Another restoration - 83' 528i

Re: Another restoration - 83' 528i

Wow Taavipa !!

you Sheetmetal skills and craftmanship are superb..Very Impressed on you work and the detail of reproduction of Sheetmetal pieces..

unbelievable...

you Sheetmetal skills and craftmanship are superb..Very Impressed on you work and the detail of reproduction of Sheetmetal pieces..

unbelievable...

-

SeattleGuy

- Posts: 737

- Joined: Jun 25, 2018 6:26 AM

Re: Another restoration - 83' 528i

Holy shitbags dude let's just call you "Tucker" because you built your own car. When you said you were gonna get another chassis I thought, ok cool a little nip and tuck here and there and you're back in The Game..... Congratulations on everything so far!

Re: Another restoration - 83' 528i

A true craftsman, amazing work. Thank you for sharing.

Re: Another restoration - 83' 528i

Thank you gents!

I doubt I fully realized what I was getting into back then.SeattleGuy wrote: Dec 04, 2020 4:29 PM When you said you were gonna get another chassis I thought, ok cool a little nip and tuck here and there and you're back in The Game.....

Re: Another restoration - 83' 528i

16 Nov - 6 Dec 2020

Last couple of weeks have been quite slow. Did some inventory and ordered some missing parts.

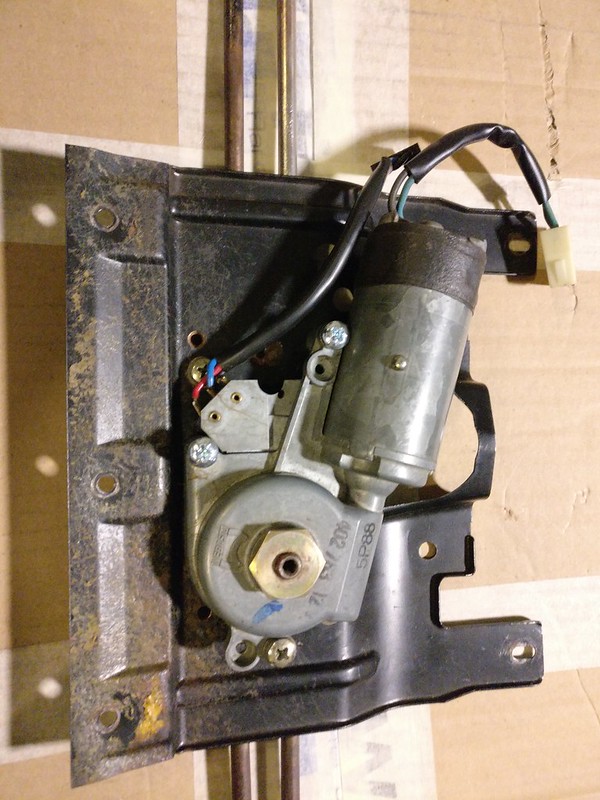

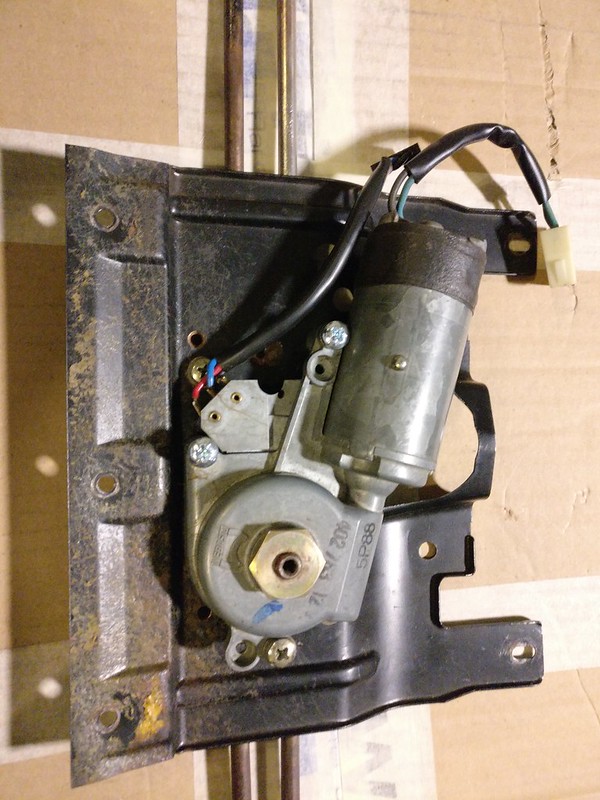

A while back I sourced an electric motor and harness for the sunroof. Instead of putting time and money into finding a correct mounting plate for the electric version I decided to repurpose my manual plate and tubes. This means cutting into the plate to make room for the motor and figuring out how to secure the motor to the plate.

Both manual crank and electric motor are mounted using three bolts but only one of them is exactly in the same position. Second hole is a little bit off, third one even more so. I decided to clean off the copper coating, weld the two holes shut and redrill them in the correct position.

Someone had already separated the plate from the tubing and put them back together using bolts, possibly for the same purpose. Well, that's one less thing for me to do.

So here's the finished product. Might do some more work on it to make it look like it originally came this way but it’s not too bad as it is. On the plate itself I just elongated the original holes, you can get an idea how much the original holes were off.

Motor mounted. I’ll replace the regular nuts with rivet nuts later to make installing the motor easier.

I also did install the cables and did a quick test run to make sure everything is aligned perfectly and the cables move feely.

There’s already some corrosion on the steel underneath the copper coating. I really wish I could zinc coat the whole tubing but I don’t believe it’s feasible to remove all the traces of copper and copper doesn’t play nice with galvanized metal. So I’ll probably just clean and paint the whole assembly later.

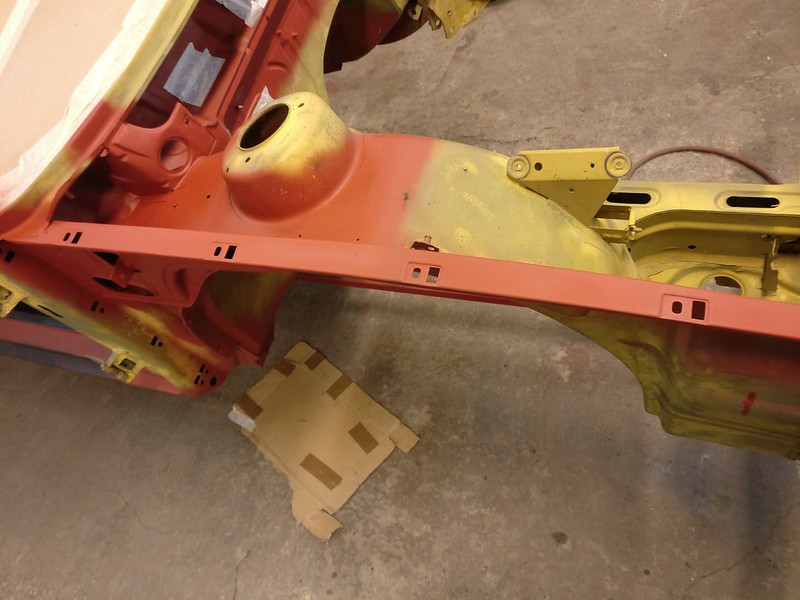

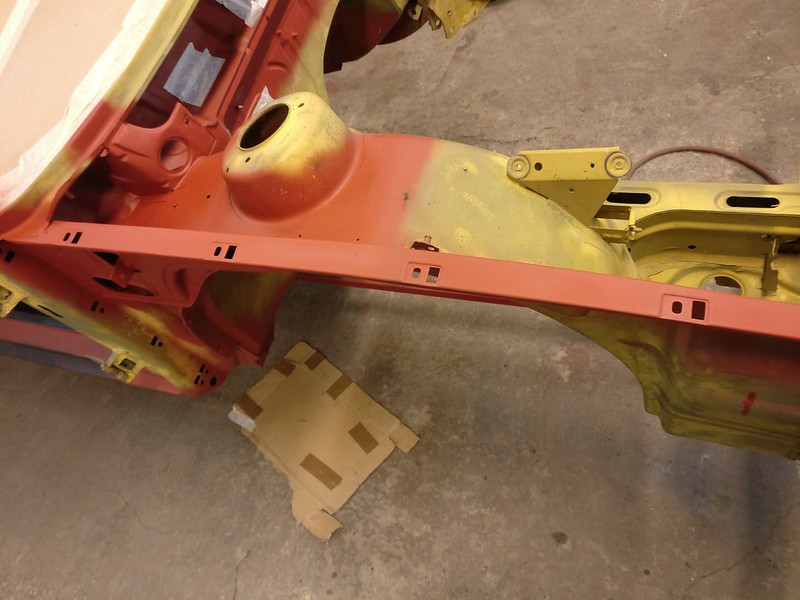

After I was done with that I began to work on the passenger side wheel arch. The whole process was similar to the other side, first make the inner patch and tack it in, then replace the outer arch.

Outer arch marked for cutting

Removed

Trimmed and tacked in the replacement

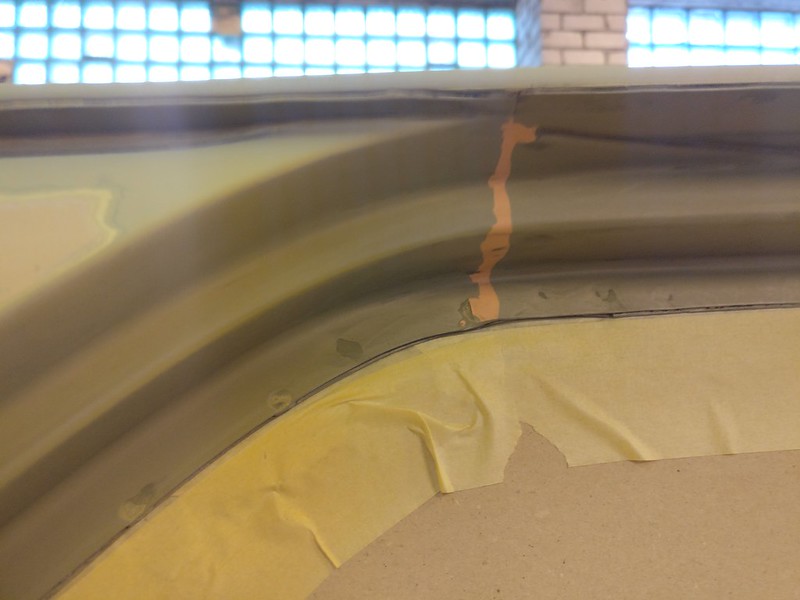

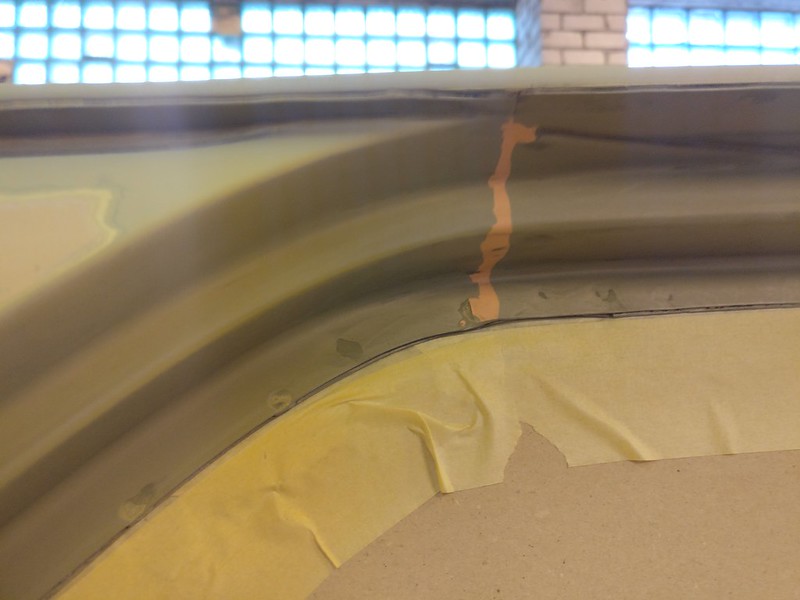

Welded

And after many hours of hammer and dolly action I was finally happy with it

This is how the inner patch looks like off car

And then some primer. If you look closely you can see a spot where I accidentally ground into the edge near the door jamb. It will need some body filler on the edge anyway as the bends on those repro panels aren’t as sharp and well defined as on originals. Still, a pity.

I really hope I can finish up everything on the inside next week and if I can borrow the glue gun for the weekend then be done with the rear arches. For some reason I haven’t enjoyed much working on these and I’d be glad to move on.

Last couple of weeks have been quite slow. Did some inventory and ordered some missing parts.

A while back I sourced an electric motor and harness for the sunroof. Instead of putting time and money into finding a correct mounting plate for the electric version I decided to repurpose my manual plate and tubes. This means cutting into the plate to make room for the motor and figuring out how to secure the motor to the plate.

Both manual crank and electric motor are mounted using three bolts but only one of them is exactly in the same position. Second hole is a little bit off, third one even more so. I decided to clean off the copper coating, weld the two holes shut and redrill them in the correct position.

Someone had already separated the plate from the tubing and put them back together using bolts, possibly for the same purpose. Well, that's one less thing for me to do.

So here's the finished product. Might do some more work on it to make it look like it originally came this way but it’s not too bad as it is. On the plate itself I just elongated the original holes, you can get an idea how much the original holes were off.

Motor mounted. I’ll replace the regular nuts with rivet nuts later to make installing the motor easier.

I also did install the cables and did a quick test run to make sure everything is aligned perfectly and the cables move feely.

There’s already some corrosion on the steel underneath the copper coating. I really wish I could zinc coat the whole tubing but I don’t believe it’s feasible to remove all the traces of copper and copper doesn’t play nice with galvanized metal. So I’ll probably just clean and paint the whole assembly later.

After I was done with that I began to work on the passenger side wheel arch. The whole process was similar to the other side, first make the inner patch and tack it in, then replace the outer arch.

Outer arch marked for cutting

Removed

Trimmed and tacked in the replacement

Welded

And after many hours of hammer and dolly action I was finally happy with it

This is how the inner patch looks like off car

And then some primer. If you look closely you can see a spot where I accidentally ground into the edge near the door jamb. It will need some body filler on the edge anyway as the bends on those repro panels aren’t as sharp and well defined as on originals. Still, a pity.

I really hope I can finish up everything on the inside next week and if I can borrow the glue gun for the weekend then be done with the rear arches. For some reason I haven’t enjoyed much working on these and I’d be glad to move on.

Re: Another restoration - 83' 528i

7 Dec - 30 Dec 2020

Discovered a couple of mess-ups.

First, found the hinge for glovebox in one of the boxes I was going through and this got me wondering how this is mounted to the firewall.

Remember this old patch on the firewall that I cut out and replaced?

Notice the screw hole next to the flange? I guess when someone patched this they didn’t bother adding a new stud there for the glovebox hinge. Going through some old photos of disassembly I realized the hinge was indeed mounted with a self-drilling screw on that side. Since I didn’t see a stud there when I replaced it I didn’t add one. I am still going to do it but I wish I discovered this before priming the cabin.

Secondly, for whatever reason I hadn’t removed the driver's side hood hinge from the car. So now, when I decided to finally take it off a bolt snapped. And, sure enough, it was the rear bolt with almost no access to it and the support plate that covers those nuts on the other side was already installed.

I was somehow able to squeeze my mig gun in there. Each try I was terrified that I might have end up welding the bolt to the chassis but fortunately that didn’t happen.

About this many nuts later I got one to stick well enough to remove the remnants of the bolt.

Thirdly, the outer rear wheel arches were under some tension and when I cut off the inner arch they relaxed a bit towards the inside. At first, I didn’t think much of that but later I realized that the quarter panel right above the wheel arch also bulged a bit. I think this is inevitable whichever way you do the arches so maybe it doesn’t qualify as a mess-up but I am glad I caught this before too late.

So the solution was to push it back out and weld in some temporary beams to keep it in position until the inner wheel arches get installed.

Until I was able to get my hands on the glue gun for wheel arches, I continued the work at the front of the car.

Decided to replace pretty much the whole lip on this panel

And then installed new support panel

Found this in one of the frame rails in engine compartment. I guess not only nuts and bolts vanish into the frame rails.

Now, back to the rear arches. I wasn’t happy how the inner patch sat on one side and redid it. Took almost a full day. Then, I wasn’t happy with the new patch so I had another go at it. Finally, everything was ready to finish the rear arches.

This is the panel adhesive I have been using.

Began with the passenger’s side.

I was hoping to do both at once but ran out of vise-grips. I guess you never have enough.

After the adhesive was dry it was time to take the welds.

And clean up

Driver’s side received the same treatment

Finished cleaning it up yesterday, so that’s about it.

Discovered a couple of mess-ups.

First, found the hinge for glovebox in one of the boxes I was going through and this got me wondering how this is mounted to the firewall.

Remember this old patch on the firewall that I cut out and replaced?

Notice the screw hole next to the flange? I guess when someone patched this they didn’t bother adding a new stud there for the glovebox hinge. Going through some old photos of disassembly I realized the hinge was indeed mounted with a self-drilling screw on that side. Since I didn’t see a stud there when I replaced it I didn’t add one. I am still going to do it but I wish I discovered this before priming the cabin.

Secondly, for whatever reason I hadn’t removed the driver's side hood hinge from the car. So now, when I decided to finally take it off a bolt snapped. And, sure enough, it was the rear bolt with almost no access to it and the support plate that covers those nuts on the other side was already installed.

I was somehow able to squeeze my mig gun in there. Each try I was terrified that I might have end up welding the bolt to the chassis but fortunately that didn’t happen.

About this many nuts later I got one to stick well enough to remove the remnants of the bolt.

Thirdly, the outer rear wheel arches were under some tension and when I cut off the inner arch they relaxed a bit towards the inside. At first, I didn’t think much of that but later I realized that the quarter panel right above the wheel arch also bulged a bit. I think this is inevitable whichever way you do the arches so maybe it doesn’t qualify as a mess-up but I am glad I caught this before too late.

So the solution was to push it back out and weld in some temporary beams to keep it in position until the inner wheel arches get installed.

Until I was able to get my hands on the glue gun for wheel arches, I continued the work at the front of the car.

Decided to replace pretty much the whole lip on this panel

And then installed new support panel

Found this in one of the frame rails in engine compartment. I guess not only nuts and bolts vanish into the frame rails.

Now, back to the rear arches. I wasn’t happy how the inner patch sat on one side and redid it. Took almost a full day. Then, I wasn’t happy with the new patch so I had another go at it. Finally, everything was ready to finish the rear arches.

This is the panel adhesive I have been using.

Began with the passenger’s side.

I was hoping to do both at once but ran out of vise-grips. I guess you never have enough.

After the adhesive was dry it was time to take the welds.

And clean up

Driver’s side received the same treatment

Finished cleaning it up yesterday, so that’s about it.

Re: Another restoration - 83' 528i

Brilliant as usual. Keep it up!

And happy New year!

And happy New year!

Re: Another restoration - 83' 528i

Happy new year!

-

Nebraska_e28

- Beamter

- Posts: 9056

- Joined: Apr 13, 2006 11:18 PM

- Location: Council Bluffs, IA

- Contact:

Re: Another restoration - 83' 528i

Awesome work! Definitely an inspiration!

Re: Another restoration - 83' 528i

1 Jan - 24 Jan 2021

Everything is pretty much done on the rear end (minus the sway bar mounts) so back to the front.

Removed battery plate and ABS plate. It looks like the guy who did the nose job on that car wasn’t able to get the battery plate to fit and just hammered it in.

Some crust around the battery plate, replaced the bottom section here.

Passenger’s side received similar treatment.

Made new brake line mounts for the wheel housings.

The mount on the driver’s side got installed. Also, the bottom lip of the wheel housing was replaced but it looks like I didn’t take any photos. Will try to remember to take some for the next time.

All that done, I took a closer look on the battery and ABS plates. Battery plate was complete junk. As it’s been NLA for quite some time, this needs to be replicated. I could patch up ABS plate and reuse. Or make a new panel and patch in C-3PO from the original. It makes sense to reuse this section as it would be difficult to replicate and I can’t make the whole panel in one piece anyway. I'll sit on that for a while.

First, I made myself a few tools as I don’t have a bead roller. Really hope to get one some day, it would make many things so much easier.

I began with the inner beads. A lot of prestretching to avoid warpage.

These came out fine.

Despite prestretching the metal, I still got some warpage after doing more beads.

In the end I was able to work most of the extra metal towards the edges and use my shrinker to take care of it. I was careful not to make many shrink marks on the main section as these are PITA to get out.

Next task was to work out some imperfections and to hammer out any high and low spots to get the panel nice and straight.

Finally, it was time to mark the edges and hit down the flanges. The bended sections took some doing, especially in the rear outer corner. Didn’t get it perfect there but the original panel had quite loose fit in that corner, so it should work.

A photo of the bottom.

And a couple of the top side.

After I had already primed one side, I realized I also had forgot about the two tiny louver things that keep the battery mount from rotating. No biggie but it would have been nice to do these before primer.

Finished the difficult part today. Now I have to get a M6 weld nut and attach all the brackets.

All in all, it came out better than I expected. The beads aren’t as deep as the originals. The rear outer corner is a bit off. Furthermore, if you take a closer look on the original panel, there’s a groove around the battery mount nut. This one I left out intentionally, as it would just trap water in there.

Everything is pretty much done on the rear end (minus the sway bar mounts) so back to the front.

Removed battery plate and ABS plate. It looks like the guy who did the nose job on that car wasn’t able to get the battery plate to fit and just hammered it in.

Some crust around the battery plate, replaced the bottom section here.

Passenger’s side received similar treatment.

Made new brake line mounts for the wheel housings.

The mount on the driver’s side got installed. Also, the bottom lip of the wheel housing was replaced but it looks like I didn’t take any photos. Will try to remember to take some for the next time.

All that done, I took a closer look on the battery and ABS plates. Battery plate was complete junk. As it’s been NLA for quite some time, this needs to be replicated. I could patch up ABS plate and reuse. Or make a new panel and patch in C-3PO from the original. It makes sense to reuse this section as it would be difficult to replicate and I can’t make the whole panel in one piece anyway. I'll sit on that for a while.

First, I made myself a few tools as I don’t have a bead roller. Really hope to get one some day, it would make many things so much easier.

I began with the inner beads. A lot of prestretching to avoid warpage.

These came out fine.

Despite prestretching the metal, I still got some warpage after doing more beads.

In the end I was able to work most of the extra metal towards the edges and use my shrinker to take care of it. I was careful not to make many shrink marks on the main section as these are PITA to get out.

Next task was to work out some imperfections and to hammer out any high and low spots to get the panel nice and straight.

Finally, it was time to mark the edges and hit down the flanges. The bended sections took some doing, especially in the rear outer corner. Didn’t get it perfect there but the original panel had quite loose fit in that corner, so it should work.

A photo of the bottom.

And a couple of the top side.

After I had already primed one side, I realized I also had forgot about the two tiny louver things that keep the battery mount from rotating. No biggie but it would have been nice to do these before primer.

Finished the difficult part today. Now I have to get a M6 weld nut and attach all the brackets.

All in all, it came out better than I expected. The beads aren’t as deep as the originals. The rear outer corner is a bit off. Furthermore, if you take a closer look on the original panel, there’s a groove around the battery mount nut. This one I left out intentionally, as it would just trap water in there.

Re: Another restoration - 83' 528i

25 Jan - 21 Feb 2021

Progress has been slow. Weather’s been quite cold here and the shop’s often too cold to work in. Been doing more cleaning and sorting of stuff than chassis work. But here's what's done so far.

Bottom sections of front wheel arches got patched and new mounts for brake lines installed.

Ordered a new piece that goes on top of ABS panel.

And installed it right away.

Made new mounts for ABS plate. Cup was saved from original mount.

Decided to go with the patching route with the ABS panel. Most of the flanges were gone plus a rusted area underneath one of the pump mounts. Not particularly proud of doing it this way but the alternative wasn’t good either.

A large patch to the right side

And then some more to get to this

Added missing holes and new mounts to the battery plate

What better things to do on cold evenings than to learn new stuff. Turns out CAD can be extremely useful in this line of work.

The piece is supposed to replace this one that was cut in half and welded up during previous nose job.

Fortunately the other side was unmolested so I was able to get good measurements.

Printed out a template, laid on top of sheet metal and cut it out.

Took the bends

And removed some extra metal to make the tab

The real reason I went for CAD was to design new rear sway mounts. On the left is the original mount that my early chassis came with. New mount on the right is boxed, with an extra attachment point and made out of 1.5mm metal instead of 1.2mm the original was. Clamps are still to be made but will be 2mm thick. And attach with two bolts instead of a tab and a bolt.

In the process I decided the top (or bottom?) cover is ugly and cut it off so the finished product differs a bit from the initial drawing.

Welded together on the back

Still needs a bit tuning at this point but it will sit like this

Rinse and repeat

Progress has been slow. Weather’s been quite cold here and the shop’s often too cold to work in. Been doing more cleaning and sorting of stuff than chassis work. But here's what's done so far.

Bottom sections of front wheel arches got patched and new mounts for brake lines installed.

Ordered a new piece that goes on top of ABS panel.

And installed it right away.

Made new mounts for ABS plate. Cup was saved from original mount.

Decided to go with the patching route with the ABS panel. Most of the flanges were gone plus a rusted area underneath one of the pump mounts. Not particularly proud of doing it this way but the alternative wasn’t good either.

A large patch to the right side

And then some more to get to this

Added missing holes and new mounts to the battery plate

What better things to do on cold evenings than to learn new stuff. Turns out CAD can be extremely useful in this line of work.

The piece is supposed to replace this one that was cut in half and welded up during previous nose job.

Fortunately the other side was unmolested so I was able to get good measurements.

Printed out a template, laid on top of sheet metal and cut it out.

Took the bends

And removed some extra metal to make the tab

The real reason I went for CAD was to design new rear sway mounts. On the left is the original mount that my early chassis came with. New mount on the right is boxed, with an extra attachment point and made out of 1.5mm metal instead of 1.2mm the original was. Clamps are still to be made but will be 2mm thick. And attach with two bolts instead of a tab and a bolt.

In the process I decided the top (or bottom?) cover is ugly and cut it off so the finished product differs a bit from the initial drawing.

Welded together on the back

Still needs a bit tuning at this point but it will sit like this

Rinse and repeat

-

ilovemycat

- Posts: 175

- Joined: Jul 03, 2017 4:05 PM

- Location: victoria bc

Re: Another restoration - 83' 528i

man it takes serious skill to be able to do sheet metal like that , wow. Making me feel bad about the 2 cars I've cut up for parts in the past 2 years.

Re: Another restoration - 83' 528i

22 Feb - 29 Apr 2021

It’s been a while. Some progress has been made, although some in vain.

To continue where we left off, rear sway mounts got finished and installed. On the pictures is the newer style sway bar. In addition to not clearing diff mount it could potentially hit the edge of the crossbeam. Not that I had any hope of using it...

I should probably make one of the bolt holes on the clamp oblongated to facilitate installing. And get them zinc plated.

Rear mounts done I went on and started sanding the cabin, underside and engine compartment to prep for paint/primer. Nasty and slow work. At the same time I begun to work on the fenders.

I had two OEM fenders for passenger’s side, this one seemed to be in better shape overall. Needs new bottom section, other rust is superficial and cleaned off well enough. Also had a couple of small dents to be worked out but nothing major.

Put some cheap black primer on it to protect the metal until it gets properly coated. Plan was to later cover it with clear coat which should help to identify all the remaining dents.

I don’t intend to use the side markers but this fender had holes cut out so these had to be filled.

Fixed up support plates for both sides.

And made a patch for the bottom section

Tacked in. I was hoping my buddy would later TIG all those patches in so it would be easier to planish the welds. The rear line where it meets the door is a bit off but nothing that couldn’t be worked out.

A little bit hammer work and the door line is already better.

I then started removing paint from the only left side fender I had and it turned out to be in awful shape. The metal was really wavy like it had suffered from excess heat. This was kind of surprising as both the interior and exterior side still had original primer on them. But I guess you could put too much heat into it without sanding through all layers of paint.

Either way, all the waviness and rust made me not want to deal with this fender at all and I decided to get a new one. And you simply can’t replace one side without the other. So I wrote off all the hours put into the other fender as practice and carried on with other stuff.

Here’s a shot of the cabin, all sanded and ready for paint. You can also spot the read area where I installed the missing stud for glove box hinge. In addition to cabin, underside and engine room are also cleaned, sanded and ready for primer.

Front sway bar mounts. Decided to go for a flat mount and a simple clamp design that would accept universal bushings. This would give me the best versatility in terms of bar thickness and would be easy enough to fabricate.

Made the mounts out of 3mm sheet metal so they’d be strong enough for any bar. Hardest part was to decide on the shape of the legs. The legs on the OEM mount look a bit odd so instead copying that I made them wider and angled like this. These mounts look fast, don’t they?

I’m yet to make the clamps. Maybe I’ll just order the bushings with clamps and be done with it.

Now, all that’s left to do on the chassis is the nose section so it was time to lose the rotisserie and put the car on the table.

Followed by mounting and adjusting all the panels so I could align the new nose frame properly.

Here you can see how uneven the surface of the driver’s side fender is.

A little bit of drilling and cutting and off it was.

Perfect time to clean the insides of frame rails. In the driver’s side rail there was a lot of liquid cavity wax which had turned into a thick layer of mud. Took me half a day to get it cleaned. I guess a session with power washer before starting the metal work would have helped a lot. I try to keep that in mind if I ever tackle another project like that. Luckily, other side was pretty clean already.

Some new pieces to fix the hack job on the frame rail.

New side pieces. Need a bit more work but pretty much in shape.

Clamped on the new nose frame to see how it fits.

This week I’ve been just putting it together and taking apart, adjusting doors, fenders and hood to get everything right.

Passenger’s side is looking pretty good like this.

On the other side I have some minor issues but it looks like it will work. Don’t mind the hood gap. This hood has some damage here, so the corner is pushed down and surrounding metal has rised up. I’ll try on another straight hood today so it should help with aligning things.

IMG_20210428_174952

IMG_20210428_174952

Tomorrow I’ll get some help from a professional restorator and hopefully we get the nose frame attached by the evening.

It’s been a while. Some progress has been made, although some in vain.

To continue where we left off, rear sway mounts got finished and installed. On the pictures is the newer style sway bar. In addition to not clearing diff mount it could potentially hit the edge of the crossbeam. Not that I had any hope of using it...

I should probably make one of the bolt holes on the clamp oblongated to facilitate installing. And get them zinc plated.

Rear mounts done I went on and started sanding the cabin, underside and engine compartment to prep for paint/primer. Nasty and slow work. At the same time I begun to work on the fenders.

I had two OEM fenders for passenger’s side, this one seemed to be in better shape overall. Needs new bottom section, other rust is superficial and cleaned off well enough. Also had a couple of small dents to be worked out but nothing major.

Put some cheap black primer on it to protect the metal until it gets properly coated. Plan was to later cover it with clear coat which should help to identify all the remaining dents.

I don’t intend to use the side markers but this fender had holes cut out so these had to be filled.

Fixed up support plates for both sides.

And made a patch for the bottom section

Tacked in. I was hoping my buddy would later TIG all those patches in so it would be easier to planish the welds. The rear line where it meets the door is a bit off but nothing that couldn’t be worked out.

A little bit hammer work and the door line is already better.

I then started removing paint from the only left side fender I had and it turned out to be in awful shape. The metal was really wavy like it had suffered from excess heat. This was kind of surprising as both the interior and exterior side still had original primer on them. But I guess you could put too much heat into it without sanding through all layers of paint.

Either way, all the waviness and rust made me not want to deal with this fender at all and I decided to get a new one. And you simply can’t replace one side without the other. So I wrote off all the hours put into the other fender as practice and carried on with other stuff.

Here’s a shot of the cabin, all sanded and ready for paint. You can also spot the read area where I installed the missing stud for glove box hinge. In addition to cabin, underside and engine room are also cleaned, sanded and ready for primer.

Front sway bar mounts. Decided to go for a flat mount and a simple clamp design that would accept universal bushings. This would give me the best versatility in terms of bar thickness and would be easy enough to fabricate.

Made the mounts out of 3mm sheet metal so they’d be strong enough for any bar. Hardest part was to decide on the shape of the legs. The legs on the OEM mount look a bit odd so instead copying that I made them wider and angled like this. These mounts look fast, don’t they?

I’m yet to make the clamps. Maybe I’ll just order the bushings with clamps and be done with it.

Now, all that’s left to do on the chassis is the nose section so it was time to lose the rotisserie and put the car on the table.

Followed by mounting and adjusting all the panels so I could align the new nose frame properly.

Here you can see how uneven the surface of the driver’s side fender is.

A little bit of drilling and cutting and off it was.

Perfect time to clean the insides of frame rails. In the driver’s side rail there was a lot of liquid cavity wax which had turned into a thick layer of mud. Took me half a day to get it cleaned. I guess a session with power washer before starting the metal work would have helped a lot. I try to keep that in mind if I ever tackle another project like that. Luckily, other side was pretty clean already.

Some new pieces to fix the hack job on the frame rail.

New side pieces. Need a bit more work but pretty much in shape.

Clamped on the new nose frame to see how it fits.

This week I’ve been just putting it together and taking apart, adjusting doors, fenders and hood to get everything right.

Passenger’s side is looking pretty good like this.

On the other side I have some minor issues but it looks like it will work. Don’t mind the hood gap. This hood has some damage here, so the corner is pushed down and surrounding metal has rised up. I’ll try on another straight hood today so it should help with aligning things.

IMG_20210428_174952

IMG_20210428_174952Tomorrow I’ll get some help from a professional restorator and hopefully we get the nose frame attached by the evening.

-

muleskinner

- Posts: 1339

- Joined: Sep 08, 2007 11:17 AM

- Location: John Graham ATL

Re: Another restoration - 83' 528i

says a professional restorator.Tomorrow I’ll get some help from a professional restorator

Re: Another restoration - 83' 528i

Truly inspirational.

Your pictures are excellent. The ARB section was very helpful. I'm just working on that bit myself.

Keep the updates coming.

Your pictures are excellent. The ARB section was very helpful. I'm just working on that bit myself.

Keep the updates coming.

Re: Another restoration - 83' 528i

May - June 2021

An update is long overdue.

First attempt at getting the nose fitted was kind of a bust. After spending many hours trying to get those old rusty fenders to fit we decided it would be best to wait until the new ones arrive so if anything needs adjustment (read: hammering) it gets adjusted with the actual panels going on the car.

So, until fenders arrived I had to focus on other stuff. I don’t have much anything to show from May, thus the lack of updates. Took last trim pieces and trinkets off the doors, went through the axles removing some old bushings and getting things ready for sandblasting. Installed the replica steering box reinforcement piece I had bought from e28goodies. Fits well, unfortunately no pics for now.

Built myself a small sandblasting cabinet out of an old oil drum so I could conveniently blast smaller things. Designed it so I could stick the gun of my large (is it though!?) sandblaster into the cabinet but this didn’t work out very well - the hose is really stiff and you can’t move it around much. Need to get a small siphon type blasting gun just for the cabinet.

Can't find a photo of finished cabinet but you get the gist.

Then I began to strip the hood and the trunk lid of paint. I knew I had to do some repairs near the cabin air intakes are but first I wanted to be sure there aren’t any other big surprises waiting for me underneath the paint. Under the green paint (hood was from the first car) were original layers of paint and primer, so all good.

Here’s a pic of the hood from later on, already waiting for the primer.

Some patches were due.

And one patch for the other side

Sometime in the beginning of June my new fenders arrived. This time they had put some effort into packaging. Not sure if I mentioned it before but the nose frame was just delivered loosely in a cardboard box.

Since there was plenty of surface rust around all the openings in the bottom structure of the hood, I decided to strip this as well. In the large middle sections I just sanded it down to the e-coat. But damn this factory e-coating is tough...

Getting here (paint and one layer of primer removed) took about 1.5-2 hours.

Getting through all the e-coating took about me about 7 hours (including the breaks but still).

Here you can see the tool I used to strip the bottom structure, attached to it are 3M stackable bristle discs. Really nice abrasive for something like this.

Bottom side all cleaned up

Trunk lid, on the other hand, had about 9 layers on it, including a layer of spray putty. So I was rather surprised not finding any damage after cleaning off this side.

But there were plenty of dents in other sections.

At least all those layers came of pretty quickly and most of those dents shouldn’t be hard to remove. Rust-wise this panel is really solid. I do have another trunk lid but it has the holes for the lip and a large opening underneath the badge, most likely from an attempt to unlock the trunk. Welding these shut would bring up another bunch of issues so I’ll stick to this lid.

Cleaned up

Time to shoot some acid primer on these panels.

Notice that I forgot to shoot some primer on the area in the middle. According to the datasheet the following primer is okay to put on bare metal so I didn’t bother running another session just for that small area underneath the hood.

Some days later I shot the underside of both panels.

Top sides were done by my buddy as I didn’t want to risk messing these up.

This allowed me to get some shots of him in the action.

Both panels done and dry

This dark primer will also work as a guide coat for the dent guy. Haven’t met him yet but he should be really good at that stuff. I believe he specializes in what you call paintless dent repair. Looking forward to seeing him in action.

Last week I was playing around with my new fenders adjusting everything here and there so we could give another go at the nose frame. The main issue were the edges on which the fenders rest. Remember, I did some repairs there and I had angled the edge too high. This was causing some fitment issues near the doors. But some bending and tapping later the panels started to fit well. Well enough that when my buddy came over again to help me out we went on and welded in the frame straight away.

Hood gaps are good, driver’s side fender fits really nice, passenger’s side could do with a little bit more tinkering. After taking it apart and putting it back together for more than 25 times, I’m really glad to finally have the nose frame installed. Well almost installed, as I still need to fit the corner pieces and then the ABS and battery plates. But after that all the metal work on the chassis should be done.

An update is long overdue.

First attempt at getting the nose fitted was kind of a bust. After spending many hours trying to get those old rusty fenders to fit we decided it would be best to wait until the new ones arrive so if anything needs adjustment (read: hammering) it gets adjusted with the actual panels going on the car.

So, until fenders arrived I had to focus on other stuff. I don’t have much anything to show from May, thus the lack of updates. Took last trim pieces and trinkets off the doors, went through the axles removing some old bushings and getting things ready for sandblasting. Installed the replica steering box reinforcement piece I had bought from e28goodies. Fits well, unfortunately no pics for now.

Built myself a small sandblasting cabinet out of an old oil drum so I could conveniently blast smaller things. Designed it so I could stick the gun of my large (is it though!?) sandblaster into the cabinet but this didn’t work out very well - the hose is really stiff and you can’t move it around much. Need to get a small siphon type blasting gun just for the cabinet.

Can't find a photo of finished cabinet but you get the gist.

Then I began to strip the hood and the trunk lid of paint. I knew I had to do some repairs near the cabin air intakes are but first I wanted to be sure there aren’t any other big surprises waiting for me underneath the paint. Under the green paint (hood was from the first car) were original layers of paint and primer, so all good.

Here’s a pic of the hood from later on, already waiting for the primer.

Some patches were due.

And one patch for the other side

Sometime in the beginning of June my new fenders arrived. This time they had put some effort into packaging. Not sure if I mentioned it before but the nose frame was just delivered loosely in a cardboard box.

Since there was plenty of surface rust around all the openings in the bottom structure of the hood, I decided to strip this as well. In the large middle sections I just sanded it down to the e-coat. But damn this factory e-coating is tough...

Getting here (paint and one layer of primer removed) took about 1.5-2 hours.

Getting through all the e-coating took about me about 7 hours (including the breaks but still).

Here you can see the tool I used to strip the bottom structure, attached to it are 3M stackable bristle discs. Really nice abrasive for something like this.

Bottom side all cleaned up

Trunk lid, on the other hand, had about 9 layers on it, including a layer of spray putty. So I was rather surprised not finding any damage after cleaning off this side.

But there were plenty of dents in other sections.

At least all those layers came of pretty quickly and most of those dents shouldn’t be hard to remove. Rust-wise this panel is really solid. I do have another trunk lid but it has the holes for the lip and a large opening underneath the badge, most likely from an attempt to unlock the trunk. Welding these shut would bring up another bunch of issues so I’ll stick to this lid.

Cleaned up

Time to shoot some acid primer on these panels.

Notice that I forgot to shoot some primer on the area in the middle. According to the datasheet the following primer is okay to put on bare metal so I didn’t bother running another session just for that small area underneath the hood.

Some days later I shot the underside of both panels.

Top sides were done by my buddy as I didn’t want to risk messing these up.

This allowed me to get some shots of him in the action.

Both panels done and dry

This dark primer will also work as a guide coat for the dent guy. Haven’t met him yet but he should be really good at that stuff. I believe he specializes in what you call paintless dent repair. Looking forward to seeing him in action.

Last week I was playing around with my new fenders adjusting everything here and there so we could give another go at the nose frame. The main issue were the edges on which the fenders rest. Remember, I did some repairs there and I had angled the edge too high. This was causing some fitment issues near the doors. But some bending and tapping later the panels started to fit well. Well enough that when my buddy came over again to help me out we went on and welded in the frame straight away.

Hood gaps are good, driver’s side fender fits really nice, passenger’s side could do with a little bit more tinkering. After taking it apart and putting it back together for more than 25 times, I’m really glad to finally have the nose frame installed. Well almost installed, as I still need to fit the corner pieces and then the ABS and battery plates. But after that all the metal work on the chassis should be done.

Re: Another restoration - 83' 528i

Impressive. Subscribed!

Re: Another restoration - 83' 528i

July 2021

After refitting the driver’s side fender a bunch of times again I was happy with how it sat and it was time to move on with the corner section. Put in some temporary support pieces to keep the nose frame where it has to be and started stretching the piece to form the beads.

Beads done, shape adjusted and trimmed - ready for welding.

Tacked in

Welded and planished. Managed to make a couple of slight grind marks on the inside. Grinding upside down in tight places can be quite a challenge. Fortunately they are hidden from plain sight and not really visible looking down into engine bay.

Battery plate installed

New mount for ground. No copper plating though...

Now need to repeat it on the other side. Last night already got the passenger side fender sitting really nice.

On the driver's side there's this flat area below fuse box that also needs some more planishing. I hammered out a long deep dent there and was left with quite a bit of tin-canning. Shrunk it with torch and have to smooth it all out now.

Thinking about all the paint that still needs to be removed I decided to give chemical paint strippers a try. Issue is that a while back EU banned all the good stuff and consensus is current strippers don’t do much to car paints. But I was quite sure the spray can yellow paint would come off without any issues and that’s already a lot of sanding I don’t have to do.

First test piece was passenger side rear door since it had a nasty low section underneath the door handle that called out trouble. Top layer flaked off in a matter of minutes.

The non-OEM paint underneath that was a bit more resilient but still came off easy enough revealing all the filler.

I might be better off using another door I have but we’ll see.

Other than the filler it was probably about 30-45 minutes of hands on time in total to get the whole outer side stripped to bare metal. So it’s a win. To see what this stripper could do to OEM paint I left a small section on sunroof cooking overnight. It seemed to at least soften the paint on that sunroof so if it doesn’t flake off itself maybe I could still scrape it off.

After refitting the driver’s side fender a bunch of times again I was happy with how it sat and it was time to move on with the corner section. Put in some temporary support pieces to keep the nose frame where it has to be and started stretching the piece to form the beads.

Beads done, shape adjusted and trimmed - ready for welding.

Tacked in

Welded and planished. Managed to make a couple of slight grind marks on the inside. Grinding upside down in tight places can be quite a challenge. Fortunately they are hidden from plain sight and not really visible looking down into engine bay.

Battery plate installed

New mount for ground. No copper plating though...

Now need to repeat it on the other side. Last night already got the passenger side fender sitting really nice.

On the driver's side there's this flat area below fuse box that also needs some more planishing. I hammered out a long deep dent there and was left with quite a bit of tin-canning. Shrunk it with torch and have to smooth it all out now.

Thinking about all the paint that still needs to be removed I decided to give chemical paint strippers a try. Issue is that a while back EU banned all the good stuff and consensus is current strippers don’t do much to car paints. But I was quite sure the spray can yellow paint would come off without any issues and that’s already a lot of sanding I don’t have to do.

First test piece was passenger side rear door since it had a nasty low section underneath the door handle that called out trouble. Top layer flaked off in a matter of minutes.

The non-OEM paint underneath that was a bit more resilient but still came off easy enough revealing all the filler.

I might be better off using another door I have but we’ll see.

Other than the filler it was probably about 30-45 minutes of hands on time in total to get the whole outer side stripped to bare metal. So it’s a win. To see what this stripper could do to OEM paint I left a small section on sunroof cooking overnight. It seemed to at least soften the paint on that sunroof so if it doesn’t flake off itself maybe I could still scrape it off.

Re: Another restoration - 83' 528i

August 2021

First of all, the paint stripper works rather well. Especially on OEM paints. It looks like the clear coat usually bubbles up, paint and primer underneath it doesn’t but once it soaks through these layers and reaches factory e-coat everything just comes off the metal at once.

Seems like it doesn’t work as well on some newer paints. The sunroof I have is actually a replacement panel (black e-coat underneath) and it really struggled getting anything off of it. Fortunately most of the panels and chassis are still under factory paint.

Here’s some proof of it

One of these doors was completely rust free, a couple of dents though. Other door needed a small patch and a new bottom channel for the gasket.

Used some panel adhesive and a couple of plug welds on the channel but that didn’t work as well as I had hoped. Might have to redo it later.

It’s quite a struggle to get these channels attached and I have four more channels to redo on other two doors. I wouldn’t risk relying only on adhesive as the gasket squishes it quite a bit when you open and close the doors. There’s almost no access to grind down the welds. I’ve thought about all kinds of rivets, screws or studs but there’s absolutely no room or panel thickness for these. So I guess my only option is to just plug weld these, skip the adhesive, try to grind down as much as possible and seal them all around with some sealer.

Finished up the nose job by fixing the other corner. For some reason getting the patch into arrangement didn’t go as smoothly as on the other side. At some point remade the replacement piece from scratch. Other than that it’s pretty much the same as other side.

Maybe you noticed I decided to remove all the mounts for ABS pump. This car won’t be having an ABS and thus I prefer the cleaner look.

That’s pretty much all metalwork done on the chassis now. Going through vinceg’s recent posts to his M535i thread I realized I didn’t make lower mounting holes for the front mud guards. Some other minor adjustments here and there.

As the rotisserie is not fit for paint work I built a dolly. It’s pretty much the same that cek had for Minerva, just moved the front mounting points forward so I could bolt it directly to the frame rails.

Car still has to go back on the rotisserie to coat the underside but I though I’d better strip the outer shell and cover with some acid primer first.

Shot primer on the sunroof and on some other trinkets I had lying around.

A nice uneven coat of acid primer.

Followed by this

The cabin air intakes for the hood will be attached using adhesive and stainless steel rivets, thus the holes on the flanges.

Meanwhile, started stripping the roof.

A little bit of DA action later

While cleaning the door jambs I discovered that the attachments for the rear door brakes had become loose and have been fixed in the past. One side was poorly tacked back on from the outside, other side was fixed with a bolt. Also on passenger’s side there were some cracks right next to it in the B-pillar. Not sure how I hadn’t spotted it before but now all got properly fixed.

Decided to do the chassis in two stages, first the door jambs and roof and then the rear end. So here we have first part cleaned, masked and ready.

The tops of these repro side sills are ugly. If I’d have to do it again I’d probably remove the original sills, patch the rusted sections, planish the welds off car and then reinstall. I hope that body shop can make something presentable out of these. At least the ugly parts will be covered by the doors…

Back to yellow

I like how the acid primer highlights the brazings

Almost forgot, these arrived

Look and feel great. I had about 8 different ideas how I could fix or replace my front wire boots but I pretty much hated each one. Get yours before they run out of stock!

First of all, the paint stripper works rather well. Especially on OEM paints. It looks like the clear coat usually bubbles up, paint and primer underneath it doesn’t but once it soaks through these layers and reaches factory e-coat everything just comes off the metal at once.

Seems like it doesn’t work as well on some newer paints. The sunroof I have is actually a replacement panel (black e-coat underneath) and it really struggled getting anything off of it. Fortunately most of the panels and chassis are still under factory paint.

Here’s some proof of it

One of these doors was completely rust free, a couple of dents though. Other door needed a small patch and a new bottom channel for the gasket.

Used some panel adhesive and a couple of plug welds on the channel but that didn’t work as well as I had hoped. Might have to redo it later.

It’s quite a struggle to get these channels attached and I have four more channels to redo on other two doors. I wouldn’t risk relying only on adhesive as the gasket squishes it quite a bit when you open and close the doors. There’s almost no access to grind down the welds. I’ve thought about all kinds of rivets, screws or studs but there’s absolutely no room or panel thickness for these. So I guess my only option is to just plug weld these, skip the adhesive, try to grind down as much as possible and seal them all around with some sealer.

Finished up the nose job by fixing the other corner. For some reason getting the patch into arrangement didn’t go as smoothly as on the other side. At some point remade the replacement piece from scratch. Other than that it’s pretty much the same as other side.

Maybe you noticed I decided to remove all the mounts for ABS pump. This car won’t be having an ABS and thus I prefer the cleaner look.

That’s pretty much all metalwork done on the chassis now. Going through vinceg’s recent posts to his M535i thread I realized I didn’t make lower mounting holes for the front mud guards. Some other minor adjustments here and there.

As the rotisserie is not fit for paint work I built a dolly. It’s pretty much the same that cek had for Minerva, just moved the front mounting points forward so I could bolt it directly to the frame rails.

Car still has to go back on the rotisserie to coat the underside but I though I’d better strip the outer shell and cover with some acid primer first.

Shot primer on the sunroof and on some other trinkets I had lying around.

A nice uneven coat of acid primer.

Followed by this

The cabin air intakes for the hood will be attached using adhesive and stainless steel rivets, thus the holes on the flanges.

Meanwhile, started stripping the roof.

A little bit of DA action later

While cleaning the door jambs I discovered that the attachments for the rear door brakes had become loose and have been fixed in the past. One side was poorly tacked back on from the outside, other side was fixed with a bolt. Also on passenger’s side there were some cracks right next to it in the B-pillar. Not sure how I hadn’t spotted it before but now all got properly fixed.

Decided to do the chassis in two stages, first the door jambs and roof and then the rear end. So here we have first part cleaned, masked and ready.

The tops of these repro side sills are ugly. If I’d have to do it again I’d probably remove the original sills, patch the rusted sections, planish the welds off car and then reinstall. I hope that body shop can make something presentable out of these. At least the ugly parts will be covered by the doors…

Back to yellow

I like how the acid primer highlights the brazings

Almost forgot, these arrived

Look and feel great. I had about 8 different ideas how I could fix or replace my front wire boots but I pretty much hated each one. Get yours before they run out of stock!

Re: Another restoration - 83' 528i

It has come a long way, some great work done to get to this stage. You should be very proud of your work. You could pay a lot of money for work from professionals which would not come close to your standard.

With regard to the doors I have found the same problem with the channel for the seal. I tacked at the top of the channel and at the bottom alternating along the length. 'The bottom is easy to grind down and a thin layer of sealer covers and seals the gap.

For the next doors I have to do I might try a tig spot weld, which should leave no grinding.

For the top and confined space I use a 75mm grinding wheel on an air grinder. As it is at a right angle it fits down into the channel. The dremel grinding discs are good as well but do not have the reach of the larger 75mm disc.

With regard to the doors I have found the same problem with the channel for the seal. I tacked at the top of the channel and at the bottom alternating along the length. 'The bottom is easy to grind down and a thin layer of sealer covers and seals the gap.

For the next doors I have to do I might try a tig spot weld, which should leave no grinding.

For the top and confined space I use a 75mm grinding wheel on an air grinder. As it is at a right angle it fits down into the channel. The dremel grinding discs are good as well but do not have the reach of the larger 75mm disc.

Re: Another restoration - 83' 528i

I wish I had a TIG every time I do some welding on the car. It's on my bucket list but for now a MIG must do.///M wrote: Aug 29, 2021 11:01 AM For the next doors I have to do I might try a tig spot weld, which should leave no grinding.

That's what I used to grind down a couple of these but some of my welds are in the corners and disc doesn't fit well in there. A small used up disc would fit but then I had trouble reaching the weld. I guess I should plan the welds out better and might get away with it.///M wrote: Aug 29, 2021 11:01 AM For the top and confined space I use a 75mm grinding wheel on an air grinder. As it is at a right angle it fits down into the channel. The dremel grinding discs are good as well but do not have the reach of the larger 75mm disc.

Another thing I bought was a very thin flap wheel that fits into the channel. This might help to get a bit nicer finish.

Also maybe some properly sized carbide burrs could do but I haven't explored this option yet.

Re: Another restoration - 83' 528i

So much win! Awesome

Re: Another restoration - 83' 528i

September 2021

I gave it some more through and this

Stripped the rear end. All original paint job (under the spray can top coat) so not many unpleasant surprises. Levelled out couple of my welds a bit better. The flat area where license plate goes needed a lot of work - for some reason it got sandblasted together with the underside and was all wavy from it. Not sure how I hadn’t noticed it before, guess I just subconsciously ignored the mess it was. I was afraid to stretch it out even more working on it. In the end, I got it better and was able to avoid oil-canning. Not perfectly straight, but will do.

My initial plan was to only shoot the acid primer on the outside for some protection and leave the rest for the paint shop. But when I went to buy some more primer my paint gal talked me into doing the whole chassis myself. Her arguments were that it would give much better protection and since it gets sanded down during the body/filler work anyway it doesn't matter if you mess it up. So I took her advice and messed it up.

Actually rear end didn’t come out that bad. First, a layer of etching primer followed by surfacer the next day.

Roof and sides a couple of days later. Pillar areas are where I mostly screwed up - a lot of paint runs. Roof came out quite nice. It would have been better haven’t the gun run out in the middle of the panel. I guess planning isn’t my strong suit.

Then back into the rotisserie for underside, trunk and engine compartment.

Did the underside, wheel arches and trunk in one go. It was rather nasty. First all the scuffing, cleaning and masking. Then the paint gun doesn’t fit where you want it to fit. All that primer flying back at you from the wheel arches and trunk. But eventually, once the car matched the color of my face, everything was all right.

Now It was finally time to install something back on the chassis, namely the trunk plugs.

Also glued in the large plug in the bottom of the spare wheel housing and installed the remaining rivet nuts for fuel/brake line clips.

To have a small break from all that paint work I welded the adjustable rear subframe kit in place. The kit was bought from Bimmertune. Quality seems good. Still need to slot the bolt holes, cut and reinforce the inner brackets. Then I can finally take all the subframe parts to sandblasting.

A wise man would have shot the engine compartment together with underside to avoid all that masking nightmare. But with all the nooks and brackets there I really didn’t want to risk doing it myself. Furthermore I didn’t see much reason do redo the nose frame at this point as I’m sure paint shop will shoot another layer of primer on top of it later on. And I still had some dark gray primer left so I rather had the whole engine compartment in matching color.

Anyway, yesterday my buddy made a really nice job on it.

This is how it sits now. Hopefully, I’m able to shoot the undercoat upcoming weekend. Then make new brake lines while car’s still on rotisserie and after that it can stay right-side-up for good.

I gave it some more through and this

sounds like good advice. As I wasn’t really happy with the installation of the previous channel rail it got removed and a new one is ready to go on. Though, installation’s been left on the back burner til I get some more done on the chassis.///M wrote: Aug 29, 2021 11:01 AM I tacked at the top of the channel and at the bottom alternating along the length.

Stripped the rear end. All original paint job (under the spray can top coat) so not many unpleasant surprises. Levelled out couple of my welds a bit better. The flat area where license plate goes needed a lot of work - for some reason it got sandblasted together with the underside and was all wavy from it. Not sure how I hadn’t noticed it before, guess I just subconsciously ignored the mess it was. I was afraid to stretch it out even more working on it. In the end, I got it better and was able to avoid oil-canning. Not perfectly straight, but will do.

My initial plan was to only shoot the acid primer on the outside for some protection and leave the rest for the paint shop. But when I went to buy some more primer my paint gal talked me into doing the whole chassis myself. Her arguments were that it would give much better protection and since it gets sanded down during the body/filler work anyway it doesn't matter if you mess it up. So I took her advice and messed it up.

Actually rear end didn’t come out that bad. First, a layer of etching primer followed by surfacer the next day.

Roof and sides a couple of days later. Pillar areas are where I mostly screwed up - a lot of paint runs. Roof came out quite nice. It would have been better haven’t the gun run out in the middle of the panel. I guess planning isn’t my strong suit.

Then back into the rotisserie for underside, trunk and engine compartment.

Did the underside, wheel arches and trunk in one go. It was rather nasty. First all the scuffing, cleaning and masking. Then the paint gun doesn’t fit where you want it to fit. All that primer flying back at you from the wheel arches and trunk. But eventually, once the car matched the color of my face, everything was all right.

Now It was finally time to install something back on the chassis, namely the trunk plugs.

Also glued in the large plug in the bottom of the spare wheel housing and installed the remaining rivet nuts for fuel/brake line clips.

To have a small break from all that paint work I welded the adjustable rear subframe kit in place. The kit was bought from Bimmertune. Quality seems good. Still need to slot the bolt holes, cut and reinforce the inner brackets. Then I can finally take all the subframe parts to sandblasting.

A wise man would have shot the engine compartment together with underside to avoid all that masking nightmare. But with all the nooks and brackets there I really didn’t want to risk doing it myself. Furthermore I didn’t see much reason do redo the nose frame at this point as I’m sure paint shop will shoot another layer of primer on top of it later on. And I still had some dark gray primer left so I rather had the whole engine compartment in matching color.

Anyway, yesterday my buddy made a really nice job on it.

This is how it sits now. Hopefully, I’m able to shoot the undercoat upcoming weekend. Then make new brake lines while car’s still on rotisserie and after that it can stay right-side-up for good.

Re: Another restoration - 83' 528i

Are you intending to lower the car more than standard? If you are then I would suggest you slot the outer trailing arm mount to give increased toe in. The lower the car goes then the toe out increases. The nature of trailing arm suspension is the lower you go then toe out keeps increasing. Making the slot towards the front of the car so that the larger part of the cam lobe of the adjuster is facing the rear gives you maximum toe in to correct for lowering,

Re: Another restoration - 83' 528i

Car will most likely get Spax springs. Plan B is H&R.///M wrote: Sep 30, 2021 1:56 PM Are you intending to lower the car more than standard? If you are then I would suggest you slot the outer trailing arm mount to give increased toe in. The lower the car goes then the toe out increases. The nature of trailing arm suspension is the lower you go then toe out keeps increasing. Making the slot towards the front of the car so that the larger part of the cam lobe of the adjuster is facing the rear gives you maximum toe in to correct for lowering,

I followed the instructions on Garagistic website. Toe plates went in so that the original hole is centered to give equal amount of toe correction in either direction. Camber plates were installed to provide only positive camber correction.

I guess it makes sense to also install the toe plates asymmetrically but it's already done. And by now one side is slotted as well. We'll see if that's enough or not once the car is back together.