Noob M30B35 Build

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

I want to be home right now wrenching so bad. But work.

Anything I should know about installing my refurbished driveshaft? I've read Bentley's, Haynes, and the factory repair manual. I don't see anything non-intuitive, but just wanted to make sure.

Anything I should know about installing my refurbished driveshaft? I've read Bentley's, Haynes, and the factory repair manual. I don't see anything non-intuitive, but just wanted to make sure.

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Its a lot easier if your rear wheels are free and the car is in neutral, so put your jack back there. I wrote up a thing on how to pull a driveshaft in 15 min or so. I have gotten very good at it. Don't forget to pre-load the center support bearing before tightening it. Simply push it forward a quarter inch or so.

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Did you take the cap off of the reservoir?

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Yes, I had my son watching for bubbles...wkohler wrote:Did you take the cap off of the reservoir?

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Is this a reverse bleeding thing?

I think that slave can be salvaged.

I think that slave can be salvaged.

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

I use this and am successful 100% of the time. I just replaced a slave and clutch line and brake master, calipers etc and no issues.

MV6835 Vacuum Brake Bleed Kit

MV6835 Vacuum Brake Bleed Kit

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

How can it be salvaged if it squirts fluid when under pressure?demetk wrote:Is this a reverse bleeding thing?

I think that slave can be salvaged.

-

trevmmeister

- Posts: 847

- Joined: Mar 02, 2014 9:20 PM

- Location: Newnan, GA

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

something wasnt right, is metal line from the bottom of the master down to the slave twisted or kinked? was the master cylinder attached to the pedal correctly and pulled up, not compressed to the floor? only two things I can think of that would have restricted flow.

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

All you did was push the piston rod out of the bore. There is a rubber cup attached to the piston rod that does the real pressure work. That diaphragm is just weather protection. Easy to take it apart and see how simple the design is. Push the piston back in without tearing the rubber cup and you're good to go.cek wrote:How can it be salvaged if it squirts fluid when under pressure?demetk wrote:Is this a reverse bleeding thing?

I think that slave can be salvaged.

We all have to do this at least once. Here's mine,

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Haha. I pulled it apart just before you posted that...I see what you mean. Why do I continue to be surprised with how simple this stuff can be.demetk wrote: We all have to do this at least once.

Still don't know where the blockage is....

-

Kyle in NO

- Posts: 17638

- Joined: Feb 12, 2006 12:00 PM

- Location: Nasty Orleans------> Batten-Rooehjch------>More Souther LA

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Is the clutch pedal all the way up while you are doing this? If not...

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

Kyle in NO wrote:Is the clutch pedal all the way up while you are doing this? If not...

There's my follow-up question.

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

I think the first time I tried it, I must have had the pedal depressed. The slave was in the transmission.

Then, after I had to pull the tranny off to fix the water leak, I decided to use the time to bleed the clutch. I had the pedal out, but.... the slave wasn't in the transmission. Nothing was holding the piston back. So the piston pushed out into the boot and from there it was all down hill.

After pulling both slaves apart I've decided the one that was in the car is perfectly fine. It's a higher quality housing, the weather seal is in great shape, and the piston is tight.

I installed it in the transmission (oh, yea, I've got the transmission & headers back on after getting a new gasket today for the gooseneck... and, yes, I used #3 permatex and anti-seize). WIth it in the transmission and the pedal out I made progress! My son has abandoned me for the night so I don't have him to watch the overflow, so I just did it part way. But now the clutch actually works!

Now I know.

New gasket with #3.

I also got torq bolts to replace the allen head bolts the PO had installed.

I re-filled coolant/water and bled the cooling system. Then we removed the spark plugs and used the starter to turn the motor a bunch.

No leaks. Yay.

I have an issue with my UUC shifter kit. It has a defective part. I was going to just live with it, but this delay caused me to call them. A replacement part will be here tomorrow. This means I can't put the drive shaft in tonight.

I won't be able to wrench tomorrow, until late at night, if at all, so first start wont' happen until thursday night at the earliest now.

I'm going to button a few more things up tonight...

Then, after I had to pull the tranny off to fix the water leak, I decided to use the time to bleed the clutch. I had the pedal out, but.... the slave wasn't in the transmission. Nothing was holding the piston back. So the piston pushed out into the boot and from there it was all down hill.

After pulling both slaves apart I've decided the one that was in the car is perfectly fine. It's a higher quality housing, the weather seal is in great shape, and the piston is tight.

I installed it in the transmission (oh, yea, I've got the transmission & headers back on after getting a new gasket today for the gooseneck... and, yes, I used #3 permatex and anti-seize). WIth it in the transmission and the pedal out I made progress! My son has abandoned me for the night so I don't have him to watch the overflow, so I just did it part way. But now the clutch actually works!

Now I know.

New gasket with #3.

I also got torq bolts to replace the allen head bolts the PO had installed.

I re-filled coolant/water and bled the cooling system. Then we removed the spark plugs and used the starter to turn the motor a bunch.

No leaks. Yay.

I have an issue with my UUC shifter kit. It has a defective part. I was going to just live with it, but this delay caused me to call them. A replacement part will be here tomorrow. This means I can't put the drive shaft in tonight.

I won't be able to wrench tomorrow, until late at night, if at all, so first start wont' happen until thursday night at the earliest now.

I'm going to button a few more things up tonight...

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

I'm SHOCKED! SHOCKED! A UUC kit with a defective part. Unheard of.

Re: Noob M30B35 Build. 2014-07-07: I Effed up. Twice.

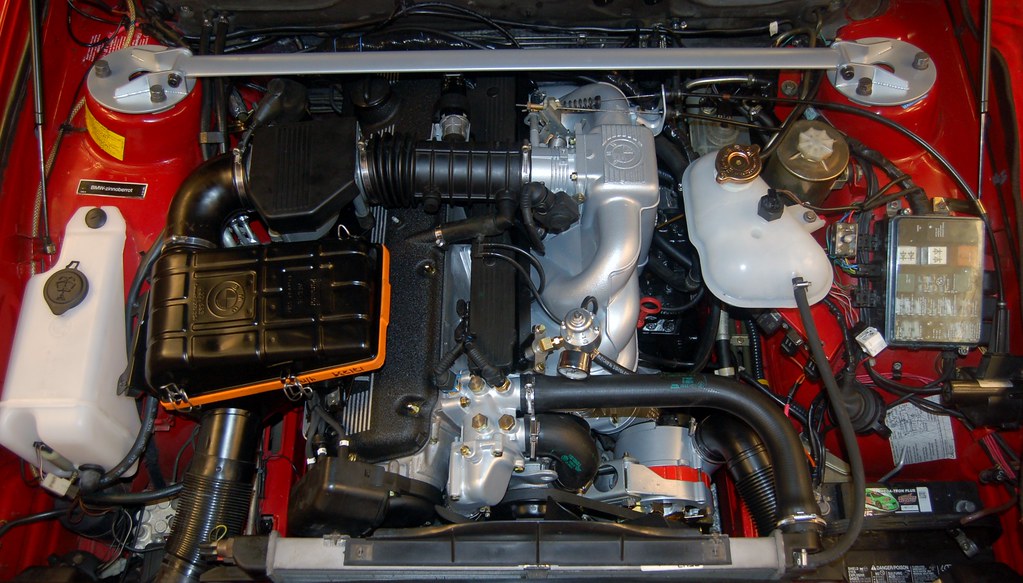

Updated To-Do List:

- Mount the B35 coil (DONE).

- Put new coolant overflow tank in and connect (DONE).

- Tighten belts (DONE).

- Attach fuel hose from tank to rail (DONE).

- Connect new grounds for wiring harness on RHS (DONE).

- Put new wiper tank in and connect (DONE).

- B35 bellhousing has hole w/ plastic cap. Plastic cap wants to fall out. Buy cap at Ace hardware that fits! (DONE)

- Install short-shift kit. (DONE)

- Install lightened & balanced flywheel and new clutch. (DONE)

- Have beer. Watch Sounders game. (DONE)

- Put radiator back in. (DONE)

- Final attach AFR (waiting for the UPS man for some brass fittings). (DONE)

- Splice in new O2 sensor using connector bimmerguy got me (DONE)

- Re-do (+) battery connections. Charge battery. (DONE)

- Shift knob, etc... (DONE)

- Fill coolant. (DONE)

- Fill break-in oil; manually turn crank? (DONE)

- Install plugs. (DONE)

- Put air filter housing in. (DONE)

- Put in 179 ECU and plug it in. (DONE)

- Fill brake fluid; bleed. (DONE, sort-of)

- Fill PS fluid. (DONE)

- Finish removing transmission. (DONE)

- Figure out why gooseneck is leaking. (DONE)

- Install new gasket (Ordered, will be her tomorrow) (DONE)

- Attach transmission. AGAIN. (DONE)

- Attach headers. AGAIN. (DONE)

- Reattach steering support bar, etc... AGAIN. (DONE)

- Install powder coated strut brace (DONE).

- Tighten steering column nut (DONE)

- Straighten steering wheel (DONE)

- UUC is sending me a replacement part for the short-shift kit; what they sent me would work, but it was clearly defective. Should be here tomorrow.

- Install rebuilt driveshaft, new guibo.

- Reinstall exhaust. (once the car is drivable I'm taking it into a shop and having the exhaust rebuilt)

- Final bleed clutch

- Put fuel in tank.

- Test fuel pump.

- Cross fingers and start it up. 20 minutes, then re-torque head bolts.

- Have beer.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

It *looks* good. Hope things progress without further issues. Hope you're learning a lot, too!

Re: Noob M30B35 Build. 2014-07-08: Back on track.

I think it looks good too. Will look better when I have time to invest in putting in the E34 air filter housing.wkohler wrote:It *looks* good. Hope things progress without further issues. Hope you're learning a lot, too!

Fingers are crossed that there are no more issues. But there are so many things I could have done wrong with the wiring... I tested the heck out of everything; double and triple checked. But so many things...

I am learning a lot. Tons. Sometimes only once, too.

It's amazing how much easier it was putting that transmission in the 2nd time

Re: Noob M30B35 Build. 2014-07-08: Back on track.

I guess put me in the minority on the B35 airboxes. I think they really look out of place in the E28.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

So do E34 Sport Seats, right?wkohler wrote:I guess put me in the minority on the B35 airboxes. I think they really look out of place in the E28.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

Yes. May as well go all the way then.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

I'm going to be selling the B34 I pulled out of Vlad. It's a great engine, but I have no idea what I should ask for it. Here's what I know.

- Came out of a 1987 535is 5-speed with 177K miles, for no good reason.

- Recent dyno results at 176K miles on 4/11/14: 172.72 rwhp / 188.01 rwtrq @ 5500 rpm.

- PPI at 170K miles showed compression of 175, 150, 175, 175, 175, 175

- Burns 1qt of oil every 1500-2000 miles.

- Plugs, cap, rotor, plug wires all replaced (Bosch) at 172k.

- Blackstone Oil Analysis done at 177k. "Lead was a little high in this sample, but everything else looks great. Universal averages show

typical wear for the 3.4L BMW M30 engine after ~4,300 miles on the oil. Your run was a bit longer, and most

metals fell in line accordingly. We expect iron to track directly with time on the oil, and the other metals

should stay pretty close to average even if you run longer on the oil next time. No contamination was found

in the sample, and the oil was physically in good shape, so we don't see any reason why you can't go longer

on the next oil. Try 7,000 miles and check back." - PO (87k miles - 172k miles) was more anal retentive than even I. Fed nothing but top grade oil. I use Brad Penn.

- Pulled from car with care. Nothing cut.

- Includes PS pump, 90A alternator (new regulator), B34 wiring harness, injectors, plugs, and 059 ECU.

- Does NOT include fan, AC compressor, AFM, intake boot, or air cleaner assembly.

- PO had oil pump, tension rail, timing chain, oil pump chain, tension piston, chain tensioner, sprocket cams all replaced at 112k due to "Oil pressure problem"

- PO had oil pump tensioner replaced again at 167K miles.

- Needs: Starter (solenoid fails to engage 25% of time).

- Wants: Rear main seal might be leaking (oil pressure sender definitely was, but that was fixed...no leaks after, but that was for only about 200 miles).

- Wants: Head gasket WAS leaking at intersection of head & timing covers. This was fixed with some externally applied FPIG gasket maker and a tightening of the timing cover bolts. No leaks in 2000+ miles.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

While putting the transmission in my son & I noticed that the lower hole for the starter bulge had no bolt. I scratched my head on this. I am 100% certain that I did not lose any of these bolts. When I put it on the first time, I just didn't notice that hole (it's hard to see looking down the transmission tunnel) and since I had no extra bolts it never occurred to me to look harder. But the 2nd time around, with my son present, I noticed.

I think that when the PO's mechanic had the transmission off (at 91k miles) "Clutch kit - surface flywheel, helicoil" at "Hei-mac Motors, Goleta, CA" they not only put on the stupid allen bolts for the top two bolts, but DIDN'T put this one bolt in.

Might have been good enough for this car for the last 85k miles, but not good enough for me. Glad BMW of Bellevue had one (literally, they had only one) in stock.

I think that when the PO's mechanic had the transmission off (at 91k miles) "Clutch kit - surface flywheel, helicoil" at "Hei-mac Motors, Goleta, CA" they not only put on the stupid allen bolts for the top two bolts, but DIDN'T put this one bolt in.

Might have been good enough for this car for the last 85k miles, but not good enough for me. Glad BMW of Bellevue had one (literally, they had only one) in stock.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

Add me. I'm thinking the stock airbox looks in keeping with the engine. Less new car plastic molded refrigerator parts looking and more of that lightweight aluminum (almost air craft style) hardware appeals to me. I hate the look of some new cars with a big plastic cover over almost everything like Acura does for example.wkohler wrote:I guess put me in the minority on the B35 airboxes. I think they really look out of place in the E28.

Build looks almost like it came from the factory.

You know you will also need to swap to green coolant instead of blue to keep that factory look going.

Re: Noob M30B35 Build. 2014-07-08: Back on track.

Gonna start her up in maybe an hour. Putting exhaust on now!

I have a startup/break-in proceedure from my machinist. I'd like to get a few more perspectives from others who've done it. Can those of you with experience building new BMW engines chime in with how you break them in?

I have a startup/break-in proceedure from my machinist. I'd like to get a few more perspectives from others who've done it. Can those of you with experience building new BMW engines chime in with how you break them in?

Re: Noob M30B35 Build. 2014-07-08: Back on track.

F**k yea!!!

It started the first time!

Running at 2k RPM for 30 minutes now.

Sounds SMOOTH!

F**k yea!!!!

It started the first time!

Running at 2k RPM for 30 minutes now.

Sounds SMOOTH!

F**k yea!!!!

-

Mark 88/M5 Houston

- Posts: 8548

- Joined: Feb 12, 2006 12:00 PM

- Location: Far North Houston

Re: Noob M30B35 Build. 2014-07-10: F*ck yea! Started 1st tim

Very satisfying when a new motor fires off properly, Congrats!

Re: Noob M30B35 Build. 2014-07-10: F*ck yea! Started 1st tim

Mostly all good news.

After the first start we noticed it was surging at idle. At first I thought it was the intake boot not being on all the way. After it was warm it was better, but I'm wondering if the coolant temp switch is wired backwards (see above :0)).

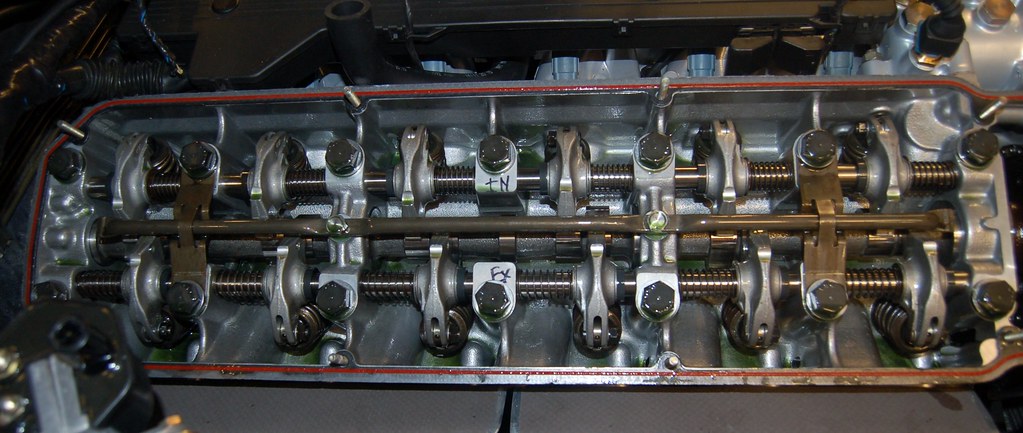

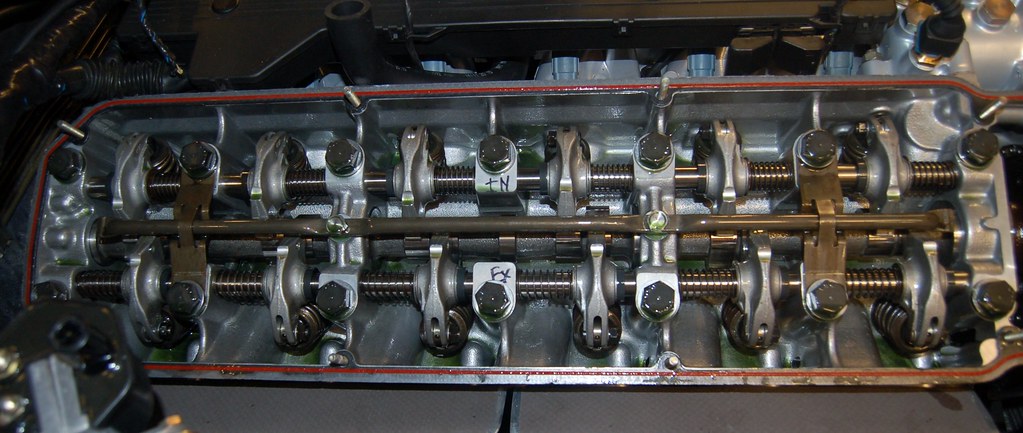

We ran it for 30 minutes at 2k RPM as my machinist said we should. Then pulled the valve cover gasket to adjust the valves and final tighten the head bolts.

Looking over all the cam lobes and rockers and everything looks nice and lined up. It's clear that oil is circulating nicely.

We drained the break-in oil and re-filled it with Brad Penn.

Then I noticed that I had pulled the #6 plug wire apart when I pulled the plugs out to take the valve cover gasket off (the headers were still hot and I didn't want the plastic cover falling down there so I pulled the plugs). Ooops. Bad move.

Fortunately the ends of theses plugs just press into the ends (which seems really odd, but ok), so the fix was easy. But it was a nervous bit because #6 has the induction coil that feeds the timing reference sensor.

After it was all back together it started fine but now seems to be running richer and really wants to stall anytime it's below about 1000 rpm.

We went for a 30 minute drive, keeping RPM below 3500, I had to keep my foot on the throttle to keep it from stalling at stop signs and stuff. Not sure what's going on as I've never had this symptom before.

It pulls very strong; the butt dyno is very, very happy. Smooth power all the way to 3500 rpm. Sounds great.

I'm off to search for rough idle and stalling threads (again). Any tips would be appreciated as I really want to drive it to work tomorrow!!!!

After the first start we noticed it was surging at idle. At first I thought it was the intake boot not being on all the way. After it was warm it was better, but I'm wondering if the coolant temp switch is wired backwards (see above :0)).

We ran it for 30 minutes at 2k RPM as my machinist said we should. Then pulled the valve cover gasket to adjust the valves and final tighten the head bolts.

Looking over all the cam lobes and rockers and everything looks nice and lined up. It's clear that oil is circulating nicely.

We drained the break-in oil and re-filled it with Brad Penn.

Then I noticed that I had pulled the #6 plug wire apart when I pulled the plugs out to take the valve cover gasket off (the headers were still hot and I didn't want the plastic cover falling down there so I pulled the plugs). Ooops. Bad move.

Fortunately the ends of theses plugs just press into the ends (which seems really odd, but ok), so the fix was easy. But it was a nervous bit because #6 has the induction coil that feeds the timing reference sensor.

After it was all back together it started fine but now seems to be running richer and really wants to stall anytime it's below about 1000 rpm.

We went for a 30 minute drive, keeping RPM below 3500, I had to keep my foot on the throttle to keep it from stalling at stop signs and stuff. Not sure what's going on as I've never had this symptom before.

It pulls very strong; the butt dyno is very, very happy. Smooth power all the way to 3500 rpm. Sounds great.

I'm off to search for rough idle and stalling threads (again). Any tips would be appreciated as I really want to drive it to work tomorrow!!!!

Re: Noob M30B35 Build. 2014-07-10: F*ck yea! Started 1st tim

Just went for another 10 mile drive. Lovely. Just lovely. I love my new shifter too! And the lightweight clutch. Wow. Zippy.

Won't (always) start without throttle; idle stall.

What I've tried.

Here's the "first start video": https://www.youtube.com/watch?v=oImgDeopk78

Won't (always) start without throttle; idle stall.

What I've tried.

- Changed AFMs to the one that used to be on Vlad's B34. No change.

- Swapped in another ICV. No change.

- Swapped in another ECU. No change.

- Swapped wires on coolant temp sensor. No change. (brand new CTS).

- Checked TPS.

- Vacuum lines are connected.

Here's the "first start video": https://www.youtube.com/watch?v=oImgDeopk78

Re: Noob M30B35 Build. 2014-07-10: F*ck yea! Started 1st tim

Little unclear but I think you are saying it won't run under about 1000 even with some slight throttle input? This makes it sound like a mixture problem and not the idle control system. Best guesses are unmetered air either vacuum leaks or the AFM bypass screw way to far off, possible the AFM spring adjustment also but you've tried switching that already.

Try monitoring the O2 sensor voltage as you let the revs fall and see if it pegs one way, either high or low voltage without dithering could indicate an extreme mixture problem. Generally I think it will sputter and cough if too rich and just falls flat like ignition switched off if too lean. A big old vacuum leak will drive it too lean and it will not run.

Have you got a vacuum gauge you can stick on the manifold and see what you've got there also. That would give a clue since it should run maybe 14-20 range as you approach closed throttle and idle. If it's low it points to vac leak.

Your description of the fuel relay buzzing is also very odd. It should be either on or off. On if the rpm over 20 and off below. I suppose if the relay realy is buzzing on/off/on it could lead to fuel starvation. You might just jump the pumps and see if that makes it run then figure out what up with the fuel relay. Oh and if you are jumping the relay use your DMM and measure the current to the pumps to make sure thay are pulling proper power. Something like 6 amps IIRC.

Try monitoring the O2 sensor voltage as you let the revs fall and see if it pegs one way, either high or low voltage without dithering could indicate an extreme mixture problem. Generally I think it will sputter and cough if too rich and just falls flat like ignition switched off if too lean. A big old vacuum leak will drive it too lean and it will not run.

Have you got a vacuum gauge you can stick on the manifold and see what you've got there also. That would give a clue since it should run maybe 14-20 range as you approach closed throttle and idle. If it's low it points to vac leak.

Your description of the fuel relay buzzing is also very odd. It should be either on or off. On if the rpm over 20 and off below. I suppose if the relay realy is buzzing on/off/on it could lead to fuel starvation. You might just jump the pumps and see if that makes it run then figure out what up with the fuel relay. Oh and if you are jumping the relay use your DMM and measure the current to the pumps to make sure thay are pulling proper power. Something like 6 amps IIRC.