External links now open in a new browser tab - turn this off in your UCP - Read more here.

Fix for slop in front drivers seat frame and motor?

-

GaAlpinaOwner

- Posts: 1120

- Joined: Feb 12, 2006 12:00 PM

- Location: Atlanta Georgia USA

Fix for slop in front drivers seat frame and motor?

Yea I know, they all do it eventually. Mine moves about a 1/8 inch to 1/4 inch back and forth and the right side even more, and it is irritating to say the least.

I have determined the gear in the motor and the gear in the frame both have wear and I may need to find a replacement pin for the right side of the frame. Problem - no new replacement parts. Lots of used motors and other parts but the chance of wear on these is about 90%.

Seems to me there was some fix a while back using shims or ?

What have you experts done to remedy the slop in these power seats? Can they be fixed? Who is the Seat Meister?

thanks

David

I have determined the gear in the motor and the gear in the frame both have wear and I may need to find a replacement pin for the right side of the frame. Problem - no new replacement parts. Lots of used motors and other parts but the chance of wear on these is about 90%.

Seems to me there was some fix a while back using shims or ?

What have you experts done to remedy the slop in these power seats? Can they be fixed? Who is the Seat Meister?

thanks

David

-

GaAlpinaOwner

- Posts: 1120

- Joined: Feb 12, 2006 12:00 PM

- Location: Atlanta Georgia USA

-

Kyle in NO

- Posts: 17638

- Joined: Feb 12, 2006 12:00 PM

- Location: Nasty Orleans------> Batten-Rooehjch------>More Souther LA

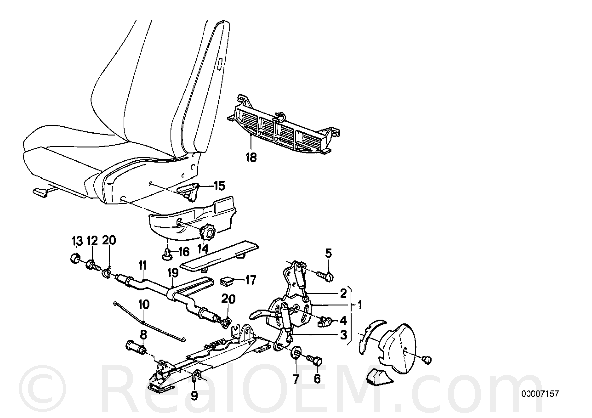

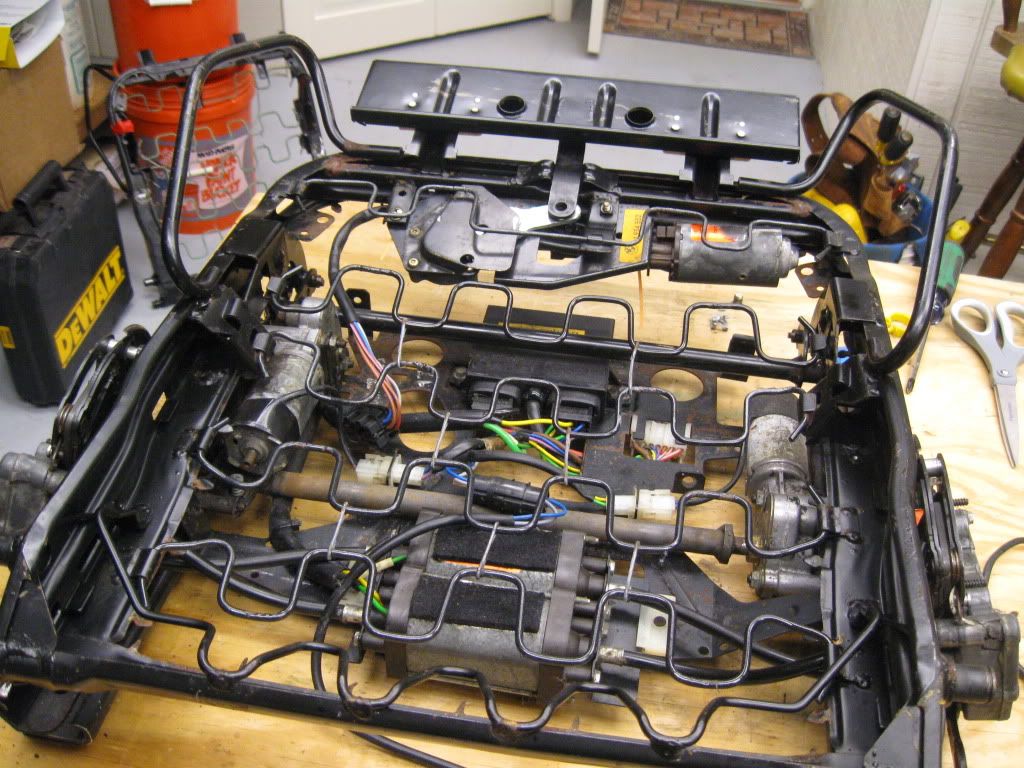

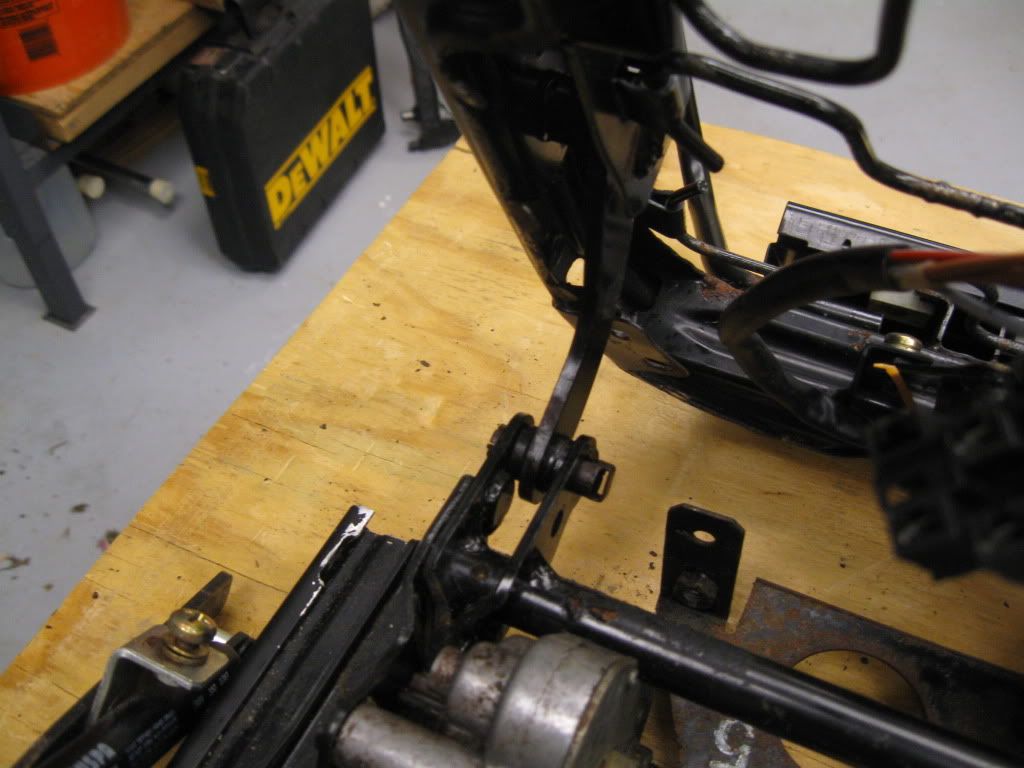

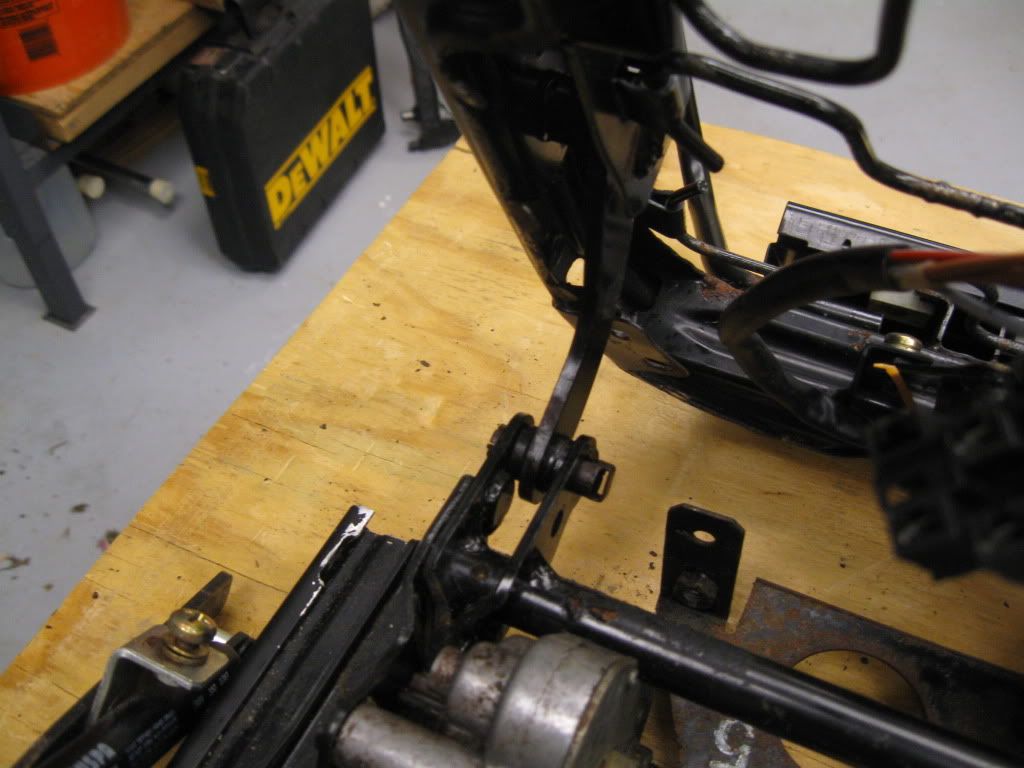

I looked at my seats while disassembled for upholstery. The hinges don't appear to have the capacity for the play you describe. I think the weak point in this sport seat assembly is the forward hinge and bearing pins on the seat. That'd explain in part the scenario Kyle describes (full down and full up the hinges are out of play, but in between the bearing pins need to have strength). Here's a picture of the forward lower bearing pins and points.

These steel pins and their bearing surfaces seem the logical point of failure to me.

If you remove your seat from the car then disassemble the back from the base (see Chris' description here it is relatively easy to pull off the hinges then raise the seat bottom/tilt it forward to see if these forward bearing pins or surfaces are damaged.

The hinge (rear on the seat frame) mounting points appear to be quite strong, and the only hardware holding them in place is the seat belt bolt and circlip.

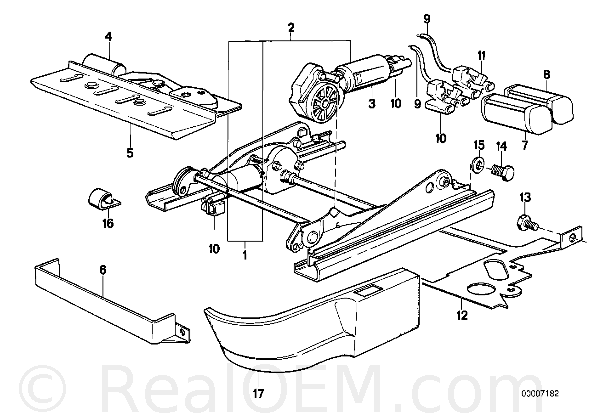

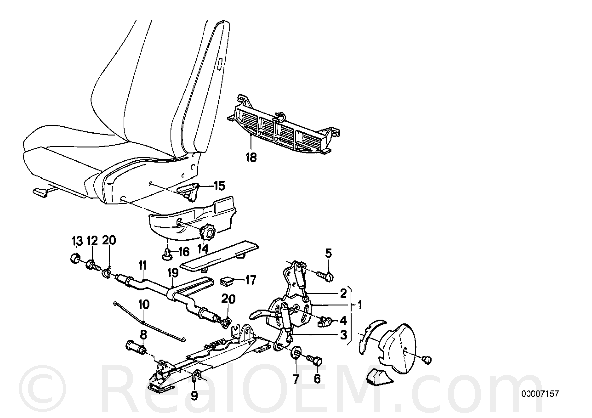

The support frame bolts with the shim I see in the diagram #14, 15 won't cause the movement you describe. The vertical seat adjuster and shaft #2 are really quite solid.

The vertical seat adjuster and shaft #2 are really quite solid.

I don't see these steel bearing pins in one of the RealOEM diagrams. We may need assistance from Bryan to identify them for replacements. Could be that it is #8 in this diagram, but these have an integrated spring, not a circlip or ering fastener.

I hope this helps, don't know what else it could be unless your frames are cracked/broken. Len and I both had to resolve that by disassembling the entire seat and doing some welding. Let us know what you learn.

These steel pins and their bearing surfaces seem the logical point of failure to me.

If you remove your seat from the car then disassemble the back from the base (see Chris' description here it is relatively easy to pull off the hinges then raise the seat bottom/tilt it forward to see if these forward bearing pins or surfaces are damaged.

The hinge (rear on the seat frame) mounting points appear to be quite strong, and the only hardware holding them in place is the seat belt bolt and circlip.

The support frame bolts with the shim I see in the diagram #14, 15 won't cause the movement you describe.

The vertical seat adjuster and shaft #2 are really quite solid.

The vertical seat adjuster and shaft #2 are really quite solid.

I don't see these steel bearing pins in one of the RealOEM diagrams. We may need assistance from Bryan to identify them for replacements. Could be that it is #8 in this diagram, but these have an integrated spring, not a circlip or ering fastener.

I hope this helps, don't know what else it could be unless your frames are cracked/broken. Len and I both had to resolve that by disassembling the entire seat and doing some welding. Let us know what you learn.

Last edited by Mab1957 on Oct 29, 2011 8:21 PM, edited 1 time in total.

-

GaAlpinaOwner

- Posts: 1120

- Joined: Feb 12, 2006 12:00 PM

- Location: Atlanta Georgia USA

-

mooseheadm5

- Beamter

- Posts: 23035

- Joined: Apr 08, 2009 10:30 PM

- Location: Charlottesville, VA

- Contact:

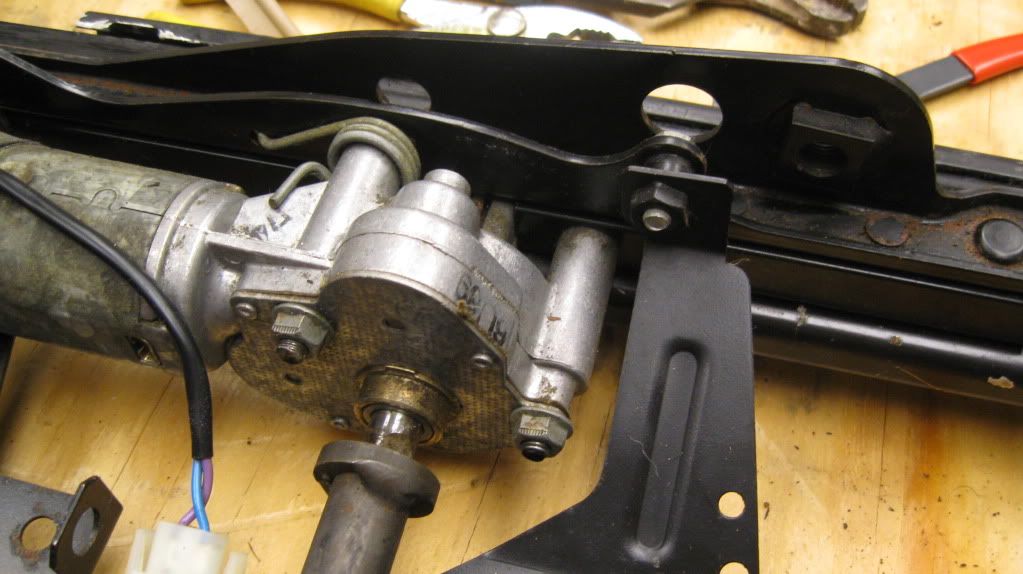

I will take you up on your offer. As you already probably know there at Moosehead Engineering, the forward upper mounting pins are shoulder bolts. That is where the slop is really evident in my driver seat frame.

The upper forward hinge point

is a shoulder bolt that is welded to the frame after running through the hinge bearing point

The type of sloppy movement GAAlpina Owner describes is clearly evident here. No doubt the same fat ass driver (FAD) that broke the frame put a lot of stress on this hinge point.

Not a great pair of pictures but look at the gap between the hinge and the frame. I hold the hinge outward

and inward

becomes at least 1/4" in AM (ass measure) up at seat level.

I looked at the passenger seat again and they're pretty sturdy. Comparing the frames I see its upper mounting points are similarly stamped with no obvious bends that would indicate a source for the driver seat sloppy movement. So, no simple fix is evident. I did notice that FAD had put so much pressure on these that they pushed the seat frame tabs ahead of them up and forward

so I bent them back out, unnecessarily.

EDIT: - Turns out this hole receives the fastener that helps hold the side cover in place. It needs to be in proper position to function!

Only one thing to do, grind it out and evaluate the bearing surfaces.

There's only the shoulder bolt through the hinge point (tube). Mine are rusty, dirty and way too much clearance. Note there is a spring on the shoulder bolt which I suppose helps to maintain a right angle position on the hinge arm during operation.

Now here we are with a seat frame that needs rebushed front upper hinge points. Can MHE provide a solution? It'd be ideal to install reinstall a shoulder bolt that doesn't require welding.

The upper forward hinge point

is a shoulder bolt that is welded to the frame after running through the hinge bearing point

The type of sloppy movement GAAlpina Owner describes is clearly evident here. No doubt the same fat ass driver (FAD) that broke the frame put a lot of stress on this hinge point.

Not a great pair of pictures but look at the gap between the hinge and the frame. I hold the hinge outward

and inward

becomes at least 1/4" in AM (ass measure) up at seat level.

I looked at the passenger seat again and they're pretty sturdy. Comparing the frames I see its upper mounting points are similarly stamped with no obvious bends that would indicate a source for the driver seat sloppy movement. So, no simple fix is evident. I did notice that FAD had put so much pressure on these that they pushed the seat frame tabs ahead of them up and forward

so I bent them back out, unnecessarily.

EDIT: - Turns out this hole receives the fastener that helps hold the side cover in place. It needs to be in proper position to function!

Only one thing to do, grind it out and evaluate the bearing surfaces.

There's only the shoulder bolt through the hinge point (tube). Mine are rusty, dirty and way too much clearance. Note there is a spring on the shoulder bolt which I suppose helps to maintain a right angle position on the hinge arm during operation.

Now here we are with a seat frame that needs rebushed front upper hinge points. Can MHE provide a solution? It'd be ideal to install reinstall a shoulder bolt that doesn't require welding.

Last edited by Mab1957 on Feb 12, 2012 10:59 PM, edited 1 time in total.

So, Jlucas, that's what I did. I bought a pair for $60.

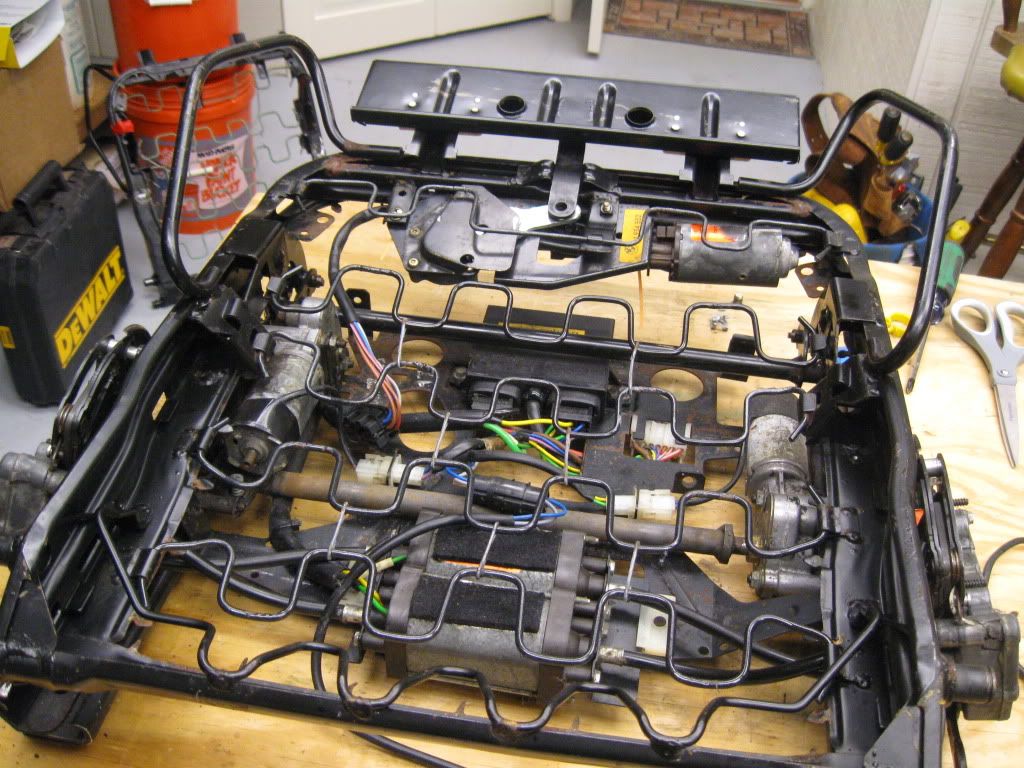

They were left outside for more than a year, but the frame on the passenger side is good.

The hinge points are OK. The upper and lower hinges on both sides seem as tight as they are able to be.

The recovering with the kit from Jim's is going pretty well. I only have the driver's seat bottom to do now. With this frame replaced I can finish pulling on the covers and then install and test the seat functions. I learned in the process that BMW installation had these ties/cords sewn into the leather using a backing.

Jim's didn't do that, so in order to obtain that 'buttoned' look I added some cord pulls attached to the stitching.

The cords and ties are secured to wire stays. One seat had the stay outside the foam cushion, the others the stay was pushed into the foam. In the back seats the stay is secured to the spring frame.

I may have to work with the covers a bit to smooth them out. The Jim's kit looks very nice.

I bought one set of foam before I knew I'd have to obtain another pair of parts seats. The foam was made in '86. Why do you suppose this cut out was in the side bolster?

I'll still try to get together with Paul at Moosehead Engineering to see if there's a way to tighten the upper hinge point on that frame (sitting on the floor in the photo above). It would be nice to have a method to remove the slop without having to reupholster the seat bottom.

They were left outside for more than a year, but the frame on the passenger side is good.

The hinge points are OK. The upper and lower hinges on both sides seem as tight as they are able to be.

The recovering with the kit from Jim's is going pretty well. I only have the driver's seat bottom to do now. With this frame replaced I can finish pulling on the covers and then install and test the seat functions. I learned in the process that BMW installation had these ties/cords sewn into the leather using a backing.

Jim's didn't do that, so in order to obtain that 'buttoned' look I added some cord pulls attached to the stitching.

The cords and ties are secured to wire stays. One seat had the stay outside the foam cushion, the others the stay was pushed into the foam. In the back seats the stay is secured to the spring frame.

I may have to work with the covers a bit to smooth them out. The Jim's kit looks very nice.

I bought one set of foam before I knew I'd have to obtain another pair of parts seats. The foam was made in '86. Why do you suppose this cut out was in the side bolster?

I'll still try to get together with Paul at Moosehead Engineering to see if there's a way to tighten the upper hinge point on that frame (sitting on the floor in the photo above). It would be nice to have a method to remove the slop without having to reupholster the seat bottom.

Last edited by Mab1957 on Jan 03, 2012 9:54 AM, edited 1 time in total.

-

John in VA

- Posts: 5305

- Joined: Feb 12, 2006 12:00 PM

- Location: Leesburg, VA

-

GaAlpinaOwner

- Posts: 1120

- Joined: Feb 12, 2006 12:00 PM

- Location: Atlanta Georgia USA

-

GaAlpinaOwner

- Posts: 1120

- Joined: Feb 12, 2006 12:00 PM

- Location: Atlanta Georgia USA

-

John in VA

- Posts: 5305

- Joined: Feb 12, 2006 12:00 PM

- Location: Leesburg, VA

http://www.jimsautoupholstery.com/BuzzBomb wrote:Sorry if I missed it but can you provide a link for info on ordering a upholstery set like you bought?

Yes. This set was made for Ron P & GAAlpinaOwner by Jim's in San Diego. Other suppliers include your local upholsterer andJohn in VA wrote:http://www.jimsautoupholstery.com/BuzzBomb wrote:Sorry if I missed it but can you provide a link for info on ordering a upholstery set like you bought?

http://www.worlduph.com/

http://www.gahh.com/store.php?cPath=28_ ... amily_id=2

and Creative Options near Atlanta (email here)

kchinn@creativeoptions.info <kchinn@creativeoptions.info>

Here's a related post

http://www.mye28.com/viewtopic.php?t=81660

So, my driver seat still had slop!  Only one place left to look - the hinges. Out comes the seat again.

Only one place left to look - the hinges. Out comes the seat again.

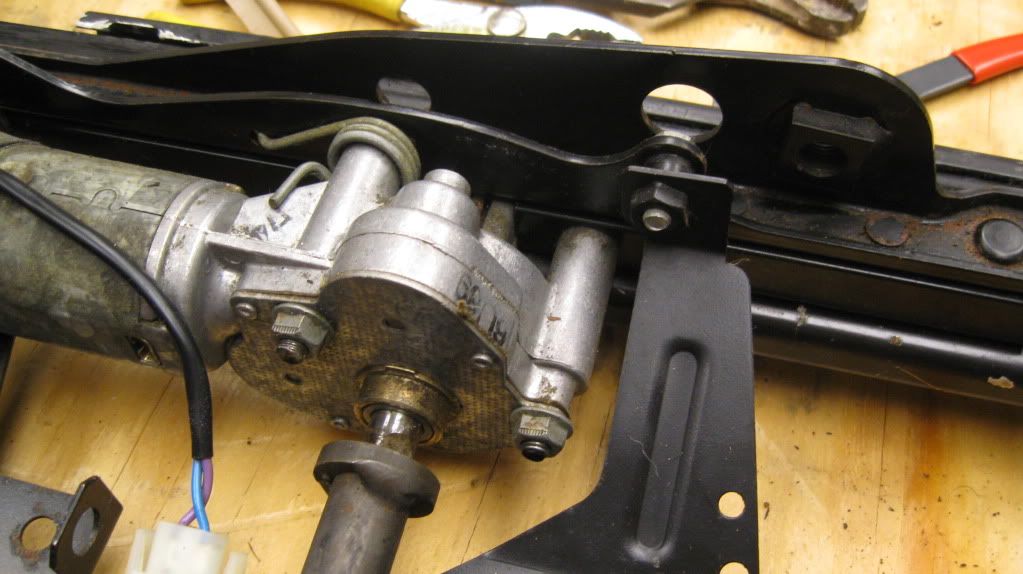

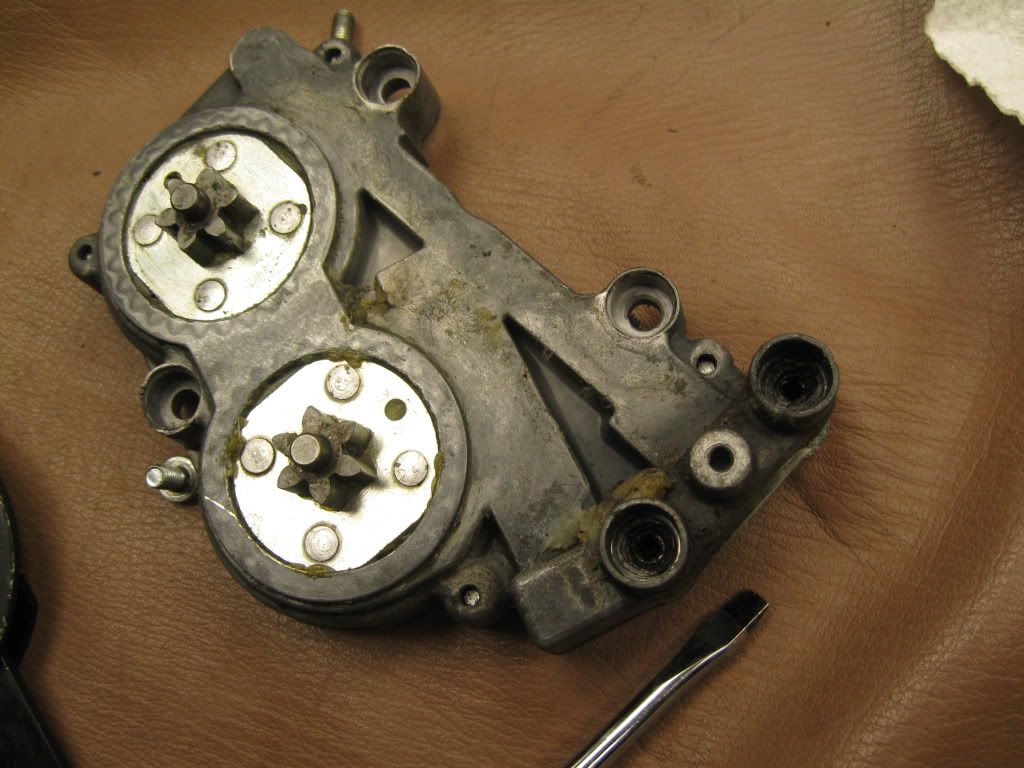

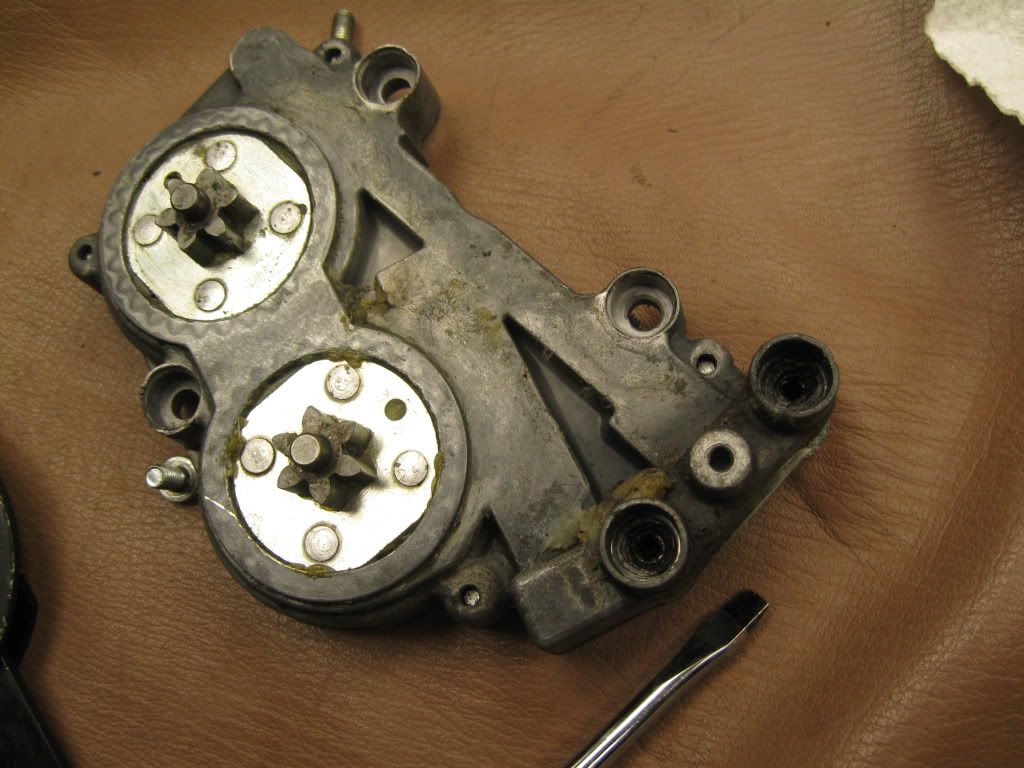

Back on the work bench I remove both hinges and see what I should've noticed before I chose to use these POSs - broken gear case.

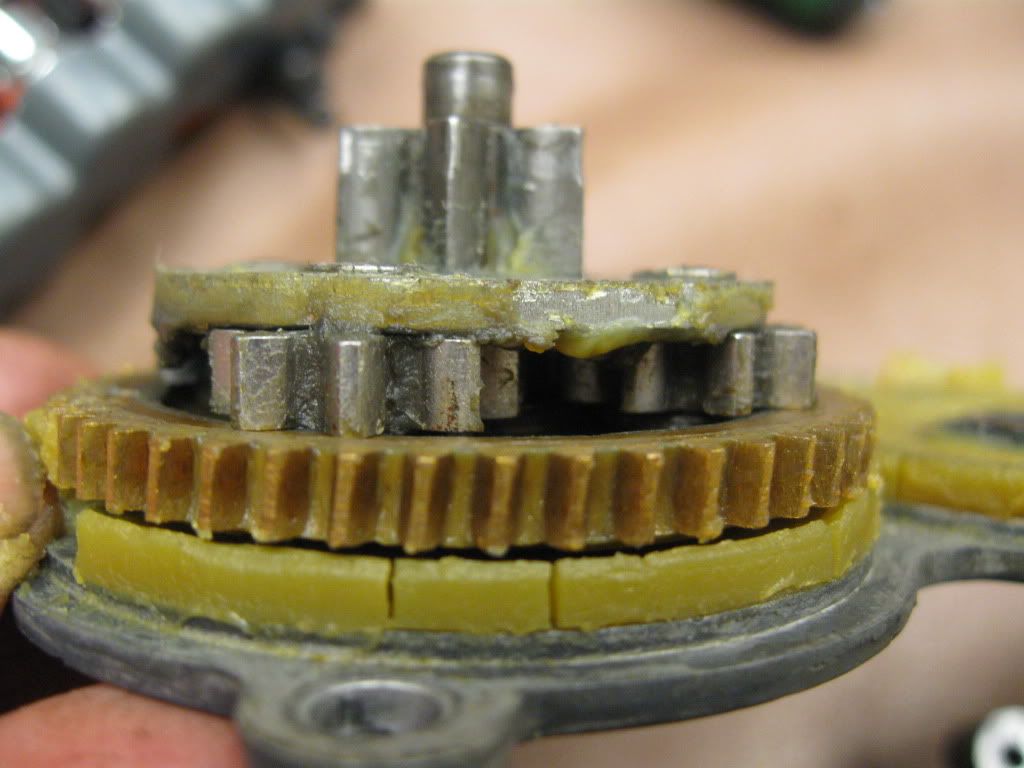

The FAD had put a lot of stress on this seat. The gear still functions but there was a lot of slop in the seat back, at the hinge and when the seatback-forward/aft tilt gear reached about 80 degrees it fell back. WTF! Opening the hinges I see the teeth are worn and broken, and the lever is loose = SLOP.

I was also able to move the gear drive in the housing = MORE SLOP!

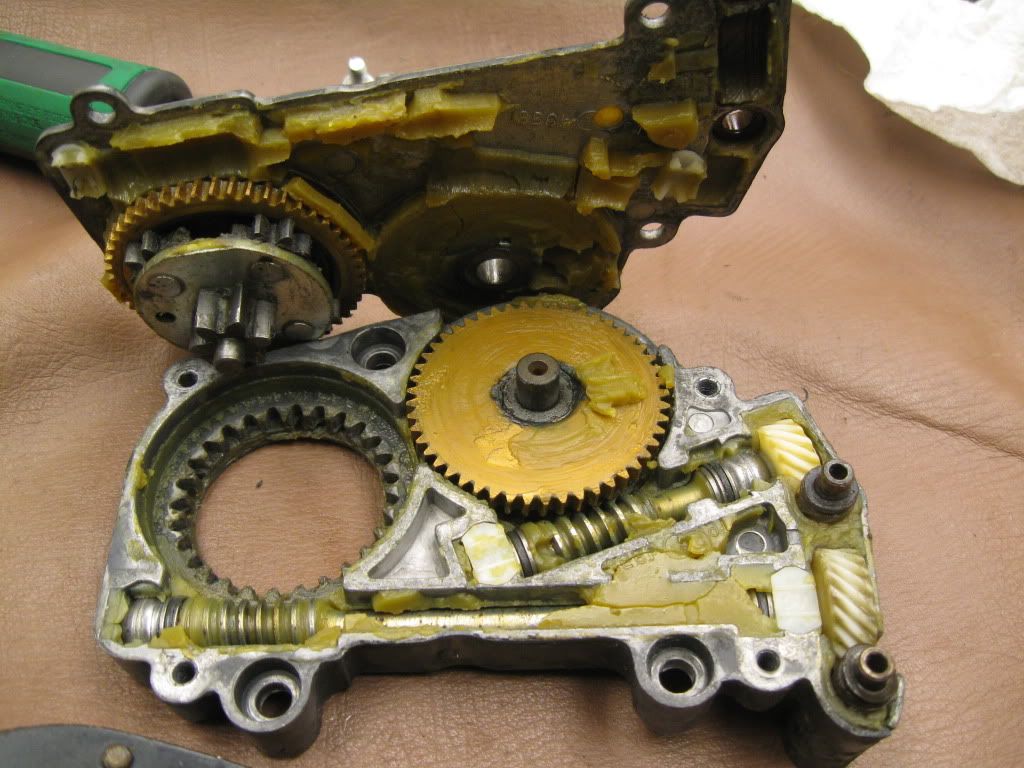

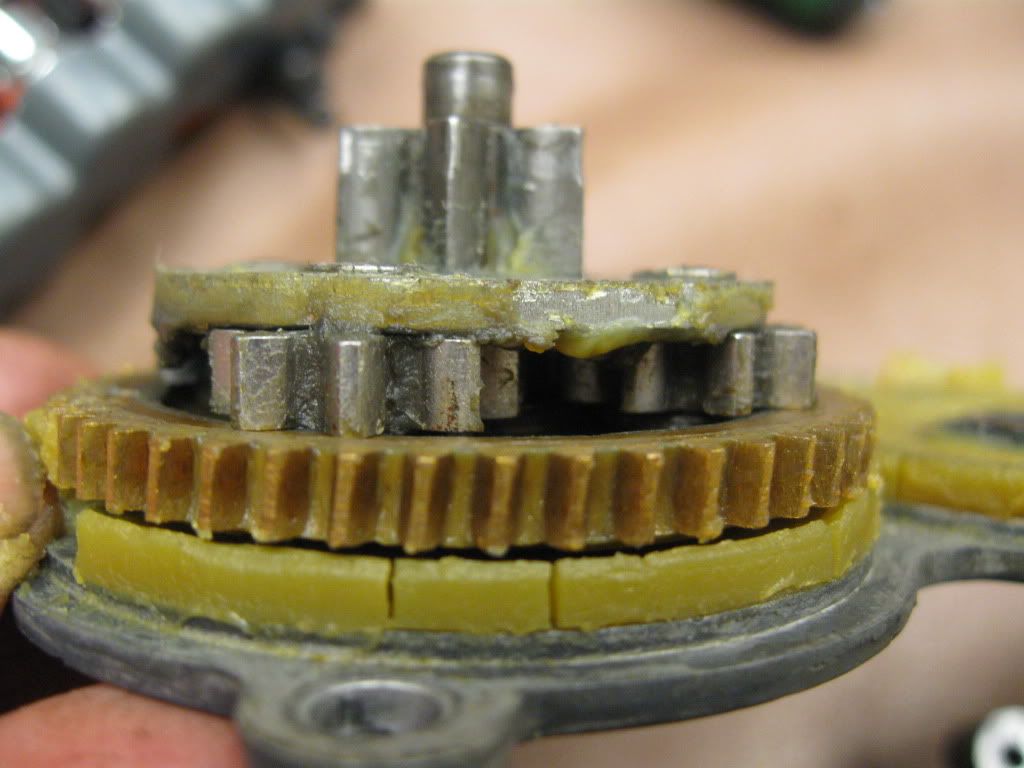

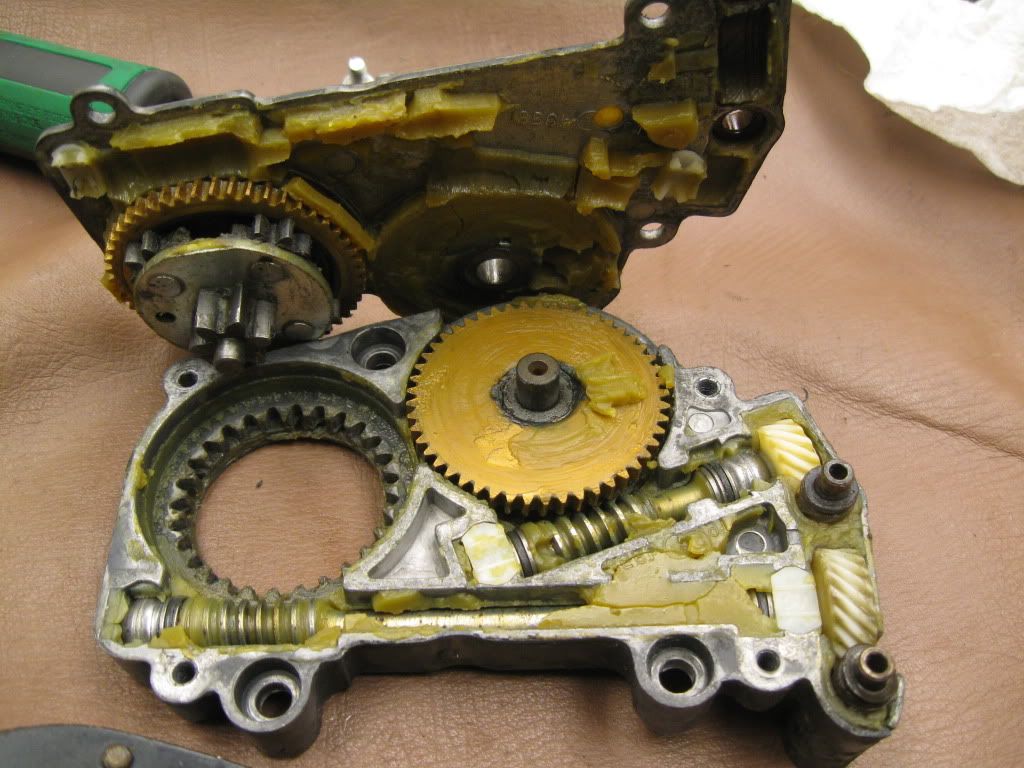

So, let's see what is in one of these.

More gears, but there's plenty of them to share the load, and well lubricated.

There is some wear on the drive gear that engaged the teeth (expected considering some were broken).

The internal gears don't look so bad though.

I used the hinges off the extra seat I bought. If you choose to do this, thoroughly inspect your seat frame and all the components. I'd have saved myself a lot of time and effort by starting with a better core (that passenger seat that had been sitting outside for a year). I used the hinges from that parts seat after cleaning and squirting some loose juice in the drive gear ports. The motor drive cables are square and fit into ports on the bottom of the hinge. One for forward/aft and one for up/down. They're the two motors at the back of the seat base.

What I didn't do was operate them on the bench. So after putting the seat back in the car I wasn't able to bump start the seatback-forward/aft tilt motor or the seatback-up/down motor (the two new hinges were seized). I rigged up a square bit on 1/4 extension and wobble, put it in my drill.

So after putting the seat back in the car I wasn't able to bump start the seatback-forward/aft tilt motor or the seatback-up/down motor (the two new hinges were seized). I rigged up a square bit on 1/4 extension and wobble, put it in my drill.

I was able to tilt the seat forward in the car to access the motor drive cables. I disconnected the drive cables and used the drill to spin the hinges full range for both functions. I learned to reverse the drill for left and right so I could position the hinges at approximately the same place when I finished. After that the motors would operate the seat hinges on their own and I was able to reassemble install and test.

Now the driver seat feels pretty solid and is fully functional. I confess though that I'll now wonder if the other components are stressed from FAD abuse. When the weather improves I intend to thoroughly test it.

So I'm sorry for the long drawn out answer to your original question GAAlpinaOwner. I recommend that you get a passenger side sports seat for parts. Pull your seat disassemble it and swap the good plastics covers/foam/heaters/leather to a good seat frame. The seat frame may need bolsters welded and confirm it has tight front upper/lower pivot points. Then install the hinges from the parts frame on your base (your motors are known working) after bench operating and lubrication. It is a big PITA to put these seats in and out of the car so give yourself the best shot at doing it only one time. Good luck! I hope this is helpful to you and others who want to put another 20 years on their M5's heated sports seats.

Back on the work bench I remove both hinges and see what I should've noticed before I chose to use these POSs - broken gear case.

The FAD had put a lot of stress on this seat. The gear still functions but there was a lot of slop in the seat back, at the hinge and when the seatback-forward/aft tilt gear reached about 80 degrees it fell back. WTF! Opening the hinges I see the teeth are worn and broken, and the lever is loose = SLOP.

I was also able to move the gear drive in the housing = MORE SLOP!

So, let's see what is in one of these.

More gears, but there's plenty of them to share the load, and well lubricated.

There is some wear on the drive gear that engaged the teeth (expected considering some were broken).

The internal gears don't look so bad though.

I used the hinges off the extra seat I bought. If you choose to do this, thoroughly inspect your seat frame and all the components. I'd have saved myself a lot of time and effort by starting with a better core (that passenger seat that had been sitting outside for a year). I used the hinges from that parts seat after cleaning and squirting some loose juice in the drive gear ports. The motor drive cables are square and fit into ports on the bottom of the hinge. One for forward/aft and one for up/down. They're the two motors at the back of the seat base.

What I didn't do was operate them on the bench.

I was able to tilt the seat forward in the car to access the motor drive cables. I disconnected the drive cables and used the drill to spin the hinges full range for both functions. I learned to reverse the drill for left and right so I could position the hinges at approximately the same place when I finished. After that the motors would operate the seat hinges on their own and I was able to reassemble install and test.

Now the driver seat feels pretty solid and is fully functional. I confess though that I'll now wonder if the other components are stressed from FAD abuse. When the weather improves I intend to thoroughly test it.

So I'm sorry for the long drawn out answer to your original question GAAlpinaOwner. I recommend that you get a passenger side sports seat for parts. Pull your seat disassemble it and swap the good plastics covers/foam/heaters/leather to a good seat frame. The seat frame may need bolsters welded and confirm it has tight front upper/lower pivot points. Then install the hinges from the parts frame on your base (your motors are known working) after bench operating and lubrication. It is a big PITA to put these seats in and out of the car so give yourself the best shot at doing it only one time. Good luck! I hope this is helpful to you and others who want to put another 20 years on their M5's heated sports seats.

-

GaAlpinaOwner

- Posts: 1120

- Joined: Feb 12, 2006 12:00 PM

- Location: Atlanta Georgia USA