Page 6 of 28

Posted: Jul 11, 2013 11:47 PM

by tig

Bead blasted the flywheel. After talking with seller more, I'm mostly convinced it'll be fine. But when I take it to get refinished I'll ensure it is balanced perfectly. Teeth look great.

Also, plan for tomorrow was to take the head & block to the engine guy. Came home today from work with the intention of loading it in the Q7.

Turns out when wife & daughter left this morning for a trip, they decided to take the Q7 and not my wife's 135i.

Guess what? An M30 block will fit in the trunk of a E28, but only if the hoist you have will fit. In my case the hoist is too big and won't let it fit. No strong backs/weak minds around to help tonight, so I'm gonna just take the head and will take the block next week or something.

Posted: Jul 13, 2013 10:04 PM

by tig

I saw a thread where someone powder coated their flywheel. Is there any reason to do that? Do new (steel) flywheels come finished in some way?

Posted: Jul 13, 2013 11:29 PM

by Mike W.

cek wrote:

Guess what? An M30 block will fit in the trunk of a E28, but only if the hoist you have will fit.

No way will a M30 fit in the trunk of an E28. Well, maybe...

What's the big deal about a hoist, you just need a chain on the end of it.

Posted: Jul 14, 2013 11:22 AM

by Heathcliffe

Just because you can doesn't necessarily make it a good idea...

Posted: Jul 14, 2013 12:00 PM

by tig

Heathcliffe wrote:Just because you can doesn't necessarily make it a good idea...

Just because you can post a content-less response doesn't necessarily make it a good idea...

Seriously, I'm trying to learn here and it would be nice, if you actually have knowledge on the topic if you'd share it.

Posted: Jul 14, 2013 1:58 PM

by tig

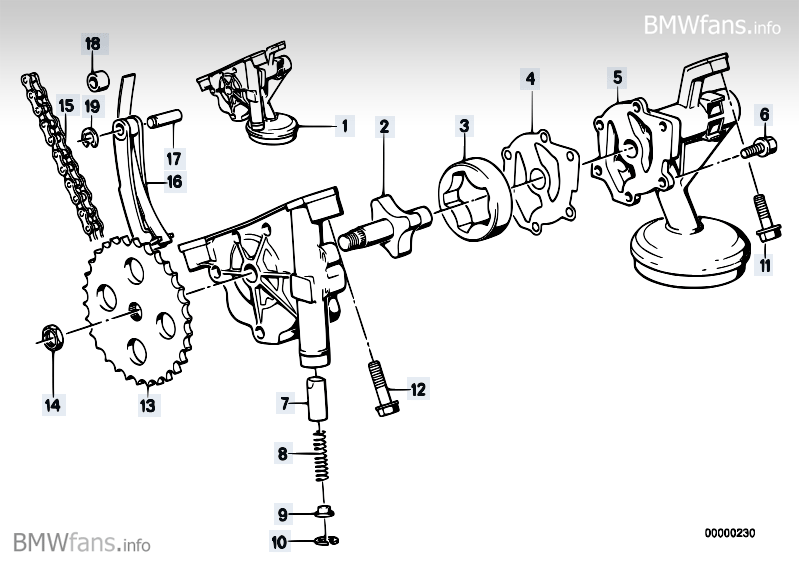

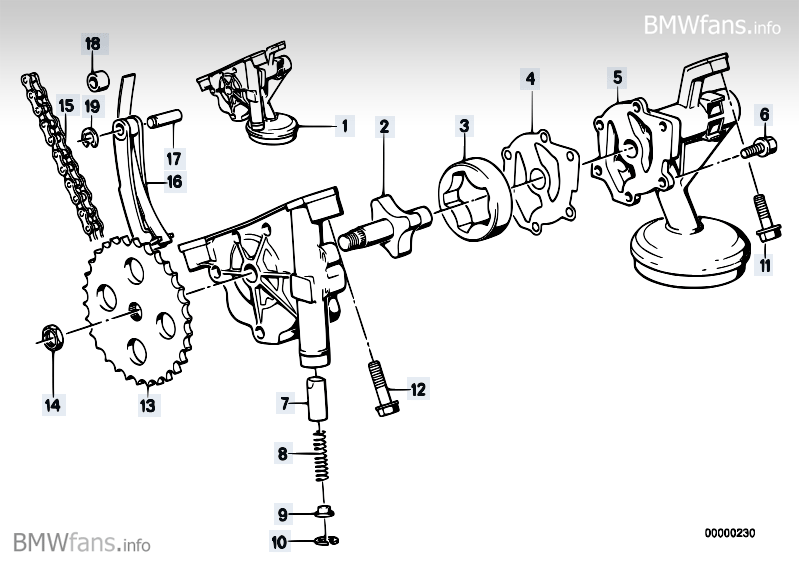

Oil pump sprocket, # 13 here

On one side, the teeth are angled.

Which way does it get installed, with the angled side of teeth facing the pump or away?

Posted: Jul 14, 2013 2:20 PM

by BuzzBomb

cek wrote:

Which way does it get installed, with the angled side of teeth facing the pump or away?

Earlier B34 engines, as the chain wears, it's recommended to add shims under the sprocket side of the pump. In theory, as the pump angles away from the block, it makes sense to chamfer one edge of the sprocket so the chain rolls easier over it's teeth (angled edge away from the pump). Since B35s have a tensioner, I'd say just put the pretty side out...

Posted: Jul 14, 2013 4:33 PM

by _marshall

This may be a little pre-emptive, but out of curiosity are you going to do any restoration work on your wiring harness? At some point along the way in my rebuild I managed to snap an injector wire clean in two and I'm trying to decide my next steps, since the whole harness isn't really in great shape.

Also from your pictures it looks like you're ahead of me on this, but for dropping my engine back into my 6er, I'm going to attempt to install trans and engine separately instead of mating them up outside of the car and angling it in. We bashed a few too many things for my comfort on the way out the last time. Here's praying my ABS still works...

Posted: Jul 15, 2013 1:50 AM

by Heathcliffe

cek wrote:Heathcliffe wrote:Just because you can doesn't necessarily make it a good idea...

Just because you can post a content-less response doesn't necessarily make it a good idea...

Seriously, I'm trying to learn here and it would be nice, if you actually have knowledge on the topic if you'd share it.

No need to get spicy. I was simply trying to be humorous about stuffing your motor in the trunk and specifically about the post above with the photo showing that. Maybe I should have been more specific in referencing that. I actually have a rebuilt B35 and tranny ready to drop in my 87 635 and have gone thru the entire process you are so I have been reading and enjoying your posts regularly. Maybe just a little more cheek my friend

Posted: Jul 15, 2013 1:53 AM

by tig

Heathcliffe wrote:cek wrote:Heathcliffe wrote:Just because you can doesn't necessarily make it a good idea...

Just because you can post a content-less response doesn't necessarily make it a good idea...

Seriously, I'm trying to learn here and it would be nice, if you actually have knowledge on the topic if you'd share it.

No need to get spicy. I was simply trying to be humorous about stuffing your motor in the trunk and specifically about the post above with the photo showing that. Maybe I should have been more specific in referencing that. I actually have a rebuilt B35 and tranny ready to drop in my 87 635 and have gone thru the entire process you are so I have been reading and enjoying your posts regularly. Maybe just a little more cheek my friend

I thought you were responding to the flywheel powder coating question. Sorry for being snippy. Maybe it's that time of the month or something.

Posted: Jul 15, 2013 1:56 AM

by tig

_marshall wrote:This may be a little pre-emptive, but out of curiosity are you going to do any restoration work on your wiring harness? At some point along the way in my rebuild I managed to snap an injector wire clean in two and I'm trying to decide my next steps, since the whole harness isn't really in great shape.

Also from your pictures it looks like you're ahead of me on this, but for dropping my engine back into my 6er, I'm going to attempt to install trans and engine separately instead of mating them up outside of the car and angling it in. We bashed a few too many things for my comfort on the way out the last time. Here's praying my ABS still works...

I'm pretty worried about the wiring harness. I have some electrical gremlins with the current motor (may not be harness related) and it would really suck to put a nice new engine in the car and have some wires be broken (or about to break).

But, then again, I have not really looked at the harness very hard...yet.

I actually plan on dropping the B34 from the bottom, and putting the B35 in the same way. Taking the B35 out of the donor made me realize that it's a sure way to scratch things up...but we didn't care because that E32 was truly a parts car.

Posted: Jul 15, 2013 2:17 AM

by Heathcliffe

cek wrote:Heathcliffe wrote:cek wrote:Heathcliffe wrote:Just because you can doesn't necessarily make it a good idea...

Just because you can post a content-less response doesn't necessarily make it a good idea...

Seriously, I'm trying to learn here and it would be nice, if you actually have knowledge on the topic if you'd share it.

No need to get spicy. I was simply trying to be humorous about stuffing your motor in the trunk and specifically about the post above with the photo showing that. Maybe I should have been more specific in referencing that. I actually have a rebuilt B35 and tranny ready to drop in my 87 635 and have gone thru the entire process you are so I have been reading and enjoying your posts regularly. Maybe just a little more cheek my friend

I thought you were responding to the flywheel powder coating question. Sorry for being snippy. Maybe it's that time of the month or something.

All good . This is a pic of the motor im hopefully dropping in the next month or so. Im waiting for a left side motor which is coming on a slow boat from Germany. Some Motor Pix

Posted: Jul 15, 2013 2:20 AM

by tig

Nice! I can't wait until I'm at that point.

Don't forget to tighten the manifold nuts on #6 before you install it though :-)

Posted: Jul 15, 2013 2:22 AM

by Heathcliffe

cek wrote:

Nice! I can't wait until I'm at that point.

Don't forget to tighten the manifold nuts on #6 before you install it though :-)

Did the pix work?I cant seem to get them to appear in the body of the post as an image rather than an URL

Posted: Jul 15, 2013 2:23 AM

by tig

Heathcliffe wrote:cek wrote:

Nice! I can't wait until I'm at that point.

Don't forget to tighten the manifold nuts on #6 before you install it though :-)

Did the pix work?I cant seem to get them to appear in the body of the post as an image rather than an URL

Link worked. Here's the img

Posted: Jul 15, 2013 2:30 AM

by Heathcliffe

cek wrote:

Nice! I can't wait until I'm at that point.

Don't forget to tighten the manifold nuts on #6 before you install it though :-)

Right! Yeah I was just playing with it for photo purpose. I think I am unfortunately going to have to install the headers after I drop it in. There are no gaskets on there. I just wanted a couple shots before those beeyootiful headers get buried in the engine bay.

Posted: Jul 15, 2013 12:59 PM

by _marshall

cek wrote:_marshall wrote:This may be a little pre-emptive, but out of curiosity are you going to do any restoration work on your wiring harness? At some point along the way in my rebuild I managed to snap an injector wire clean in two and I'm trying to decide my next steps, since the whole harness isn't really in great shape.

Also from your pictures it looks like you're ahead of me on this, but for dropping my engine back into my 6er, I'm going to attempt to install trans and engine separately instead of mating them up outside of the car and angling it in. We bashed a few too many things for my comfort on the way out the last time. Here's praying my ABS still works...

I'm pretty worried about the wiring harness. I have some electrical gremlins with the current motor (may not be harness related) and it would really suck to put a nice new engine in the car and have some wires be broken (or about to break).

But, then again, I have not really looked at the harness very hard...yet.

I actually plan on dropping the B34 from the bottom, and putting the B35 in the same way. Taking the B35 out of the donor made me realize that it's a sure way to scratch things up...but we didn't care because that E32 was truly a parts car.

Yeah, that's pretty much exactly what I was thinking about my harness. Long term, I'm not sure whether I want to hunt down a clean harness, try to get one made, or attempt to piece together some kind of frankenstein harness out of old connectors. I have one known-good (i think...) harness, so I can survive for a while without making a big project of it.

I imagine you have a lift (?), and that makes me so jealous.

Posted: Jul 18, 2013 2:39 PM

by kzolee

Don't forget to order the pressure valve, if you see signs of wear on it. It is very cheap, but makes a big difference.

Number 7-8-9-10 on the image:

http://bmwfans.info/parts/catalog/E32/S ... ith_drive/

http://bmwfans.info/parts/catalog/E32/S ... ith_drive/

Posted: Jul 18, 2013 7:26 PM

by tig

Well, seeing I broke the clip getting it off I'll do that. That. Thanks.

Posted: Jul 21, 2013 3:55 PM

by tig

Quick update on the block.

I dropped it off at the machinist Friday and he took a peek at the rust in #6. His reaction "Not bad. We should be able to just hone this as there does not appear to be any pitting."

Whew. Keeping my fingers crossed.

Posted: Jul 29, 2013 6:53 PM

by tig

Update on the head from the machinist:

"Cam is serviceable but if you want to do it right I suggest you get it reground or source a new one. You'll also want to do new (or rebuilt) rocker arms too. Valves look good. Springs are fine. Head's been bead blasted."

On the block: "Will get at it tomorrow, but am optimistic."

So, on the cams:

My goal with this engine is to make it smooth and bulletproof. Thus getting a more aggressive cam is not in play for me. But I want to do it right, so 'serviceable' is not good enough.

What are my options on cams then?

1) Find someone to grind these, send them off...?

2) Buy a new set?

3) Buy an already ground used set?

Same with rockers. Do I just bite the bullet and buy new rockers or should I have these ground along with the cam; assuming I do #1?

Posted: Jul 29, 2013 7:25 PM

by tig

Hmmm...

Got 3 quotes on getting the cams reground to factory specs.

1) WEB-CAM (

www.webcamshafts.com) - Debbie was quite nice and helpful. $250 per camshaft. They cannot do the rockers.

2) Oregon Camshaft (

www.oregoncamshaft.com) - Bill was hard to understand and sounded "salty". They want $50 per shaft and $6 per rocker.

3) Delta Camshaft in Tacoma (

www.deltacam.com). This was the shop recommended by my machinist after I called him about the above saying "wow, something's not right with the price spread". Ken at Delta says they want $82.50 per shaft and $3.50 per rocker.

Why the eff would WEB-CAM be so massively more expensive?

Anyone have direct experience with #2 or #3?

Posted: Aug 02, 2013 1:12 AM

by tig

Cam Pr0n, with some questions below...

Note that the five rockers in the top left of this photo have large serial numbers and the 7 on the bottom right have small?

Large:

Small:

Large one's say "6.2" on other side. Small S/N rockers say "8.2":

Is there any practical difference between the "6.2" (large serial numbers) and "8.2" (small serial numbers) rockers?

Why do some have the holes drilled on one side and some the other (4 one way, 8 the other)?

Is it possible that this is evidence this engine has had the head rebuilt/rockers replaced? Why would BMW install two different 'generations' of rockers in a car?

Finally, my machinist seems to think there's no issues with these rockers and once I get them re-ground they will work great. Any of you "experts" want to disagree with him and suggest that I just buy new ones? Just making sure. :-)

I'm sending these to Delta Camshaft tomorrow...

Posted: Aug 02, 2013 12:23 PM

by ahab

I am no expert but I will tell you two things I'm certain of. A cam and set of rockers should wear together from new. Cheaping out on rockers is a bad idea. It seems like you're building this thing pretty bulletproof, why stop now.

Posted: Aug 02, 2013 12:56 PM

by tig

This is too perfect.

I mentioned a few pages back that I had a line on a set of new rockers for cheap. At the time they were on Craigslist in Seattle. Last night I checked to see if they were still for sale, and sure enough.

This morning a nice kid in a black tricked-out E34 535i pulled up in front of my building at work (right across the street from the Seattle Police station) and handed me two baggies with stuff in them. I handed him a C-note.

Delta would have charged $3.50 per rocker to restore ~$42. So for $58 I have brand new ones :-).

Shipped the camshaft off to Delta this morning too.