I weld

Re: I weld

What did you use to cut all of the steel?

Re: I weld

Since I needed to cut the 6x1/2" stuff, I begged my wife for an early Christmas present. She got me this:bkbimmer wrote:What did you use to cut all of the steel?

https://www.amazon.com/DEWALT-DW872-14- ... =ceklog-20

Which is kinda like cheating. The cuts are not as clean as the Hemsaw, but in retrospect, it's what I should have bought first.

I'll use the Hemsaw for detailed stuff. For quick cuts on big stuff the Dewalt will be my go-to. Until I get a plasma cutter, of course :-()

Re: I weld

Nice, I had to look up hemsaw, I had never heard that before.

I've always wanted a cold saw.

I've always wanted a cold saw.

Re: I weld

I have officially completed my first real welding project. The welding table is DONE.

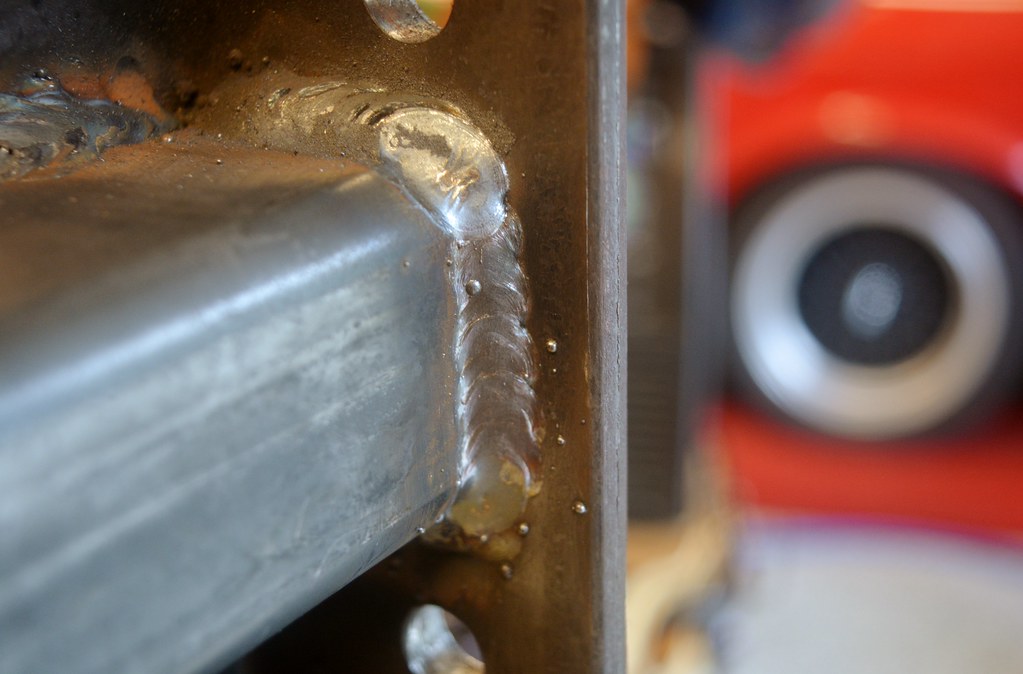

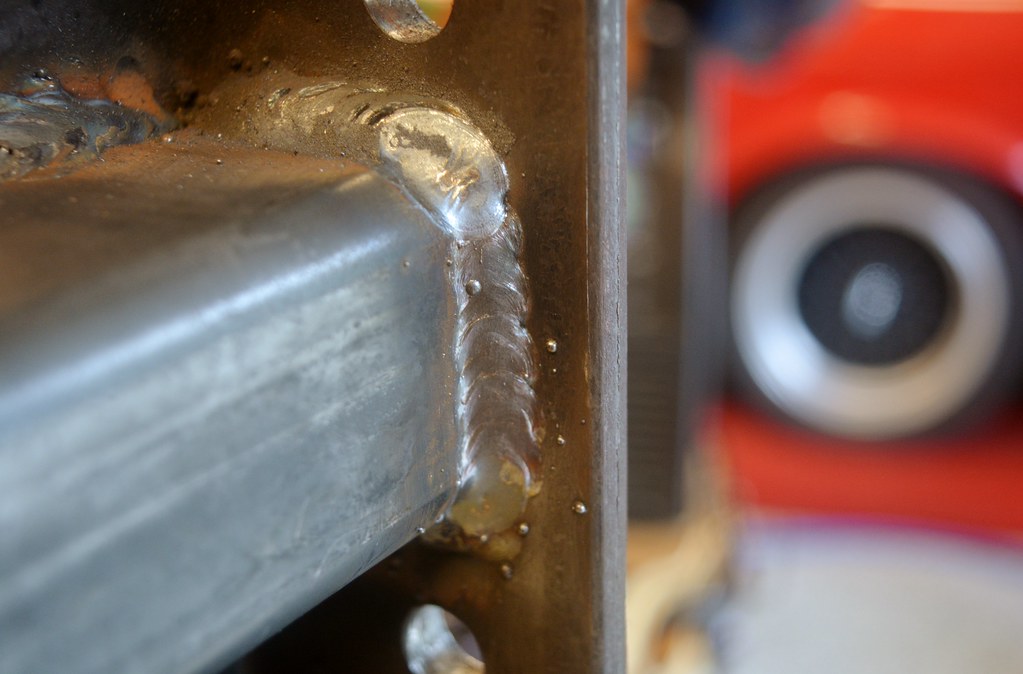

Some of my welds are actually respectable too.

I actually went in today and cut out a few welds that I butchered. In one case it was a totally cold weld that looked like lava. I now have the hang of it.

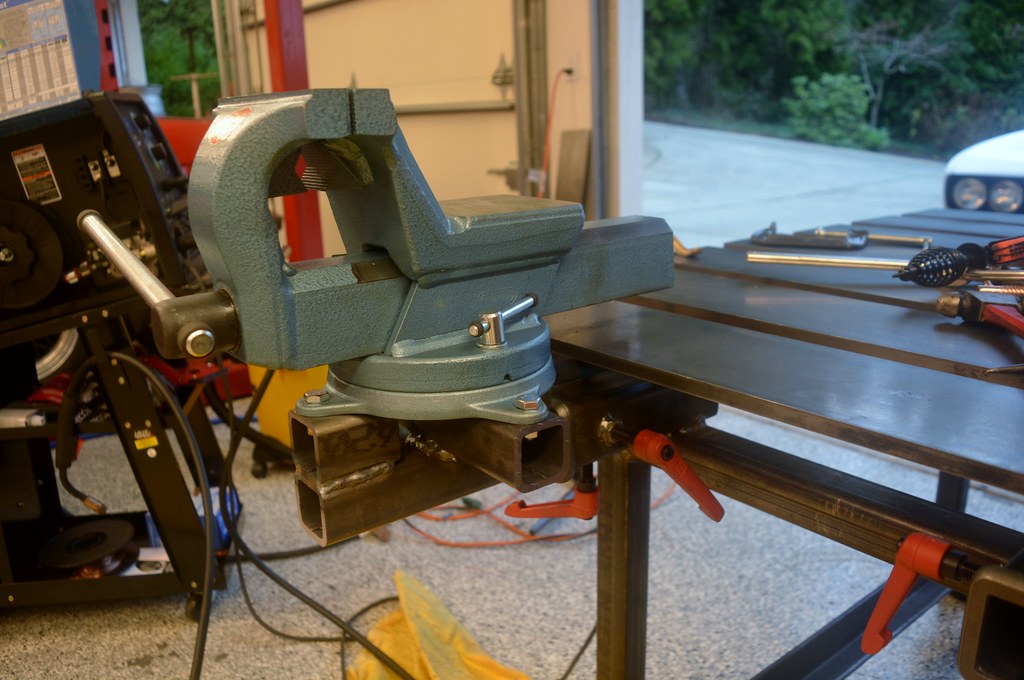

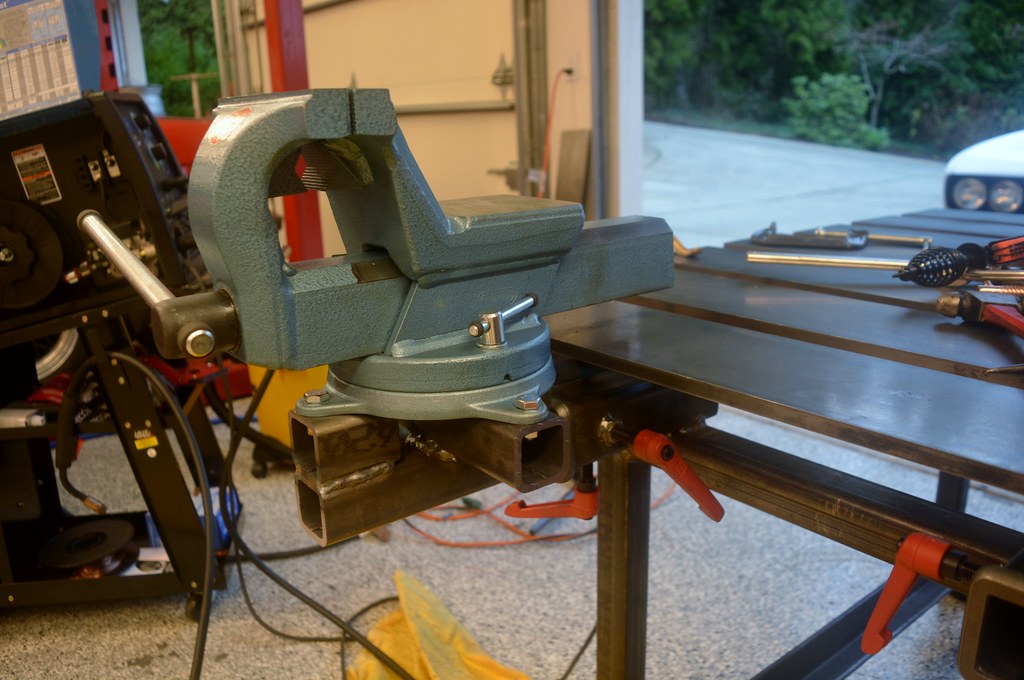

I bought two trailer hitch receivers for mounting tools, like my new vise. At McMaster Carr they sell these trick adjuster handles. Please don't laugh at my welds on the nuts. Not pretty, but I'm pretty sure they'll hold

Kinda fun building a mount for the Rigid vise my son got me for Christmas. You could say it was the first welding project I completed using the new welding table! I need to get some 1/2" bolts; the ones you see here are temporary.

Glorious!

Some of my welds are actually respectable too.

I actually went in today and cut out a few welds that I butchered. In one case it was a totally cold weld that looked like lava. I now have the hang of it.

I bought two trailer hitch receivers for mounting tools, like my new vise. At McMaster Carr they sell these trick adjuster handles. Please don't laugh at my welds on the nuts. Not pretty, but I'm pretty sure they'll hold

Kinda fun building a mount for the Rigid vise my son got me for Christmas. You could say it was the first welding project I completed using the new welding table! I need to get some 1/2" bolts; the ones you see here are temporary.

Glorious!

Re: I weld

Very nice, you do nice work. I'll be asking for your opinion on fabrication before you know it. I'm getting out of car building so let me know if you want me to send you referrals.

Re: I weld

I'm a ticketed welDer and fabricator if u got any ?

Re: I weld

MIG = Maybe its good?

Now that you have a welding table you need to upgrade to a TIG.

I bought this a few months back:

I barely use the MIG anymore.

Now that you have a welding table you need to upgrade to a TIG.

I bought this a few months back:

I barely use the MIG anymore.

Re: I weld

I have both, I rarely use my tig.

Re: I weld

bkbimmer wrote:I rarely use my tig.

Re: I weld

George wrote:bkbimmer wrote:I rarely use my tig.

I'm a hillbilly.

Re: I weld

This weekend after making final tweaks to Maytag's suspension, instead of starting a new project (engine cradle or chassis dolly) or working on an existing important project (prepping components for the blue car) I decided to procrastinate and further perfect my welding table (and steel skillz):

Added two more receiver hitches for good measure.

I decided I wanted to store stuff. So I used some 3" stock to make cross members. They are flush with the top. Yes, I know I still need to work on better penetration.

Then I decided those lower 2x2 tubes were superfluous so I'm cutting them out. This will make the shelving more easily accessible. No pics of that yet, but I'm certainly learning the value of not over-welding on something that you may want to modify. And I'm getting quite proficient with my angle and die grinders...

Added two more receiver hitches for good measure.

I decided I wanted to store stuff. So I used some 3" stock to make cross members. They are flush with the top. Yes, I know I still need to work on better penetration.

Then I decided those lower 2x2 tubes were superfluous so I'm cutting them out. This will make the shelving more easily accessible. No pics of that yet, but I'm certainly learning the value of not over-welding on something that you may want to modify. And I'm getting quite proficient with my angle and die grinders...

-

muleskinner

- Posts: 1339

- Joined: Sep 08, 2007 11:17 AM

- Location: John Graham ATL

Re: I weld

Don't we all? Well, at least those of us getting to be of a certain age.cek wrote:Yes, I know I still need to work on better penetration.

Re: I weld

That makes me feel warm and fuzzy inside.bkbimmer wrote:Nice work.

Re: I weld

Must be nice.

Re: I weld

Got the re-do of the base done. I used a plethora of cutting tools to get those 2x2s cut out including my new electric angle grinder, my old air angle grinder, my die grinder, and my sawzall. I am now pretty well practiced in those tools as a result. I think I said this before but it's easy to over-weld things. I'm learning that just because you CAN put a weld somewhere doesn't meant you need to.

I also expanded the holes the support bolts go through for the top planks from 1/2" to 5/8". I did the first one using a 5/8" drill bit and that was a BITCH. Even with a big drill with a side-handle, the torque just about killed me. Then I tried this little bugger on my die grinder... Easy as cake.

This lets me move the top planks laterally a little bit so they are better aligned.

I also expanded the holes the support bolts go through for the top planks from 1/2" to 5/8". I did the first one using a 5/8" drill bit and that was a BITCH. Even with a big drill with a side-handle, the torque just about killed me. Then I tried this little bugger on my die grinder... Easy as cake.

This lets me move the top planks laterally a little bit so they are better aligned.

-

EventuallyAyrton

- Posts: 975

- Joined: Oct 12, 2015 11:47 PM

- Location: Wherever the E28 happens to be parked- Morrisville, NY

Re: I weld

That table is coming along quite well. MIG welding is not difficult to get good at but can take a little practice to master, your welds look pretty nice. Next step is TIG! It's way more fun than MIG, although I still find some sort of strange comfort in stick welding...

Re: I weld

Ya know, I've been welding for almost 15 years now. About half of that time I did it as a profession and I still have no idea how to stick weld. Nor am I sure why stick welding would be preferable to TIG. Can you enlighten me?EventuallyAyrton wrote:That table is coming along quite well. MIG welding is not difficult to get good at but can take a little practice to master, your welds look pretty nice. Next step is TIG! It's way more fun than MIG, although I still find some sort of strange comfort in stick welding...

CEK, I would highly recommend a rotating vice as a future additional to your welding table. It is really nice to be able to hold what you'd welding in the correct position for optimal weld.

I use a cheap home depot version:

but there are much nicer versions available.

Re: I weld

I think he meant like this.cek wrote:My vise rotates.

Re: I weld

O.Karl Grau wrote:I think he meant like this.cek wrote:My vise rotates.

Slick.

Re: I weld

O.Karl Grau wrote:I think he meant like this.cek wrote:My vise rotates.

Slick.

Note I can mount my vise at any 90°.

Re: I weld

Yes, 2 directions of rotations.