I've had a whole bunch of folks ask me if I'd put together a build thread for my E28. I figured I'd at least put something together. It'll take me a bit to do the whole thread, and truth be told, with my track record, I'll get partway done and then not come back and finish the thread. But a start is better than nothing I suppose! I also didn't take photos of much of the build process, except for with my phone, so honestly this thread is more of an inside look at the car and the parts on it, as opposed to a start-to-finish build progression.

I've had the old girl out on track at Chuckwalla and Buttonwillow and it's been driving phenomenally, and I'm very excited to continue dialing in and tuning the suspension to maximize the car's potential.

For the sake of thoroughness, here's my "build sheet" of what all is done to the car. It's probably missing a few things, but it's mostly there.

1984 533i, 165,279 miles on chassis.

Custom “Original Teile” Livery, based on GR. A E24

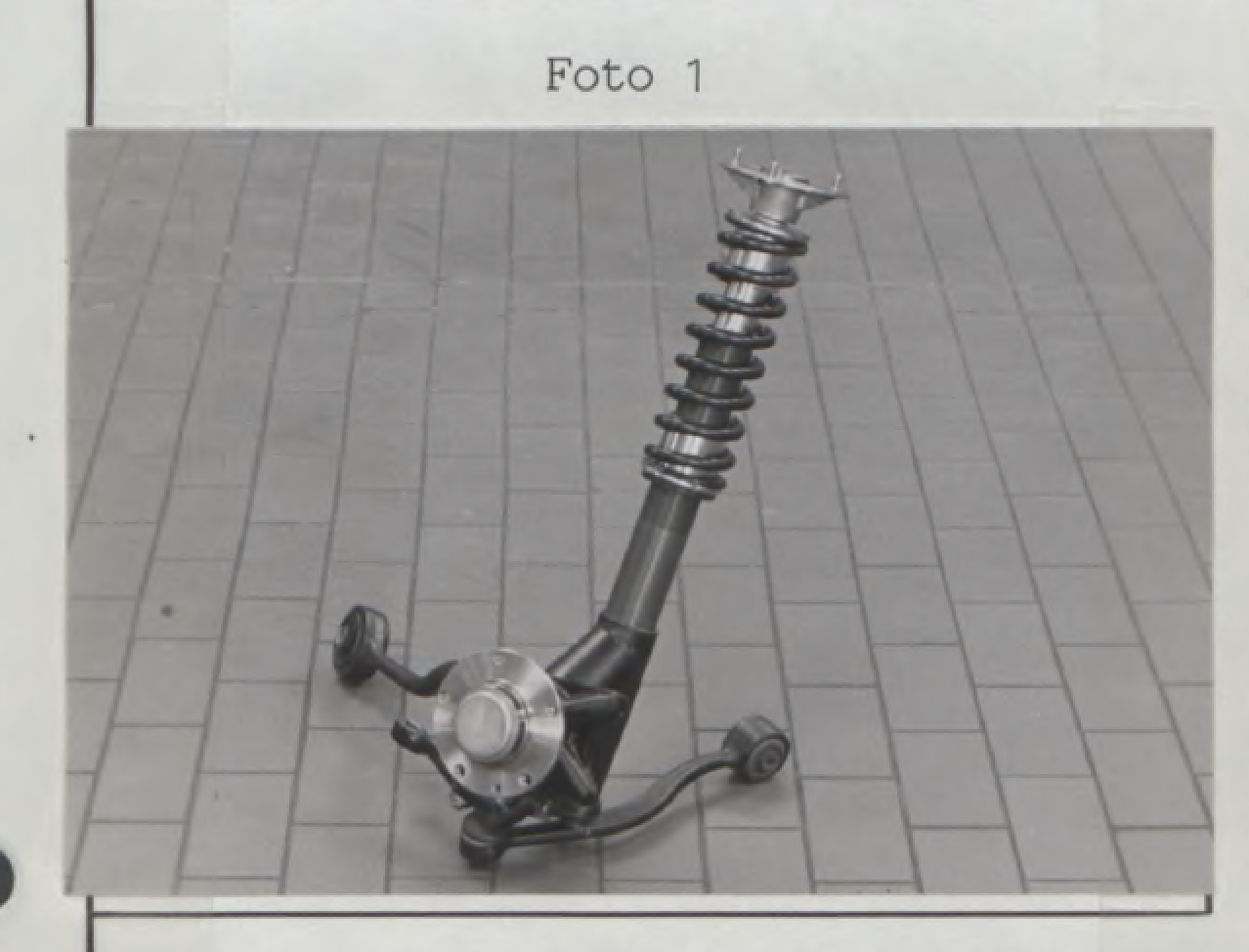

Suspension:

H&R Coilovers, custom made in Germany

H&R Sway bars, one-off, custom made. 30mm front, 25mm rear

Custom adjustable swaybar links

Custom fabricated reinforced swaybar mounts

Ground Control race camber plates

E31 aluminum lower control arms

Powerflex black race bushings for:

Front LCAs

Front UCAs

RTABs

Rear Subframe

Complete suspension overhaul, all OEM:

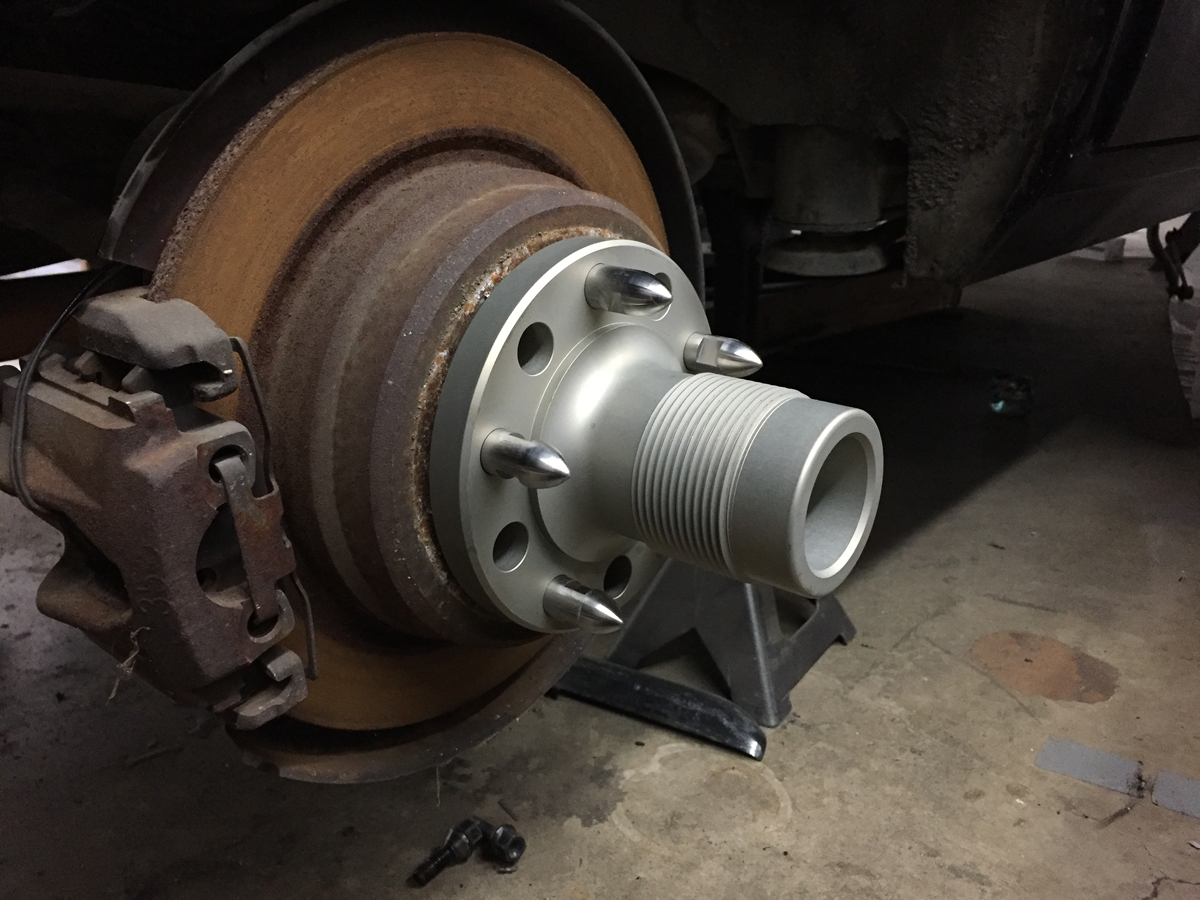

New front wheel bearings/hubs

New rear wheel bearings

New lock rings and collar nuts

New dog bones

New axles

New rear shock mounts

New front LCAs

New front UCAs

New tie rods and center link

New steering idler arm

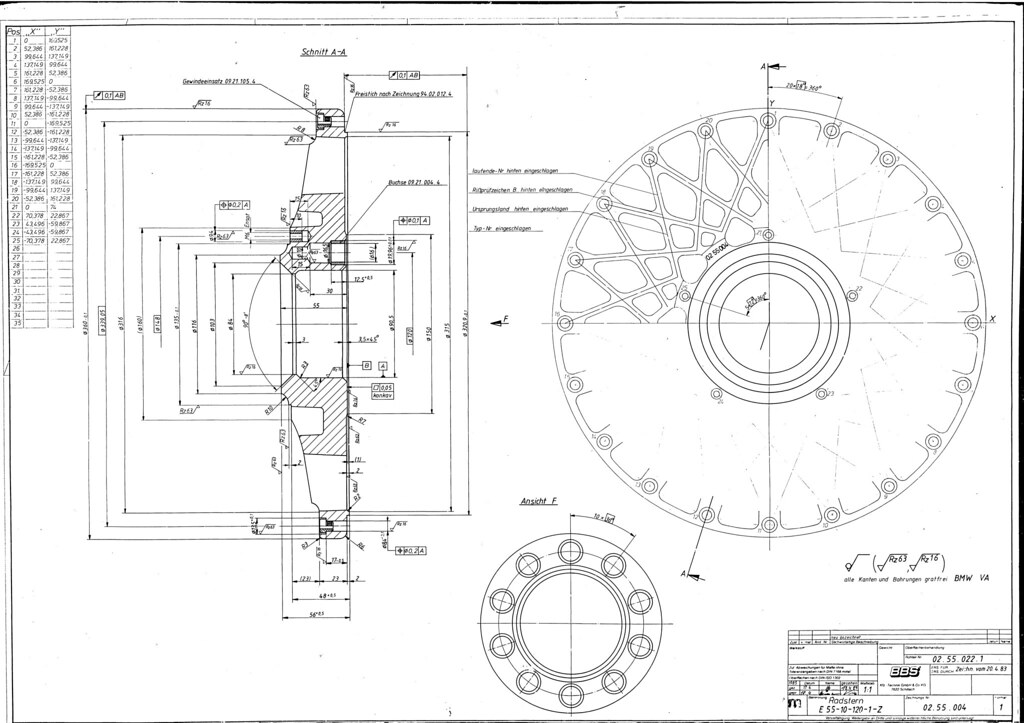

Custom 7075 alloy Centerlock hub adapters, Steel drive pins, built to Gr. A E28 spec

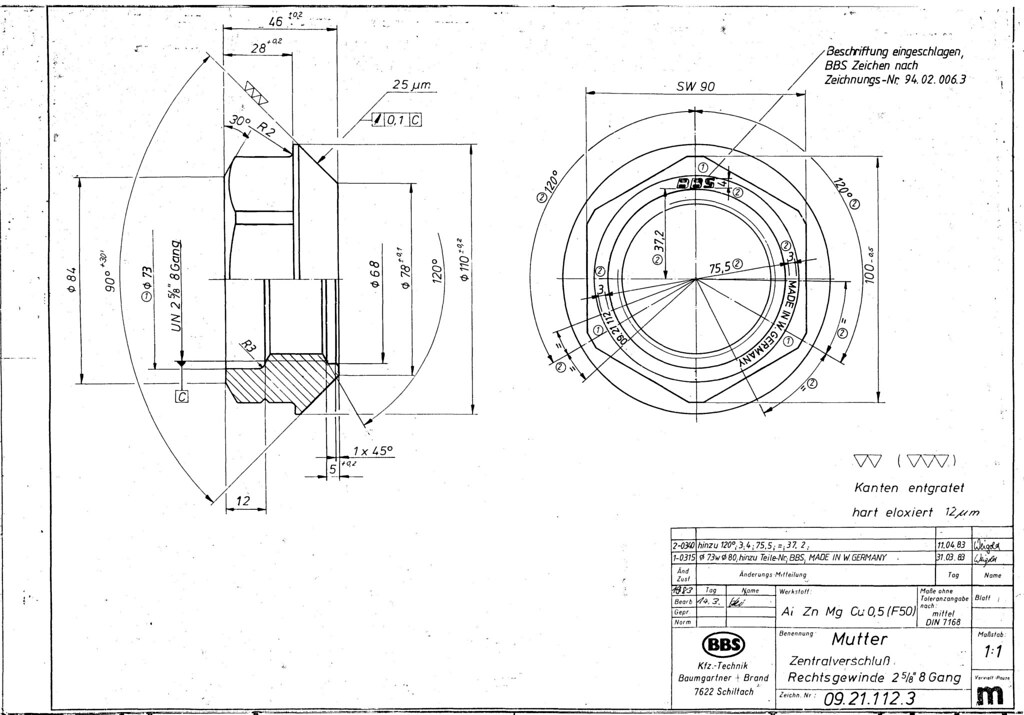

Brand new BBS centerlock nuts

Ronal Racing centerlock wheels, 16x8 square

Built with brand new BBS rim halves, sealing rings, and hardware

Pirelli P-Zero Trofeo R 225/45 tires

Tarox 6-pot aluminum big brake calipers, front

E32 750 rear brake calipers

310x26mm slotted front rotors

300x20mm slotted rear rotors

Tarox Corsa track brake pads

Exterior:

European bumpers front and rear

Euro M5 front air dam

Euro headlamps and grilles, with custom crosshairs

M5 rear spoiler

Interior:

NASA legal, 1985 FIA Group A-spec 6-point Roll cage, 1.75” .120 DOM

Pair of Momo Daytona fixed back seats, FIA compliant til 2020

VAC machined seat mounts

Pair of Willains 6-point harnesses, FIA compliant til 2020

Vintage Momo Futura steering wheel

Rennstall white delrin RSKT2 shift knob

Stripped and fully painted interior

Black headliner

Black door cards

Driveline:

S38B35 Engine swap - Pulled from 125k mile car, cluster accurate.

Swap includes complete M5 driveline:

G280 transmission

Rebuilt 4.10 E30 M3 Limited Slip Differential, converted to 3-clutch setup

Custom reinforced rear differential mount

Euro “bundle of snakes” headers

Conforti software

JB Racing 11.5lb flywheel

Clutchmasters 6-puck sprung clutch

Custom short-shift kit

CSF Aluminum radiator

SPAL 16” fan

Maintenance includes:

Complete top end rebuild, fully redone cylinder head

New timing chain

New timing chain guides

New head gasket

New front and rear main seals

New ancillary gaskets

New waterpump

New thermostat

etc.

Fueling:

ATL 120-liter Aluminum fuel cell, 1982 GR. A touring spec

3-liter fuel swirl pot/surge tank

Bosch 044 inline fuel pump

Holley Red lift pump

As a bit of an opener, the car is a bit of a mashup of ideas, most notably, it's inspired by the '82 Group A Eggenberger E28 ETCC race cars.

None of them were blessed with particularly beautiful liveries, so in building a tribute car, I went with something with a bit more flair, and pulled inspiration from the E24 factory works "x-ray" cars.

But, because those are E24s, they're not quite right in terms of simply copying the livery, so I had my good friend and business partner Andrew Ritter redesign the graphics to correctly portray an E28, including the rear seat, doors, etc. We also changed the engine and transmission to reflect M5 components.

M5 components are reflected because that's the final piece to my puzzle. While a built 2.8 M30 would be more correct in the car, it felt wrong to do anything but go for the best the E28 had to offer, despite the fact that the S38 was never homologated for FIA racing. I used an M5 donor car to contribute all of the parts, including tidbits like M5 door sills, to keep things authentic.

The build itself is something I've been planing for quite a few years, but last year I was given the opportunity to realize the vision and bring it to fruition. While the Group A E28s serve as the basis for the build, my initial inspiration was a french Superproduction E28. I had originally planned to copy this car, to a T, but with the influx of Marlboro-themed cars out there, I didn't want the effort to go to waste in the mix of something trendy, so I shifted my gears and worked towards the car I have today. (Humorously, halfway through my build, this exact car surfaced and went up for sale. When I had found photos a year or two prior, I had assumed it was long gone.)

Anyway, on July 1 of last year (2016), I picked up a reasonably nice example of an early body E28, which I wanted due to the fact that the race cars were also early-body. It was white over cardinal red in good overall shape.