I'm in the break-in stages of my most recent M30 turbo engine build. This one is a fully forged bottom end with 9:1 DP pistons and PPF rods. I wanted to add piston cooling nozzles to this build, and while I was ok with machining a B34 block, I found a local M106 to use instead. Long story short, I ended up going through a couple of blocks to find one that didn't have rusted out cylinders. Maybe I should've machined a B34, hind-sight is 20/20. Once I had a good useable block, the machine shop went to work roto-blasting the crap off and working their magic. Ever since I moved to North Texas, I was on the hunt for a good machine shop. I found a really interesting place in Alvarado called Engineered Performance Racing. They cater to the Nissan crowd, and when I dropped all my stuff off, he was finishing a build on an NPT90 twin turbo v6 engine from one of the 1990 IMSA GT cars.

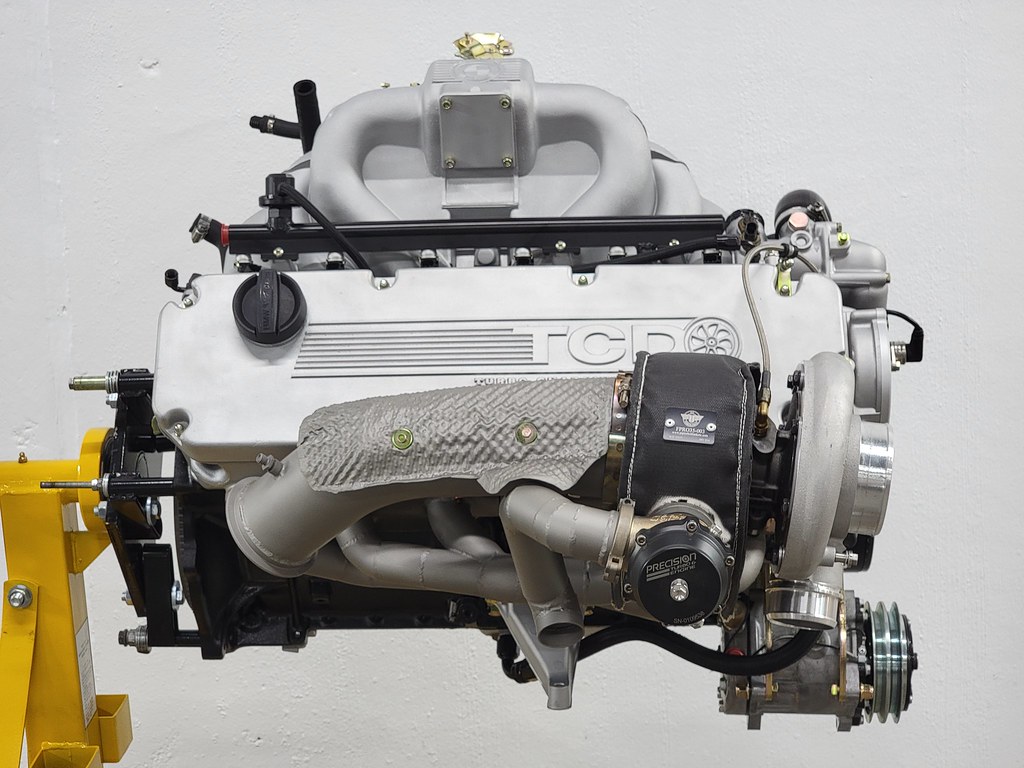

The work done on the block includes torque plate bore and hone, deck and line-hone. The crank was polished, the rods were checked and honed to match the pins and crank and the reciprocating assembly was balanced. Everything was blueprinted and assembled after cleaning and painting of the block. New piston coolers from BMW were installed, along with a double row timing set and new chain. The oil pump was spec'd and rebuilt with all new internal components from BMW.

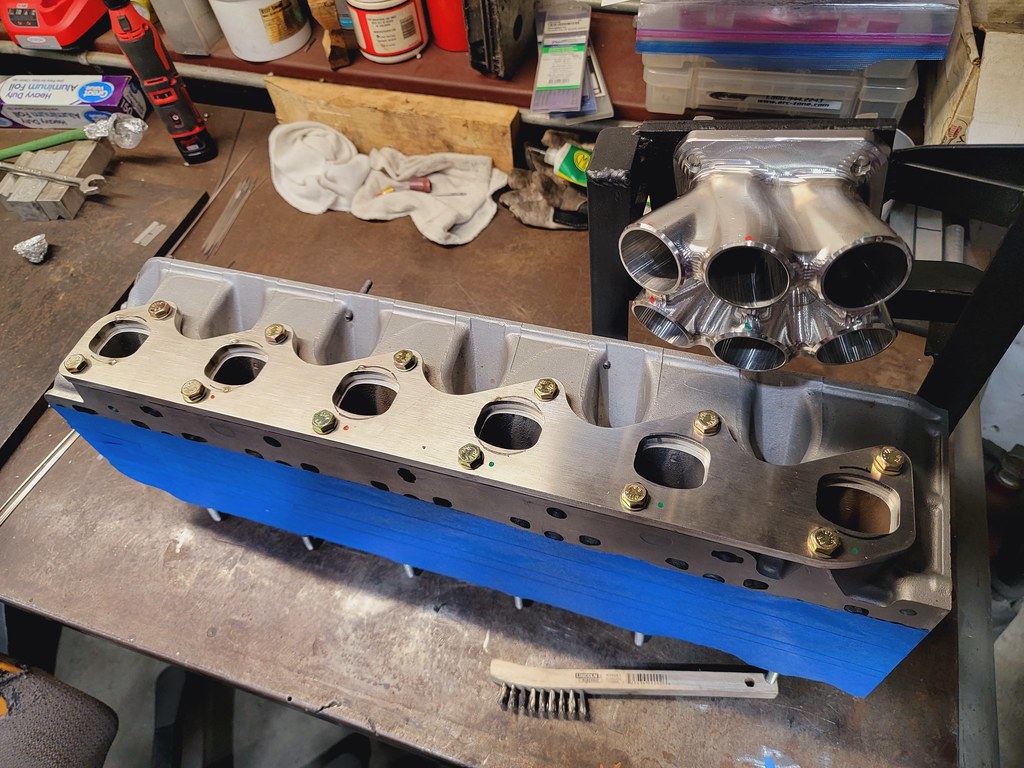

The head needs no introduction; a fully CNC ported piece from Paul Burke. The cam is the same PB turbo cam I purchased from him directly about 10 years ago. All new valve springs were checked and fitted, as well as the rest of the valvetrain- all per PB specs. I basically replaced everything but the rocker arms and followed the same setup procedure he outlined when I first installed the cam way back in the day. The exhaust ports were much larger than B35 exhaust gaskets, and it was no easy task gasket matching that side of the engine. The b35 intake is tiny in comparison to the intake ports, and this engine will most likely need different induction at some point. For now, I want to see numbers from the flipped LS TB B35 intake. Oh, and I'm sure staged injection to run E85 at full boost will definitely be required. But, for now, we're going to see what the B35 does on a dyno so I have some data to compare to.

Everything on the engine was vapor honed, plated, cerakoted, painted, custom made or replaced. I don't feel like I could build a newer engine than this, at least one setup with the proven driveability and reliability this one has given me for so many years and miles. My only regret is not driving the car more between revisions or improvements, but we are a full decade on with what started as a side project car that was my winter beater.

Finally getting around to the MRT Engineering crank hub and adapter to use an ATI Super Damper was a fun project, for sure. Adapting an OE quality serpentine drive on this engine was no walk in the park. While several of the components are off-the-shelf BMW parts, using them meant lots of machine work. The goal was to have a slack side tensioner, idler between p/s and alt- all while retaining side-of-the-road serviceability. The only part you can't buy that would fail, is the alternator. My particular setup did not allow for a serpentine drive a/c compressor, since my aftermarket radiator doesn't give me the space needed. So there is a V-belt pulley that looks ugly by covering up the ATI damper, so it was left off for the photo shoot. Don't worry, there's no blue tooth A/C on the car. There is still room for improvement with this setup, like a pad mount alternator maybe, but it is working as intended and I am currently developing this system further for anyone interested in this as a kit.

Other than a brand new super core Borg Warner SX366E turbo, most of the forced induction hardware is unchanged. The turbo manifold is a Rapid Spool twin scroll that Otis made. I've capped off the wastegate port and moved it to the turbine housing. I also cut the flange into 2 banks and milled the surface to prevent leaks. Precision Turbo wastegate into an open dump that's seen about 40k miles and sounds fantastic. ID1000 injectors and my own custom -8 fuel rail, Aeromotive adjustable fuel pressure regulator and a Radium surge tank with two Aeromotive 340 pumps. MS3X runs it all with closed loop idle and EGO that makes the MS1 days seem like carbs.

I'm sure I'm leaving out a ton of details about everything that's gone into this setup over the years. Just ask about anything not covered.

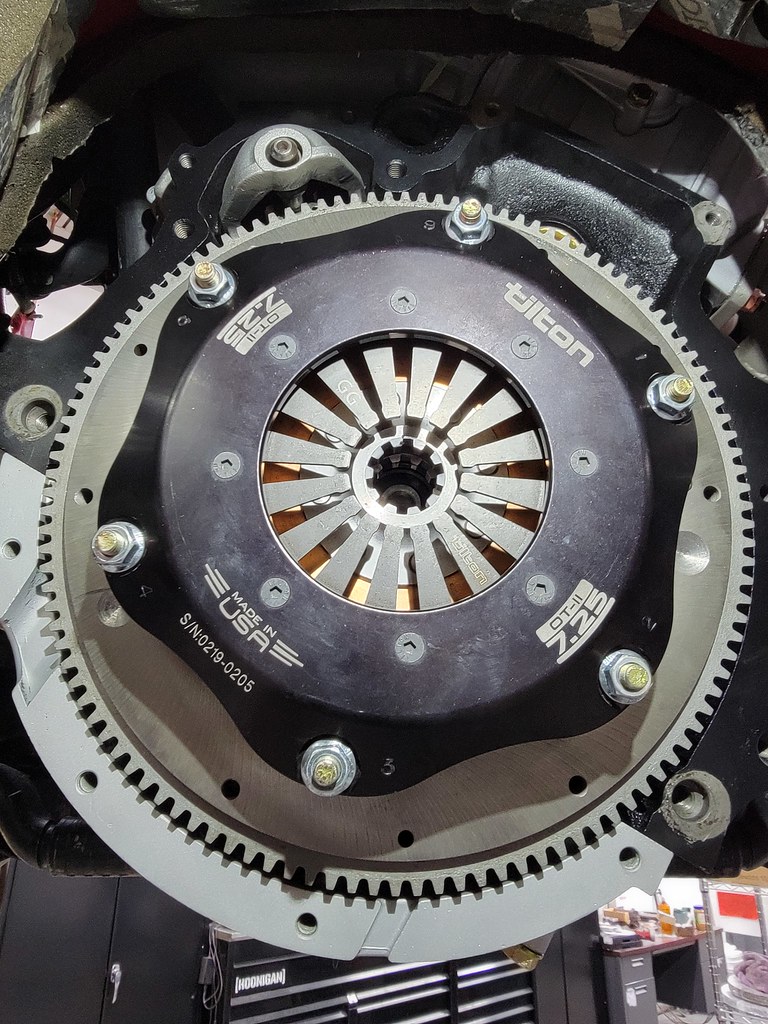

To get the car driving, and out of curiosity, I assembled the Tilton clutch to use the stock master and slave cyl, like I had for many years. Since I like the idea of stock-like driveability, I'm adding a 6200 series Tilton hydraulic release bearing into the bell housing of the G265 trans. Since the pilot shaft tube has more girth than King Kong, no off-the-shelf bearing would slide over it. I had a new pilot tube made with a more industry-standard size. Since this tube simply replaces the stock tube, it is fully reversible. The piston area of the HRB is matched to the stock clutch master cylinder, so I'm expecting a smooth pedal feel. A co-worker has confirmed it with experience using this HRB, so fingers crossed.

I'll dive into more about the engine and car in later updates, and be sure to add plenty of pics. For now I just wanted to poke my head in and say Hi to this forum that lead me on such a great automotive journey.

Previous engine: