17 Nov 2013:

Gentleman Drivers,

Recently I installed a Miller 3rd gen MAF & WAR chip combo in my E28 M5. I thought I'd describe the install and a few bumps I found along the road. Miller's instruction manual is good, but little bit dated now and some of the installation is different than described.

I'll break up the install into a few different categories since the installation covers a few different areas of the car.

-MAF Installation

-WAR chip Installation

-Wiring modification

-Programing the WAR chip

-Things I didn't know before the project began

-Initial impressions

Below is what Arrived after a decent wait (ordered in August, arrived in early November) as Miller apparently is having a hard time with production keeping up with demand. I think there are worse situations in this world than too much demand!

-Miller WAR chip (quality piece!)

-Millers custom 4" MAF that plugs straight into the old AFM plug.

-4" to 3" silicone reducer made specifically for the gap between the MAF air plenum.

DSC_7534

DSC_7534 by

ericandshovin, on Flickr

The old bits before the tools come out.

DSC_7535

DSC_7535 by

ericandshovin, on Flickr

MAF Installation:

Removing the airbox and AFM is quite simple. Undo two hose clamps, remove the plug connecting the AFM to the engine harness, and undo a 10mm nut on the right side of the airbox. The most difficult part of removing the airbo/AFM is the coolant return lines get in the way a bit. You can wiggle around them, or just remove the hose connected to the coolant reservoir to gain more access. I am terrible at installing those push lock hose clamps, therefore I elected to wiggle the whole assembly around the small coolant lines.

Once you remove the airbox & open it up, you can see exactly what the S38 breathes through in stock form.

DSC_7540

DSC_7540 by

ericandshovin, on Flickr

I didn't want to just go buck-wild with a grinder, so I made a little template using a sharpie and an old document envelope to trace out the MAF. This type of cardboard is thin enough to easily cut, but stiff enough to keep it's form. Cereal boxes work well for templates too.

IMG_3506

IMG_3506 by

ericandshovin, on Flickr

Cut out with a razor blade, and compared to the AFM's gasket.

DSC_7541

DSC_7541 by

ericandshovin, on Flickr

Comparing the template to the original opening it becomes clear that the new MAF is significantly larger than the OE AFM. The internet can argue until it's blue in the face whether or not the S38 should have a 4" MAF or a smaller one. I'm not an engineer and have not studied fluid dynamics so I'll reserve judgment.

DSC_7542

DSC_7542 by

ericandshovin, on Flickr

After the initial cut using a dremel, I was a bit conservative, so a little bit more needed to be trimmed. To cut the metal I used the cutoff wheel to remove a bulk of the metal, and the "561 Multipurpose Cutting Tool" to trim it down to size making sure I kept my fingers well clear of the spinning digit shredder.

DSC_7544

DSC_7544 by

ericandshovin, on Flickr

Once the big hole was cut, I drilled 3 new holes for the bolts to secure the MAF to the airbox, and made a quick trip to Lowe's to grab some new M6 nuts and bolts that were the correct length. Lowes/Home Depot's metric selection is usually quite terrible, but in this instance they had some nice black bolts with washers already attached in the "automotive" drawer. To me, this makes the install look more OEM and draw less attention.

To seal the MAF to the airbox, I used a bit of black permatex gasket maker and bolted it all together letting it sit overnight. I have a 1 year old and a 4 year old so my garage time is usually pretty limited.

IMG_3258

IMG_3258 by

ericandshovin, on Flickr

The next afternoon I put a new BMW air filter in the airbox and got to work sticking it all back together. The neat-o silicone tube is much much stiffer than the rubber boot it replaces, so putting the airbox + MAF + tube was nearly impossible. I found that if you shoved the 4" side as far up the MAF as possible (past the moulded in stops) it helped tremendously. To get the 3" side onto the air plenum I did my best shoving & twisting the tube onto the intake opening until most of it was on. Then I pulled out my harbor freight dental pics and started pulling and prodding the last bit of the silicone tube onto the air plenum. It was not simple since the silicone is so stiff, but with a bit of determination, It finally slipped on.

I was a bit short on pictures for the installation, but here is the finished product. Also, notice the coolant temp sensor hanging off the side of the radiator. If you get too rough with wedging the airbox back in it's spot, this can crack the radiator resulting in an expensive mistake.

DSC_7598

DSC_7598 by

ericandshovin, on Flickr

Now the astute reader might notice that the plug for the MAF is on the opposite side compared to the AFM plug. As you can see below, there is not enough cable to easily connect the MAF to the factory harness. Pulled very tight it will physically connect, but I do not trust it as a long term solution.

DSC_7600

DSC_7600 by

ericandshovin, on Flickr

So a trip to the U-Pull-N-Pay junkyard was in order, and I came up with these guys from a donor E30 325iC. The pin layout for the AFM on the M20/M30/S14/S38 is all the same, so a few snips, a couple of screws removed and my extension cable idea was becoming a reality. As a side note, I found it sad that there was only 1 80's vintage BMW in the lot. 5 years ago old BMW's in yards was much more popular.

DSC_7546

DSC_7546 by

ericandshovin, on Flickr

A bit more of Dremel "561 Multi Cutting Tool" trimmed down the AFM side connector, a terrible attempt at soldering, and some harbor freight heat shrink resulted in this little beauty.

DSC_7603

DSC_7603 by

ericandshovin, on Flickr

And here is the final product tucked in nice an happy.

DSC_7604

DSC_7604 by

ericandshovin, on Flickr

WAR Chip Installation

Moving on to replacing the factory 28 pin e-prom that controls fuel & timing tables with the sophisticated WAR processor. This process is no harder than replacing the factory chip with a Mark D or Conforti chip, but it does have a few extra steps that isn't needed with a conventional chip replacement .

The WAR chip is not specific to the S38 or any other engine like a normal performance chip would be. To make the chip unique to your motor, you must load tunes onto it using the supplied USB cable and software provided by Miller (more on that later). You can load the tunes either before or after the chip is installed in the ECU.

Pulling the ECU is pretty straight forward. Open the glove box, remove the leather flap to expose the ECU. Remove the four 10mm bolts holding the ECU to the dash, and disconnect the wire harness by pushing on the silver metal tab on the firewall side of the ECU (grab a flashlight if you cannot feel it).

Once the ECU is out of the car, use a small flat head screw driver to pry the 10 tabs up.

DSC_7569

DSC_7569 by

ericandshovin, on Flickr

Once I get them up a bit, I use a set of needle nose pliers to pull them straight up. You can accomplish the same results with just the screwdriver, but this is easier. Caution that the tabs aren't bent too far back as they can break easily.

DSC_7570

DSC_7570 by

ericandshovin, on Flickr

The circuit board is visible once the cover is removed and you can see that it is actually two separate boards with a bit of ribbon cabling connecting the two. The chip is on the top board, so separating the boards is the next step. No need to remove any screws, just pop the little plastic stanchions on either side of the ribbon cable. Place your fingers on either side of the stanchion and gently apply pressure up and down evenly until it pops, then move to the next one. Being delicate here is important since these parts are NLA.

Before:

DSC_7575

DSC_7575 by

ericandshovin, on Flickr

After:

DSC_7576

DSC_7576 by

ericandshovin, on Flickr

Next, you need to depress the two tabs holding the circuit board up against the black plastic connector housing. Here you can see the tabs after the circuit board has been removed.

DSC_7578

DSC_7578 by

ericandshovin, on Flickr

These are the tabs before removing the circuit board. To release them, use your flathead screwdriver and depress one while simultaneously gently prying the edge of the circuit board away from the black plastic connector housing. This is where a third hand comes in handy.... While maintaining enough pressure to prevent the tab from snapping back into it's place, depress the other tab and gently pry the other side of the circuit board.

DSC_7595

DSC_7595 by

ericandshovin, on Flickr

Once both tabs have been depressed pull the circuit board away from the black plastic connector housing to reveal the guts of your ECU! As you can see my car was already running the Jim Conforti/Turner Performance chip. A solid upgrade in it's own right and much better than the Dinan chip that was previously in the car.

DSC_7579

DSC_7579 by

ericandshovin, on Flickr

Gently pry the chip out of it's socket taking care not to bend any pins. Then place the Miller WAR chip in the old chips place. There is a 1/2 circle notch on the WAR chip that needs to be lined up with the 1/2 circle detent on 28 pin receptacle. Both the notch and the detent are visible in the picture below

DSC_7585

DSC_7585 by

ericandshovin, on Flickr

Now your war chip is installed! At this point you can either button everything back up (basic reverse of disassembly) and the WAR chip will function like the chip you just replaced running solely on the default map (we'll get into that later) or you can hook up the cables to truly get the maximum potential out of the WAR chip.

DSC_7586

DSC_7586 by

ericandshovin, on Flickr

Two cables accompany the WAR chip. A USB cable that allows you to hook a Windows XP laptop up to the chip and a TCM (Tune-Control-Module) knob that allows you to select 4 different tunes. Plug the cables into the designated ports on the WAR chip as shown below.

MINI USB:

DSC_7587

DSC_7587 by

ericandshovin, on Flickr

TCM:

DSC_7588

DSC_7588 by

ericandshovin, on Flickr

Together (playing around with my 50mm 1.4 lens...)

DSC_7589

DSC_7589 by

ericandshovin, on Flickr

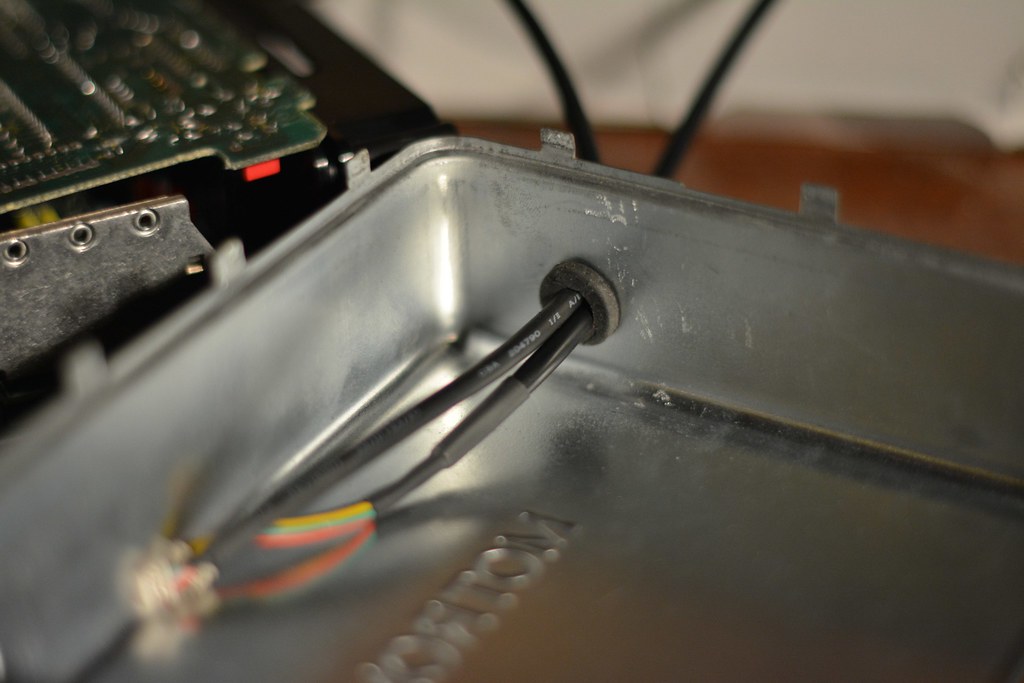

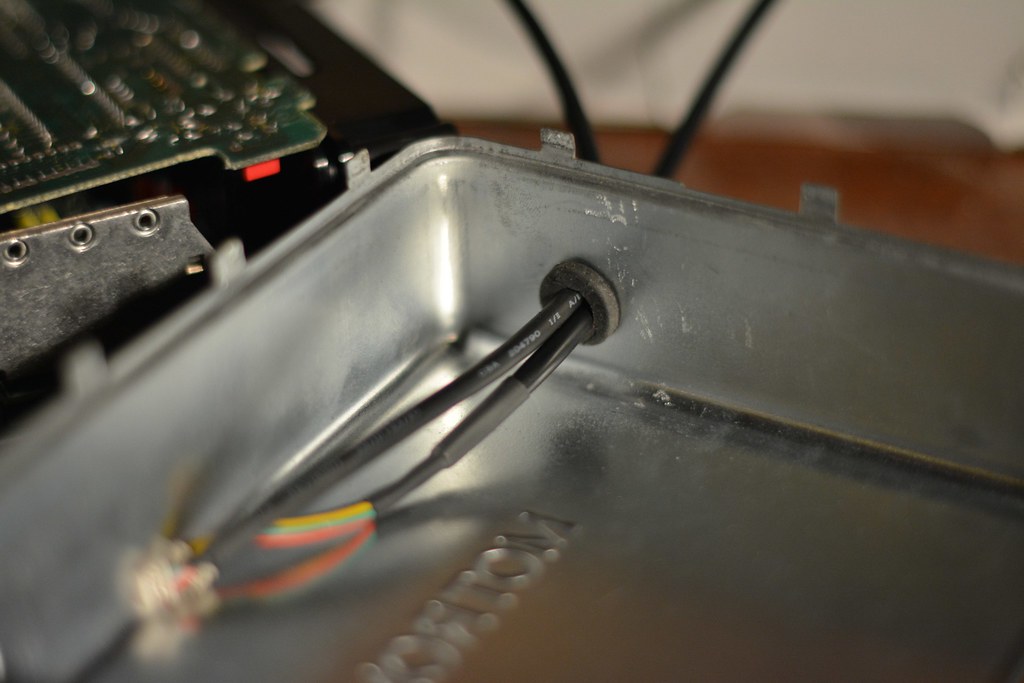

However these cables do no good if they are not accessible. To be able to actually use them, you need to drill a hole in the side of the metal ECU case. Another trip to Lowe's netted these nice rubber grommets to keep the wiring from chaffing on the metal case. Miller sells a grommet for about a buck which is probably a better piece than my Lowe's one.

DSC_7592

DSC_7592 by

ericandshovin, on Flickr

I chose to drill the hole in the back of the case as that seamed like a less congested area of the circuit boards. Routing the wires in the most direct configuration didn't look that good to me as it would be resting on different components that more than likely get quite hot. Once I drilled out the hole to the appropriate size, installation of the circuit board and case was a simple reversal of disassembly. The extra wiring made it slightly more cumbersome but not difficult.

Wiring modification

The final piece of the puzzle before you can put it all back together involves a bit of soldering. It is not difficult, but does require permanent modification to the wire harness. Take your time reading Miller instruction manual and double checking that you are cutting/modifying the correct wires!

The large connector that the ECU plugs into needs to be modified a little bit to ensure the MAF talks to the ECU correctly. Millers directions work well here, but their pictures are from a different car.

To remove the cover and expose the wire harness, first remove the small screw at the end of the harness, then clip the zip ties at the back of the harness where the plastic cover meets the factory electrical tape. 223,000 miles of use made my tape a bit stubborn and I had to persuade it with a box cutter to free up the plastic cover.

Once the cover is free you need to slide it away from the harness and the pin-out area. I put my flathead screwdriver in the gap between the pin-out and the cover and pry'd it apart a little bit. Below you can see the opening that is created as the cover starts to slide.

DSC_7555

DSC_7555 by

ericandshovin, on Flickr

Slowly work the cover off until it slides completely off.

Once you have removed the cover you need to locate two cables. One is located at pin 9 and the other is pin 35. Miller specifies multiple times that the wire color is often what they described, but not always. My S38 powered M5 was exactly as they described.

Pin 9 is usually a grey/white wire

DSC_7558

DSC_7558 by

ericandshovin, on Flickr

And pin 35 is red/blue (note, another wire nearby looks similar but is blue/red so ensure you get the correct one!).

DSC_7568

DSC_7568 by

ericandshovin, on Flickr

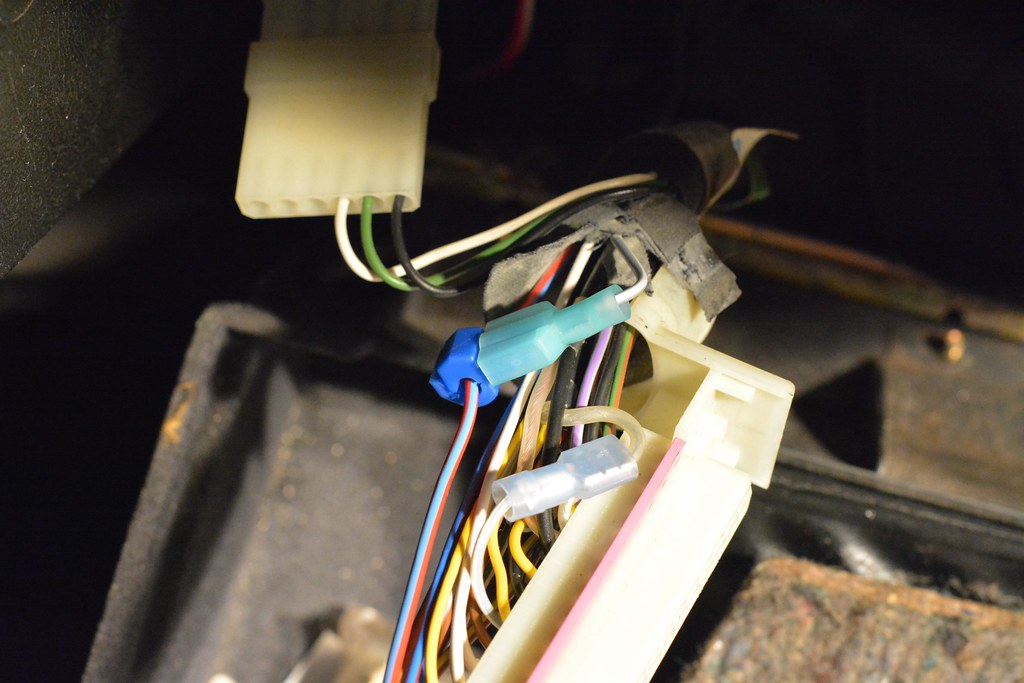

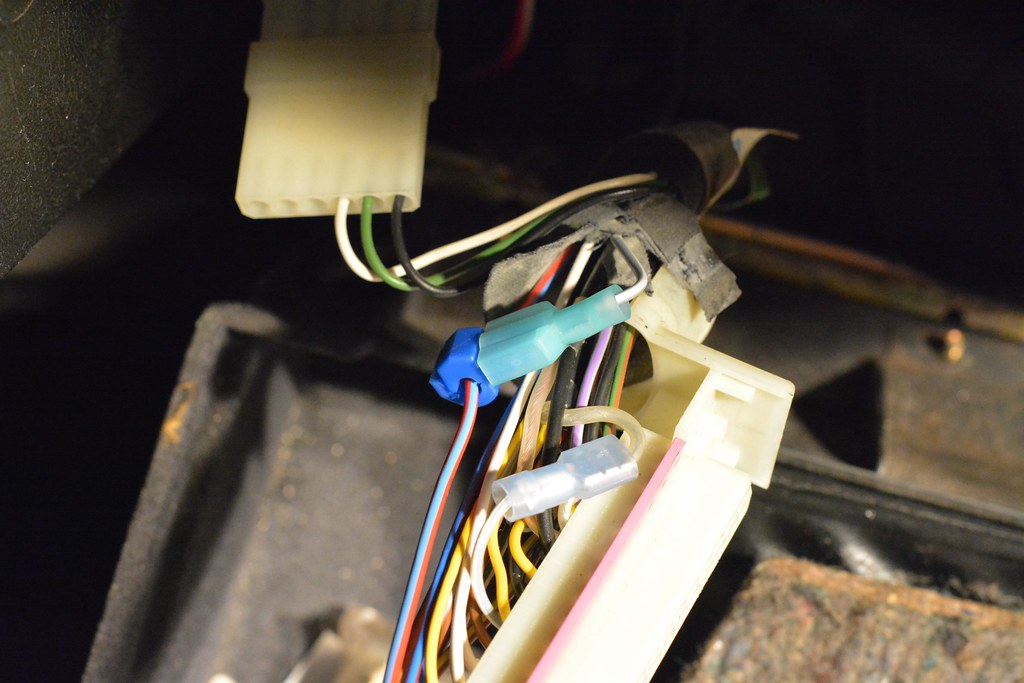

After you locate the wires highlighted above, cut the wire that belongs to pin 9 and connect it to the wire that belongs to pin 35. I used a t-joint and a crimp connector to make the wiring modification because I plan to dyno tune the car in a month or so. During the dyno session I plan on reverting the car back to stock to see if there is a measurable difference between stock/Miller MAF/custom dyno tuned Miller MAF.

DSC_7567

DSC_7567 by

ericandshovin, on Flickr

The above method works, but is FAR to bulky to allow the plastic cover be re-installed and I will be soldering this connection together after the dyno session has happened.

Once you have finished the solder job and taped up the new joint, put everything back the way you found it ensuring none of the wiring becomes pinched as you put the cover back on. Reconnect and reinstall the ECU as this part is finished!

[

b]Programing the WAR chip[/b]

I am not a huge computer person. Not to say that my googlefu isn't impressive, I'm just not that great with software anomaly resolutions. Once I acquired a laptop and installing the appropriate programs, I was able to pull up Millers software program and create my own chip.

I set the ECU type to the S38's 079, and loaded 4 tunes. Miller has a few video's tutorials that explain how to program the chip as well as how to modify it. I'd highly recommend you watch their vids as it really helps out!

Things I didn't know before the project began

I thought I had done my due diligence before beginning this project, and although I read the S38/M88 installation instructions on Millers site & many articles on forums; I still found a few things that bothered me a little bit with the kit.

-Miller states, "You may need to trim the opening to get the full 4” benefits."

--Trimming is an understatement! So much of the airbox was cut away, I will no longer be able to use it if I wanted to revert back to the stock AFM. If for some reason I ever want to go back to stock, I will need to purchase another airbox.

-Millers MAF instructions show an older (I'm assuming GEN II) normal looking chip in their S38 instruction manual. You must read the Miller WAR instructions for WAR specific instructions.

--It would have been nice if the MAF installation guide reference the WAR instruction PDF for the users that are installing the WAR chip instead of the regular GEN III chip. I thought I had read up on everything pertinent, but I missed a pretty big chunk of useful information!

-Handy links that I wish I had found earlier

S38 MAF install:

https://www.millerperformancecars.com/f ... GENIII.pdf

-WAR chip install:

https://www.millerperformancecars.com/f ... Manual.pdf

-Software tutorials (very helpful to me):

http://forums.millerperformancecars.com ... topic=48.0

-Windows XP computer (laptop) required.

--Since I did not read the WAR instruction PDF until day 3 (kids take up a lot of time) I did not know that only XP computers could be used with Millers proprietary software. I've been virus free on a macbook for the last 4 years, so I was a bit bummed that I'd need to start hunting down an old laptop on craigslist instead of testing out the M5 later that evening. Luckily a co-worker had an old laptop that soon became mine for a delightful $15.

-Java is required

-- If you have recently acquired a co-workers laptop, make sure you have Java installed. Millers software does not work without it...

-MAF plug wrong side.

--I'm sure Miller uses the same MAF for multiple applications, but having to make an extension plug is a bit annoying. An E30 M3 friend of mine says he needed to make the same thing for his install.

Initial impressions

I've driven the car exactly twice since installing the MAF and the car feels pretty good. I don't notice a gigantic increase in power over the AFM/Jim C combo but throttle response does feel quicker. This could be all in my head too, but RPM's seam to fall quicker when lifting.

Currently it's cold here in Colorado, and the car starts and idles nicely with no indication that your running anything other than OEM components. A few of the tunes I have tried out had problems with very small throttle inputs. An example is driving at 50mph with the cruise control on and the grade of the road increases slightly. The car stumbles for a bit before regaining composure. Or at idle, a blip of the throttle causes the RPM to drop and engine stumbles. One of the tunes runs fine, and I haven't messed with the others since.

I'll continue to add to this review as I drive the car more, hopefully with a bit of track time later this month, and a dyno session before the year is over.