Noob M30B35 Build

Well, shit.

Talked to machinist and got clarity.

1) He's not happy with the piston ring grooves on the pistons. He says they will work, but given the importance of tight fit, and the money/time I'm spending on this engine, he is really recommending I get new pistons.

2) He meant thousandths of an inch. And my bores are currently 92.0508mm (0.002" oversized).

Via getbmwparts.com, "Nueral/alcan" 92,485MM(+0,50) pistons are $181 ($1086 for the set). It is not clear if they include rings, but everyone I've talked to seems to believe they do.

On eBay I see I can get a set of Maxsil pistons (which include rings) for $619. My machinist said he's worked with Maxsil pistons before and they'll be "ok" for a non-tuned engine like mine.

Or, I could change my rules for this build, and go with CP Forged pistons (10:1 compression) for $1,049.95. I'd then be building a tuned M30B35 which has never been my intent. If I started down this path I'd likely get sucked in and end up doing a different cam grind, etc...

Lots to think about. I love everyone's input...

Talked to machinist and got clarity.

1) He's not happy with the piston ring grooves on the pistons. He says they will work, but given the importance of tight fit, and the money/time I'm spending on this engine, he is really recommending I get new pistons.

2) He meant thousandths of an inch. And my bores are currently 92.0508mm (0.002" oversized).

Via getbmwparts.com, "Nueral/alcan" 92,485MM(+0,50) pistons are $181 ($1086 for the set). It is not clear if they include rings, but everyone I've talked to seems to believe they do.

On eBay I see I can get a set of Maxsil pistons (which include rings) for $619. My machinist said he's worked with Maxsil pistons before and they'll be "ok" for a non-tuned engine like mine.

Or, I could change my rules for this build, and go with CP Forged pistons (10:1 compression) for $1,049.95. I'd then be building a tuned M30B35 which has never been my intent. If I started down this path I'd likely get sucked in and end up doing a different cam grind, etc...

Lots to think about. I love everyone's input...

Seems like a no brainer now that the whole thing is apart, IMO. Unless you had a budget in mind

Bump the compression a bit, get a hotter cam, slightly larger fuel injectors, and then get Mark D'sylva to burn you a custom chip for the 179. He should have a pretty good idea what you'd need based on the modifications. Maybe throw in some head porting and do larger valves, too.

Bump the compression a bit, get a hotter cam, slightly larger fuel injectors, and then get Mark D'sylva to burn you a custom chip for the 179. He should have a pretty good idea what you'd need based on the modifications. Maybe throw in some head porting and do larger valves, too.

Now we're cooking with fire...

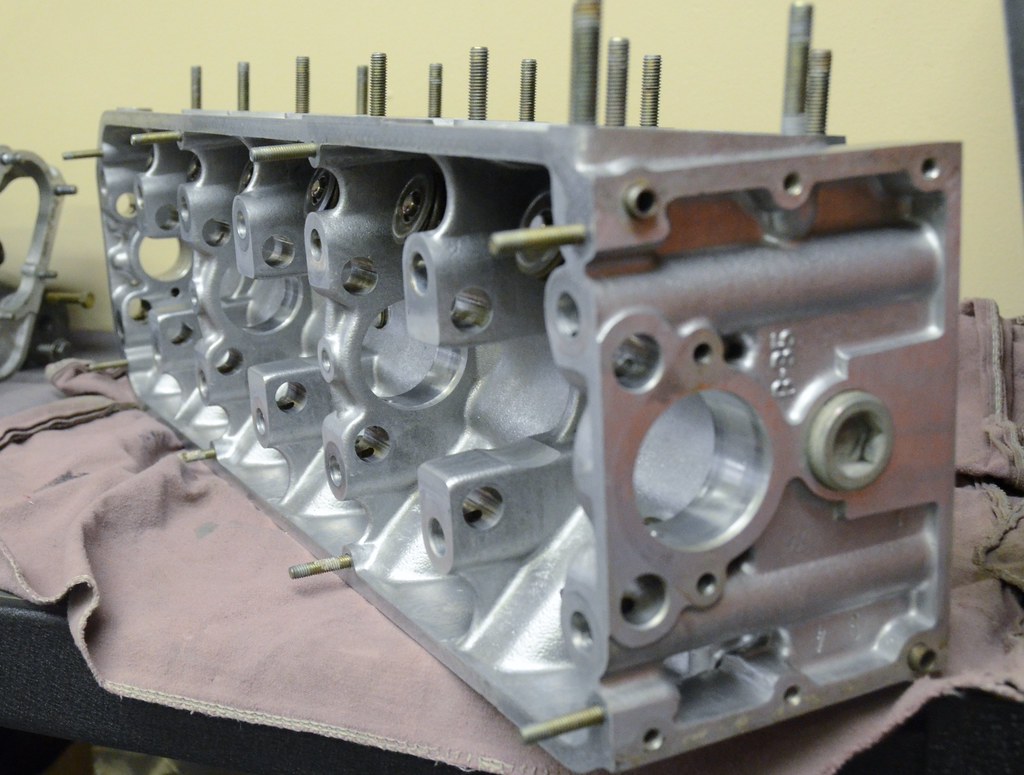

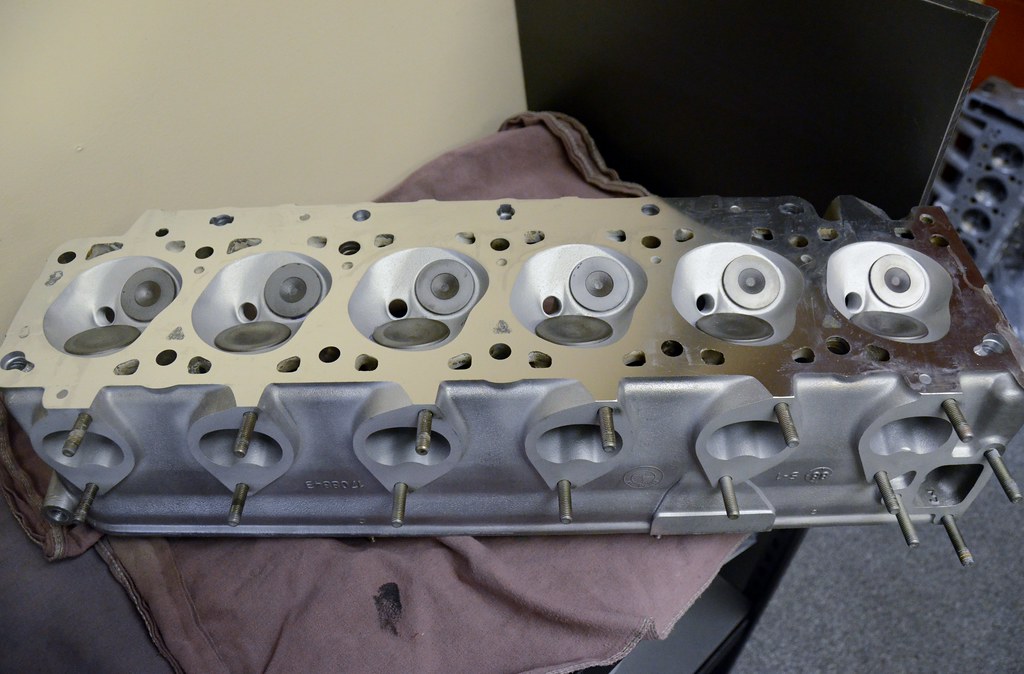

I just got off the phone with the legendary Paul Burke. We have a plan. I'm going to go with his mild cam and 10:1 pistons. Once I get the cam from him, my head is ready to go with the new rocker arms I bought and the 3-sided valve grind my machinist has already done.

He says my rods are ideal but I should replace the rod bolts. He also says that the crank is ideal.

The only wrinkle in the plan is that Paul really does not think I should use this block, as it is one of the later "lightweight" B35 blocks and is prone to cracking ("1 in 5 crack in stock form"). I may argue with some of you, but I'm not going to argue with Paul Burke. I have not yet purchased motor mount adapters that I'd have to use if I continued down the previous path, so that's some lemonade here...

Paul says the 179 ECU (Motronic 1.3) will drive this engine fine, but I'll want to increase the fuel pressure.

So now I'm on the hunt for either an early B35 (stamped Nov. 1987 on the block) or a B34 block. Anyone in WA have a good one for cheap? :-)

I just got off the phone with the legendary Paul Burke. We have a plan. I'm going to go with his mild cam and 10:1 pistons. Once I get the cam from him, my head is ready to go with the new rocker arms I bought and the 3-sided valve grind my machinist has already done.

He says my rods are ideal but I should replace the rod bolts. He also says that the crank is ideal.

The only wrinkle in the plan is that Paul really does not think I should use this block, as it is one of the later "lightweight" B35 blocks and is prone to cracking ("1 in 5 crack in stock form"). I may argue with some of you, but I'm not going to argue with Paul Burke. I have not yet purchased motor mount adapters that I'd have to use if I continued down the previous path, so that's some lemonade here...

Paul says the 179 ECU (Motronic 1.3) will drive this engine fine, but I'll want to increase the fuel pressure.

So now I'm on the hunt for either an early B35 (stamped Nov. 1987 on the block) or a B34 block. Anyone in WA have a good one for cheap? :-)

Cool !! I have been following your thread and I have to say I am excited to read this.

I just completed the following:

b34 block bored to 92.5

Paul Burke b35 10.5:1 pistons

Paul Burke N31 cam

port match and valve job

b35 head and intake manifold

bavauto headers

I also did the Miller maf and WAR chip with 24lb injectors but I am pretty sure others have run 10:1 on a 179 ecu without issue (don't quote me on that)

You will be very happy !!!

I just completed the following:

b34 block bored to 92.5

Paul Burke b35 10.5:1 pistons

Paul Burke N31 cam

port match and valve job

b35 head and intake manifold

bavauto headers

I also did the Miller maf and WAR chip with 24lb injectors but I am pretty sure others have run 10:1 on a 179 ecu without issue (don't quote me on that)

You will be very happy !!!

So that's who was tying up the line!cek wrote: I just got off the phone with the legendary Paul Burke.

Is yours running yet? How do you like that cam? I'm hoping to take delivery of my project later this month, and I can't wait!shwaa wrote:I just completed the following:

b34 block bored to 92.5

Paul Burke b35 10.5:1 pistons

Paul Burke N31 cam

port match and valve job

b35 head and intake manifold

bavauto headers

The new plan summary is:shwaa wrote:Cool !! I have been following your thread and I have to say I am excited to read this.

I just completed the following:

b34 block bored to 92.5

Paul Burke b35 10.5:1 pistons

Paul Burke N31 cam

port match and valve job

b35 head and intake manifold

bavauto headers

I also did the Miller maf and WAR chip with 24lb injectors but I am pretty sure others have run 10:1 on a 179 ecu without issue (don't quote me on that)

You will be very happy !!!

- B34 block (yet to be acquired) bored to 92.5mm

- Paul Burke B35 10.5:1 "806" M30 B35 CNC Dome piston set

- Paul Burke N21 camshaft (a bit more mild than the N31 you got)

- 3-sided valve grind (done)

- B35 head, rods, springs, crank, manifold

- 19lbs mustang injectors (should I go 24?)

- 179 ECU

- Bav Auto headers and Ireland Engineering exhaust

- 17lbs flywheel

I will shortly have a whole bunch of B34 engine parts to sell as well as my perfectly good B35 block.

Last edited by tig on Aug 09, 2013 3:12 PM, edited 1 time in total.

Yep ... Got about 650 miles on it. I love the cam and the motor all together. Tons of torque and runs out smooth all the way up. I still have some tuning to do with the Miller stuff but overall .. all good.Brian D wrote:

Is yours running yet? How do you like that cam? I'm hoping to take delivery of my project later this month, and I can't wait!

I don't know the numbers but B35 blocks cracking is common knowledge. Around the bolt holes.cek wrote:The only wrinkle in the plan is that Paul really does not think I should use this block, as it is one of the later "lightweight" B35 blocks and is prone to cracking ("1 in 5 crack in stock form"). I may argue with some of you, but I'm not going to argue with Paul Burke. I have not yet purchased motor mount adapters that I'd have to use if I continued down the previous path, so that's some lemonade here...

Sounds like you're in for quite a build, I'd love to do similar but my checkbook isn't up for it.

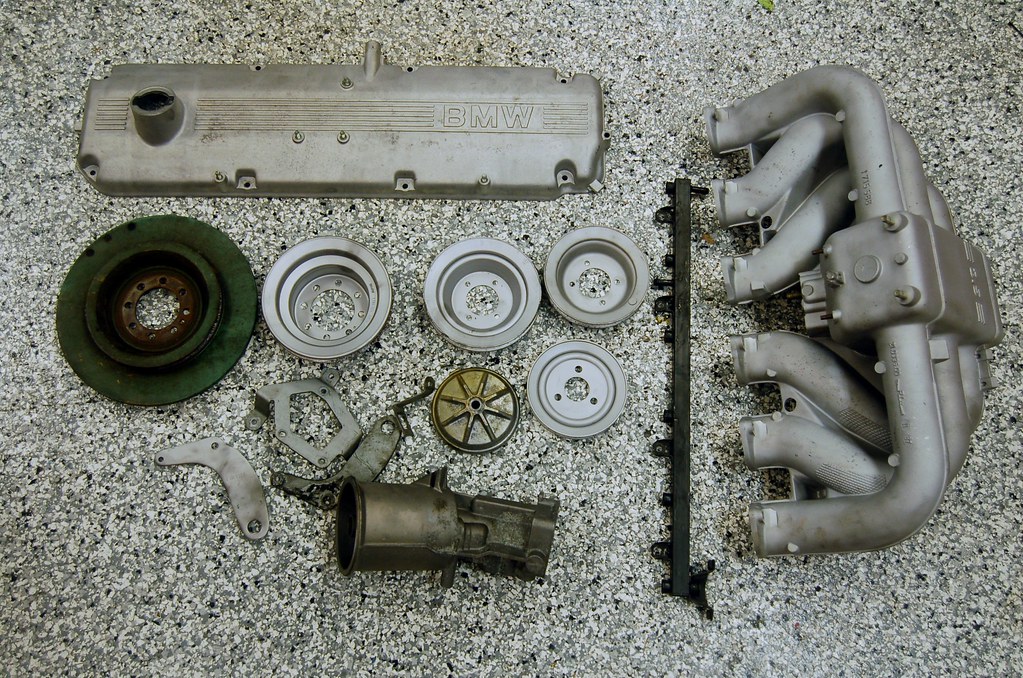

At about 11:30am yesterday this got dropped off at our house.

By 2pm, CJ & I had it all the way down to the block.

This engine came off the same car (an '88 white 535is) that my exhaust came off of, but via a different seller. Small world.

The inside of the valve cover is spotless. Supposedly the head had recently been redone and it has a "euro camshaft". I hope I can find a buyer for the head and other parts; lots of good stuff. I'm going to hold on to most of it until the engine is rebuilt, just in case I need any of it, but if anyone in the Seattle area needs B34 parts, let me know...

But best of all, we now have a good B34 block to build the new engine on and it was dirt cheap. From a budget perspective, ignoring the fact that buying the Paul Burke camshaft & piston kit about doubled what we were planning on spending, I get to save because we won't have to buy motor mount adapters for that B35 block. Tee-hee.

By 2pm, CJ & I had it all the way down to the block.

This engine came off the same car (an '88 white 535is) that my exhaust came off of, but via a different seller. Small world.

The inside of the valve cover is spotless. Supposedly the head had recently been redone and it has a "euro camshaft". I hope I can find a buyer for the head and other parts; lots of good stuff. I'm going to hold on to most of it until the engine is rebuilt, just in case I need any of it, but if anyone in the Seattle area needs B34 parts, let me know...

But best of all, we now have a good B34 block to build the new engine on and it was dirt cheap. From a budget perspective, ignoring the fact that buying the Paul Burke camshaft & piston kit about doubled what we were planning on spending, I get to save because we won't have to buy motor mount adapters for that B35 block. Tee-hee.

I want to confirm some things:

The oil pump design on the B34 and B35 is quite different. I plan on using the B35 oil pump I've rebuilt and the B35 oil pan on the final build. Those parts will fit on the B34 block, right?

Are the accessory mounts (e.g. for A/C, PS, Alternator) the same between the B34 and B35 blocks?

The oil pump design on the B34 and B35 is quite different. I plan on using the B35 oil pump I've rebuilt and the B35 oil pan on the final build. Those parts will fit on the B34 block, right?

Are the accessory mounts (e.g. for A/C, PS, Alternator) the same between the B34 and B35 blocks?

My plan is to use a standard AFM and stock 179 chip initially. But it seems likely I'll want more control over the tune; maybe as far as having a Miller WAR chip.

So I snapped up a used Miller MAF and Miller 179 chip. I figure if I don't end up using it I can just re-sell it.

Pistons and camshaft are due next week. Realized yesterday I need to source new rod bolts/nuts and piston wrist pins. Paul Burke says just use OEM so that's what I'm going with...

So I snapped up a used Miller MAF and Miller 179 chip. I figure if I don't end up using it I can just re-sell it.

Pistons and camshaft are due next week. Realized yesterday I need to source new rod bolts/nuts and piston wrist pins. Paul Burke says just use OEM so that's what I'm going with...

Great thread- I always like the engine build threads. I'm an E28 guy now, but used to be an E21 guy. I rebuilt my engine in my 83 for a project, for pretty cheap. I had a local shop in PDX do the machine work, and I used Maxil pistons. After 7 years, they are still close to the same compression on all for cylinders- good job on me  I only had them balance the crank to the flywheel, and it was a pretty smooth engine.

I only had them balance the crank to the flywheel, and it was a pretty smooth engine.

Rebushing the rockers with new rocker shafts will quiet the head down, also. People always think it's the valves that need to be adjusted, and while that's true for the most part, the valve train as a whole gets worn, and you can't turn that out by adjusting valves. I had a very un-bmw sounding engine- very quiet

Rebushing the rockers with new rocker shafts will quiet the head down, also. People always think it's the valves that need to be adjusted, and while that's true for the most part, the valve train as a whole gets worn, and you can't turn that out by adjusting valves. I had a very un-bmw sounding engine- very quiet

-

Russianblue

- Posts: 415

- Joined: Feb 12, 2006 12:00 PM

- Location: Charlotte, NC

I've got a set of 8 flow-tested 19lb injectors (orange) with about 3k miles of use on my M20 pre-turbo.

yours for the cost of shipping ($5) if you want em.

you might consider rebuilding your alternator:

http://www.bimmerfest.com/forums/showth ... p?t=454325

yours for the cost of shipping ($5) if you want em.

you might consider rebuilding your alternator:

http://www.bimmerfest.com/forums/showth ... p?t=454325

-

Russianblue

- Posts: 415

- Joined: Feb 12, 2006 12:00 PM

- Location: Charlotte, NC

speaking of quieting the head, I rebuilt mine with the Metric Mechanic beehive valve springs...which made a HUGE difference in the sound as much as is possible with an M20/M30. They are a bit pricey though and I'd defer to Paul Burke on all things head related.waferman wrote: Rebushing the rockers with new rocker shafts will quiet the head down, also. People always think it's the valves that need to be adjusted, and while that's true for the most part, the valve train as a whole gets worn, and you can't turn that out by adjusting valves. I had a very un-bmw sounding engine- very quiet

Let me know on the injectors.

The pump will bolt on but there are differences in the gear/chain and tensioner. Lots of info here. I prefer the B35 gear and chain but used shims because I didn't have the tensioner pin.cek wrote:I want to confirm some things:

The oil pump design on the B34 and B35 is quite different. I plan on using the B35 oil pump I've rebuilt and the B35 oil pan on the final build. Those parts will fit on the B34 block, right?

No, the mounting points on the B35 oil pan for the power steering pump and alternator bracket stuff is different. The alternator may work (can't remember) but the PS pump and bracket are wider on the B35. AC side is the same.cek wrote:Are the accessory mounts (e.g. for A/C, PS, Alternator) the same between the B34 and B35 blocks?

I've had the new camshaft for about 2 weeks but just have not had a chance to get to the machinist to drop everything off during the week. I asked the machinist if he could meet me today (Saturday) and he agreed so my son & I drove up there and dropped off the B34 block, the new camshaft and pistons, rocker arms, wrist pins/bushings, and flywheel.

Now the machinist has all the parts to finish the head and the lower. He says he'll have it done in about a week and a half.

Now I've finally got to get the the powder coater and get all the fastners off to be plated.

Light at the end of the tunnel?

Now the machinist has all the parts to finish the head and the lower. He says he'll have it done in about a week and a half.

Now I've finally got to get the the powder coater and get all the fastners off to be plated.

Light at the end of the tunnel?

Stopped by the machinist on Friday to get him my timing chain covers. I spaced that he'd need them to machine the head faces.

Took some pics of the block and pistons. He says everything should be ready for me to pick up this week! Which is a good thing because the B34 currently in Vlad has started leaking oil again (through the temporary fix I applied to the timing cover/head 3 way joint).

Took some pics of the block and pistons. He says everything should be ready for me to pick up this week! Which is a good thing because the B34 currently in Vlad has started leaking oil again (through the temporary fix I applied to the timing cover/head 3 way joint).

Going through all my parts to get stuff sent off for powder coating and plating.

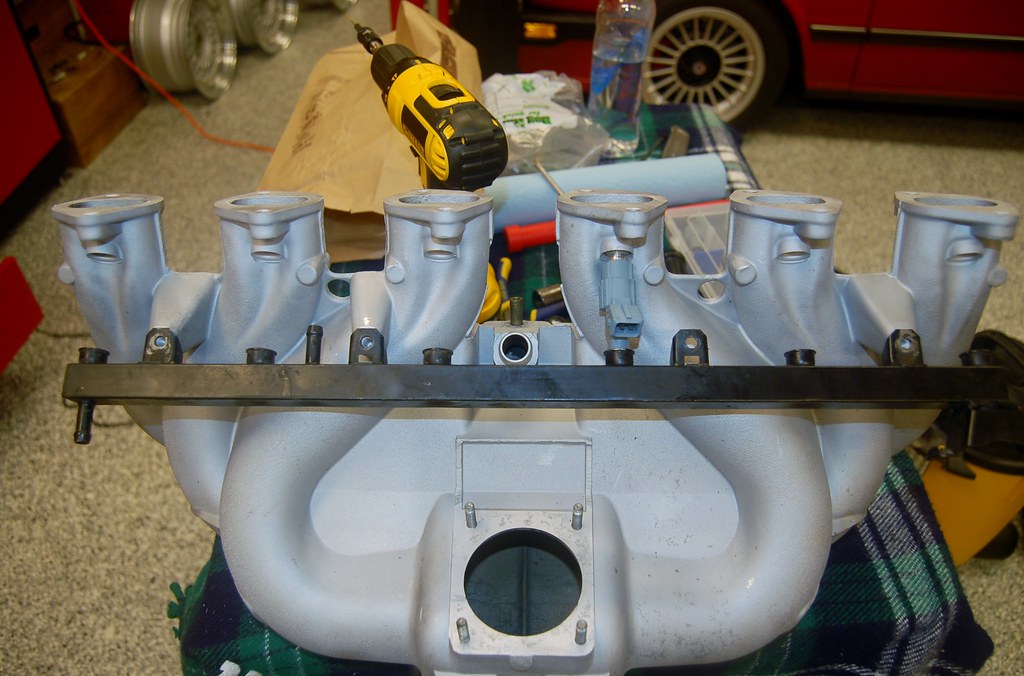

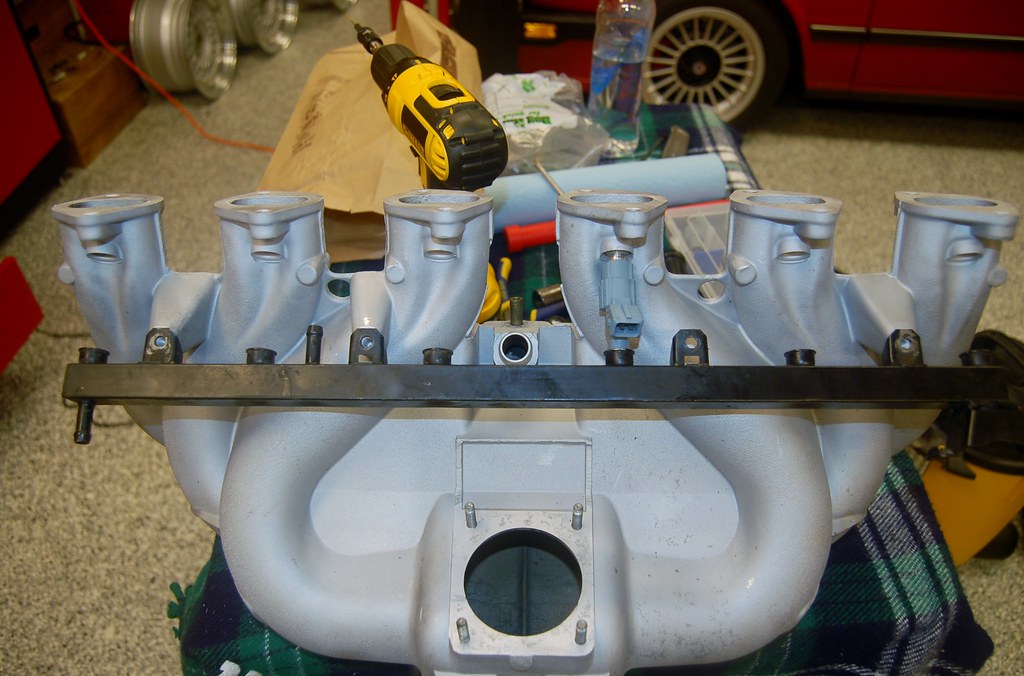

I discovered the B35 didn't come with a fuel rail. I knew the injectors were missing, but since I'd never taken apart a motor before I had no idea the fuel rail was missing when I took it apart.

The B34 donor motor has a good fuel rail. I searched and it appears the B35 and B34 rails are the same other than the B34 rail having 4 mounting points. I test fitted the B34 rail on my B35 intake and it seems fine.

Am I really ok? Just trying to double check everything.

I discovered the B35 didn't come with a fuel rail. I knew the injectors were missing, but since I'd never taken apart a motor before I had no idea the fuel rail was missing when I took it apart.

The B34 donor motor has a good fuel rail. I searched and it appears the B35 and B34 rails are the same other than the B34 rail having 4 mounting points. I test fitted the B34 rail on my B35 intake and it seems fine.

Am I really ok? Just trying to double check everything.

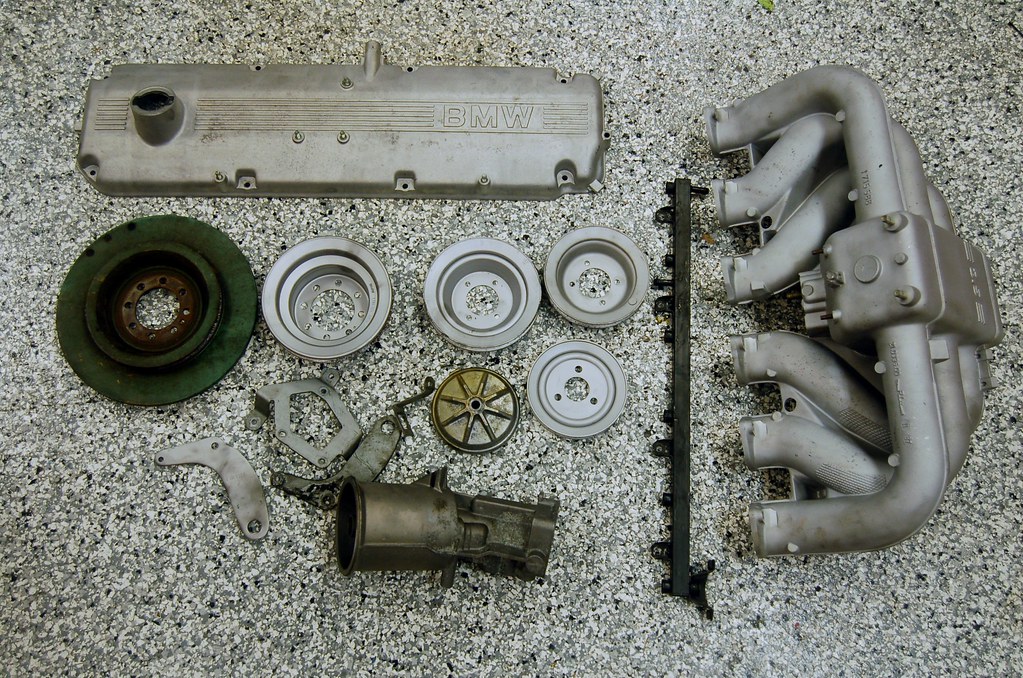

Ready for powder coating...

Valve cover will be black (crinkly) with lines & BMW polished. Fuel rail will be black. Everything else will be aluminum.

Note extra pullys. Off the B34. Might as well; maybe someone will want to buy them.

And plating...

Everything will be yellow/zinc.

This is actually everything from the B35 and B34 donor motors. For this amount of stuff the place I'm using charges the same so might as well. Before tossing it all together I carefully took pictures of each of my labeled zip-locks with the fasteners that went together all neatly laid out.

For example:

It'll still be a challenge figuring out what each fastener is for, but at least I'll have a reasonable reference.

Valve cover will be black (crinkly) with lines & BMW polished. Fuel rail will be black. Everything else will be aluminum.

Note extra pullys. Off the B34. Might as well; maybe someone will want to buy them.

And plating...

Everything will be yellow/zinc.

This is actually everything from the B35 and B34 donor motors. For this amount of stuff the place I'm using charges the same so might as well. Before tossing it all together I carefully took pictures of each of my labeled zip-locks with the fasteners that went together all neatly laid out.

For example:

It'll still be a challenge figuring out what each fastener is for, but at least I'll have a reasonable reference.

Last edited by tig on Nov 06, 2013 11:52 PM, edited 1 time in total.

The B35 filter housing *seems* better. I never saw anything wrong with the earlier style, but apparently there are some people who can't keep liquid in a cup.

I've never seen anyone explain this better than this:

There's a passage in the B35 that needs to be plugged. It's already tapped and just requires insertion of a DIN 908 screw plug (M10x1). It tightens and seals. If you absolutely have to have BMW parts, you want 11 12 7 539 543.

That's a good idea on how to keep the parts identified. I've got a ton of fasteners that I'm going to send in for yeller cad and I am afraid to send stuff in off of a car for fear of losing it.

I've never seen anyone explain this better than this:

Now for our listeners at home, some might ask, "Well whaddya do if'm ya wanna put one o' dem der B34 housins on dat der B35 block?"Shawn D. wrote:If you don't like the oil in the filter housing draining out, then go for it!

The B34 doesn't have the drainback passage that the B35 does, so if you put a B35 housing on a B34, the housing will remain full of oil when you change the filter.

There's a passage in the B35 that needs to be plugged. It's already tapped and just requires insertion of a DIN 908 screw plug (M10x1). It tightens and seals. If you absolutely have to have BMW parts, you want 11 12 7 539 543.

That's a good idea on how to keep the parts identified. I've got a ton of fasteners that I'm going to send in for yeller cad and I am afraid to send stuff in off of a car for fear of losing it.

You'll note in the photo above that there's a B34 harmonic balancer but no B35. Why?

Well, as I was falling asleep last night I wondered the same thing. Fortunately I convinced myself it had to be SOMEWHERE and was able to fall asleep.

This morning I searched the garage and could not find it. What. The. Eff?

I checked the photos of the motor and verified that, yes, it was on there when we bought it.

Then I noticed my parts washer in the corner of the garage...

At least it's clean.

Well, as I was falling asleep last night I wondered the same thing. Fortunately I convinced myself it had to be SOMEWHERE and was able to fall asleep.

This morning I searched the garage and could not find it. What. The. Eff?

I checked the photos of the motor and verified that, yes, it was on there when we bought it.

Then I noticed my parts washer in the corner of the garage...

At least it's clean.

Anyone who has trouble with the E28 era oil filter needs, just once, to change the filter in an early M30, say pre 77 or so with the bottom bolt steel canister and a spring you had to compress while lying on your back. Once with that and they would never again complain about the E28 type.wkohler wrote:The B35 filter housing *seems* better. I never saw anything wrong with the earlier style, but apparently there are some people who can't keep liquid in a cup.

This is why I'm loving this project so much:

I dropped by the machinist this eve to get him some rocker parts and I was telling him about losing the harmonic balancer in my parts washer. He said "oh, you don't want to powder coat that...it has rubber in it."

I'm not afraid to admit I'm a noob and maybe it is obvious to everyone that a harmonic balancer works via the rubber dampening the harmonics in the crankshaft, but I simply hadn't really thought about it. Makes total sense now.

If you had asked me to speculate how one worked before I would have suggested it was simply a rotating mass on the "free" end of the engine and that was enough to dampen vibrations. Hence my not noticing/realizing they have rubber in them.

So, no powder coating for the harmonic balancer...ill just clean it up in the media blaster, masking off the rubber bushing, and spray paint it.

anything else super obvious about these things that I'm missing?

I dropped by the machinist this eve to get him some rocker parts and I was telling him about losing the harmonic balancer in my parts washer. He said "oh, you don't want to powder coat that...it has rubber in it."

I'm not afraid to admit I'm a noob and maybe it is obvious to everyone that a harmonic balancer works via the rubber dampening the harmonics in the crankshaft, but I simply hadn't really thought about it. Makes total sense now.

If you had asked me to speculate how one worked before I would have suggested it was simply a rotating mass on the "free" end of the engine and that was enough to dampen vibrations. Hence my not noticing/realizing they have rubber in them.

So, no powder coating for the harmonic balancer...ill just clean it up in the media blaster, masking off the rubber bushing, and spray paint it.

anything else super obvious about these things that I'm missing?