I started a thread already for a simple mild N/A build, but that is now not the path I am taking. So here we go gents...

Goal is a healthy 350- knocking on 400 whp... really the goal is to get motor in car and running with boost and learn a lot along the way

Car

-1990 535is 5-speed (290K miles...blown HG on motor that's in the car)

-3.46 lsd, single mass flywheel, billy sports + h&r'S

IMG_0764

IMG_0764  PhotoGrid_1453295381489

PhotoGrid_1453295381489 Engine

-M30b35 pulled from an 88' e34 635is (<100k miles)

Plans: ( I have 3 spare long blocks, so I want to go ahead and use a stock one, good low mileage motor, and get it in car and making boost/learn about it, tune it, and then have two other long blocks to prep when I am itching for more HP lol, or I blow this stock motor

-Bottom end-leave stock (inspect and leave alone)

-Head leave stock... maybe 284 cam/HD roackers/springs... but right now I'm planning on staying stock (refresh/valve seals/inspect cam/resurface)

-ARP's

-Either MLS, or stock... (waiting to find quote on machine shop cost for block/head RA requirements)

-Good N Tight/RapidSpool Industries Turbo Manifold

-EV14 62# Injectors

-Walbro 255

- BW SX366 .88 ar / BW S362SX-E .88 ar...or even maybe HX40/50 depending on funds

- Clutch ...I am uncertain at the moment... input/wisdom welcome!

- FM Intercooler of some sort, car has aftermarket cheap fiberglass from bumper on it now that I am not afraid to chop up

Engine management... some specifics I am still gathering

-MS pnp (V2)

-Innovate MTX-L wideband O2 sensor

-Aeromotive 13129 FPR

-GM IAT sensor

Progress so far

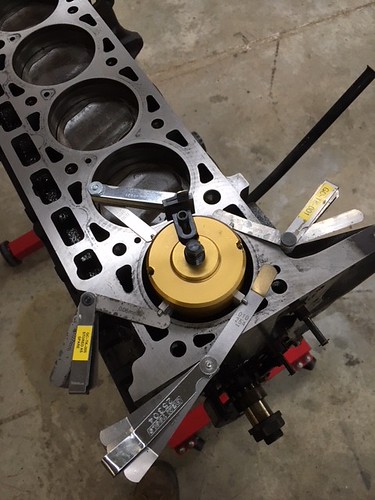

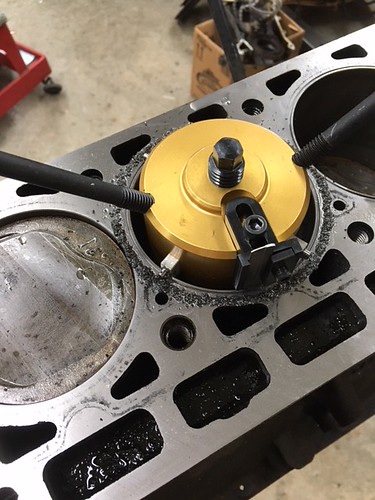

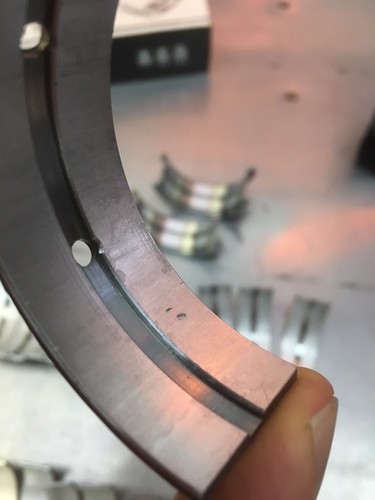

Tearing into M30 out of the 635is...

IMG_1920

IMG_1920 Cyl walls look pretty good, no lip at top...

IMG_1923

IMG_1923 IMG_1921

IMG_1921 IMG_1922

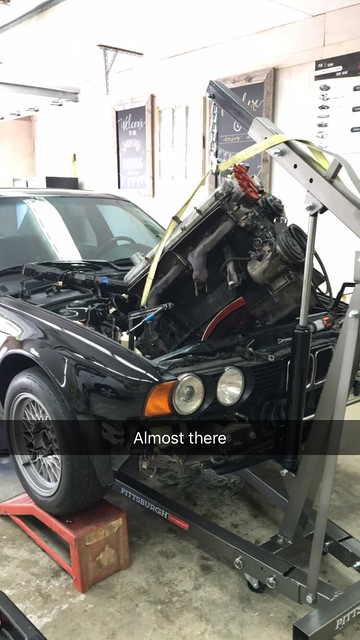

IMG_1922 Getting ready to pull motor/engine that's in car

IMG_1942

IMG_1942