535 shortblock tech.

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

Looking at my M90 head this afternoon, that 26 degrees really limits intake port movement doesn't it? If a guy wants a straighter shot at the back of the valve, that's a hell of a lot of work to do.

The valve flow coef of .3 might indeed be low. I've seen figures ranging from .19 to .49 . I don't have enough data on BMW engines to guess where it might be so your numbers might be more accurate. When it comes to cylinder finishing, Honda has everyone beat. Not only do they finish-hone their cylinders fast (I seem to recall 3 seconds per hole), but I'm told by "connected" individuals that they've not been able to duplicate the cylindricity even in the serious race shops. I've also heard rumours of laser-peening the cylinder bore finish, active honing heads making not-round shapes intentionally...It's still half black-art and half science.

. I don't have enough data on BMW engines to guess where it might be so your numbers might be more accurate. When it comes to cylinder finishing, Honda has everyone beat. Not only do they finish-hone their cylinders fast (I seem to recall 3 seconds per hole), but I'm told by "connected" individuals that they've not been able to duplicate the cylindricity even in the serious race shops. I've also heard rumours of laser-peening the cylinder bore finish, active honing heads making not-round shapes intentionally...It's still half black-art and half science.

The valve flow coef of .3 might indeed be low. I've seen figures ranging from .19 to .49

Canuck,Canuck YYC wrote:Mahle is, in my opinion, the only piston manufacturer. I've used spec. ordered stuff from J&E, Wiseco and OEM aftermarket parts of unknown manufacturer and hands-down the Mahle parts were always the nicest.

Please elaborate on this comment.

I'm planning a buildup using high-comp pistons and would probably be using the original 10:1 Mahles as installed on the Euro M30's, if they were still available. However, I've been told they are NLA and that the J&Es and Wisecos are high quality alternatives. I've never used either brand before.

In what way did you feel the Mahles were far superior? Were they better quality forgings? Were the machined tolerances more accurate and/or consistent?

Larry

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

Larry, He is referring to Mahle Motorsport, not OE Mahle. They are forged and you would have to custom order them through Mahle North America. They are very good quality and quite expensive, I use them in my circle track Chevrolet stuff. If I new that I could sell them for BMWs, I would have some made. One of the guys that used to work on my BMW pistons, now works for them.

Paul

Paul

The stock Mahle's in my 528 are over 260k miles, the last 30 thousand of which have been under the stresses of reckless forced induction and brutal daily abuse. The only thing I dont do is open it up until its thoroughly warmed up, but other than that those pistons have gone through hell and they're still going.LarryM wrote: Canuck,

Please elaborate on this comment.

I'm planning a buildup using high-comp pistons and would probably be using the original 10:1 Mahles as installed on the Euro M30's, if they were still available. However, I've been told they are NLA and that the J&Es and Wisecos are high quality alternatives. I've never used either brand before.

In what way did you feel the Mahles were far superior? Were they better quality forgings? Were the machined tolerances more accurate and/or consistent?

Larry

I'd be afraid to run any other kind of piston. The stock BMW stuff has left no room for improvement in my experience.

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

I've found the Wiseco parts to be effective but noisy even when warm. The JE stuff also works, but when I'm dealing with a manufacturer of something, I want them to know more than I do. I'm not saying the folks of J&E don't, but when talking to their sales department there was a lot of "yeah, whatever you want". I have no problem saying that I don't know everything about piston and ring design - when I call someone like JE or Mahle I have an (perhaps unwarranted) expectation that the individual on the other end of the phone has more knowledge and understanding than I do, afterall pistons are their job. When I get the telephone equivalent of blank stares and shrugged shoulders with a yeah, whatever attitude, I can't recommend them.LarryM wrote:Canuck,Canuck YYC wrote:Mahle is, in my opinion, the only piston manufacturer. I've used spec. ordered stuff from J&E, Wiseco and OEM aftermarket parts of unknown manufacturer and hands-down the Mahle parts were always the nicest.

Please elaborate on this comment.

I'm planning a buildup using high-comp pistons and would probably be using the original 10:1 Mahles as installed on the Euro M30's, if they were still available. However, I've been told they are NLA and that the J&Es and Wisecos are high quality alternatives. I've never used either brand before.

In what way did you feel the Mahles were far superior? Were they better quality forgings? Were the machined tolerances more accurate and/or consistent?

Larry

I had good technical and product experience with the KB hypereutectic pistons from United Engine and Machine, but strange politics and deals made business a nightmare. On Monday the price for 10 sets of pistons would be X, the following Monday it would be 1.5X and by Friday they would not be allowed to sell them to me. Then, the next time I ordered something, it would be smooth as glass. Go figure. I've seen one of these pistons come in with a crack running in excess of 2/3rds the circumference of the skirt and still holding together. Remarkably tough.

Mahle is, as Paul pointed out, expensive but their products are works of art and engineering. Their sales rep was way more than willing to spend time with me until I got what I wanted, and he always knew the answer or someone that did. I've not yet had a problem with a Mahle Motorsport piston, perhaps I've not pushed them hard enough. While we are talking their Motorsport division, the fact that they are OE for so many speaks volumes about their knowledge and understanding of the piston.

Mahel OE BMW M30. I'm not sure which particular M30 you're looking for, but that's a link to Mahle's M30B35 w/260ps from the 86-89 635CSi, for starters.

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

Andrew, no negatives on Mahle pistons, but if you're looking at something which may be out of the ordinary, e.g., pin placement, non-stock ring profiles, specialized off-center dish location, etc. I don't know if Mahle could do it other than at major $$$.

When the pistons were built for LH, admittedly a FI project, there was a lot of back-and-forth on the dimensions. This meant telling JE that we needed to talk directly with the engineers to get things ironed out. Paul's done quite a bit with JE and what we got was what was asked for.

This meant that there were specific instructions as to alloy in the forging as well as just about every other dimension and variable.

If you, the customer, are in a position to know just what it is you're after, it makes things a whole lot easier for the engineer to understand what you're trying to accomplish. Thus, there may be observations, insights and suggestions based on his expertise that can help matters along.

Oftentimes the phone desk guys may not have the in-depth expertise to anser all your questions. So once again, doing the homework (and the "science", Dan, ) may save you a whole lot of time grief and money.

) may save you a whole lot of time grief and money.

When the pistons were built for LH, admittedly a FI project, there was a lot of back-and-forth on the dimensions. This meant telling JE that we needed to talk directly with the engineers to get things ironed out. Paul's done quite a bit with JE and what we got was what was asked for.

This meant that there were specific instructions as to alloy in the forging as well as just about every other dimension and variable.

If you, the customer, are in a position to know just what it is you're after, it makes things a whole lot easier for the engineer to understand what you're trying to accomplish. Thus, there may be observations, insights and suggestions based on his expertise that can help matters along.

Oftentimes the phone desk guys may not have the in-depth expertise to anser all your questions. So once again, doing the homework (and the "science", Dan,

Must be a California thing. You were probably dealing with products of the L.A. Unified School System.Canuck YYC wrote: ......The JE stuff also works, but when I'm dealing with a lmanufacturer of something, I want them to know more than I do. I'm not saying the folks of J&E don't, but when talking to their sales department there was a lot of "yeah, whatever you want". I have no problem saying that I don't know everything about piston and ring design - when I call someone like JE or Mahle I have an (perhaps unwarranted) expectation that the individual on the other end of the phone has more knowledge and understanding than I do, afterall pistons are their job. When I get the telephone equivalent of blank stares and shrugged shoulders with a yeah, whatever attitude, I can't recommend them.

Top End Performance (a BMW engine building shop, also in the L.A. area) was recommended for machine work. They also sell J&E pistons and have told me they can have the pistons made to whatever compression ratio spec I want. At least that way, with Top End acting as the middleman, I wouldn't have to deal with airheads. Still, I wouldn't want to be running pistons made by guys with that kind of attitude.

Thanks for the Mahle Motorsport link. I'll get in contact with them and see how much a set of pistons would run.

Larry

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

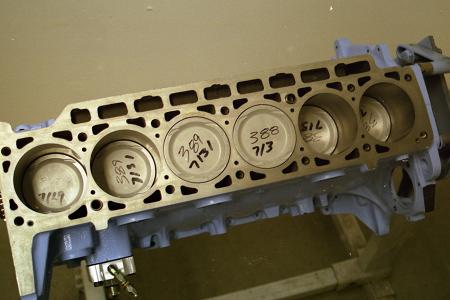

Larry, not necessarily the clearest photos, but they may give you some idea of what JE came up with. In the first photo, you can see the eyebrow cuts for radial clearance on the valve faces where they intersect the annular ring of the squish area. The dished central area , or "reverse dome" is obvious.

Worth mentioning, the thickness of the piston crown at the bottom of the dish is approximarely 10.5 mm. This thick mass provides both strength and acts as a heat sink, reducing heat transfer out of the CC and into the rest of the piston itself.

IIRC, the pistons themselves were forged out of 2618 alloy.

The piston crowns have been coated with a zirconium oxide porcelain for reduced heat transfer as well. Stuff comes out sort of flat light gray.

This coating was also applied to the cylinder head and the exhaust tracts.

The numbers reference piston weight in grams, and bore diameter in inches, e.g., 3.7131 for keeping things straight during assembly.

The second photo, showing the side of the piston, shows the amount of distance between the piston crown and the top #1 oil ring. This distance was kept large to provide a metral hear sink and protect the #1 ring from combustion temperature temps. The series of grooves above the ring are a series of so-called "balancing grooves" which effectively add area and help reduce heat transfer from the CC down to the #1 ring.

Between the #1 and #2 rings is another balancing groove which serves to equalize pressure between the two rings and reduces ring lifting. It also acts as an additional barrier to heat transfer.

Under the oil scraper ring, a couple of the oil drain-back holes are visible.

The aluminum end plugs outboard of the wrist pins are obvious, as is the moly disulfide based (?) antifriction coating on the piston skirt, which extends to the underside of the piston.

A dummy con rod is in place in this picture.

Worth mentioning, the thickness of the piston crown at the bottom of the dish is approximarely 10.5 mm. This thick mass provides both strength and acts as a heat sink, reducing heat transfer out of the CC and into the rest of the piston itself.

IIRC, the pistons themselves were forged out of 2618 alloy.

The piston crowns have been coated with a zirconium oxide porcelain for reduced heat transfer as well. Stuff comes out sort of flat light gray.

This coating was also applied to the cylinder head and the exhaust tracts.

The numbers reference piston weight in grams, and bore diameter in inches, e.g., 3.7131 for keeping things straight during assembly.

The second photo, showing the side of the piston, shows the amount of distance between the piston crown and the top #1 oil ring. This distance was kept large to provide a metral hear sink and protect the #1 ring from combustion temperature temps. The series of grooves above the ring are a series of so-called "balancing grooves" which effectively add area and help reduce heat transfer from the CC down to the #1 ring.

Between the #1 and #2 rings is another balancing groove which serves to equalize pressure between the two rings and reduces ring lifting. It also acts as an additional barrier to heat transfer.

Under the oil scraper ring, a couple of the oil drain-back holes are visible.

The aluminum end plugs outboard of the wrist pins are obvious, as is the moly disulfide based (?) antifriction coating on the piston skirt, which extends to the underside of the piston.

A dummy con rod is in place in this picture.

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

Precisely. I don't feel it's my place to to be a piston engineer, a con rod engineer, a pin engineer, bearing shell engineer...you get my drift. When I deal with a manufacturer like Mahle or JE or any other in-house manufacturing vendor, I expect them to know more than I do about the intricacies of their product. A complete engine, much less a complete vehicle is far too large for me to be on the leading edge of current technology all the time. As race teams and OEMs around the world focus tremendous resources on individual areas, it's foolish to think I can keep pace on my own.Ken H. wrote:Paul's done quite a bit with JE and what we got was what was asked for.

This meant that there were specific instructions as to alloy in the forging as well as just about every other dimension and variable.

It's the same principle any business operates on - you form strategic partnerships with vendors that compliment your business. As we've seen, there are a number of piston manufacturers out there - I can do business with any of them, and if I know all the answers to all the questions then who I'm doing business with is of little consequence assuming things like delivery and quality are met. And really, if I know all the answers, why don't I manufacture my own and utilize the rest of the capacity to sell to others?

PhD in Chemical Engineering, PhD in Mechanical Engineering, PhD in Physics and then the real-world experience to qualify, quantify, measure and evaluate everything you learned...there are not enough hours in this lifetime. My job is understand my client's wants, needs and constraints (300hp M30, NA preferred, daily driver, budgeted), evaluate the three areas to determine which gets met and what needs to be adjusted (275hp NA M30 daily driver, solid budget), formulate the plan of action (94 x 90, 11:1, PB heads etc etc), communicate with my strategic partners (Paul, here's what we're doing, here's what I'm thinking, this is what I need from you, what do you think?), take any final tweaks back my client for their information and then bring it all together. Think of it like being the General Contractor on a construction project for lack of a better analogy.

Allright I guess I will tell you guys about my motor build I have had going for a while and things just pop up along the way and it gets put on the back bunners.

I thought I would take a chance and build a mild F1 m30 motor. I started with a m106 block and went out on the limb and bought some air cooled vw 94mm pistons they are mahles. Now when the machine shop overbored the block on one cylinder I wind up taking my L block to the machine shop and he did the right thing and bored it himself and cut the holes for the oiler and drain hole for turbodrain return.

Now I had problems finding out what alloy the mahle vw pistons were made out of and the clearence I should run on them.

Also I will be running a b35 ported head with 39mm exhaust valves one question I had for paul was should I drill an extra steam hole in the b35 head too match the m90 block. Also does anybody know what alloy the mahle vw big bore kits are made out of. For the price I cant see them being 2618 I have gone with the smaller clearence of the 4032.

I will be running a m106 manifold with the upgraded kkk 60 trim I know its not going give me what the tcd kits put out but the car is a daily driver and I want to stay a little conservative.

After reading all the post I know now I should have used my spare b35 block but at the time I thought it would make it easier on the machine shop redoing the L block. Any feedback will be great. I have had second thoughts about the vw pistons and thought about getting some je pistons but part of the build was to see if we could use the vw pistons on a mild F1 build I think its just a matter of getting the clearence issue resolved.

Paul I know your the man and my hat goes off too you and ken for what you have done for the bmw motor performance and sharing what you have.

I also have not decided what thickness to go with on the head gasket we took off .010thds on the head and .010 off the block. I will also be calling paul for a adjustable cam sprocket.

Jimmie

I thought I would take a chance and build a mild F1 m30 motor. I started with a m106 block and went out on the limb and bought some air cooled vw 94mm pistons they are mahles. Now when the machine shop overbored the block on one cylinder I wind up taking my L block to the machine shop and he did the right thing and bored it himself and cut the holes for the oiler and drain hole for turbodrain return.

Now I had problems finding out what alloy the mahle vw pistons were made out of and the clearence I should run on them.

Also I will be running a b35 ported head with 39mm exhaust valves one question I had for paul was should I drill an extra steam hole in the b35 head too match the m90 block. Also does anybody know what alloy the mahle vw big bore kits are made out of. For the price I cant see them being 2618 I have gone with the smaller clearence of the 4032.

I will be running a m106 manifold with the upgraded kkk 60 trim I know its not going give me what the tcd kits put out but the car is a daily driver and I want to stay a little conservative.

After reading all the post I know now I should have used my spare b35 block but at the time I thought it would make it easier on the machine shop redoing the L block. Any feedback will be great. I have had second thoughts about the vw pistons and thought about getting some je pistons but part of the build was to see if we could use the vw pistons on a mild F1 build I think its just a matter of getting the clearence issue resolved.

Paul I know your the man and my hat goes off too you and ken for what you have done for the bmw motor performance and sharing what you have.

I also have not decided what thickness to go with on the head gasket we took off .010thds on the head and .010 off the block. I will also be calling paul for a adjustable cam sprocket.

Jimmie

Ken,

Do you have any idea how much lighter the JE pistons are compared to the stock, cast Mahles? Also, are you running aftermarket rods? From what I've read the stock rods are fine for most performance work but it looks like you're going all-out. I've heard that Carrillo and a company called Pauter produce forged rods for the M30. Any experience with either one?

Larry

Do you have any idea how much lighter the JE pistons are compared to the stock, cast Mahles? Also, are you running aftermarket rods? From what I've read the stock rods are fine for most performance work but it looks like you're going all-out. I've heard that Carrillo and a company called Pauter produce forged rods for the M30. Any experience with either one?

Larry

-

Rich Euro M5

- Posts: 6098

- Joined: Mar 10, 2006 6:20 AM

- Location: Klein, Texas

Larry,

I can't speak to the M30 pistons, however there is a significant weight difference between stock M88/3 and custom forged JE. Along time 0ago I posted the difference as it pertained to my M88 build in the M5 forum, unfortunately I don't recall the exact numbers. My best recollection is about 355 grams for the JE pistons, and 600 to 650 for the cast stock pistons.

About the rods, both Carrillo and Pauter produce custom rods for our engines. Other companies that do this type of work probably can as well.

Rich

I can't speak to the M30 pistons, however there is a significant weight difference between stock M88/3 and custom forged JE. Along time 0ago I posted the difference as it pertained to my M88 build in the M5 forum, unfortunately I don't recall the exact numbers. My best recollection is about 355 grams for the JE pistons, and 600 to 650 for the cast stock pistons.

About the rods, both Carrillo and Pauter produce custom rods for our engines. Other companies that do this type of work probably can as well.

Rich

Larry, I don't know about the stock S38B35 piston weights, but I think they're about 600 gm. I don't have a gram scaleLarryM wrote:Do you have any idea how much lighter the JE pistons are compared to the stock, cast Mahles?

My JEs are in the 388.5-389 gm range; I think I wrote a bit about this in the "Lucifer's Hammer " series, Part 6, IIRC.

Mine are somewhat heavier than Rich's, but as I've indicated, the piston crowns were made hell for stout.

I'm running Carillo rods, with Carr bolts. When we made the choice, I looked closely at both Pauter and Oliver as well. All three have excellent reputations. The cost difference was within 5%; Pauter being lower, but had the longest delivery time. In my experience, Carillo has always offered superlative quality, both in terms of the machining and in their fanatic quality control re. the alloys used. In the scheme of things, these off-the-wall rods may be overkill, but we know for double-dam-sure that the bottom end isn't going to be where this motor sells out. 8)LarryM wrote:Also, are you running aftermarket rods? From what I've read the stock rods are fine for most performance work but it looks like you're going all-out. I've heard that Carrillo and a company called Pauter produce forged rods for the M30. Any experience with either one?

I agree that the stock M30 or S38 rods are probably more than solid enough, but getting them properly prepped runs into a bit of $$. Thus, going aftermarket may not bump the overall cost that much, assuming you have the parts. Go into realoem.com and have a look at the pricing on OEM rods, S38 in particular. Holy Crow!

Proper prep means x-ray or magnafluxing for flaws, detail surface grinding to remove any nicks, etc. (stress risers), meticulous balancing, then final shot-peening. Balancing needs to be +/- .2 gram across the set, with the total variance from zero being inside of .2 gram when you're done. This means a LOT of skilled labor and it wouldn't be difficult to see 10-12 hours going into the deal. With this, the set still isn't going to have the strength of a from-scratch custom order.

You might be able to beat the numbers I just gave you, but going in you won't know.

All that being said, I think the stock rods are probably up to the task on any NA motor you might build; for me the issue is getting the balancing spot-on and this is not cheap.

Last edited by Ken H. on Nov 24, 2008 7:53 PM, edited 1 time in total.

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

Everyone is close on piston weights. The forged stuff is around 200grams less than the OE Mahle on average, however in a NA race motor (BMW) pistons can weigh as little as 320grams.

Ken's rods are a little out of the ordinary. His engine uses a wider rod bearing, so a standard shelf rod could not be used.

As I have pointed out in other posts, there are several aftermarket rods that will fit the M30. I have been using Crower rods as of late, but there are a number of less expensive rods to select from. I stock most all of them in several different lengths.

Paul

Ken's rods are a little out of the ordinary. His engine uses a wider rod bearing, so a standard shelf rod could not be used.

As I have pointed out in other posts, there are several aftermarket rods that will fit the M30. I have been using Crower rods as of late, but there are a number of less expensive rods to select from. I stock most all of them in several different lengths.

Paul

I have read this post with great interest. But it got me wondering a 300hp M30 motor sound great if it can be made to work smoothly and reliably.

However I was wondering would it not be cheaper to fit a 3.6 mpower unit?

Anyway my main question was what is a M90? It has been mentioned a few times like it is some kind of engine code.

However I was wondering would it not be cheaper to fit a 3.6 mpower unit?

Anyway my main question was what is a M90? It has been mentioned a few times like it is some kind of engine code.

http://mye28.com/viewtopic.php?t=55967Anyway my main question was what is a M90? It has been mentioned a few times like it is some kind of engine code.

Toward the bottom.

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

Interesting. Is this strictly a pursuit of load ability/longevity? It's counter to my intuition of reduced surface drag but then turbo stuff is not my experience...come to think of it, neither are plain shell bearings.paul burke wrote:Ken's rods are a little out of the ordinary. His engine uses a wider rod bearing, so a standard shelf rod could not be used.

Paul

-

paul burke

- Posts: 844

- Joined: Sep 08, 2008 4:51 PM

- Contact:

Andrew, as you may already know, In the mid/late '90s it became common place to use Honda(1.889 crank pin) bearings in Busch and Craftsman truck engines, also in cup qualifier engines. It was determined that the bearing load capacity was adequate to support requirements (around 8000psi) the result was less parasitic loss.

In Ken's motor it was thought in the interest of reliability and the possibility of peak cylinder pressures approaching 5 figures, combined with the fact that it truly is a "driver" never seeing north of 6000rpm (I think he has over 8000 miles on it now?) we would go with a MB 300d bearing.

Paul

In Ken's motor it was thought in the interest of reliability and the possibility of peak cylinder pressures approaching 5 figures, combined with the fact that it truly is a "driver" never seeing north of 6000rpm (I think he has over 8000 miles on it now?) we would go with a MB 300d bearing.

Paul

Last edited by paul burke on Nov 27, 2008 12:30 AM, edited 9 times in total.

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

Andrew,

A couple of factors influenced the big end bearing widths.

First, the SCAT billet crank has rod journals which are somewhat larger than the stock BMW S38 84 mm unit. This meant coming up with an appropriate rod bearing shell; we settled on using ones made for the Benz 300D diesel. Tri-metal, a very good item. Second, while the crank has 95 mm throws, the layout of the counterweights contemplated knife-edging from the get-go. Additionally, the use of the 4340 degassed billet meant that the crank's rotating mass (counterweight, extension from crank rotating center to the rod journal) could be thinner and have the same or greater strength. Less rotating mass = less energy required =more power to the flywheel.

This meant that while the c-to-c distance on the bores remains the same at 100 mm, the rod bottom end journals can be wider, as well as being optimized for diameter.

You're correct that on motors where high rpm is an issue, less bearing area reduces parasitic drag. On high-revving motors, the bearing loads per unit of area can be managed somewhat by keeping reciprocating mass to a minimum. All well and good, tho' the issue of bearing longevity may be less of a consideration if we're discussing a race motor which will see rebuilding at relatively short intervals.

In my situation, we had the situation of broader con rod journals and a defined constraint on max RPM. These factors meant reduced bearing loading per unit area. A third factor was reciprocating mass. While heavier than one might have in an 8000 rpm NA race motor, my rod + piston weights are right about 1245 grams, which isn't really light, but part of the build philosophy was simplicity, strength and "best practices" engineering and assembly. Power would take care of itself.

So the short answer is yes, the bearings do increase this parasitic drag component . . . kind of at cross-purposes to everything that was done to assure dead-nuts-on alignments, balancing, etc., but I think the tradeoff was a good one.

As I've emphasized, this engine was conceived from the get-go as an endurance motor. To that end, giving up the last 10% or so of potential output in exchange for bulletproof durability--120,000 miles plus--was a very good bargain. While the math indicates a design redline of a bit over 6300 rpm, in actuality, there isn't any reason to think that the redline couldn't be moved into the 7000 rpm regime . . .the components are certainly robust enough. What would be given up, however, is longevity on moving pieces.

Nevermind that I would need a complete revisit on the turbo and IC sizing and That Thing would be basically unmanageable. As it is, the rear suspension is right on the ragged edge . . .

While 120,000 miles between opening up the motor may not necessarily sound big when compared to the 260 to 300K+ we see on NA M30s, keep in mind that a stock M30 will have a specific power output of ~61 hp/liter. LH puts out something over 211 hp/liter @ 15 psi boost. While this is certainly intermittent, I regularly see power levels on the order of 95-100 hp/liter at zero to 3 or 4 psi boost. So the loadings are fairly robust, and I am confident that with the workmanship in the build the 120,000 mile target can be comfortably surpassed.

A couple of factors influenced the big end bearing widths.

First, the SCAT billet crank has rod journals which are somewhat larger than the stock BMW S38 84 mm unit. This meant coming up with an appropriate rod bearing shell; we settled on using ones made for the Benz 300D diesel. Tri-metal, a very good item. Second, while the crank has 95 mm throws, the layout of the counterweights contemplated knife-edging from the get-go. Additionally, the use of the 4340 degassed billet meant that the crank's rotating mass (counterweight, extension from crank rotating center to the rod journal) could be thinner and have the same or greater strength. Less rotating mass = less energy required =more power to the flywheel.

This meant that while the c-to-c distance on the bores remains the same at 100 mm, the rod bottom end journals can be wider, as well as being optimized for diameter.

You're correct that on motors where high rpm is an issue, less bearing area reduces parasitic drag. On high-revving motors, the bearing loads per unit of area can be managed somewhat by keeping reciprocating mass to a minimum. All well and good, tho' the issue of bearing longevity may be less of a consideration if we're discussing a race motor which will see rebuilding at relatively short intervals.

In my situation, we had the situation of broader con rod journals and a defined constraint on max RPM. These factors meant reduced bearing loading per unit area. A third factor was reciprocating mass. While heavier than one might have in an 8000 rpm NA race motor, my rod + piston weights are right about 1245 grams, which isn't really light, but part of the build philosophy was simplicity, strength and "best practices" engineering and assembly. Power would take care of itself.

So the short answer is yes, the bearings do increase this parasitic drag component . . . kind of at cross-purposes to everything that was done to assure dead-nuts-on alignments, balancing, etc., but I think the tradeoff was a good one.

As I've emphasized, this engine was conceived from the get-go as an endurance motor. To that end, giving up the last 10% or so of potential output in exchange for bulletproof durability--120,000 miles plus--was a very good bargain. While the math indicates a design redline of a bit over 6300 rpm, in actuality, there isn't any reason to think that the redline couldn't be moved into the 7000 rpm regime . . .the components are certainly robust enough. What would be given up, however, is longevity on moving pieces.

Nevermind that I would need a complete revisit on the turbo and IC sizing and That Thing would be basically unmanageable. As it is, the rear suspension is right on the ragged edge . . .

While 120,000 miles between opening up the motor may not necessarily sound big when compared to the 260 to 300K+ we see on NA M30s, keep in mind that a stock M30 will have a specific power output of ~61 hp/liter. LH puts out something over 211 hp/liter @ 15 psi boost. While this is certainly intermittent, I regularly see power levels on the order of 95-100 hp/liter at zero to 3 or 4 psi boost. So the loadings are fairly robust, and I am confident that with the workmanship in the build the 120,000 mile target can be comfortably surpassed.

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

So...what you're saying is yes then

This is where Paul's (technical glitch) need to edit a post half a dozen times to get a single paragraph put together makes me look like an ass (and I'm good at doing that on my own thanks). If this line

While I'm not entirely versed in the specifics of your build Ken, it is as I supposed - for durability. I'm all about reducing mass in an engine which is why we spent a foolish amount of money having Arrow Precision forge us a set of one-off Ti rods and machined our own crank. Unfortunately my favourite material is still unobtanium even for the guys that think they have a big budget so I've not yet had a chance to spend time with (though Paul may have). With a density only marginally higher than aluminium and a stiffness 6 times that of normal steel it really is one of the more whizzy materials out there.

This is where Paul's (technical glitch) need to edit a post half a dozen times to get a single paragraph put together makes me look like an ass (and I'm good at doing that on my own thanks). If this line

had been in his post before my last post, I wouldn't have posted.In Ken's motor it was thought in the interest of reliability and the possibility of peak cylinder pressures approaching 5 figures, combined with the fact that it truly is a "driver" never seeing north of 6000rpm (I think he has over 8000 miles on it now?) we would go with a MB 300d bearing.

While I'm not entirely versed in the specifics of your build Ken, it is as I supposed - for durability. I'm all about reducing mass in an engine which is why we spent a foolish amount of money having Arrow Precision forge us a set of one-off Ti rods and machined our own crank. Unfortunately my favourite material is still unobtanium even for the guys that think they have a big budget so I've not yet had a chance to spend time with (though Paul may have). With a density only marginally higher than aluminium and a stiffness 6 times that of normal steel it really is one of the more whizzy materials out there.

Hmmm. Aluminum-Scandium alloy?Canuck YYC wrote:Unfortunately my favourite material is still unobtanium even for the guys that think they have a big budget so I've not yet had a chance to spend time with (though Paul may have). With a density only marginally higher than aluminium and a stiffness 6 times that of normal steel it really is one of the more whizzy materials out there.

-

Canuck YYC

- Posts: 332

- Joined: Oct 06, 2008 10:03 PM

- Location: Calgary, Alberta

Nothing that common (or cheap). As far as I know it's application is now almost exclusively military and space. It's used in satellite construction and who knows where else. It had a very brief life in F1 before it was banned ostensibly on health grounds (as a dry powder it can cause chronic lung problems in those susceptible) and is on the NHRA not-welcome list as well. It's cost is...prohibitive and the rumour is that Ferrari didn't want to go down that road. Shortly after they banned it, they turned around and banned everything with a modulus over...can't recall. Material technology was getting ahead of trying to slow them down.