Page 6 of 15

Posted: Aug 27, 2011 8:40 PM

by DieselBoost

CoyoteStarfish wrote:Sounds good.

How well did the M51 head bolts work?

Those where very easy task...

hardest part where new threads... little sweating was founded....

two washers for each bolt because m51 bolts are little longer than m21

head gasket where easy to assemble without "cyl head guides"

i used those guides in first stages of work....

i glued gasket to the block with some vht copper glue and instant Adhesive...

then i removed guides... and sprayed more vht to upper side of gasket...

next i lifted cyl head on the place...

cyl head bolt holes are now 12.1mm

so cyl head doesnt need anymore those guides...

funniest thing was when we lifted head the wrong way round

and scariest thing.... both me and my friend are specialists...

btw my friend has over 600bhp 2litre toyota celica gt-four

Posted: Aug 27, 2011 9:50 PM

by DieselBoost

Some people may think, what we do when we get bored....

This...

http://www.youtube.com/watch?v=9Qa9WfjfDOc

Posted: Aug 28, 2011 12:14 AM

by CoyoteStarfish

I see rednecks exist in other countries, too!

Posted: Sep 15, 2011 5:47 PM

by DieselBoost

i got fast working with my exhaust manifold today.... now i need only flange for cylinder head... i think i will order that from local metalworks school... their quality of work is good and all what they made is cheap.... actually im former student... but from car mechanic section...

i got my new rebuilt injectors to my cylinder head...

intake manifold is on the place too...

now the major problem... i dont have start motor

and i dont have money either...

so i must get that for free from somewhere....

Posted: Sep 16, 2011 2:24 AM

by CoyoteStarfish

Maybe this will cheer you up. 325tds with a HX35 and other stuff.

http://www.youtube.com/watch?v=tBvk7FouFF4

Posted: Sep 16, 2011 8:08 AM

by DieselBoost

nice... that went right away to my favorites in youtube!

Posted: Sep 28, 2011 12:15 AM

by DieselBoost

Boring... my flange maker is slow

Posted: Sep 28, 2011 11:28 AM

by winfred

naaaa really

http://www.carbidbus.nl/Carbid1/Carbids ... favou.html

http://www.carbidbus.nl/Carbid1/Carbids ... favou.html

CoyoteStarfish wrote:I see rednecks exist in other countries, too!

Posted: Sep 29, 2011 10:58 AM

by DieselBoost

Posted: Oct 02, 2011 4:27 PM

by DieselBoost

My friend decided to take his e28 out of road caused by terrible rust problem.... now car is only for fun.... and ice track...

but here is some fun stuff video from airfield testing....

http://youtu.be/PWAt_Lhe8lc

Posted: Oct 04, 2011 4:30 PM

by CoyoteStarfish

Holy...

That flame from the exhaust. What were the EGTs on that?

Posted: Oct 04, 2011 6:26 PM

by DieselBoost

CoyoteStarfish wrote:Holy...

That flame from the exhaust. What were the EGTs on that?

we dont have egt in this engine....

my guess is... lot

first we had 2.5bar boost in ending of video we had 2bar

exhaust pressure was 1.8bar with 2bar boost

i cant wait what my car does on that airfield

what is interesting that this car has stock head gasket...

Posted: Oct 05, 2011 2:59 PM

by Alleslowbuged

what is interesting that this car has stock head gasket...

My quess is, that the reliability of the stock headgasket is mainly affected by the surface condition of the engine block. I have to add, that this is only "true" for old engines and relatively new headgasket.

My engine has had significant deepening in the surface, i would estimate a deep of something around 0,05 mm - 0,10 mm (~ 300 000 km)

Best Regards

Alleslowbuged

(hope that my AAZ will run in EVO II mode in the next 14 days)

[/quote]

Posted: Oct 05, 2011 6:19 PM

by DieselBoost

typically block is bent from middle...

my engine surfaces was good shape... but it doesnt help either

we thought with my friend that difference betweenn my and my friend car is timing advantage...

my friend uses 0.90mm advantage while my engine has 1.15mm

so burning pressure is much higher than engine of my friend...

second thing is that my friend has much older turbo garrett t03/t04 with 50mm compressor

i have new masterpower with 56.5mm compressor

my old gasket exploded from end of the block... so this is not caused that bending phenomenon

and my friend actually has victor reinz aftermarket gasket

Posted: Oct 05, 2011 6:20 PM

by DieselBoost

btw... my exhaust manifold flanges arrived

Posted: Oct 06, 2011 3:07 AM

by Alleslowbuged

Hi,

sounds good with your flanges, i really waiting for some news from your engine.

Regarding the headgasket, i don't mean overall bending of the block surface, what i mean is very partial plane holes in some areas.

If i remember correctly, all my headgasket problems occour on cylinder 1 or between cylinder 1 and 2 on the driver side. The last one was broke directly behind the belt tigthener of the timing belt, engine still runs nearly normal (no white smoke, no extra pressure in the cooling system), but makes a noise as the head has had a big hole directly to the precup and there was nothing to see or to locate, because it was behind the tightener.

Best Regards

Posted: Oct 14, 2011 9:23 PM

by DieselBoost

soon.... very soon... my exhaust manifold is almost ready...

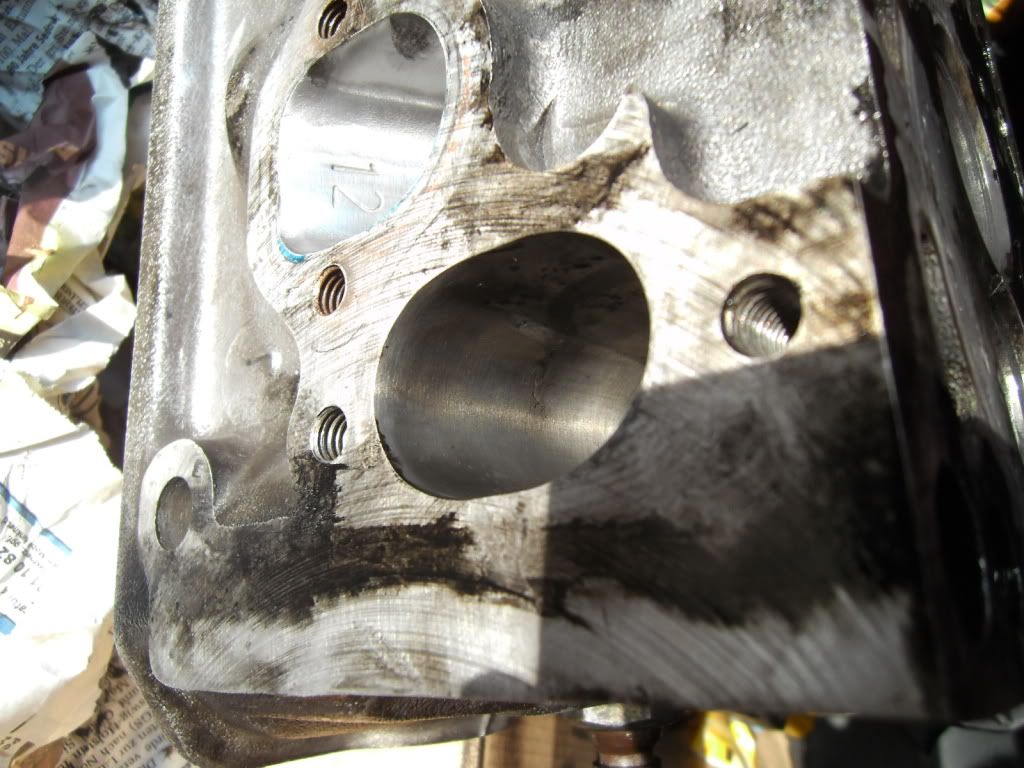

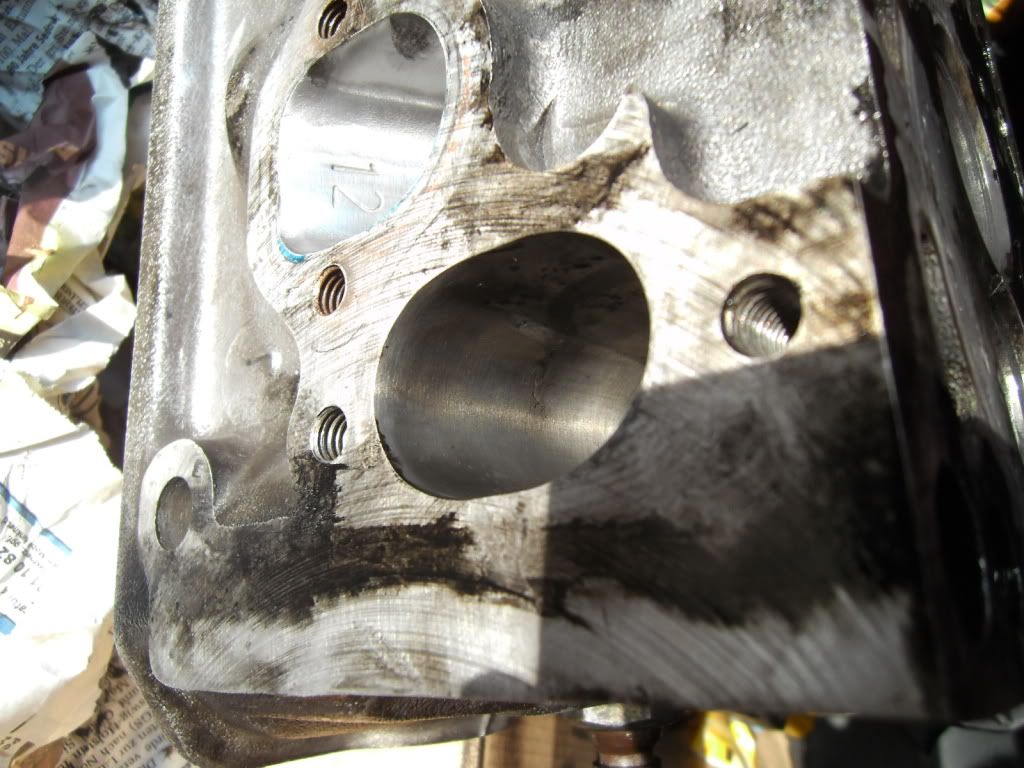

few new pics in eye candy

Posted: Oct 20, 2011 2:47 PM

by Alleslowbuged

Hi

a bit off topic.

I have finish my AAZ rebuilt und have to recognice that i have a leakage between colling water and exhaust port from cylinder 1.

Do you or you friends have experience with welding this kind of leackage on IDI cylinderheads.

Best Regards

Alleslowbuged

Posted: Oct 20, 2011 5:54 PM

by DieselBoost

My m21 head is welded up fully... it was cracked from every place...

good way to weld those is

1. open those cracks fully with grinder

2. then heat up the head

3. weld it

4. heat up again

5. very slow cooling

Posted: Oct 20, 2011 6:03 PM

by DieselBoost

My turn to go off topic...

In next saturday our electric music collective is hosting a web radio from my apartment...

Good electric music, live dj:s, funny chatting (in finnish, maybe some words in english too

)

Its free etc...

time 12:00-19:30 in our time in finland...

here is the link to the radio...

http://loudcaster.com/channels/676-harder-fi

btw there is 24/7 automatic radio...

Posted: Oct 21, 2011 4:56 AM

by CoyoteStarfish

DieselBoost wrote:My m21 head is welded up fully... it was cracked from every place...

good way to weld those is

1. open those cracks fully with grinder

2. then heat up the head

3. weld it

4. heat up again

5. very slow cooling

Hmm I need more info on this.

How hot do you heat the head?

Do you weld it hot?

Do you allow it to cool fully before heating it up again?

I had this idea using a home oven but I had not heard of this technique before. Heating, welding in 10 minute "bursts" to keep the head from cooling too much and putting it back in the oven so each weld is done while the head is hot. Then putting it in the oven and turning the temperature down every hour and allowing it to cool overnight inside the oven, maybe with some bricks inside to retain heat.

Posted: Oct 21, 2011 10:03 AM

by DieselBoost

my head is made by professional welder who has experience of many years...

he has somekind industrial oven... and yes he weld it when it is hot...

Posted: Oct 22, 2011 4:32 AM

by DieselBoost

Posted: Nov 08, 2011 6:23 PM

by DieselBoost

If you were in the belief that mb:s, vw:s and bmw:s are only powerful diesels in finland... you were wrong...

Yes this is british YORK diesel ford transit mk2

http://youtu.be/yWhrCILMIdo

Posted: Nov 21, 2011 12:57 PM

by Alleslowbuged

Hi,

did i remember correctly, when i say that you have sheduled to make a dyno in oktober?

Best Regards

Alleslowbuged

P.S. I did not found any shop for welding my AAZ cylinderhead, so i have tried to solder the crack. For soldering i have to get a temperature of min. 400°C, but even with preheating to hole cylinderhead up to 280°C and using two propan burner (each with flame temperature of 1900°C) i could not reach necessary temperature. By trying to solder i have open the crack, which is now a hole (appr. 7mm x 5mm).

I now look for a "new" AAZ cylinderhead, if any wand to sell one for a reasonable price please contact me.

Here is the crack:

Here is preheating (4,5 kW)

Here is the hole:

Posted: Nov 21, 2011 10:59 PM

by DieselBoost

interesting operation

no dyno yet... that dynoday was too early for my car...

but i will go to dyno soon only with my car.... not some dyno day event....

Posted: Nov 22, 2011 3:00 AM

by Alleslowbuged

Hi,

is your car allready running again and do you use a camshaft from a 524 na?

Best Regards

Posted: Nov 23, 2011 3:41 PM

by DieselBoost

i been little bit lazy... and nothing is happened in garage... but maybe next weekend i will do something for that...

i has new job, so it takes some time...

Posted: Nov 30, 2011 2:22 PM

by Alleslowbuged

Hi,

just as short notice, i have soldered the hole in the exhaust port, and restart the engine yesterday. It seems to be sealed.

Best regards

Posted: Nov 30, 2011 2:54 PM

by sjhertel

So how did you fix it? That look like a difficult problem to solve, I would like to know how to deal with stuff like that. Thanks.

How well did the M51 head bolts work?