Page 7 of 14

Posted: Mar 29, 2012 2:08 PM

by Ken H.

mooseheadm5 wrote:Even though you are being pretty rude to Peter, I'll help you out.

The idea that pressure cannot be different in the fuel rail at different locations is simply not true. If things were completely static, I'd say that the pressure would be damn near constant at any point in the rail. Thing is, there is flow. There is flow through the rail and there is flow though the injectors. This flow is not constant and the FPR does not necessarily react instantaneously to pressure changes in the rail. The injectors open and close which causes pressure waves through the rail. These pressure waves can cause all sorts of freaky things to happen in the rail in the same way that valves opening and closing cause flow and pressure changes in an intake manifold. Though you would generally analyze the system with the fluid being non-compressible, but there are more factors at play here, such as the momentum of the fluid. An analogous system would be the piping in a house. Here is a little info on hydraulic shock (water hammer.)

http://en.wikipedia.org/wiki/Water_hammer

You also don't design manifolds for water distribution in such a way that multiple near simultaneous consumers are teed off sequentially because there would be a pressure drop at the end. This can be mitigated by having multiple feed locations to a manifold and by making your manifold larger so that it acts as a pressure reservoir.

FYI, there are fluctuations in air pressure in a single tire when the system isn't perfectly static, just as there are pressure differences inside your intake manifold when there is flow.

Now next time you should simply ask "why is that?" instead of thinking you know everything and smacking down someone that is only trying to help, especially when you already recognize that they are an expert in their field.

A couple of numbers, taken from the datalogging when That Thing was on the dyno. MAP = ~14.95 psi

Pressure @ primary fuel pump = 58.92 psi.

Pressure @ #1 cylinder injector = 58.64 psi.

Pressure @ #6 cylinder injector = 58.51 psi.

A/F ratio @ #1 cyllinder = 10.99.

A/F ratio @ #6 cylinder = 11.01.

pressure delta = ~.23 of 1 %.

Stipulated that these #s were taken at a constant 5700 rpm, which is the peak of the hp curve.

A/F is a bit on the rich side, as we had not yet begun to dial this back or do individual cylinder trims.

HTH.

Posted: Mar 29, 2012 2:19 PM

by Murfinator

Moose: I regret that you seem to have taken offense to my comment. At least Peter didn't make so rash a reaction and provided a good explanation for which I thanked him. I was asking for clarification. If you take offense that is your decision and your problem.

Why people continually attempt to judge tone in this forum is beyond me. There are some ego's here I do not appreciate. I'm obviously posting these updates to get input and simply ask for clarification and backup when needed to clear up confusion. For some reason I come off as somewhat of an asshole to some people. That's not my intention. Sorry.

Posted: Mar 29, 2012 2:30 PM

by Murfinator

Ken H. wrote:A couple of numbers, taken from the datalogging when That Thing was on the dyno. MAP = ~14.95 psi

Pressure @ primary fuel pump = 58.92 psi.

Pressure @ #1 cylinder injector = 58.64 psi.

Pressure @ #6 cylinder injector = 58.51 psi.

A/F ratio @ #1 cyllinder = 10.99.

A/F ratio @ #6 cylinder = 11.01.

pressure delta = ~.23 of 1 %.

Stipulated that these #s were taken at a constant 5700 rpm, which is the peak of the hp curve.

A/F is a bit on the rich side, as we had not yet begun to dial this back or do individual cylinder trims.

HTH.

It amazes me the level of detail and extensive notes you've taken throughout your build Ken. Your posts and our discussions have been an invaluable resource. That being said, my earlier comment, "

I realize there may be areas where the build could be improved to squeeze a few more hp from the motor. However, the gains would likely not be worth the effort or noticeable from the driver's seat." begs the question: will 2-3 tenths PSI difference at an injector equate to much if any humanly noticeable difference to the driver? Also, is it money or time well spent to get a dead-nuts perfect tune when the vehicle is to be used for bi-weekly open track events and spirited weekend drives? If this was a dedicated race car owned by a team with a multimillion dollar R&D budget and the margin of victory was measured in tenths of a second, perhaps.

Posted: Mar 29, 2012 2:33 PM

by mooseheadm5

Ken H. wrote:

A couple of numbers, taken from the datalogging when That Thing was on the dyno. MAP = ~14.95 psi

Pressure @ primary fuel pump = 58.92 psi.

Pressure @ #1 cylinder injector = 58.64 psi.

Pressure @ #6 cylinder injector = 58.51 psi.

A/F ratio @ #1 cyllinder = 10.99.

A/F ratio @ #6 cylinder = 11.01.

pressure delta = ~.23 of 1 %.

Stipulated that these #s were taken at a constant 5700 rpm, which is the peak of the hp curve.

A/F is a bit on the rich side, as we had not yet begun to dial this back or do individual cylinder trims.

HTH.

Don't you have two fuel rails and 12 injectors, though?

As you said, this is at steady flow. Even then the readings from the gauges are time averaged in some way (with a pressure gauge they are time averaged by the capacity of the gauge, and with digital electronics, they are time averaged by the electronics.)

Posted: Mar 29, 2012 2:34 PM

by skip535i

Murfinator wrote:Also, is it money or time well spent to get a dead-nuts perfect tune when the vehicle is to be used for bi-weekly open track events and spirited weekend drives? If this was a dedicated race car owned by a team with a multimillion dollar R&D budget and the margin of victory was measured in tenths of a second, perhaps.

You just answered your own question, my friend. Absolutely not. If you're happy with knowing that

you may have left a tiny bit on the table then you'll be fine.

Posted: Mar 29, 2012 2:40 PM

by mooseheadm5

skip535i wrote:Murfinator wrote:Also, is it money or time well spent to get a dead-nuts perfect tune when the vehicle is to be used for bi-weekly open track events and spirited weekend drives? If this was a dedicated race car owned by a team with a multimillion dollar R&D budget and the margin of victory was measured in tenths of a second, perhaps.

You just answered your own question, my friend. Absolutely not. If you're happy with knowing that

you may have left a tiny bit on the table then you'll be fine.

It isn't just about the power, though. It is about proper distribution of fuel for the incoming air. You will never know the individual AFRs without 6 widebands, which isn't going to happen, so the best thing you can do is to design the injection system for equal flow and hope for the best. If your rail isn't properly designed, the result could be detonation, which will destroy the motor.

Posted: Mar 29, 2012 2:48 PM

by Murfinator

mooseheadm5 wrote:

It isn't just about the power, though. It is about proper distribution of fuel for the incoming air. You will never know the individual AFRs without 6 widebands, which isn't going to happen, so the best thing you can do is to design the injection system for equal flow and hope for the best. If your rail isn't properly designed, the result could be detonation, which will destroy the motor.

Skip: your right, I should stop the rhetoric. I already knew the answer.

Moose: It's the same rail Ken got from Paul Burke. In my case I'm running a single rail (LH has staged injectors on twin rails) with new matched 65# low-z injectors. With the upgraded fuel supply system components I will have more than adequate capacity and overhead to support extended WOT events without fear of detonation. Running E85 also helps.

Posted: Mar 29, 2012 3:50 PM

by Jeremy

How's that saying go?

You'll spend 5% of your time getting the tune 95% right. You'll spend 95% of your time on that last 5%.

It's all a matter of how much that last 5% is worth to you in terms of time, expense, and aggravation. That last 5% can be aggravating.

Posted: Mar 29, 2012 3:55 PM

by mooseheadm5

Well, like Peter said, I guess you've got it all figured out.

Posted: Mar 29, 2012 3:58 PM

by Ken H.

mooseheadm5 wrote:Ken H. wrote:

A couple of numbers, taken from the datalogging when That Thing was on the dyno. MAP = ~14.95 psi

Pressure @ primary fuel pump = 58.92 psi.

Pressure @ #1 cylinder injector = 58.64 psi.

Pressure @ #6 cylinder injector = 58.51 psi.

A/F ratio @ #1 cyllinder = 10.99.

A/F ratio @ #6 cylinder = 11.01.

pressure delta = ~.23 of 1 %.

Stipulated that these #s were taken at a constant 5700 rpm, which is the peak of the hp curve.

A/F is a bit on the rich side, as we had not yet begun to dial this back or do individual cylinder trims.

HTH.

Don't you have two fuel rails and 12 injectors, though?

As you said, this is at steady flow. Even then the readings from the gauges are time averaged in some way (with a pressure gauge they are time averaged by the capacity of the gauge, and with digital electronics, they are time averaged by the electronics.)

Yes, two rails, two sets of injectors, two pumps.

Both sets are full-sequential.

However, the primary injectors have six individual drivers. The secondaries are run by two additional drivers--1-3-5 and 2-4-6. This is because the TEC-3r has a total of 8 available drivers.

So I can do lots of wonderful things to the individual holes on the primaries; the secondaries have to be dealt with "in bunches," as it were.

That being said, the available instrumentation at Mile High was focused on getting everything to cooperate on the primaries. The secondary pump and billet controller was checked and dialed in to more or less match the primary.

Pressure @

secondary fuel pump = 60.12 psi.

Pressure @ #1 cylinder injector = 59.44 psi.

Pressure @ #6 cylinder injector = 58.51 psi.

Why the drop, I dunno.

No A/F numbers taken solely on the secondaries, as the layout doesn't allow for shutting down the primary pump and running entuirely on the secondary. Yeah, it can be done by jumpering the controllers and thereby the power to the pumps but this is hardly something that needs to be done for tuning purposes.

pressure delta = ~2.67 of 1 %.

I ought to add that the primaries are 45#. Limited on duty cycle to 75%, they are effectively tapped out at around 33# delivery. As the system is set up, as the primary d.c. gets up around 67% or so, the secondaries start to open up. This is also keyed to MAP to avoid hammering the throttle at relatively low boost, say 7 psi, and going stupid rich before boost begins to build.

What this translates into is the 72# secondaries are shut down entirely most of the time. This pattern applied on the dyno as well, so we were looking to do calibrations not so much in "real time," with the secondaries thoroughly opened, but doing a relatively brief period at full boost (maybe 15-20 seconds MAX) then assessing the datalogged results.

In the Real World, rolling into 1 bar and holding it for that long will get you to redline Right Now and give you religion.

Subsequently doing runs over the road, and doing datalogs, the A/F numbers have been in the mid-12s, with boost around 125 kPa, this accelerating with 7.25 # of boost. Under hard acceleration pulls, with boost ~185kPa, the A/F dropped as low as 10.26.

Typically, under steady cruise, with kPa between 90 and 100, the A/F is around 14.5 +/-, or right about stoich.

Posted: Mar 29, 2012 4:02 PM

by mooseheadm5

That's what I thought. Your flow rates in each rail are lower than Murph's single rail will be. As you can see, there is a definite difference in pressures through the rail.

I'm glad you took so much data, Ken. It really helps.

Out of morbid curiosity, Murph, what fuel pressure will you be running? Are you going for 500 rwhp or 500 bhp?

Posted: Mar 29, 2012 5:55 PM

by FirstFives Dictator

On single rail system I worry about Bernoulli's effect

Posted: Mar 29, 2012 6:41 PM

by Ken H.

FirstFives Dictator wrote:On single rail system I worry about Bernoulli's effect

On a properly designed system, it shouldn't apply.

Are you having fuel starvation problems on the stock BMW layout?

Consider:

1. The sizing of the piping, from fuel pickup through the transfer and main pump, forward to the fuel rail and thence into the fuel pressure regulator, needs to be of the same inside diameter.

Size things down, out of budgetary constraints, laziness or lack of understanding, and flow rates and delivered volumes will suffer.

Simply put, you cannot move the Mississippi through a straw.

2. There are a number of reliable websites which can do the calculations on flow of liquids through a pipe. Or you can reread the theory and practice in your Fluid Dynamics textbooks.

3. Quite frequently, the internal volume of the fuel rail will be noticeably larger than an equivalent length of fuel line. If you're thinking Bernoulli effect here, (lowered pressure) I can understand that. But this is why we have a FPR--to assure that fuel delivery is maintained at a stipulated pressure. If injector demands become large enough to effectively "suck the pipe dry," the most apparent solution is to remove the flow restriction, i.e., upsize the fuel line.

Posted: Mar 29, 2012 10:07 PM

by mooseheadm5

As you said, for a properly designed system, this isn't an issue. What Peter and I are saying is that this might not be a properly designed system and that the issues we are bringing up are real and potentially bad news for his engine at high power output levels.

The issue here isn't the injectors sucking the rail dry, it is a pressure gradient through the rail. At higher fueling requirements, the flow through the rail speeds up. There will be friction and pressure drop. The pressure regulator only senses the pressure at one point on the rail, so it will either over- or under-compensate depending on the location. In your case, Ken, your flow is split into two rails at high flow rates, but this build will utilize a single rail of the same design with a higher required flow rate for that single rail than you use for two rails. Basically, with a smaller rail and a single inlet, each injector will "see" different fuel pressures, which will change their flow rates. You experienced a small pressure difference at max flow, but it is measurable and it will have a small effect on AFR. With higher flow rates into the same rail, the effect will be even more pronounced. Trimming the fuel for each cylinder will make up for this, but the fuel trims take while to dial in and they would change depending on flow rate because the pressure differences in the rail increase with load.

The stock BMW layout is definitely adequate for NA, but NA cars are not nearly as susceptible to detonation damage as heavily boosted cars.

Posted: Mar 30, 2012 5:03 AM

by FirstFives Dictator

mooseheadm5 wrote:As you said, for a properly designed system, this isn't an issue. What Peter and I are saying is that this might not be a properly designed system and that the issues we are bringing up are real and potentially bad news for his engine at high power output levels.

Depending on the HP levels and injection scheme used, we're probably talking about rail fluid velocities of 200-300% of stock.

Posted: Apr 02, 2012 5:40 PM

by mooseheadm5

So, I noticed another potential problem with your calculations. If you can post your injector static flow rates, fuel pressure, and desired horsepower goals (and specify crank or wheel horsepower) I can recheck my math to make sure.

Posted: Apr 02, 2012 5:53 PM

by Murfinator

Ken has also pointed out that if I'm planning to use E85 the flow requirements will increase by ~50% due to the lower energy content of the fuel. I may be forced to keep the boost low while driving on the street with 91 octane and turn it up a bit at the track where I'll use 111 octane fuel. Otherwise I'm looking at upgrading the injectors and being near the edge of the fuel pump capacity minus recommended duty cycle of 75%.

Issues like this are exactly why I've been posting updates on the build. Thanks for all the input!

Posted: Apr 02, 2012 6:12 PM

by mooseheadm5

Murfinator wrote:Ken has also pointed out that if I'm planning to use E85 the flow requirements will increase by ~50% due to the lower energy content of the fuel.

I actually pointed that out to him. I guess he decided to contact you about it first. If you are using 65# injectors and E85, you won't get much over 400bhp before your injector duty cycle is 100%. ~350bhp for 80% max duty cycle.

Posted: May 02, 2012 3:19 AM

by Murfinator

Posted: May 02, 2012 10:23 AM

by M. Holtmeier

That fuel system is really coming together. What are you doing for a fuel rail?

Posted: May 02, 2012 11:13 AM

by Duke

Murfinator wrote:

Seems to me it would have much easier, cheaper and safer (crash worthy) to just install a fuel cell in the trunk.

Posted: May 02, 2012 11:19 AM

by shocka

Welll its not your build Duke. Looks like its coming along beautifully OP.

Posted: May 02, 2012 12:02 PM

by Murfinator

The fuel rail is a custom piece from Imagineering nearly identical to the the ones in Lucifer's Hammer though I'll only be running a single rail with 65# injectors: 91 octane street / 111 track. Ken and Moose were sharp enough to foresee issues I'd have with E85. Shouldn't need it anyhow.

Duke: I had considered taking Paul up on his offer to build a custom fuel cell but didn't feel like waiting ~3 years for it to be finished.

Decided to put the MIG to use and build a custom baffle to go with the recently released Aeromotive A1000 stealth mount pump option. The baffle box extends through the bottom of the stock fuel tank ~1/4" with the pickup and integral 100 micron filter centered in the low spot in the center/rear of the tank. Note the -6 AN return where the lift pump ports once were.

Also didn't want to give up trunk space that will be needed for luggage during road trips. That was also the justification for the sub enclosure under the rear seat and the amplifiers mounted to the trunk bulkhead, keep the trunk useful.

Posted: May 25, 2012 2:30 AM

by Murfinator

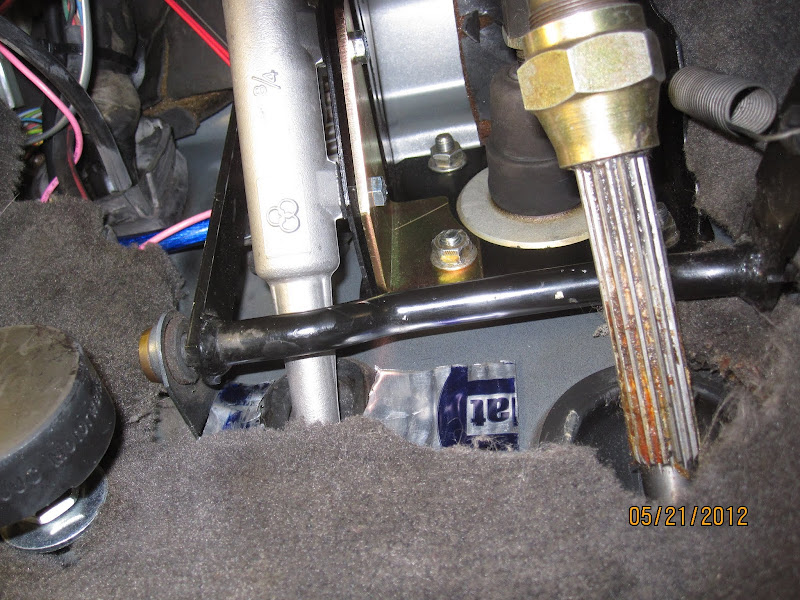

Roth USA HD pedal bracket reinforcement went in as easy as pie. The bracket had already been reinforced prior to 5-speed swap several years ago via a few weld beads along the weak areas.

I don't believe I'll have a problem now. Kudos to David Pepin for engineering a simple yet elegant solution to this malady in our cars.

Posted: Jul 10, 2012 1:01 AM

by Eta power

Wow. Amazing work.

Posted: Jul 10, 2012 11:21 AM

by Corner Carver

Damn Mike! That there is purdy!

Think it will run?

Posted: Jul 10, 2012 1:58 PM

by Mark 88/M5 Houston

Pretty! Very Pretty!

Posted: Jul 10, 2012 4:11 PM

by Brad D.

Awesome!

Posted: Jul 25, 2012 12:21 PM

by Bert-Ola

Real nice work.

Are you making these adaptors by your self, if so can I buy from you.

I have S38B36 runners going on to an 3453cc M90.