Page 7 of 14

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 13, 2016 10:40 PM

by marc79euro645

Mine is an m104 out of an 84 /745, basically an m30b34 with piston oil squirters.I'm using the stock kkk27 turbo with the m102 intake and bypass setup. I'm running ms2 for injection and spark. I'll have to post some pics of mine someday, it looks good at a distance, up close the flaws are obvious. I've debated spending the $2-$3k it would take to get the bodywork done, for right now I'm ok with it being a rat rod.

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 14, 2016 9:02 PM

by tschultz

Waiting on getting my ms2 unit back from Peter F, who found an incomplete connection to the spark output pin. He's going to repair it and install a mapdaddy sensor for on the fly barometric correction when I drive into the mountains.

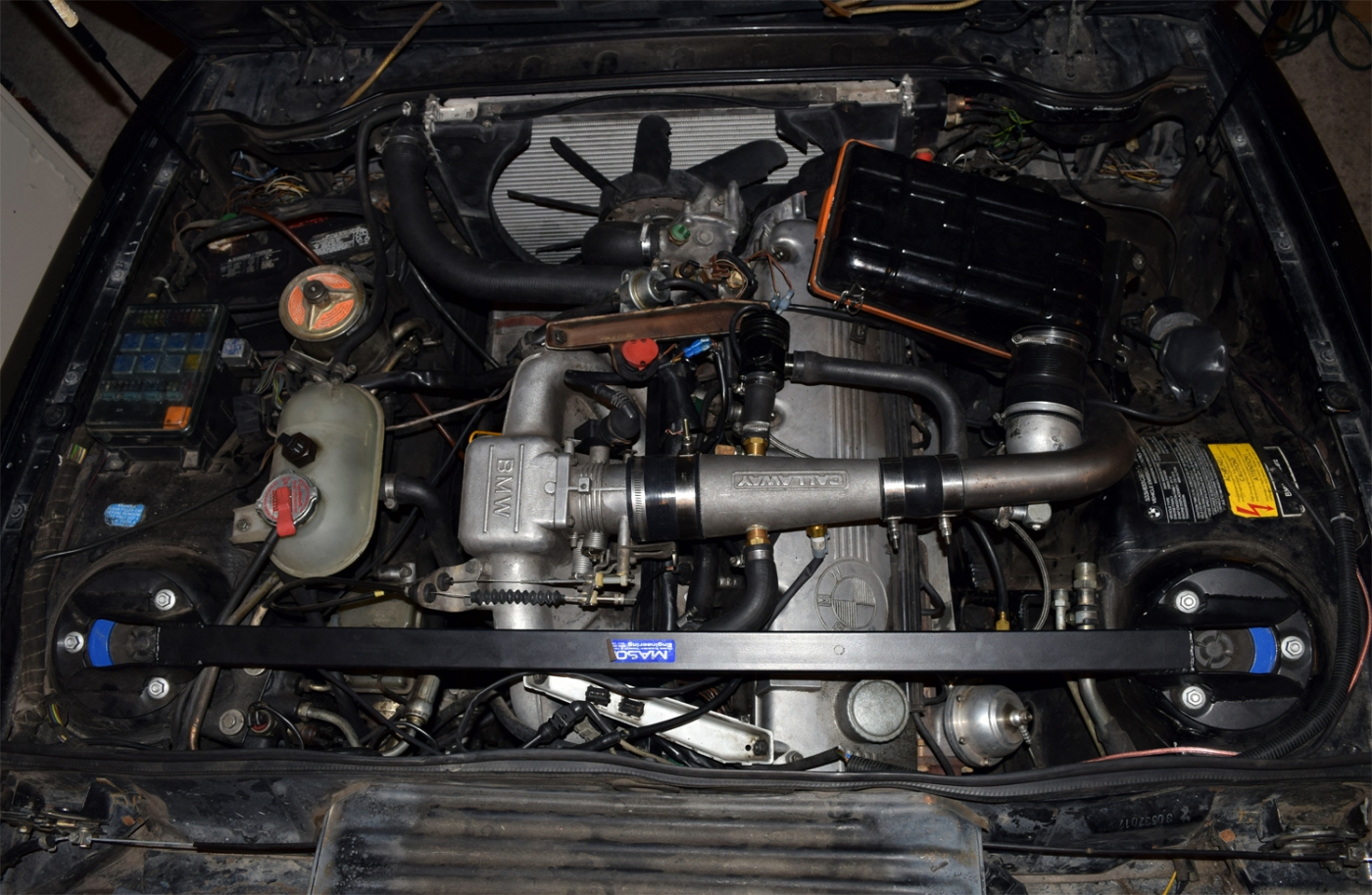

In the mean time, I decided to mess with my air box. I really didn't like the cone that I had on the car, but I didn't have many alternatives as it didn't fit in the car with the Callaway kit. Fortunately, with the megasquirt I am removing the AFM and using an IAT sensor instead. When I started looking, I realized that i can finally put a stock airbox back on the car. I got this one and have had it sitting around with the intention of installing.

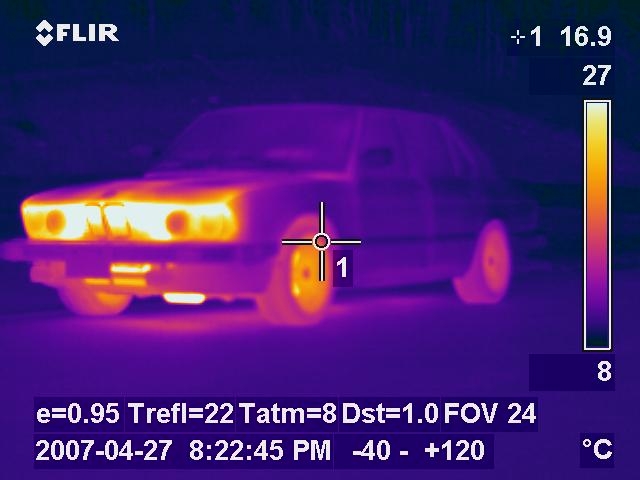

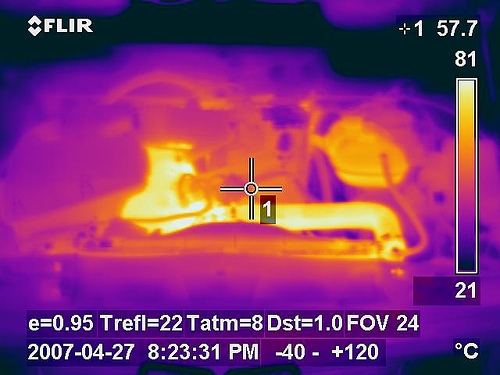

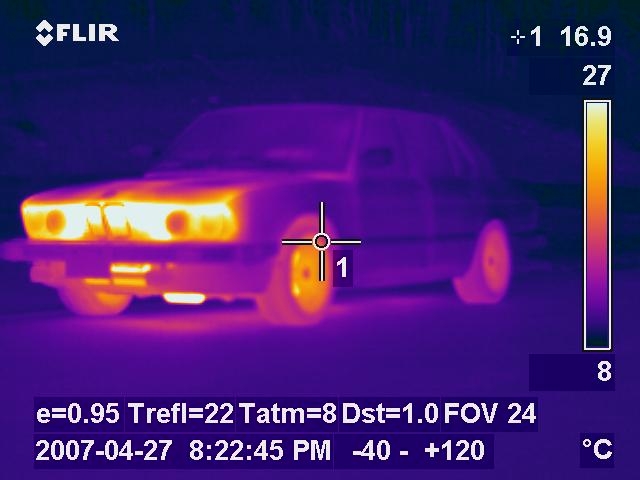

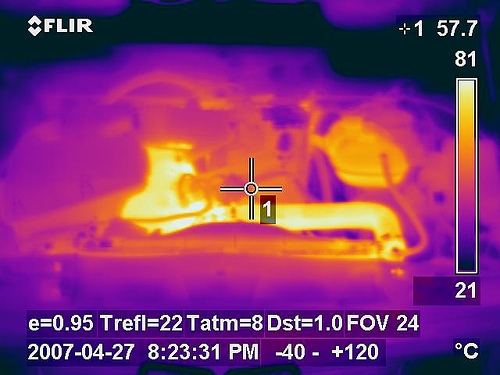

The main reason being some infared images I saw on this board back when I joined the forum. I have saved them for reference:

Its thermal sensor is 320x240. The camera is professional level designed mainly for industrial work. My buddy uses it to do diagnosing of electrical connections and equipment in commercial and industrial buildings.

Its range is -40°C To +2,000°C, thermal sensitivity 0.08°

The second picture illustrates how good the stock airbox is. I'm not sure if the car is idling or in heat soak, but either way, it works very well.

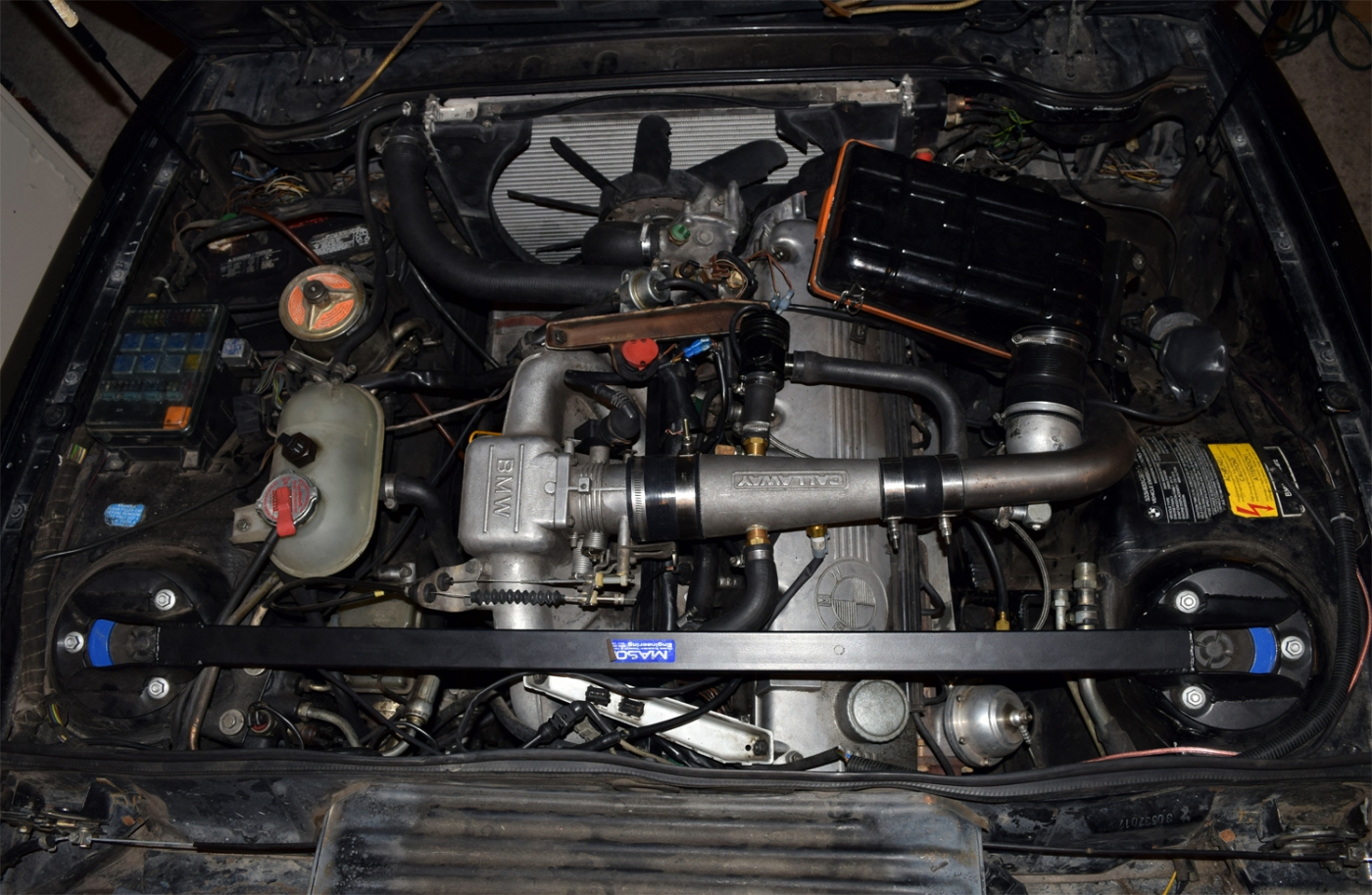

I adjusted the turbo inlet height and position of the elbow/coupling so that it would align a little better. I mocked up the air box using a bracket I had laying around, the positioning is slightly forward of stock, but the hood still closes and now the air filter is more secured than ever before.

I also like that it makes the engine bay look more stock. Now when I pop the hood, it will be less obvious that the car is turbocharged.

Here you can see the diverter valve and piping, along with the placement of the IAT sensor. I didn't even have to adjust the hole where the 7th injector used to be. The bore was very close to an NPS tap drill, so all we had to do was to tap it 3/8" NPS. I think this works better than a bung as it places the sensor closer to the center of the intake pipe.

The engine bay is looking so much better than it had been. This air box helped, along with removing the extra wiring for the Callaway Microfueler.

Oh yeah, I also removed AC components in the engine bay as I realized I wouldn't be converting it ever. I did this when I put the 60-2 toothed wheel a few weeks back. I had to remove the radiator, but otherwise it was pretty simple. I haven't removed the parts under the dash, but I still removed probably 45 lbs of weight.

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 14, 2016 11:54 PM

by marc79euro645

I would like to go 60-2 setup. Right now I have early dizzy for vr pulse, which is kinda iffy when battery low or motor cold, so obviously crank vr would be twice as fast and i hope more dependable. I've looked at all the threads about it, but still unsure as to ms2 setting.Any tips appreciated.

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 15, 2016 9:19 AM

by tschultz

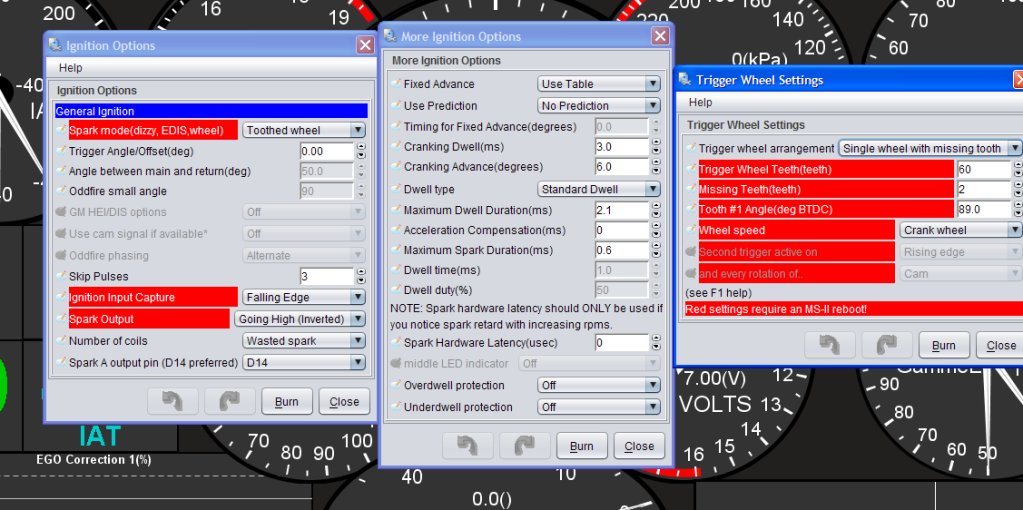

You have to take out the radiator and remove the fan and pulley. I'm sure it is easier on an e28 since the hood opens the other way. Otherwise, add the VR sensor and bracket in place of the old Motronic 1.0 sensor (who knows what that does anyway?). Since the 60-2 wheel is located via a pin, there is only one way to install it.

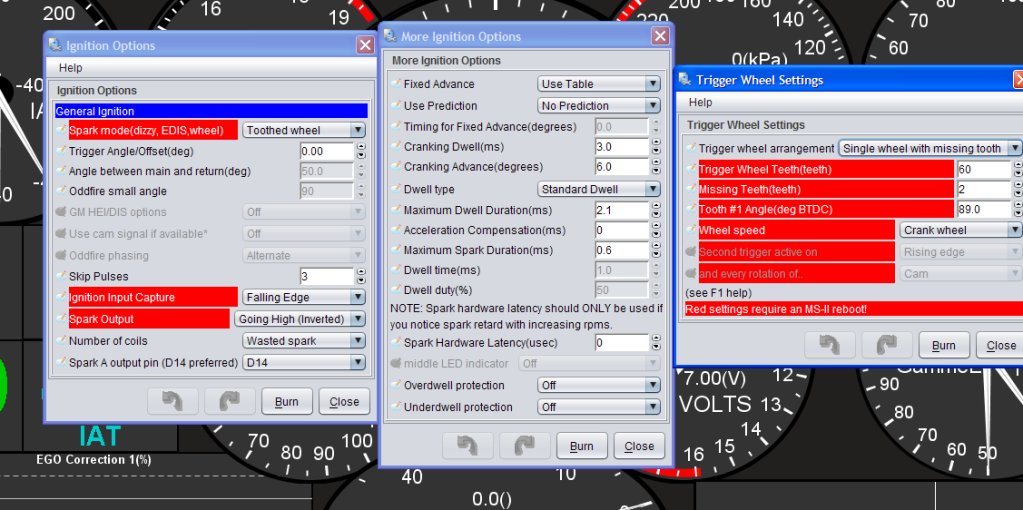

Wire it up to the pins for speed or reference sensors if you have the stock 1.0 harness and use the 60-2 settings from the MS FAQ here:

That seems to be all there is to it. From what I understand, megasquirt uses the crank signal to determine injector firing.

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 15, 2016 2:22 PM

by elcrazon

I don't know if you need enough clearance to have to pull the radiator, though I did mine when the engine was out of the car, so I can't say for sure. Make sure to install the sensor bracket before getting the 60-2 wheel torqued down, there's a mounting bolt you can't reach with the wheel installed. As for the MS2 settings, I think this might be in the FAQ a number of pages in, but the recommended setup these days is to use rising edge trigger, which gives a tooth #1 angle of about 84*, which you can verify with a timing light and fixed timing enabled.

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 16, 2016 2:33 PM

by mitch5

Before you get to far into the megasquirt tuning, i would suggest moving your iat the furthest point away from the engine heat as possible. Mine is mounted right after the intercooler behind my valance. You will almost certainly get heat soak from mounting above the valve cover. In short when you turn your car off, heat from the engine bay will radiate and heat up the sensor. The sensor will think the air is 130f when its actually 80f and will lean the engine out, this creates a big head ache when starting the car for the first few minutes. You can tune to compensate this but it way easier to move the sensor.

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 16, 2016 7:08 PM

by marc79euro645

Thanks guys, good info and tips. Now I just need to get the balancer and vr. I've changed the balancer before with the radiator in on my 6 series. I used the old balancer to make a crank holder (welded a 2x2 square tube to it), and a big cheater bar. 330 ft lbs of torque on the crank hub is serious torque.

thanks again

marc

Re: Callaway 633CSi - 8/24/2016 - MS2 Install/ No-start issu

Posted: Sep 24, 2016 9:06 AM

by tschultz

mitch5 wrote:Before you get to far into the megasquirt tuning, i would suggest moving your iat the furthest point away from the engine heat as possible. Mine is mounted right after the intercooler behind my valance. You will almost certainly get heat soak from mounting above the valve cover. In short when you turn your car off, heat from the engine bay will radiate and heat up the sensor. The sensor will think the air is 130f when its actually 80f and will lean the engine out, this creates a big head ache when starting the car for the first few minutes. You can tune to compensate this but it way easier to move the sensor.

Thanks for the comment, I will monitor this and see if it is something I need to change.

I got the Ms2 back yesterday and had some time to mess with settings. It fired up with Elcrazon's tune but I had to adjust Warmup inrichment and afterstart enrichment. It also seemed that my idle settings needed some adjustment.

My brother and I adjusted the the spark timing enough so that it wouldn't totally die and got to a point where it was able to idle and not hunt. A few things I need to resolve though:

1. Noisy signals. The CLT, TPS and AFR #'s all jump around a lot when the car gets running. I realize this was happening before megasquirt as the AFR's never seemed to settle out. Any comments here? I checked grounds at the battery/chassis, head/firewall and head/wire harness (the only 3 major ones I know of) and they all look good... Any thoughts here?

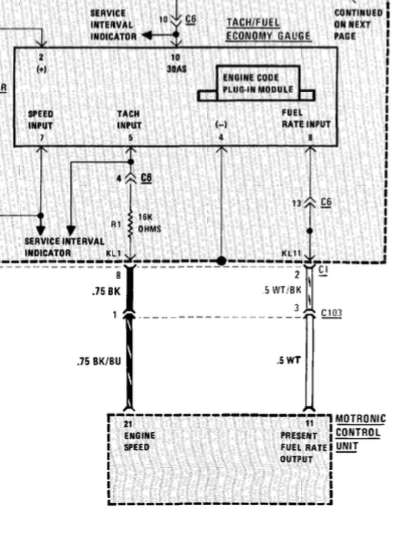

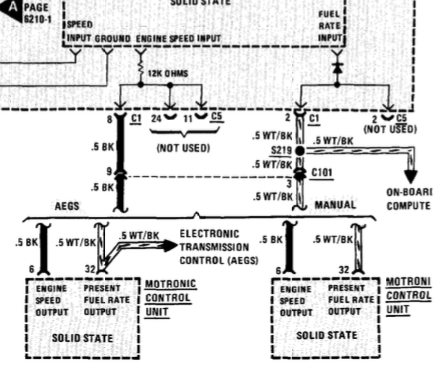

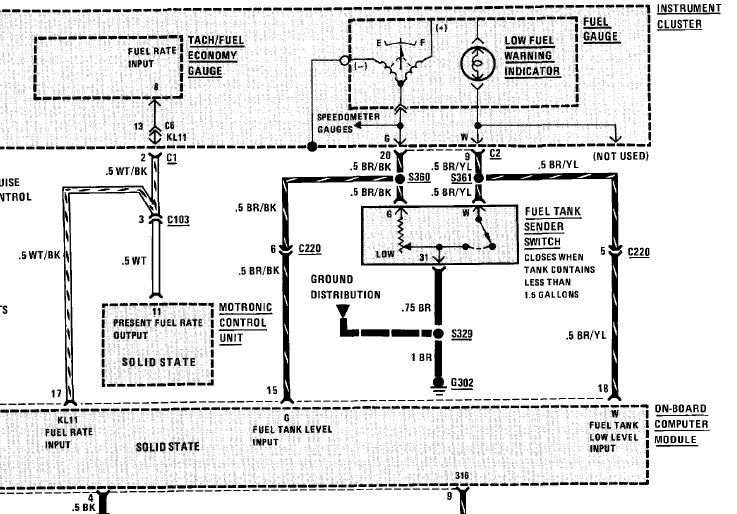

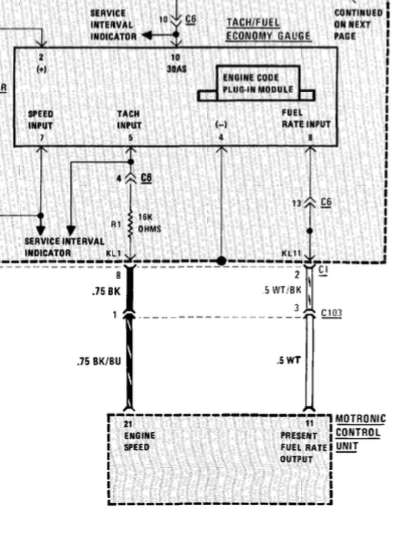

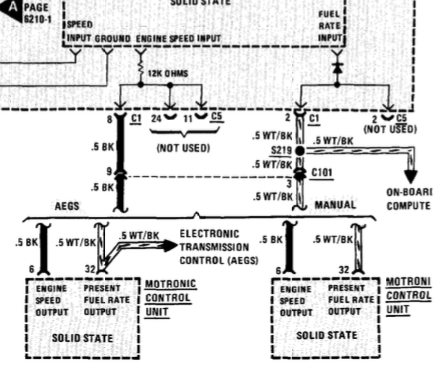

2. No tach signal on instrument cluster. I read this on E30's about jumping the engine speed output to the cluster:

the engine speed output and gives the instrument cluster the signal for the tachometer. This must be jumped to pin #32, the fuel consumption output, whichgives the cluster the signal for the econogauge

I also read about an inline resistor. Anybody been through this?

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Sep 24, 2016 10:51 PM

by elcrazon

Oh yeah, sorry, my warmup and afterstart enrichment aren't very good at the moment because I'm still playing around with the map table and it runs well enough on my car at the moment.

How noisy are your signals? The TPS can be a bit jumpy if you're hooked up to the non shielded wires in the harness that run by the injector wiring. You can smooth some of it out with the lag settings. Where do you have the o2 controller grounded to? I also pulled the grounding for the idle control circuit on the board off the low current ground plan and moved it to the high current ground plane when I thought I was having major voltage issues from the idle valve. That turned out to be caused by a bad main relay, but I think it did smooth out a little of the sensor voltage fluctuation.

For the tach signal I pulled the signal wire out of the harness near the motronic plug and connected it to a c103 connector I cut from the old 35-pin harness.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Sep 26, 2016 10:07 AM

by tschultz

elcrazon wrote:Oh yeah, sorry, my warmup and afterstart enrichment aren't very good at the moment because I'm still playing around with the map table and it runs well enough on my car at the moment.

How noisy are your signals? The TPS can be a bit jumpy if you're hooked up to the non shielded wires in the harness that run by the injector wiring. You can smooth some of it out with the lag settings. Where do you have the o2 controller grounded to? I also pulled the grounding for the idle control circuit on the board off the low current ground plan and moved it to the high current ground plane when I thought I was having major voltage issues from the idle valve. That turned out to be caused by a bad main relay, but I think it did smooth out a little of the sensor voltage fluctuation.

For the tach signal I pulled the signal wire out of the harness near the motronic plug and connected it to a c103 connector I cut from the old 35-pin harness.

Thanks for the help. I added some lag factors for now until I can get it sorted. It seems the TPS and AFR have the most noise so I will have to try to shield the TPS wiring or rewire power and ground to my AFR sensor.

I adjusted the warmup and after start enrichment and was able to get the car to start better at my elevation. I tried it this morning in 55F and it started right up. I did some reading and changed the Idle value to "Use last vale" instead of use table. This made a big difference in removing the idle hunting that I had.

Now my idle returns to about 1100rpm and takes about 6-8 seconds to activate CL Idle mode and drop to my target of 850-900rpm. I found this engine with motronic always seemed to idle higher than my 535i, so I'm ok with it.

Regarding the tach, does this sound right?

From my research of following the quote in my last post, I need to tap into Pin 11 of my motronic harness (white wire, fuel output) and connect it to the white/black wire for the tach input:

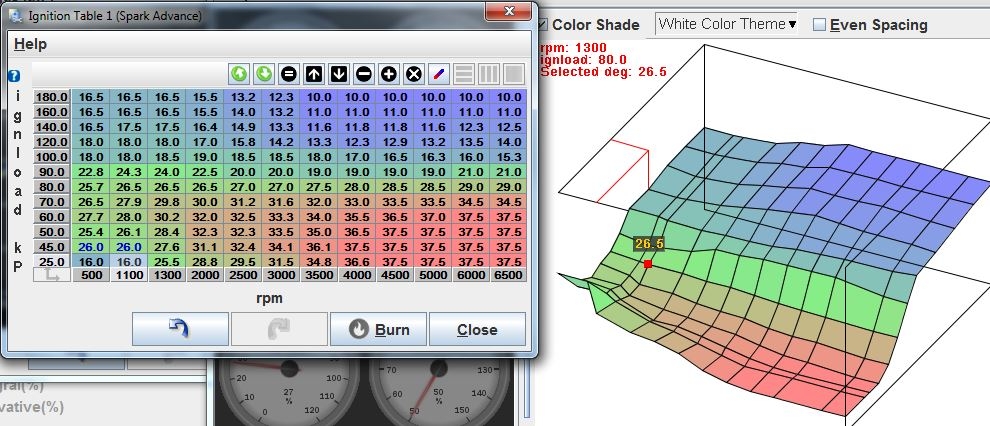

I'll try to share a video by this weekend. I am working on the base map without EGO control. With windows up I could hear some detonation/pinging with a hybrid of your tune and the FAQ ignition timing. I suspect it is related to 85octane we have here. I have removed 5-8 degrees and will continue refining. The plan is to have it ready in about 3 weeks for another track day.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Sep 26, 2016 3:18 PM

by elcrazon

You should be able to adjust the CL idle engagement settings to get it to enter CL idle faster, that sounds quite slow at 6-8 seconds. I moved away from using "Last value" for the idle valve due to an issue where it would get confused and just leave the valve all the way open, not super cool to be coasting down the street with the engine "idling" at 2500+ rpm.

I think the VE map on the tune I uploaded is a bit low across the board, I think most cells should probably go up at least 2-3 points and the high vacuum side needs to be bumped up more. And yeah, the timing is a bit aggressive since I'm running a b34.

For the tach, no, you need a black wire. I think it's basically the same thing as the ignition output. The fuel output stuff isn't going to work with megasquirt unless you get a board to actually produce the right signal for the cluster.

You need something like this:

or this:

Pin 1 on c103 to Pin 21 on a 35 pin harness or pin 6 on a 55 pin harness. Though the basic output circuit might work fine, you could need a conditioning circuit on the Megasquirt side. I have the goathumper adapter board that has something on it, but I don't remember exactly what it does and the board has terrible documentation.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Sep 27, 2016 9:55 AM

by tschultz

Thank you el crazon! That should work for me hopefully. I have another car project I am working on so I didn't have a chance to try it out last night, but I will!

I am still using 'use last value'. Going to test output mode and verifying valve duty was helpful. The old percentages were off and my new numbers are a little higher, like closed duty 36 and open duty cycle 80 (where idle speed stops going up). Part of my idle hunting was related to fuel cut settings. The activate below map value was too high, so it would go into fuel cut mode rather than closed loop idle.

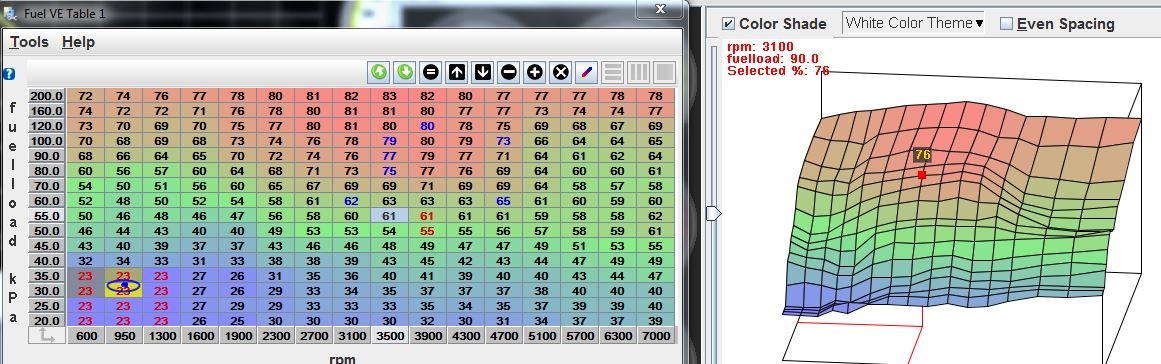

After some more tuning I have found that due to my altitude, my VE table has to be much different than yours. I have EGO control off and have found the car was rich throughout the range, even in boost (AFR's of 10.8 down to 10.0 displayed). My spark map has had to be retarded also as I had been getting pinging, probably related to the advance and 87 octane fuel. I want to tune on this fuel so that in a higher stressed environment like the track I'm not on the edge of detonation. Obviously higher intake temps will be common so I'll start with the safe tune and then buy the 91 octane for the track day. I have read max power isn't always made at max advance anyway.

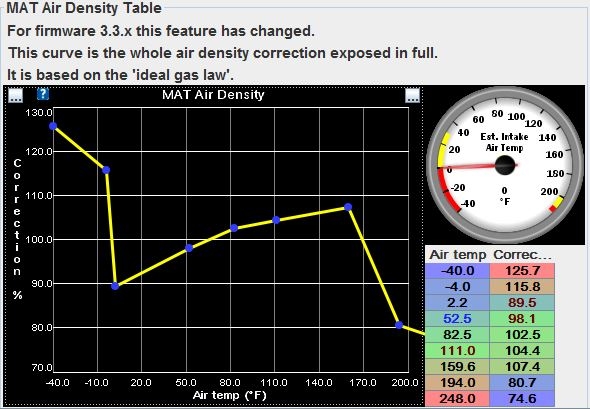

I have been working to refine both maps and have been able to drive the car to work and start it in the morning in cold 45F temperatures and drive home from work in 85F temps. I did have heat soaking like as suggested a few posts back, but I want to keep my eye on it before changing the sensor location. My theory is that a location in the charge piping may be better, but on actual hot days the basic idle settings will still see the high temps and the idle will still be lean. Apparently the GM sensor has somewhat poor response time at low airflow, so if I was stuck in traffic in 100F weather, I think the engine would start to idle lean. I read about MAT correction to help compensate the ECU into adding fuel when intake temps are high. I think this has merit because when actual intake temps are high the megasquirt won't have a tendency to remove fuel. I just hope I am using the feature correctly...

Will post VE and ignition map maybe in a week or so. I need to keep adjusting it before enabling the EGO control.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 04, 2016 9:37 AM

by tschultz

I have been driving the car, but still haven't figured out the tach. The C103 signal is connected and should be bringing the output to the tach. I don't know where my tach output pin is as there appear to be a few different outputs possible. If I change my 'tacho output' from IGN (JS10), the car won't start.

I have been getting pinging with 87 octane as I approach 120-140kPa. I assume the TCD chip was super retarded as I never had this issue before. I keep removing a few degrees at a time and my map seems very conservative compared to others I have seen. I am very close to getting the full premium (91 oct here) and tuning on that fuel instead.

This is with the TCD turbo, 41lb injectors (req fuel=8.7), and a small intercooler.

I haven't really been able to tune above that 140kPa range yet but am fairly happy with the other zones (at 70-80 F). When I drive home from work, the uncorrected EGO values are very close to my targets since this is what I have tuned. However, I get to the next morning and on my way into work, the whole range of the ve map seems to be richer than the day before. It is definitely related to temperature. I want to get a handle on this so the EGO correction doesn't have to do so much work. I have found a few threads elsewhere with similar issues but no real solutions. I have been playing with the MAT corrections and this is what I have so far.

I'm not sure it is what I want as it seems I can adjust the table slightly and AFR's come close to target in vacuum but then I think the correction compounds and removes too much fuel under boost. I may just set this table to 100%, I'm not sure yet.

I had an issue the last few days where I was losing coolant. I was hoping this didn't mean headgasket

Last night I noticed one of the water pump hoses wet with coolant. Not any dripping, but evidence of coolant turning to the green goo on the end of the hose. I also found some wet spots in the engine bay, again no drips. I'm hoping readjusting that clamp fixes my leak. I really want to get the car to the next track day Oct 16!

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 04, 2016 4:32 PM

by elcrazon

Can you post your AFR table? My approach has been to tune the VE map for 14.7 across the board and then let the O2 sensor make adjustments as necessary based on my AFR target. Though, I'm not running boost yet and I think the boosted area of the VE table should be hard coded to whatever AFR you want to make there as the O2 sensor is pretty useless there. Are you using Multiply Map? I have 42lb injectors with a similar ReqFuel and have to have much higher VE in the idle region to get a decent idle AFR.

I think you're going to need a lot of retard in there boosted region if you're trying to run on anything less than 91 octane. When I talked to Todd about my setup he didn't recommend anything less than 91, though our gas here in Cali isn't very good to begin with.

As for your MAT correction, I was under the impression that since it modeled the ideal gas law it shouldn't be changed much unless you're really sure that's the issue. Maybe you're just having issues with your temp sensor placement as previously mentioned in the thread.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 04, 2016 5:34 PM

by tschultz

Sure. I am set to multiply also:

Recall I am at higher elevation than you, so my 80kPa is close to atmospheric. I specifically wanted this region to be about 13:1. I also have lower grades of fuel available. 91 is the highest you can find in most gas stations around here, but it sounds like I may just have to always use premium.

My understanding is the MS controller references the VE map as the base fuel value (along with req_fuel). Then EGO control is allowed depending on the circumstance and preset settings in case of fluctuations between ve map and the target AFR. For example, my ego control isn't allowed over 80kpa so once I get in that zone, I am relying on the ve map. The idea is to get the base map target zones close before any corrections.

For the AFR Map, you want to tune the different zones for the application. Notice my 15.5 zones are cruise in low load, so lean is acceptable to save fuel. Approaching positive pressure I target 13:1 and above I aim for 12:1. But I have my ego control disable above atmospheric. I'm not sure what other users do.

I'll keep investigating mat corrections. The iat sensor placement seems to be related mostly to hot restarts. I have found it to run a bit lean in these conditions until closed loop idle is able to interfere and bring everything near the target. Temperatures are cooling down and I haven't had hot restart issues, but it is still on my mind.

I can send you my closed loop idle settings if you want to try them. I also have idle advance set at 15* so it never has to change timing in the idle region. I suspect my altitude has a little to do with my low ve values. Recall high elevation means less air. There's about 15% less air pressure here, and less air requires less fuel for stoich.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 05, 2016 8:37 PM

by tschultz

The good news is that I was able to get the tach working by connecting the coil to the black wire to the cluster. I did have to disconnect the blue/black (that leads back to the MS unit) as it would cause the car to die when I connected the wires.

The bad news is that yesterday I noticed my BOV and turbo all of the sudden louder than ever before. I'm not quite sure why but I hear them both more clearly even with the windows up.

I just drove around the block and afterwards noticed the dipstick popped up and oil spray all over that side of the engine. Upon further inspection, the breather screen I have is smoking much more than I ever remember before. One last check and pulling the oil cap I no longer have vacuum at idle in the head,itt is also smoking out at idle.

I think I'll look at the breather tomorrow. The car is running really well otherwise. Thoughts and ideas appreciated.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 07, 2016 6:31 PM

by tschultz

So another update.

The leaking I was getting was related to the dipstick. For some reason I have a lot more blow by all of the sudden and the breather I had on the valve cover wasn't venting well enough so the dipstick kept popping up to relieve the pressure.

I removed the breather and just ran a length of hose out to atmosphere. The dipstick isn't popping up any more, but it just seems to be smoking more than it should be out of the valve cover breather. I don't really want to plumb this breather back into the intake as I don't want the oily mess in the intercooler and charge piping...

I'm not getting any smoke out the exhaust, nor am I getting milkshake color in the oil or coolant.

I took a video to show you guys and see if you have any further thoughts:

https://www.youtube.com/watch?v=XAiu5jg3e68

My blow off valve and turbo noises coincidentally seemed to get a little louder with this development. I didn't used to be able to hear the turbo spooling up at all, only a slight high pitched whine at 6+psi if the windows were open.

Either way, you can distinctly hear the BOV and turbo spooling now with the windows up (right atmospheric). Here's a short clip:

https://youtu.be/QOxR25wHvE8

I have driven it the past week to work and will plan to drive it next week to work to verify there are no issues. It is running well but I am sort of nervous about the blow-by/smoking at idle...

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 07, 2016 8:19 PM

by Shadow

Oil coming out the breather does that mean your rings or shot?

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 07, 2016 8:53 PM

by marc79euro645

Plumb it in after the intercooler. Your car sounds good to me!

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 07, 2016 9:08 PM

by George

There is little gained by running the breather directly back into the intake. Its done on the OEsfor emissions. That ship has long sailed for this type of car.

You'll gain a little bit of vacuum if it is run pre-turbo but as you said - its an oily mess. You might want to consider an air / oil separator. When done properly they can be heated to reduce moisture build-up and they will drain excess oil back to the block. With that said, I run my mine straight to atmosphere with a 3/4" braided hose directly over the valve cover. The hose occasionally has some moisture build-up but is never oily.

This is an air / oil separator I designed for Subarus a few years back. The top was Plexiglas as it was a prototype.

Re: Callaway 633CSi - 9/24/2016 - Up and Running MS2!

Posted: Oct 07, 2016 11:43 PM

by RDAvena

Keep the catch can to separate some of the oil from the CCV,

but instead of routing it to the intake, route it to one of these:

use a check valve (in case of backfiring) before adding the hose. The exhaust will pull vacuum then you can "T"

the catch can drain back to the dipstick tube (see e39/ e36) with another in line check valve so you won't need to drain the catch can.

This will keep your intake, turbo, intercooler and manifold nice and clean.

Back and forth on how this system works via the Supra forums.

http://www.supraforums.com/forum/showth ... r-downpipe

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Jan 19, 2017 11:10 AM

by tschultz

I haven't updated this topic in a while but I haven't really driven the car either for a few reasons, but have still had it on my mind.

Mainly I believe that I have a cylinder with low compression, due to failing piston rings. This is evident by pressure escaping the valve cover as shown in the video on the previous page. Right now it is causing some oil leaks since the crank is pressurized. Sorta sad about this one but oh well. The car starts right up and runs fine (even after sitting 3 months in my yard), it just leaks some oil and puffs some smoke out from the engine bay.

In the mean time I have decided it would be most easy to pull the engine and trans and swap in my spare block and head with all of the turbo parts. My thinking is I have to take the current engine apart anyway to get access to the pistons, I might as well just do it all in a weekend and have a running car. That will make the current engine my rebuild candidate.

I have pulled 2 of these engines before and can almost go through every step in my head so I figure why not. The only caveat is the spare engine and lift is at my brother place 45 minutes away, so I am trying to align schedules so we can do it on a weekend (and I can get him his garage space back ASAP) when there isn't a lot of snow. I am targeting late Feb. or March.

The car is faster than it has ever been, even running on 5 cylinders. The megasquirt really woke up the mid range and I haven't done a lot of tuning with timing values. I also got a cheap OMP reclining seat (recaro style) that I will put in the car. I haven't been happy with the E21 Recaro that is falling apart.

Maybe I got motivated back into this because of my brothers turbo 325iX:

http://www.r3vlimited.com/board/showthr ... ost4738401

Here's an interesting website discussing effective compression ratio:

http://www.xcceleration.com/cr-boost%20101.htm

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Mar 12, 2017 7:35 PM

by tschultz

Another update although way past due.

Back in Oct I realized that I have some sort of issue with my engine and had parked the car since. I actually started it up today and pulled it out. I didn't even have to charge the battery!

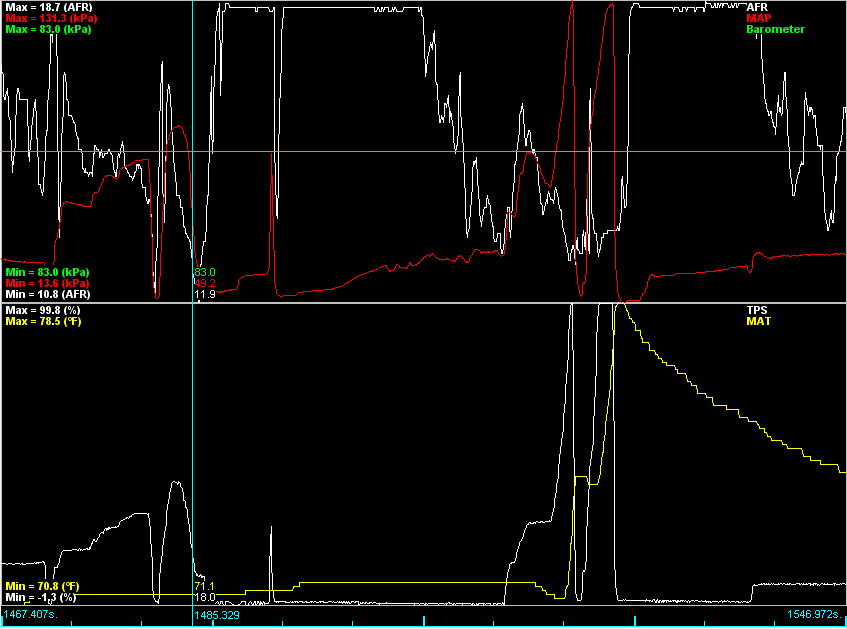

It started right up and I decided to take it around the block and try a datalog. I hadn't done this before because I thought it was in the premium version only. I took off my ball/spring mbc since I wasn't sure what was going on with my engine, but at 6psi with MS2 it feels as fast as the Motronic setup@11psi. Mostly it just has better response.

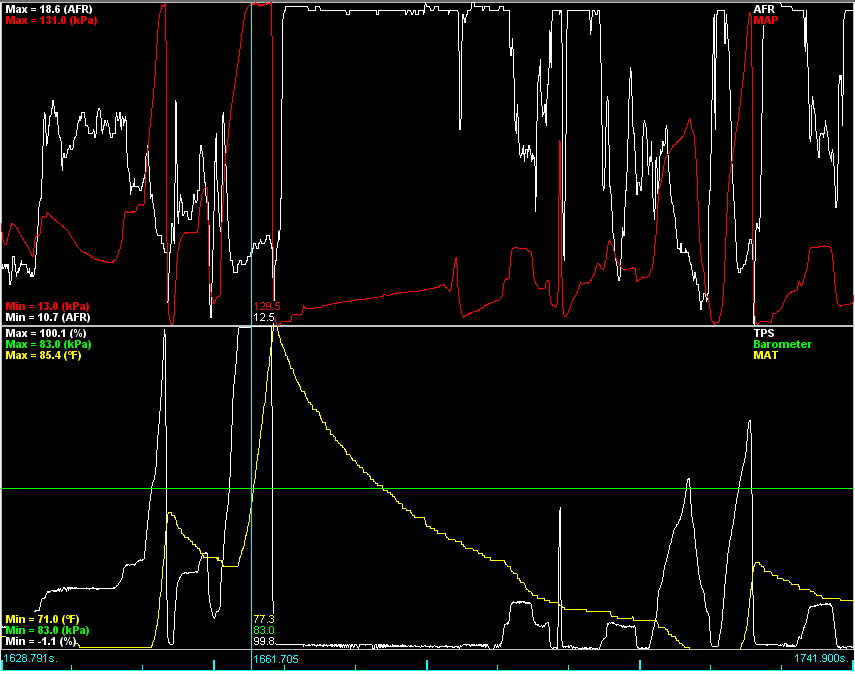

You can see my immediate need to reduce noise in the signals. These are CLT, RPM, TPS, and AFR. Also I don't think my AFR calibration is 100% accurate. It is reading slightly leaner than actual. Just a 2nd/3rd gear pull to try out the datalogging.

Still planning to swap out my spare engine in May at the latest.

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Mar 12, 2017 10:36 PM

by marc79euro645

Datalogging is great, you can concentrate on driving, then analyze in leisure. I make a log,then load the proper msq., and run the analyzer, then save the changes I want as a new tune and burn them to MS, and repeat. I keep autotune off locking the tune to the last burn. It's really helpful with hard pulls where everything is happening fast. Good luck

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Mar 16, 2017 11:21 AM

by tschultz

Great point Marc.

Can anybody explain the need for shielding of the VR sensor (And maybe TPS) wiring? I noticed it in the FAQ but don't think mine is.

I use the stock E34 vr sensor cable but then have an adapter cable that hooks it to the input to the ECU (speed/ref sensor wiring). Do i need a whole new VR sensor cable that is shielded the full length?

Where do I need to ground the shield to? ECU?

http://ns.mye28.com/viewtopic.php?f=6&t=81014

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Mar 16, 2017 11:40 AM

by RDAvena

The shielded cable on the M30B35 harness terminates/ shares its ground with the cylinder identification cable and O2 sensor, which is then ground to pin 19 of the ECU.

Fashion yourself a shield from the ecu to connector side on this cable and ground at pin 19.

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Apr 11, 2017 10:49 AM

by tschultz

Ray clarified his message. The above was for M1.3 harness. For 1.0 he suggested:

For the B34 you can tie the grounds in to the Reference point sensor ground pin on the B34 harness. Pin 5 or pin 23 which would be the shield ground point for the Engine speed sensor and the O2 sensor. The diagram can be seen on page 45 of the e28 Bentley.

From the 60-2 sensor it would just be a simple matter of pulling off some the plastic to get at the wire shielding and tie in a grounding wire to that.

Then on to the ECU grounding pin.

I ordered parts and am planning to swap the block out in about two weeks. Hope that it all works out and goes smoothly. I will take some photos and provide updates as well. I am hoping by 4/28/2017 I have it running again with the new engine.

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Apr 14, 2017 11:51 AM

by RDAvena

Tom, glad to help. What are you going to do with the block you are taking out?

Re: 633CSi Callaway Turbo - 9/24/2016 - Up and Running MS2!

Posted: Apr 14, 2017 6:27 PM

by tschultz

Unsure at this time. I will be taking the oil pan off and will take a gander underneath with the flash light. Not plans at the moment except maybe keep it as a backup.

Re: 633CSi Callaway Turbo - 4/27/2017 - Engine #2 installed!

Posted: Apr 27, 2017 6:15 PM

by tschultz

If you recall, I was having some issues with the engine in the car. It still ran fine, but leaking oil and crankcase pressure meant that I didn't want to keep running the engine.

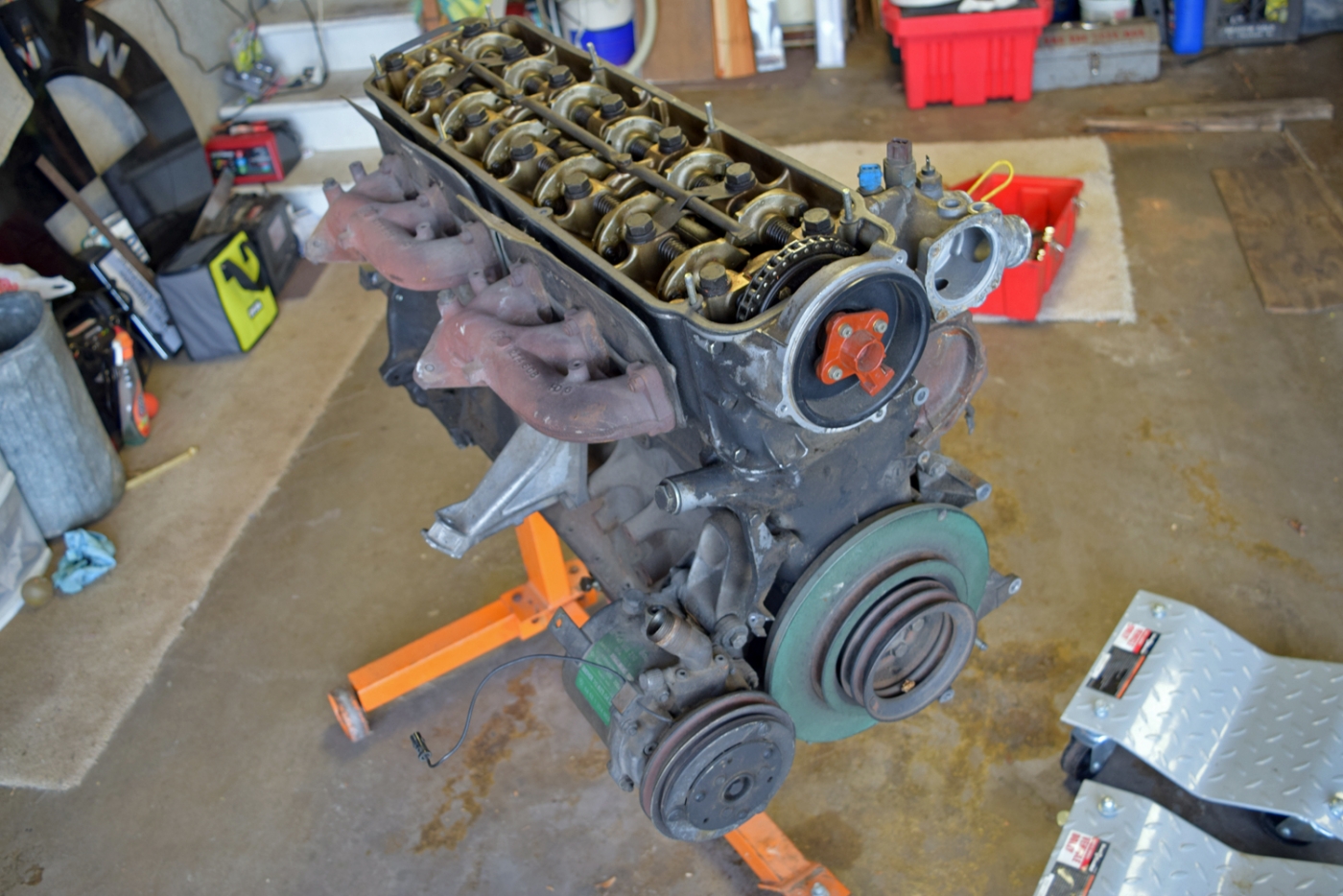

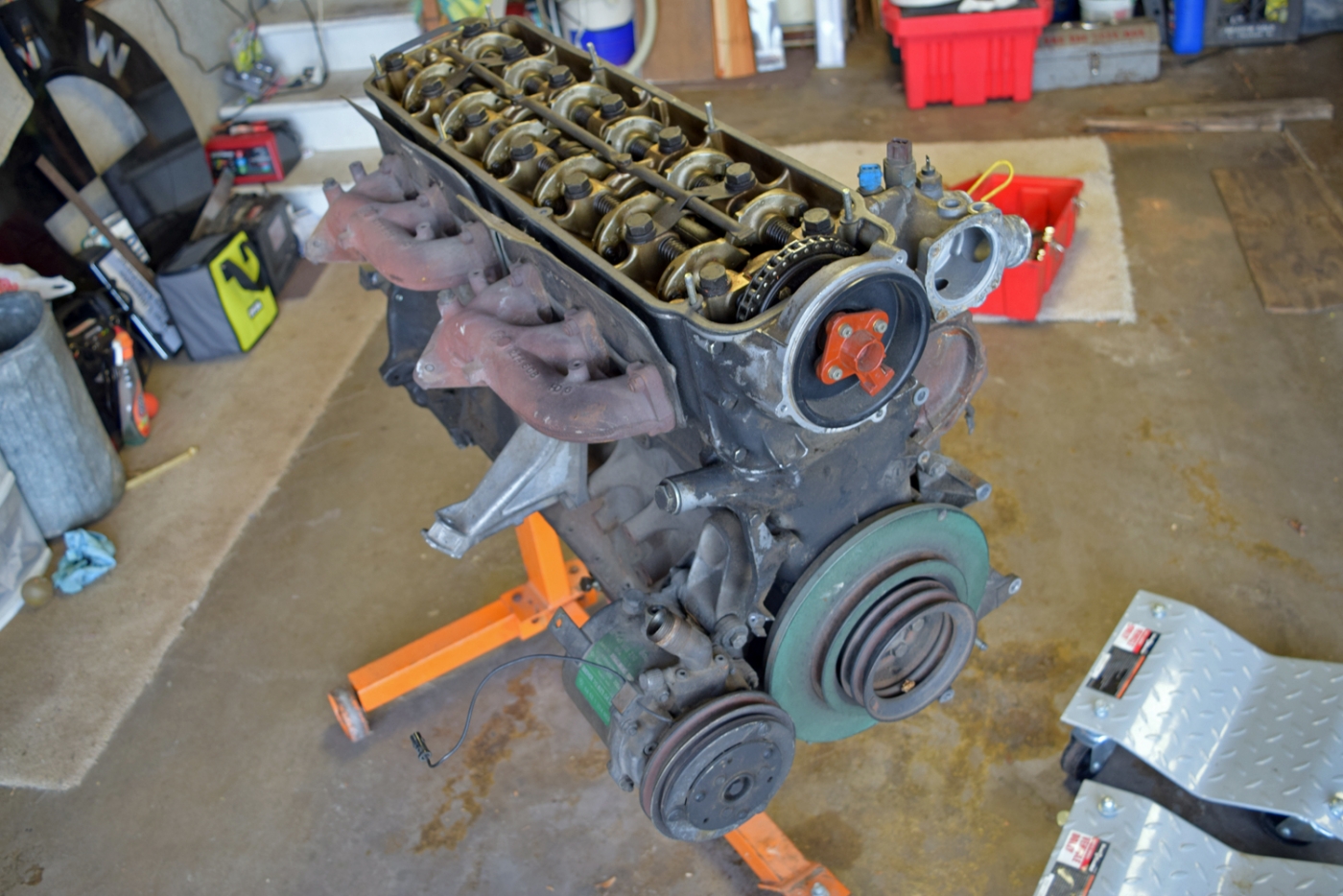

I was in and out of jobs and had some spare time to buckle down. So with some coordination, I was able to drive the car down to my brothers place and work on it. There was a hoist there as well as my spare engine block and head assembled (M30B34 US). So on Monday I drove down there and got to work in swapping the engine.

He pulled the engine out and left me an empty garage.

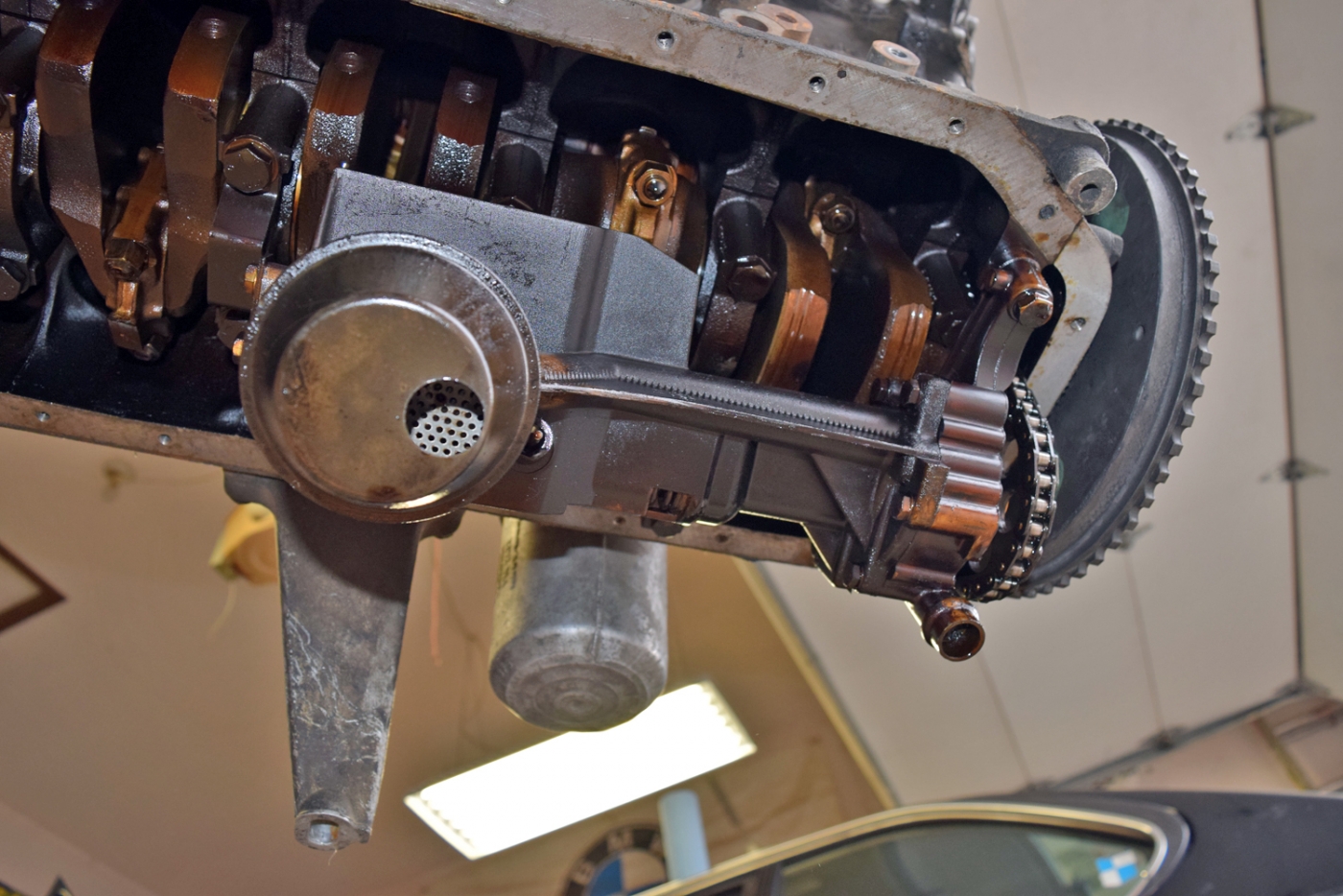

the replacement

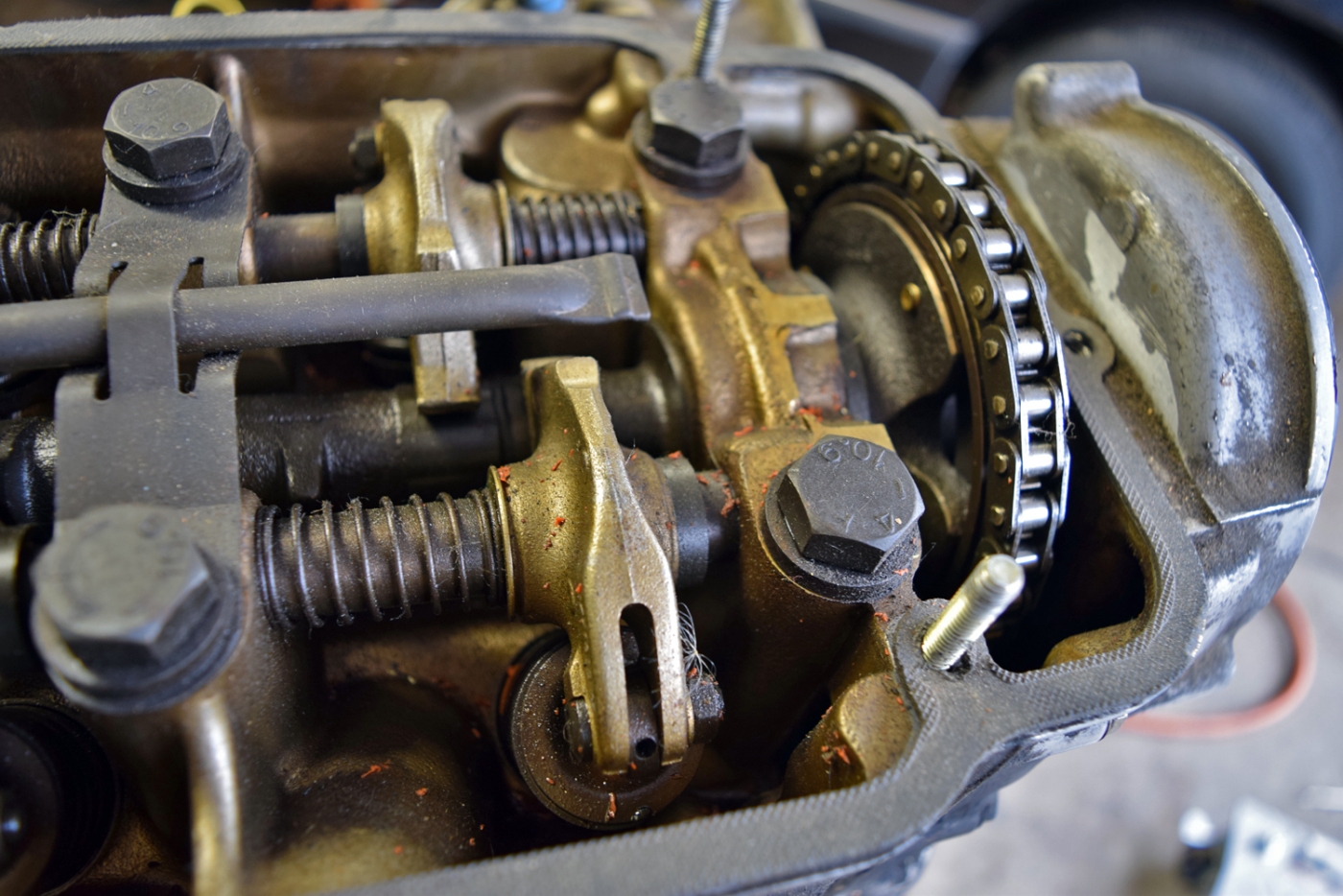

It had been sitting a while and I blew out the pieces with compressed air later when I took the oil pan off.

Somebody was having issues when this engine was retired!

By the end of the work day Monday I had the turbo manifold off and the engine ready to be pulled. So when my brother came home, we commenced progress with the pull.

Thant's a heavy mother

And I got it out by the end of Monday after almost 10 hours. The turbo bit removal made it take longer!

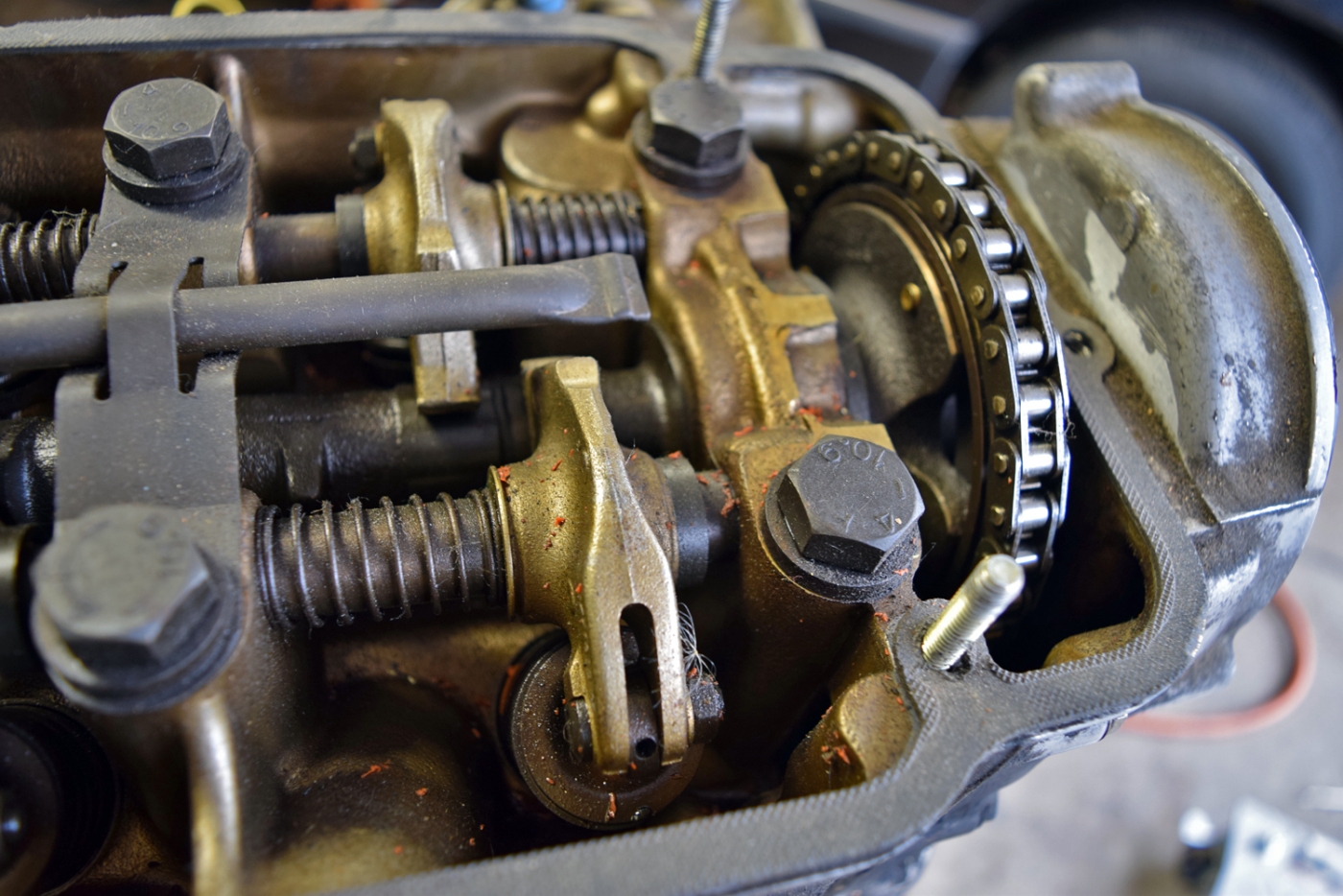

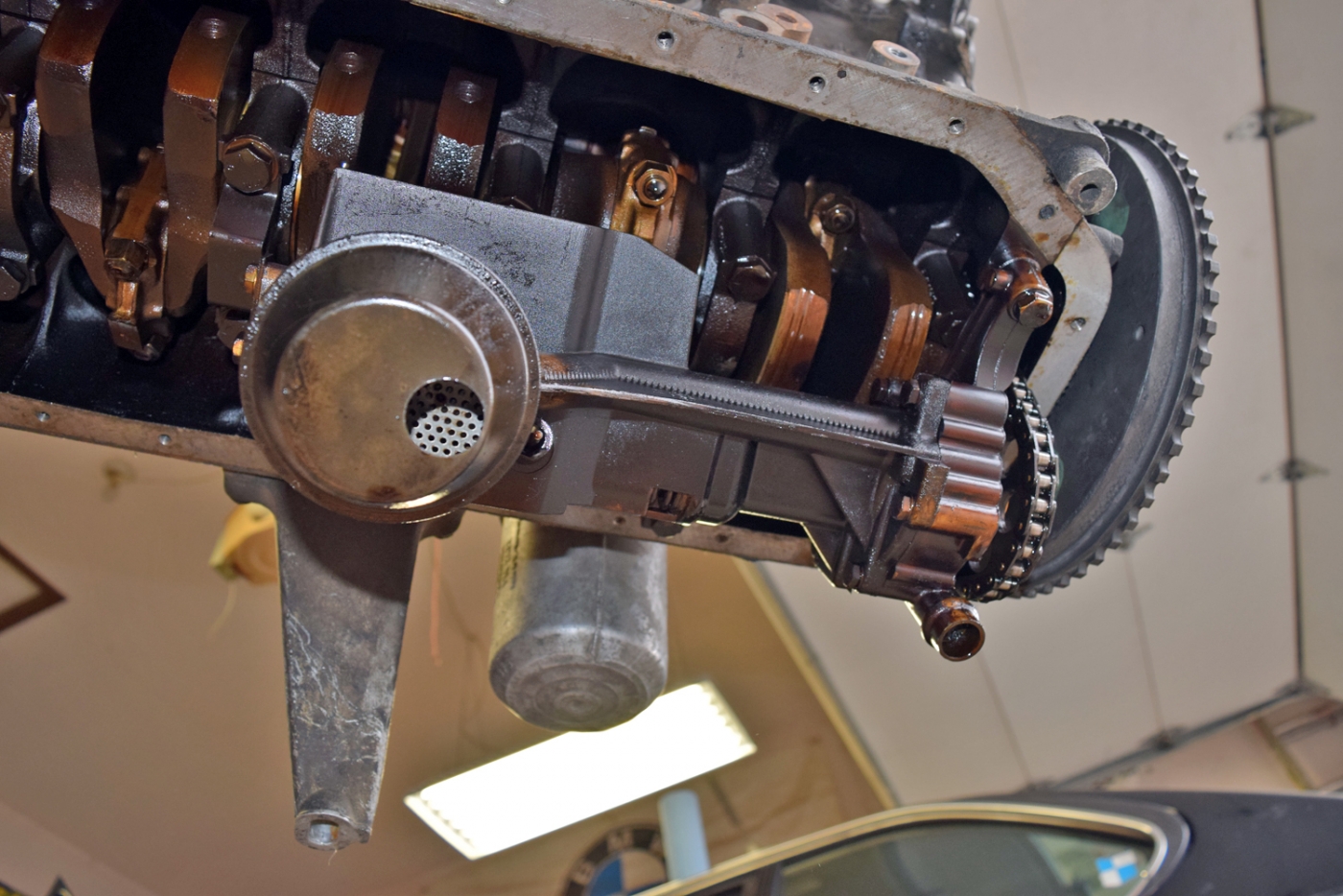

So the next day I had to switch parts over. Almost everything had to move to the new engine .Starting with the oil pan.

This wasn't encouraging to find in the oil pan. Notice that the there is a JIC nipple on the pan. Was this engine turbo'd in the past???

I really got after it and forgot to take photos along the way. I swapped the thermostat assembly, intake manifold assembly, alternator, oil filter housing (and changed the oil), cap and rotor/spark plugs, and continued with harmonic balancer, clutch/flywheel and VR sensor. Lastly, mated the 265 to the engine. So after I got the trans mated, I remembered to grab the camera. It looks the same, but this is the new engine assembled.

I also spent some time adding in the lines for my brake bias valve. I have front and rear separated now, and this car doesn't have ABS. Ready for the brake valve when it arrives. I bled the brakes and got air out of the system which took a little while.

That night my brother came home around 5pm and was able to help me put the assembled engine set into the car. Luckily we were able to get it to fit and resting in the car for the night. I didn't take any pictures but nothing was hooked up to mate the engine to the car.

That brings us to yesterday where I returned to his garage to reconnect the engine and hopefully get it running. It took a long time to get things reconnected to the engine, but once that was done, I was able to try to start the car without an exhaust. I wanted to make sure any junk in the cylinders wouldn't get into the turbo.

After adding oil and coolant, I cranked it. After remembering to hook up the spark plug wires

it fired up for a few seconds until I turned it off. So i finished hooking up the trans and driveshaft with some extra motivation.

It took all day once again, but just as my brother got home from work I worked on the last bit, reinstalling the turbo. This took an hour and a half but can be done by slightly lifting the engine and dropping it in from the top in front.

Finally at about 7 I was reassembling piping. I was in a rush to finish, so sorry that I didn't get photos. Unfortunately I found that the turbo inlet was block by the engine mounting arm! After trying to force it and realizing there was interference, we got smart and pulled off the mounting arm and taking the one from the old engine since we know it fit. It was in fact different (4 bolts vs 3). But the 4 bolt mount still would work since the engine had 3 threaded bosses in the right spots. Once we swapped that, everything fit back together and we tried starting it up. It fired and I let it idle and bleed. After a successful test drive, I took it home and made it no problem!

The O2 cable had popped off so I wasn't getting signal in MS2, but I fixed that this morning. I still have a lot of noise and I am wondering where it is coming from .Thinking back it still did this with M1.0 I am not sure where to start-- I don't really want to cut up the VR sensor.

I will be tuning it and driving it so look for more updates soon!