Looked into the bottom end shells and big end bearings

Not good, slighty worn and will need to be replaced, so ordered they were.

Cleaned up the face with wet'n'dry and taped up.

Removed the shells and crank and pistons

And left it at that.

I started on giving the block a good clean with degreaser and a wire brush attachment onto an electric drill.

All the surface rust and 20 year oil was removed, then washed down with warm soapy water and left out in the sun to dry off.

Then, sprayed Black, covered up all the water inlets, oil inlets, and masked off the block face with masking tape.

The eagle eyes ones will notice the core plugs painted too, don't worry, they;re getting replaced too, just didn't want to replace them sooner, then have to mask them up while spraying the block.

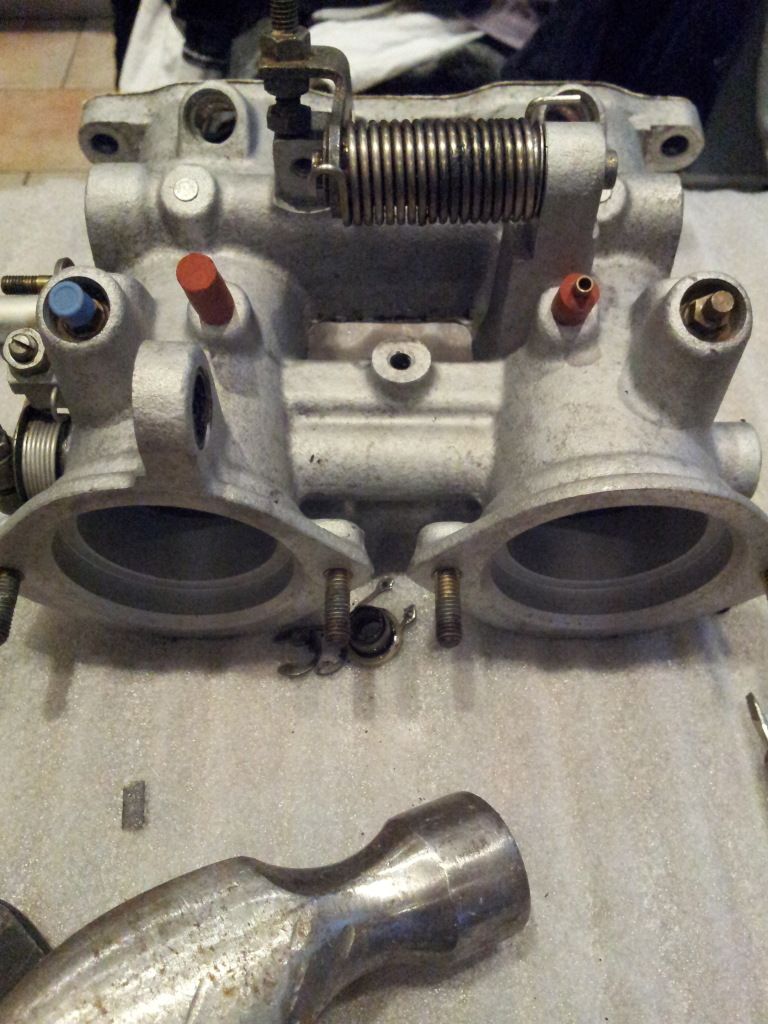

Bought a new proper Dremel 300 this morning{Bluepoint (Snap On) gave up the ghost)

as I wanted to polish the ports.

Thought about it last night and for the hassle, I thought it was worth a bit of effort.

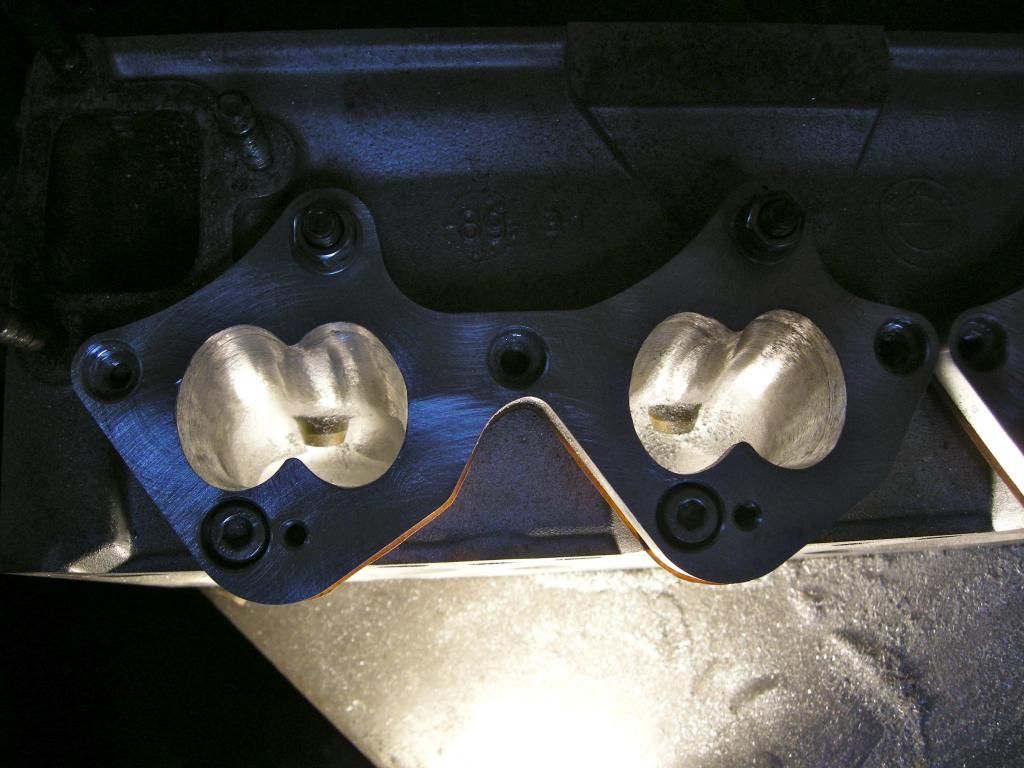

Pics below of the inlet ports, before and after.

Pics aren't the best though.

I'll take some better ones tomorrow.

After

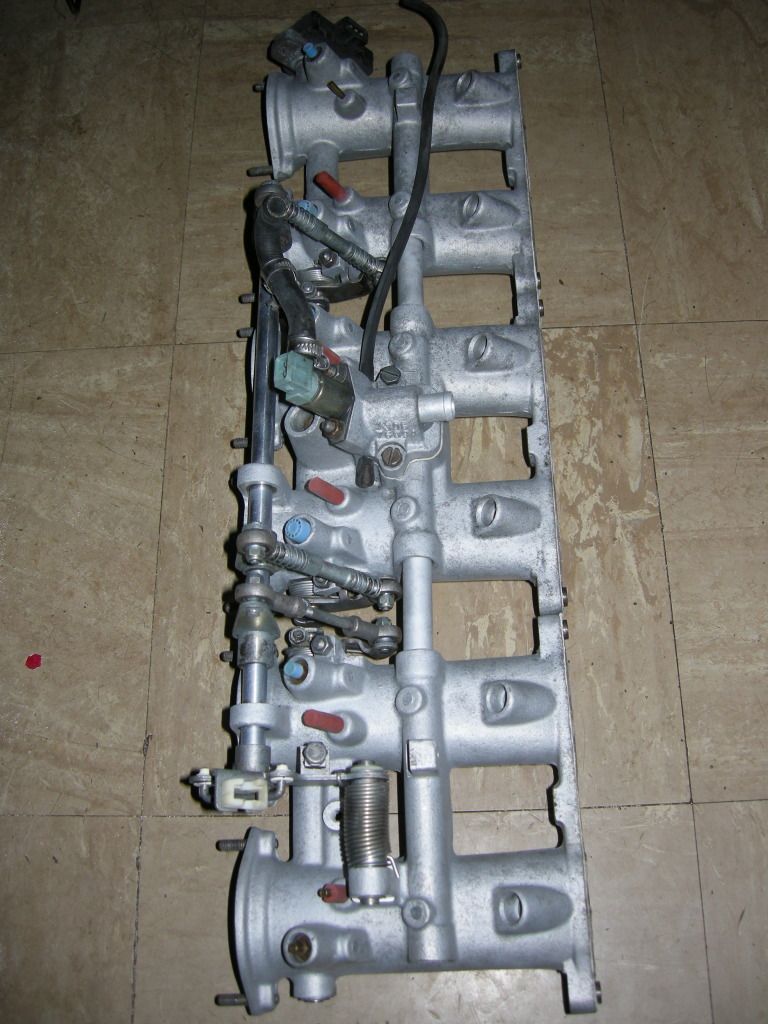

These turned up today too.

Adaptors for the ITB's

Sent off a few items to be soda blasted including the throttlebodies, so hopefully should be back soon.

Had the block honed today too, needed doing as there was slight scoring on a few of the bores.

Had a load of parts Soda and media blasted to get rid of all the oil and wax on the parts.

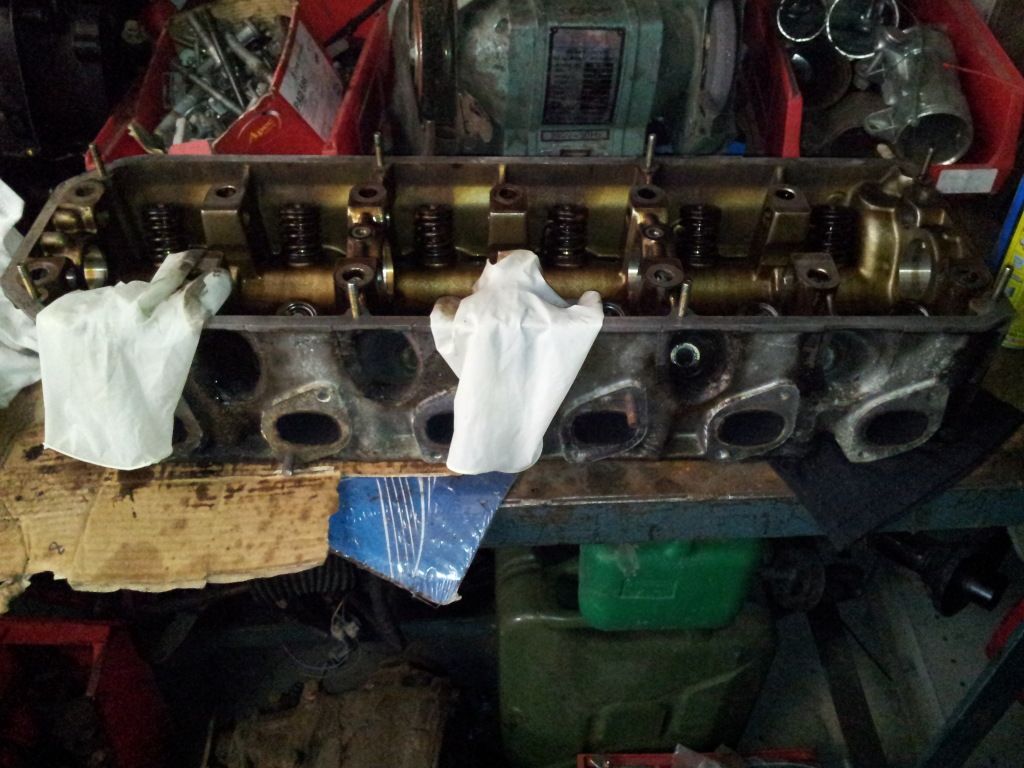

The ITB's were like this

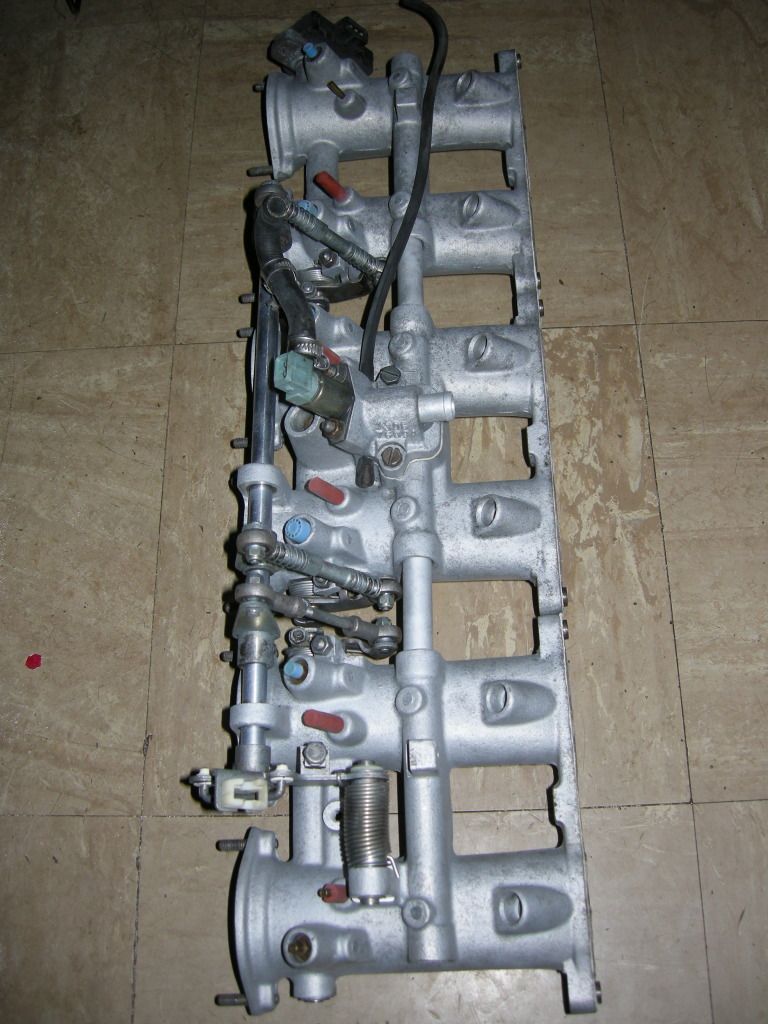

To this

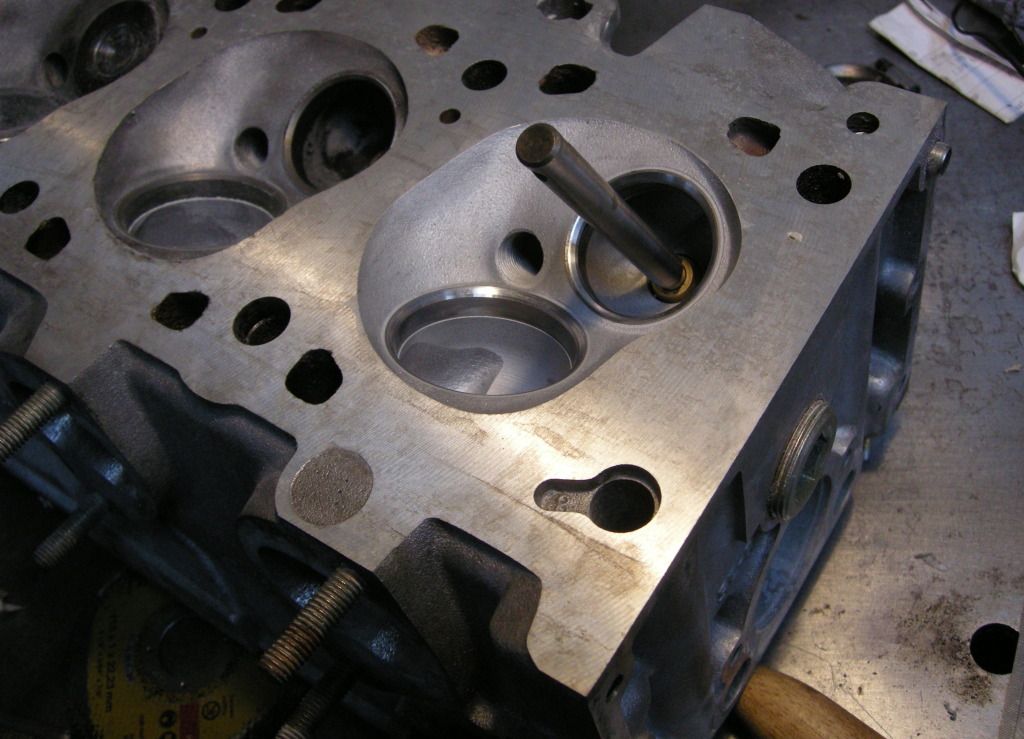

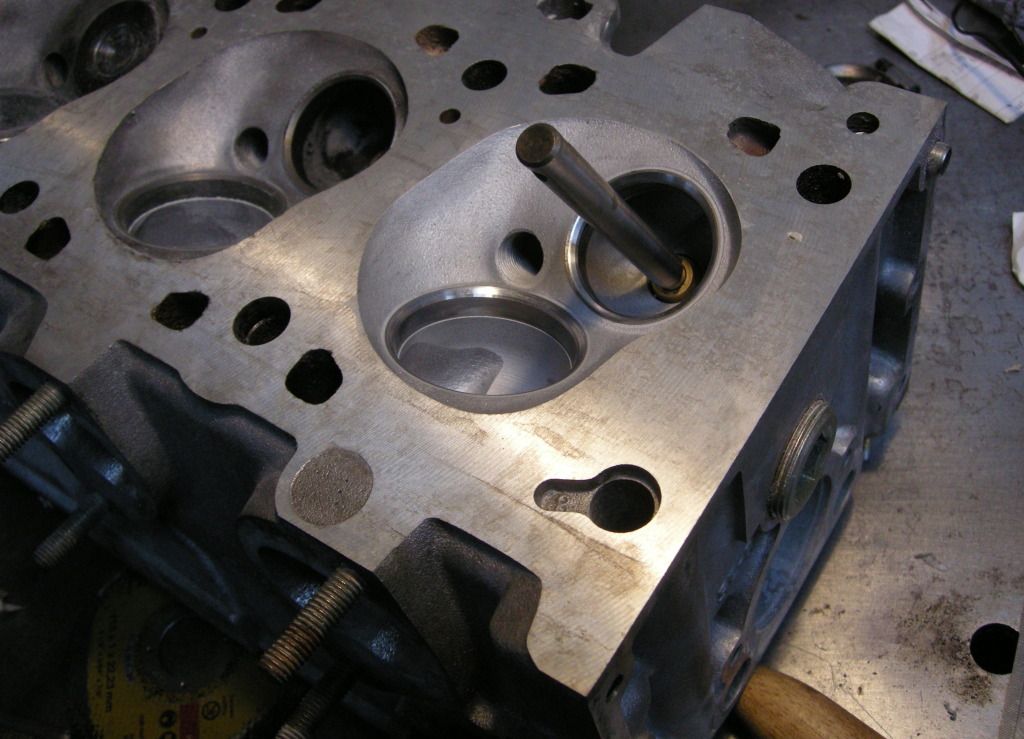

Also, had some head work done in the last few weeks too, thought it would be nice to treat it to a better flow

Had the seats and vlaves cut to 3 angled finishes.

Next new seats, cutter pilot installed.

The first cut at 60* is the bottom cut.

Followed by a 30* top cut, then the seat cut, both are on a double sided cutter. The seat cut is at 46* the two faces will bed in together within the first moments of the engine being started.

This is what you end up with after it has been soda blasted, and all the cuts finished.

A before and after, not alot of difference really as the head had already been scrubbed, but the soda gives it a nice uniform look and doesn't damage the surface of the alloy.