sitting in there, but like Mark said, when installed the shafts will only move a MM or so. Let me know if pictures will help, I should be able to mock some up with parts.

As a general rule you should avoid hammering on anything inside the cylinder head. Rocker shafts especially. Hammering means something is binding or otherwise in the way, and though you will probably get it apart this way it is very likely to damage the head casting or rocker arms in doing so.

If you can determine the source of the binding you can determine if its okay to apply force. Deposits on the shafts can cause problems.

If you can determine the source of the binding you can determine if its okay to apply force. Deposits on the shafts can cause problems.

Wow, I had no clue what you guys were talking about, until I went and had a look-see on one of my heads. Now I understand. So will the shafts align themselves with the bolt holes when the bolts go in or do they need to be tapped into alignment before you install the bolts?Mike W. wrote:Often rocker shafts on M30s require a considerable amount of force to move them. Regardless...

Here is a pic. Note the short shoulder and the notch it goes into which is already recessed some into the head.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

Wow, I messed up

when I had unwrapped the cylinder head, I almost immediate ly put it on the block. When I had about half of the bolts in, I noticed ALL of the eccentrics were not facing the right way. No bolts were torqued down, just barely finger tight. So I took the head off, and proceeded to turn the cam so I could relieve spring pressure on some valves. I stopped when I noticed the rear cover gasket had been damaged by the machine shop, no biggie wish they had told me, but I had a spare, removed the cover and proceeded to turn the cam ( NO head bolts are in at this time) maybe 180the degrees of rotation later the rockker springs forced the intake rear shaft out of the head. Keep in mind this was after i had lightly tapped the intake front rocker shaft to move the rear one so I could put the head bolts through. I put the head back on the block and held the rear intake rocker shaft with my finger and put the headbolts in, still, the rockers sat over the edge of the cam lobes on cylinders #4,5 and 6. I am very confused as the other ocker shafts did not budge at all with no bolts in their respective holes. I took it back to the machine shop, and they said they can make a spacer to fit on the end of the rocker shaft plug underneath the rear cover. Could this be detrimental to oil flow in the rear part of the head? It is just to hold the rocker shaft in place so the rockers them selves will be held in the middle of the cam lobes and so I can also put the head bolts in as well, thoughts? I am very frustrated as to why only this shaft is not staying where the others stay just fine.

when I had unwrapped the cylinder head, I almost immediate ly put it on the block. When I had about half of the bolts in, I noticed ALL of the eccentrics were not facing the right way. No bolts were torqued down, just barely finger tight. So I took the head off, and proceeded to turn the cam so I could relieve spring pressure on some valves. I stopped when I noticed the rear cover gasket had been damaged by the machine shop, no biggie wish they had told me, but I had a spare, removed the cover and proceeded to turn the cam ( NO head bolts are in at this time) maybe 180the degrees of rotation later the rockker springs forced the intake rear shaft out of the head. Keep in mind this was after i had lightly tapped the intake front rocker shaft to move the rear one so I could put the head bolts through. I put the head back on the block and held the rear intake rocker shaft with my finger and put the headbolts in, still, the rockers sat over the edge of the cam lobes on cylinders #4,5 and 6. I am very confused as the other ocker shafts did not budge at all with no bolts in their respective holes. I took it back to the machine shop, and they said they can make a spacer to fit on the end of the rocker shaft plug underneath the rear cover. Could this be detrimental to oil flow in the rear part of the head? It is just to hold the rocker shaft in place so the rockers them selves will be held in the middle of the cam lobes and so I can also put the head bolts in as well, thoughts? I am very frustrated as to why only this shaft is not staying where the others stay just fine.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin

I can't think of why it would be a problem, but why do it when all you have to do is wiggle and push the shaft while you run a bolt down. You don't have to torque it, just run a head bolt down and it should locate it.

And it doesn't strike me as odd that 3 stay in position and one moves, it's kind of random as long as the head isn't warped much.

And it doesn't strike me as odd that 3 stay in position and one moves, it's kind of random as long as the head isn't warped much.

-

VW+bimmer=bliss

- Posts: 850

- Joined: Nov 25, 2007 10:18 PM

- Location: Racine, Wisconsin