Page 9 of 14

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 16, 2017 8:41 AM

by tschultz

14 for AFR.

The harness is stock M1.0 and placed in the OEM location, same with coil and plug wires.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 18, 2017 3:21 PM

by tschultz

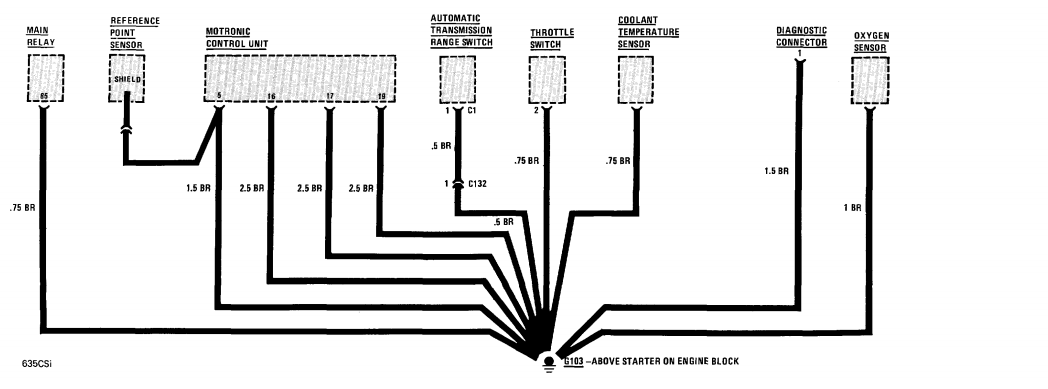

Pete Florance helped me out bigtime! I shot him an email regarding the sensor noise issue and he immediately replied that I ought to remove one of the ring terminals on the engine head stud (G103). So I looked up the ETK and found that this stud did indeed ground sensors and the engine/block--- not separated to the ECU (as suggested by the megamanual).

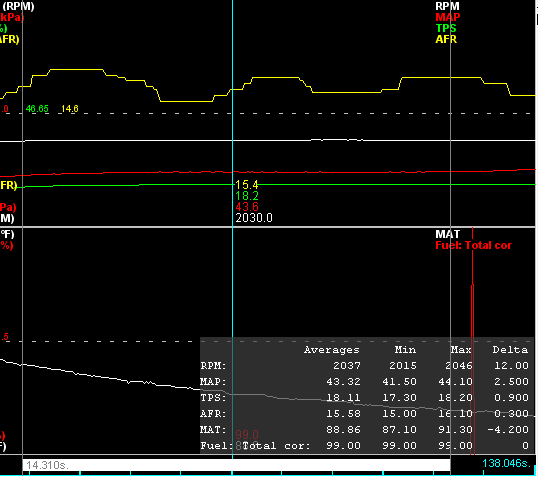

So I started up the car and found an immediate improvement in the fluctuation of my idle and AFR's. This allowed me to have smoother running in general and go out and continue tuning my MAT curve. This is a longer section of datalog I took and it has much less variation that I have been seeing.

I will have a post on this soon, but have begun on a MAT curve that is custom to my car. So far, it is increasing at temperatures increase-- much different than the ideal gas law.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 19, 2017 9:48 AM

by downforce22

That makes a lot more sense because you shouldn't have any noise with the sensors. I am surprised this is not well documented and would be interested to see if maybe it has been noted in the megasquirt thread on here. If not it might make sense to add it.

As for the MAT curve that doesn't make much sense to add fuel when temperature increases. I have found when you run VE analyze live and use the base tune that you need to note the ambient temperature as your reference point. Then with that set, your MAT curve 100% should be set at that temperature. That way you know how far the temperature change is from your base tune. I set mine to 100% around 70 F. That way when I am running at 100 F intake temps I can note whether I am too learn and adjust the curve accordingly. I found the base MAT curve to be a little aggressive, but did not find it to be completely wrong ( adding fuel when it should be removing it). I basically have removed less fuel as the temperature increase than the base map to keep it close to the shape of the original curve.

The MS fuel equation is pretty simple.

http://www.megamanual.com/v22manual/mfuel.htm

Hence, the REQ_FUEL value is the amount of fuel (in milliseconds) required for a MAP reading of 100 Kpa, manifold air temp of 70 degrees F, and a barometer of 30.00 In Hg, for one complete filling of one cylinder (Volumetric Efficiency = 100%), without any enrichments.

PW = REQ_FUEL * VE * MAP * E + accel + Injector_open_time

E = gamma_Enrich = (Warmup/100) * (O2_Closed Loop/100) * (AirCorr/100) * (BaroCorr/100)

Notice there are two other factors added to this - one is the acceleration enrichment, and the other is the injector open time.

Even if you set REQ_FUEL to zero you are still left with the injector open time (and accel enrichment if activated). The reason for adding in the open time is that it takes a finite amount of time to open the injector before one reaches a linear control state where injector time relates to fuel flow. The controller compensates for the open time by adding it to the applied total pulse width, otherwise the pulse would be too short.

If you turn off accel enrichments, your injected fuel is based on your MAP, base fueling (REQ_Fuel) and enrichments (E). With oxygen authority set to 0, baro correction turned off, and the engine warmed up at a constant RPM And MAP, the only two variables that would cause the fueling to change would be injector open time and air correction. Nothing else should cause the fueling to go learn or rich as temperatures fluctuate assuming you have the other factors turned off. One thing that could cause some of the problems with the fueling changing significantly would be possible heat soak in your engine. That or if your baro correction is enabled and accounting for some differences in air density as temperature and humidity change. With baro adjusting while aircorr is also adjusting, they could be working against each or even compounding together if they are not set right. I would work on one at a time and get it dialed in before going to the next.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 19, 2017 1:43 PM

by harrypalmer

Hello,

Way off topic here but it pertains a possible turbo set up, so my apologies for highjacking your thread.

Since I've moved to CO, been pondering the idea of a new turn key turbo system from TDC for my stock '86 535i M30B34. So I'd like to ask you how do you and your brother pass emissions over here? Is your 633 Callaway registered in Denver County? You've mentioned earlier your brother's turbo is in Colorado Springs so he may not be subjected to emissions compliance. But if both of you are required, how do you accomplish this?

Or, would you have any recommendations on how to pass the emission side of the test if I install a turbo? I am not sure I wouldn't need to pass a visual like in CA, most likely not, but I did notice when I first registered my car here in CO those inspectors were nosing not only the emissions test but going under my car and looking at the manifold side of the engine bay god knows what for before they actually gave me a successful smog passing slip. Any advice will be greatly appreciated.

BTW, great thread, it is just over the top for me. Thanks.

-Jack

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 19, 2017 2:06 PM

by tschultz

Jack,

Right now I have a few vehicles registered in El Paso county to avoid this. I had thought about going in and trying an e-test once I get the MS2 unit close to my liking-- just for kicks. This was a concern of mine going forward, however. Swapping manifold and exhaust is too much work in my opinion when you add the turbo.

But having a CAT on your car and mixtures close via wideband, I don't see why you wouldn't pass. I liked this thread regarding emissions so I saved it for later reference. The key will be staying near 14.5-14.7 AFR during the whole test (and having a hot cat.).

http://bigcoupe.com/phpBB2/viewtopic.php?t=19661

Regarding tuning MAT density vs baro correction-- I will continue to monitor. Right now my baro corrections have all been near my house within .2% of 100% fueling. I am starting to wonder if the CLT/MAT blending may be necessary for me. In a pure cold start the engine see ambient air temp. But in my experience as coolant warms, it will begin to see ~10F higher than ambient. Will continue messing with it.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 19, 2017 2:28 PM

by harrypalmer

Thank you for your prompt reply and the emissions article. I'm still hesitant but more in favor of a TDC turbo after your response. Wish you good luck!

Best,

-Jack

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Jun 20, 2017 9:07 AM

by M. Holtmeier

"Adding" fuel in the mat corr table is only lessening the leaning effects of the ideal gas law algorithm.

That's crazy about the sensor ground. I guess that's a bonus to building your own harness.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Aug 03, 2017 9:09 PM

by tschultz

So I haven't worked on this car as much as anticipated due to some issues in June was I was working on the tune. The car was running well, but I was working through the large shifts of rich/lean from drive into work at 6:00am to the drive home at 3:30pm. Over time I had been playing with MAT correction curve, Barometric correction on, dual sensor on, correction off and wasn't having a lot of luck.

The the car started running rough in early July and I got frustrated with Megasquirt so I didn't drive it or continue tuning. I tried new spark plug wires as it seemed like the issue happened after I added a thin aluminum heat shield around the turbo manifold and noticed some cracking in my plug wires. I thought the spark was arcing or something causing rough running. The car would hardly idle and would surge so I decided not to mess with it in the heat of summer.

Well, new plug wires didn't help anything so I elected to work on other car projects.

So yesterday I decided to try the old WR9LS plugs instead of the colder NGK BPR7ES. When I took them out, many of them were black and my research indicated spark plugs too cold of a range. This spark plug change seemed to help as the car immediately started faster and ran smoother. Great.

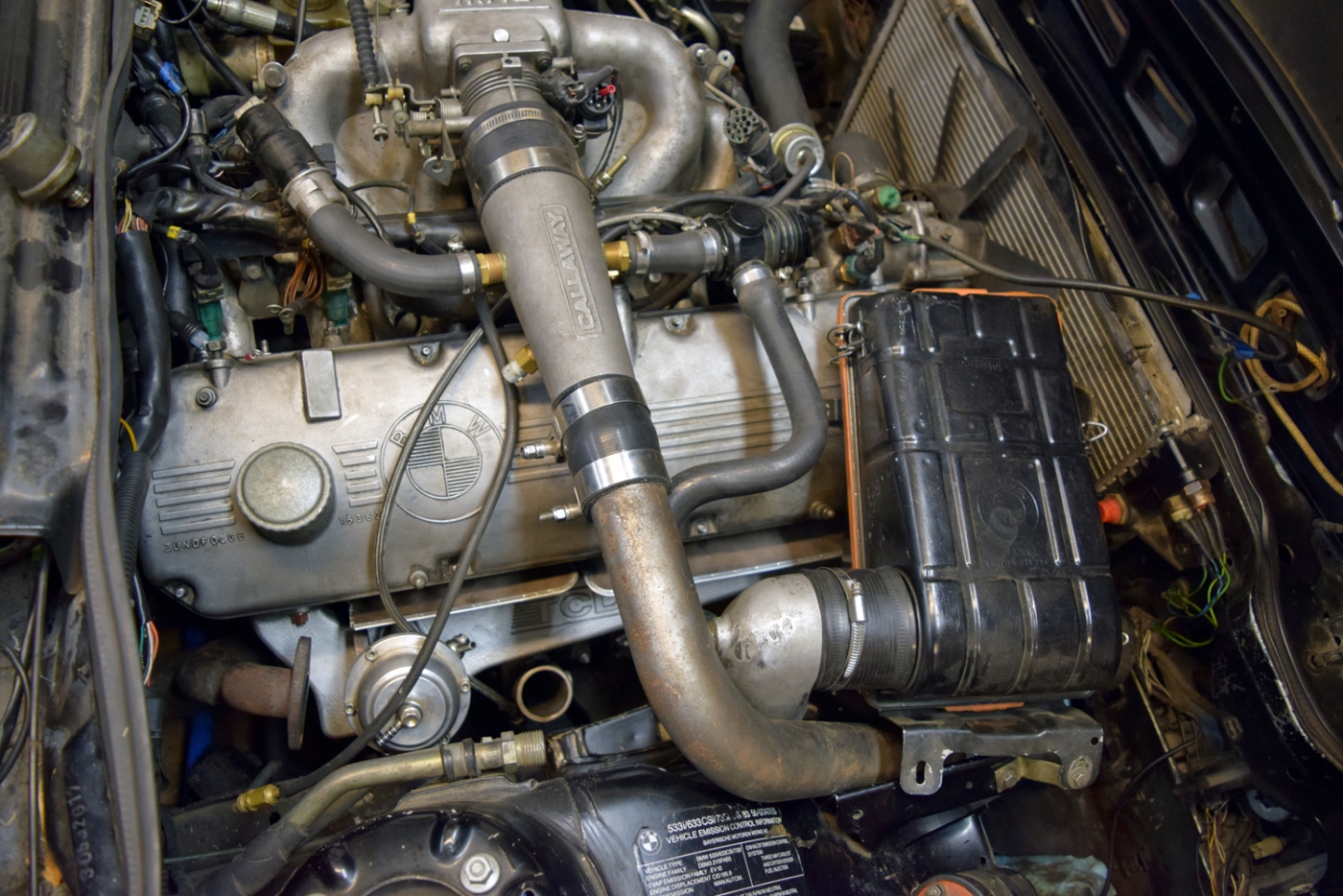

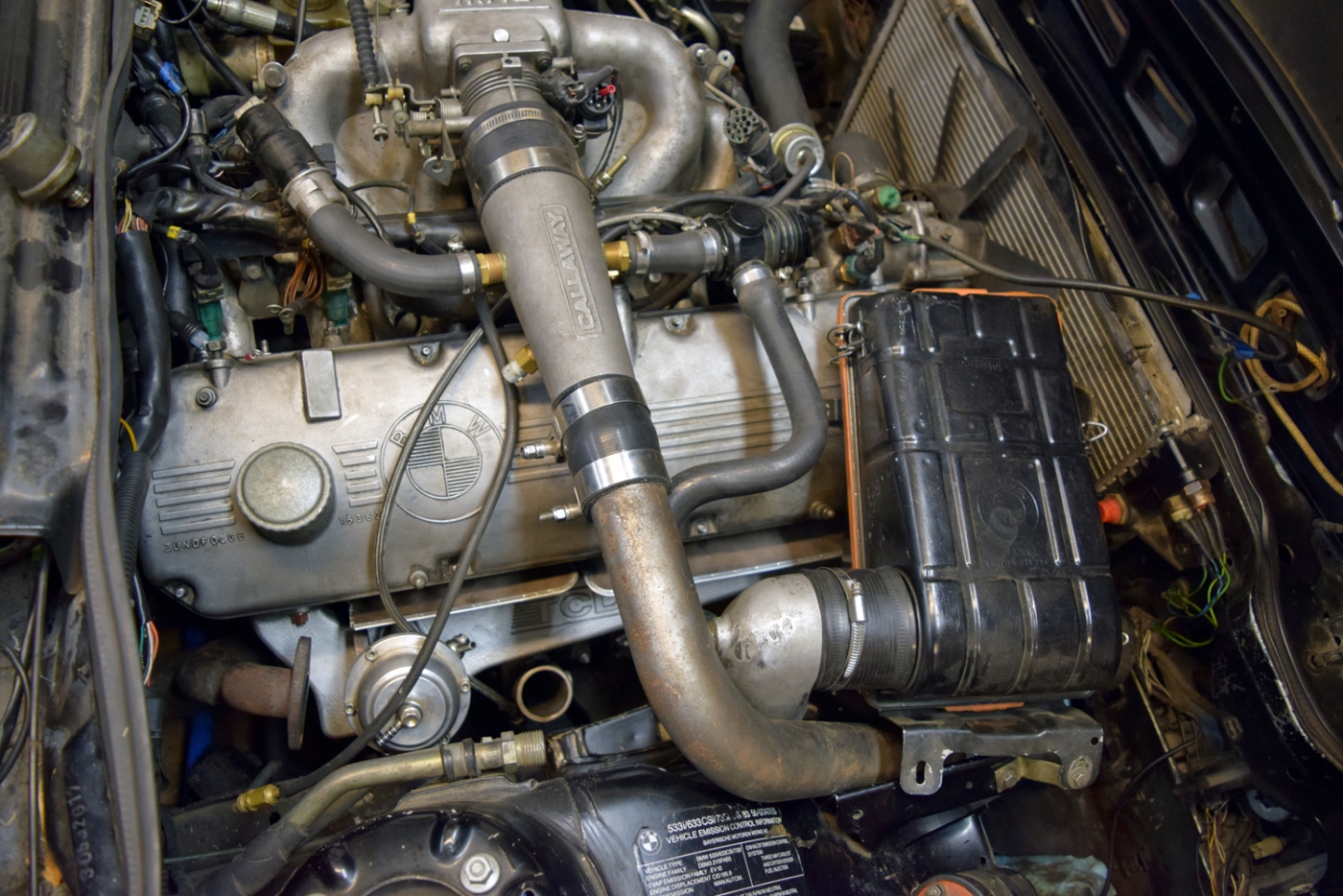

I also took the opportunity to adjust the intercooler location and piping slightly to improve the mounting method and stock kinking one of the elbows. In short, I added an elbow (visible in photos below) and was able to pull the old intercooler entrance pipe up more behind the spoiler. This took a while but I got it all mounted up much more securely than in the past.

since I had the bumper/spoiler off, I decided to try to mount an M635CSi spoiler on the car. I got this from a friend and had it since last year. Having two cars that look identical is cool, but after two years with the same spoiler on the car I thought I would see if the intercooler and piping might fit behind this one.

To my amazement, it did! The new piping also fit pretty well, and the fog light locations work to still allow airflow to the a brake ducts. The pipe is visible here

I wasn't happy with the way that the silver piping was visible and I didn't really want to paint them. So when I pulled off the spoiler to paint it I decided to try something else. I used some spare mesh I had laying around and mounted it to the openings in effort to hide the bright silver a bit. Right now it is held in with zip ties so I can remove it if I want, but I think it turned out pretty good:

It is still meant to be a track car so I'm not worried about a better paint job just yet.

Unfortunately last night the car started smoking a bunch (blue) on my way home from a short drive for these photos and I need to look at it still. I'm thinking it may be something with the oil feed or oil seals, but oil pressure still looked good, coolant and oil both looked good, coolant temperature was good. Hoping it will be simple as I was hoping to take this car to Drive 4 Corners this year... but if not, I will take the M5. (i'm very happy about the recent work in repairing the front end and getting the euro spoiler on there).

With the old spark plugs, the car was running smoother so I hope to continue working with my tune and map/settings when I figure out this oil smoke issue.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Aug 04, 2017 8:18 PM

by marc79euro645

lookin good! good luck on the blue smoke

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Aug 05, 2017 1:11 PM

by tig

Looks. Great. These cars always seem to be growing on me.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Aug 16, 2017 7:09 PM

by tschultz

I am not sure what is going on with the car. I went to start it up today and it was especially long to crank. I had to give it gas to get it started and keep it running (not sure if was flood clear mode or not) and immediately blue smoke came out of the tailpipe and it felt like it was missing.

I pulls spark plugs and found #4 full coated and oil fouled. #3 looks fouled but I couldn't tell if it was oil or not. Residue did come off on my hand.

After reading the Bentley, excessive oil consumption points to Failed headgasket, worn valve guides, or leaking valve stem seal.

There is not a lot of vacuum when pulling the valve cover at idle, but no excess pressure like I had before, nor any milkshake coloring. Coolant level seems the same as well...

Oil in the combustion chamber is mystifying me.Thoughts?

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Aug 17, 2017 1:25 PM

by George

Sounds like leaky valve stem seals.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 14, 2017 8:59 AM

by tschultz

Last night I had a chance to pull it into the garage and start pulling it apart. Symptoms include really hard start, sputters and doesn't want to rev, and then won't idle (wants to die). Additionally, lots of blue smoke out the back when revving.

No oil in the intake piping and no pools in the downpipe, so I am pretty sure the turbo seals and drain are fine.

With the turbo off, I found cylinder #4 having evidence of oil leaking near the exhaust manifold gasket. Once the turbo was off, I found a small pool of oil in the exhaust port. I suspect the valve guide or valve stem seal failed. I have a new headgasket and hope to have the head off tonight. along with a few photos.

I have a spare head on my work bench ready to go in, it has a slightly better cam, but there is some corrosion on parts of the headgasket of the mating face. I'm trying to deice if I want to just try slapping it on or doing something else. Pictures tonight or tomorrow most likely.

Re: 633CSi Callaway Turbo - 11/14/17 Engine Opened Up

Posted: Nov 14, 2017 9:28 PM

by tschultz

From last night:

The oil stain coming from CYL #4

on the tubo manifold:

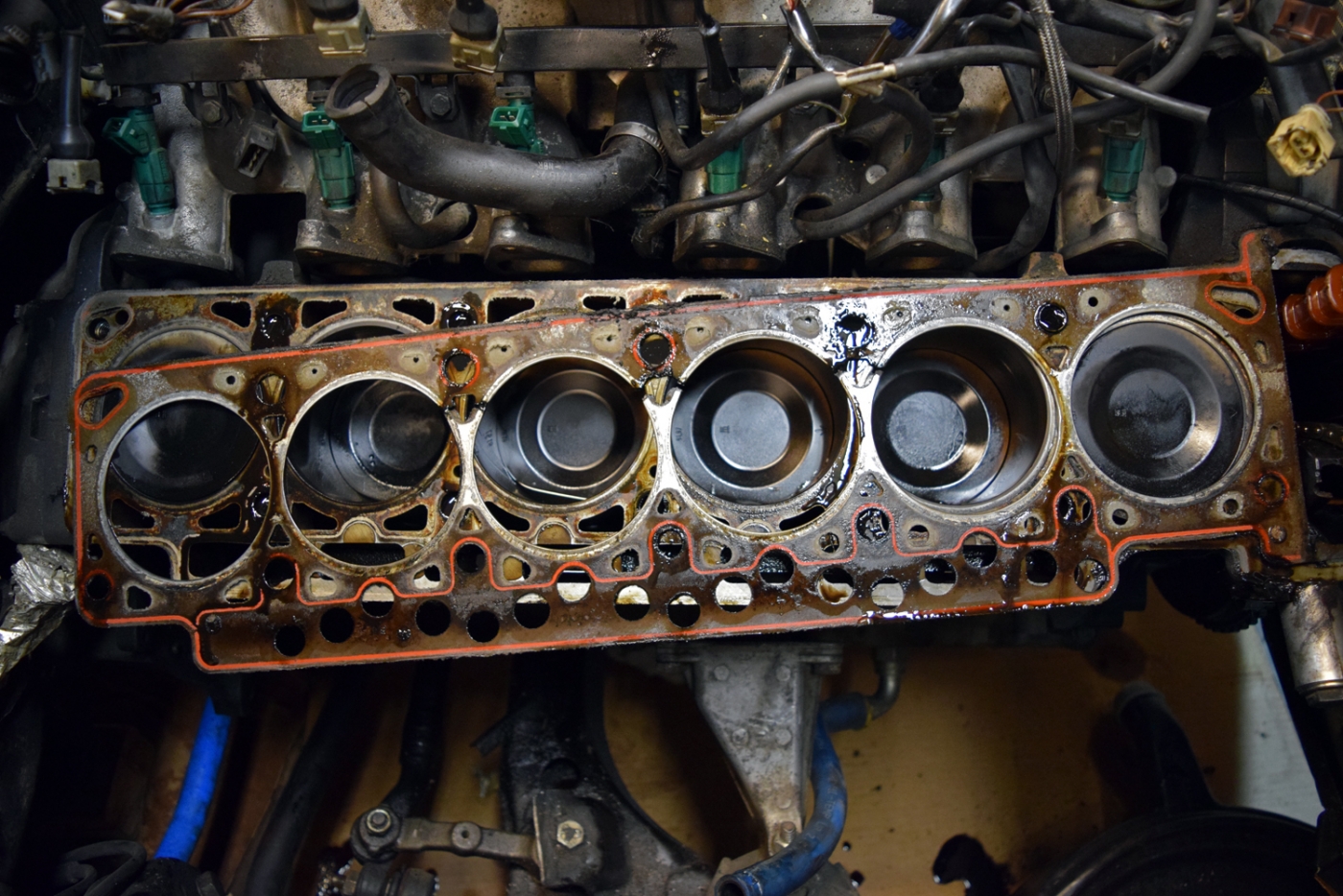

Some new tonight when taking the head off-- I wasn't expecting this! Cyl 2-4 were leaking to each other which explains why it wouldn't start or run very easily. Any ideas as to what caused the failure?

The engine seemed less strong than the one I had pulled out with the ring issue. I suspect these were partially damaged prior to me running it, but there's no way to know for sure. I had been careful to avoid detonation but had been tuning when engine started smoking badly.

The head as it came off:

Some cleaning:

Some strange scratching on the edge of cyl #2:

I'm not sure the cause but I believe it may have been partially damaged as It was installed... I'm not sure. I didn't replace the HG when I swapped engines.

I was thinking the oil burning was caused by failed valve stem seals-- obviously it wasn't. I had previously pulled my spare head but was upset to find this near cylinder #6. I think it needs reworked and I'm not going to reinstall it after all.

I have a new elring gasket, I just need to decide how much to really clean up the mating surfaces. I had just done this on my euro 635, but that was with a freshly machined head.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 15, 2017 6:39 PM

by marc79euro645

I've seen that before. I'm running arp studs @ 80#, but studs won't trump tuning. I'm also using a MS knocksense light. I tuned it to knock I could hear then set it a little more sensitive. It definitely helps. I have the light mounted in my a pillar gauge pods, so that it blinds me, and I lift.

good luck

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 17, 2017 3:46 AM

by RobertRO

I believe that the 3.2l M30 engine (89mm bore / 86mm stroke) is a better choice for forced induction, compared to the 3.4l M30 (92mm bore / 86mm stroke).

It provides additional 3mm between bores, which means more "meat" in the cylinder head gasket, which in turn renders cylinder to cylinder leakage less likely.

Also, the smaller bore provides better resistance to knock.

And the trade-off of lower cc (only about 0.2l less) does not have a big impact of performance, in forced induction applications.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 17, 2017 8:05 PM

by Nebraska_e28

Is that corrosion in the passage in the head?

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 17, 2017 9:47 PM

by tschultz

Yeah exactly LJ, that head was my spare head and it hadn't failed but I'm not sure if it can be salvaged. Maybe with welding work?

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 19, 2017 8:38 PM

by George

I would say that the corroded head isnt worth trying to save...espescially on a FI motor that is going to see hotter than normal combustion temps.

Any reason you're not considering an MLS gasket?

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 19, 2017 8:58 PM

by tschultz

George wrote:I would say that the corroded head isnt worth trying to save...espescially on a FI motor that is going to see hotter than normal combustion temps.

Any reason you're not considering an MLS gasket?

That was my suspicion as well. Waiting to hear what the head expert suggests after looking at the head that came off.

I read that those require a better surface finish of block and head and I don't have the tools to get the block prepped to that level. I also have read about a lot of people having good success with stock. I was planning to use Elring Klinger 11121730223 which seem to be going NLA.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 19, 2017 9:07 PM

by George

Meh.

Scotch Brite the block and keep any crap out of the cylinders and coolant/oil passages. Get the head decked. Nothing needed beyond that in my opinion. Cleanliness is next to godliness when putting is all back together.

Re: 633CSi Callaway Turbo - 6/5/2017 - More Megasquirt Tunin

Posted: Nov 24, 2017 9:39 AM

by tschultz

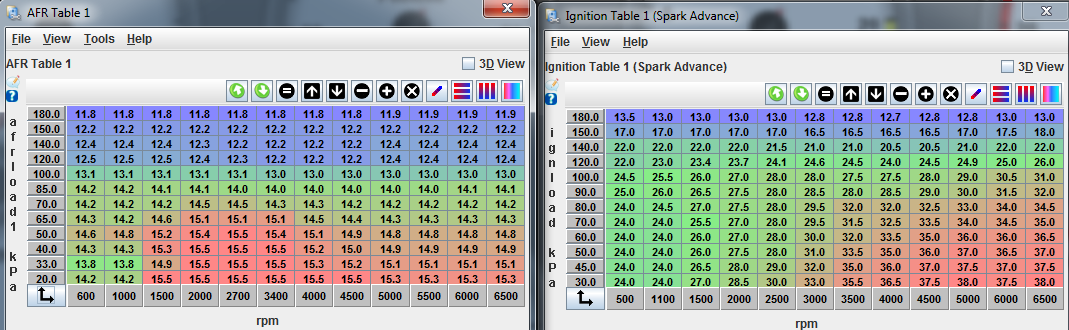

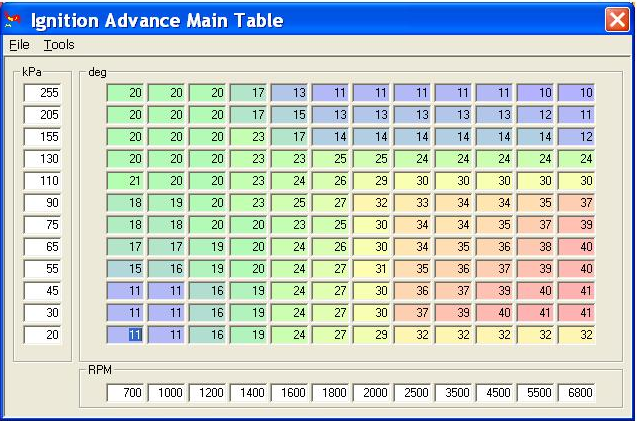

I went back into Tuner Studio and pulled my settings from the time that the oil smoke started. I was running 91 octane and these settings:

From my research, nothing here looks out of place except I may have the AFR targets slightly lean in the cruise range.

the 24* timing in the lower rpm's is also concerning, so I will be adjusting that down. Seems like a typo or something may have caused this. From my research, here is M Holtmeir's map from 2008 running 91 octane and a US B34 turbo...

I still don't know the cause of the failure or even how old the headgasket was, nor the condition of it when I got the engine. For all I know it had already had partial failure when I got it...

I have a sneaking suspicion it could have been related to the noise in my wiring harness. So I got my hands on a good used harness and have it mostly installed. I will be trying to start the car without the accessories like my vTPS hooked up to hopefully get the car to start and see if I still have signal noise. If I still have issues, I will methodically eliminate the possible causes of the noise one by one as the car idles.

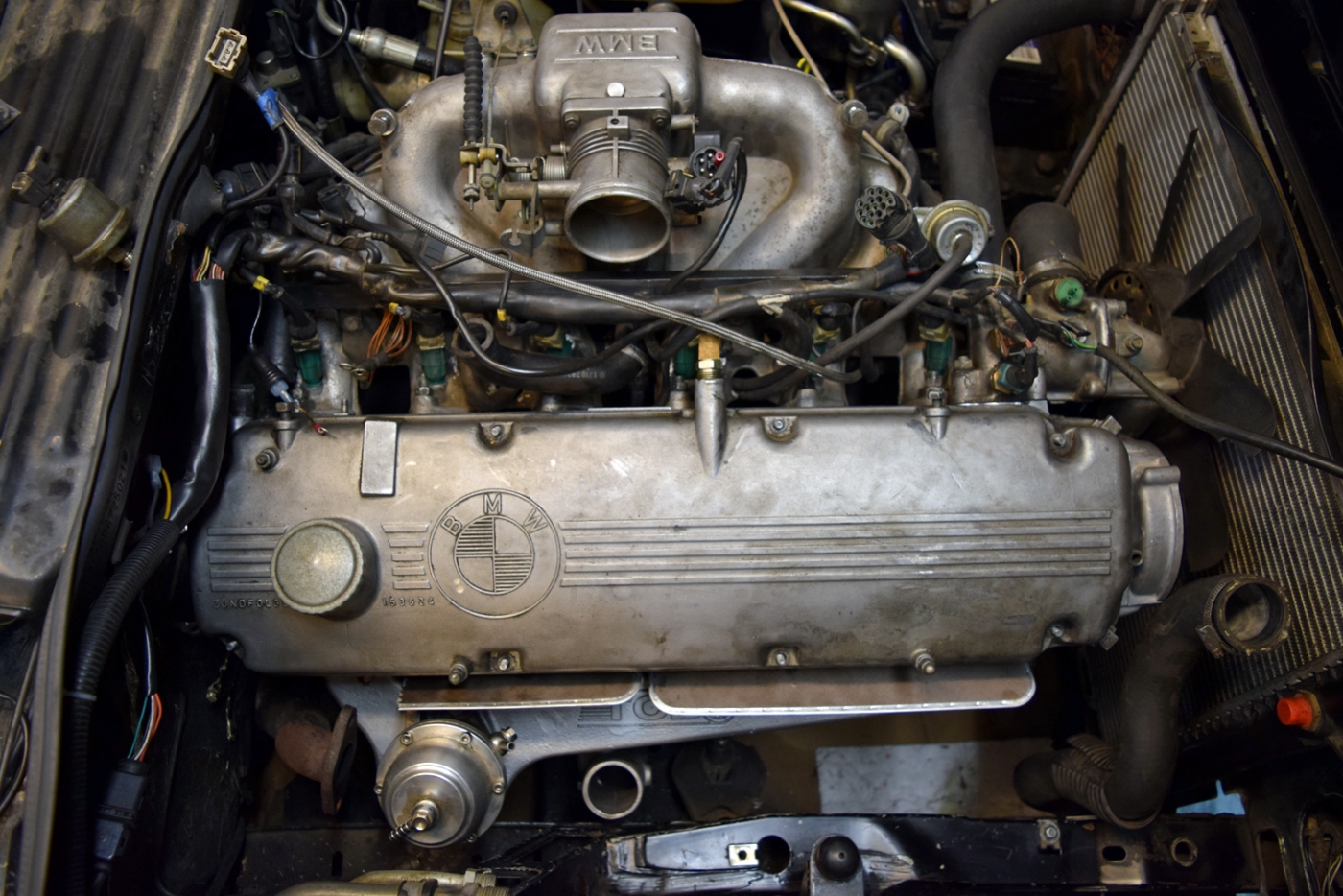

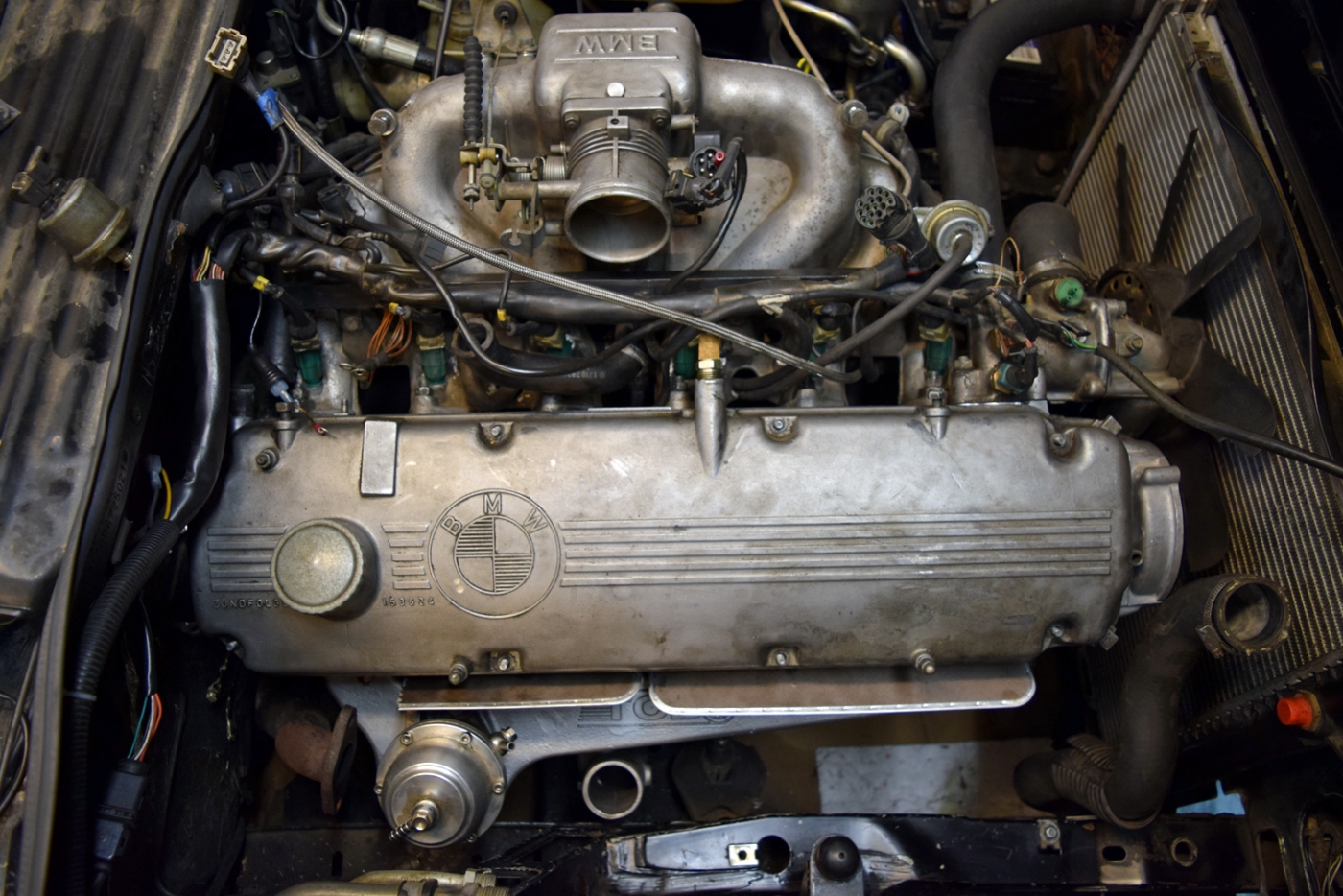

As it sits right now:

The head is still out being disassembled and then milled. Apparently it is only .003" away from being flat but had some leakage through the valves. The cam also had some wear so I am hoping I can use my spare (from the head that has the corrosion in the cooling passage near cyl #6.

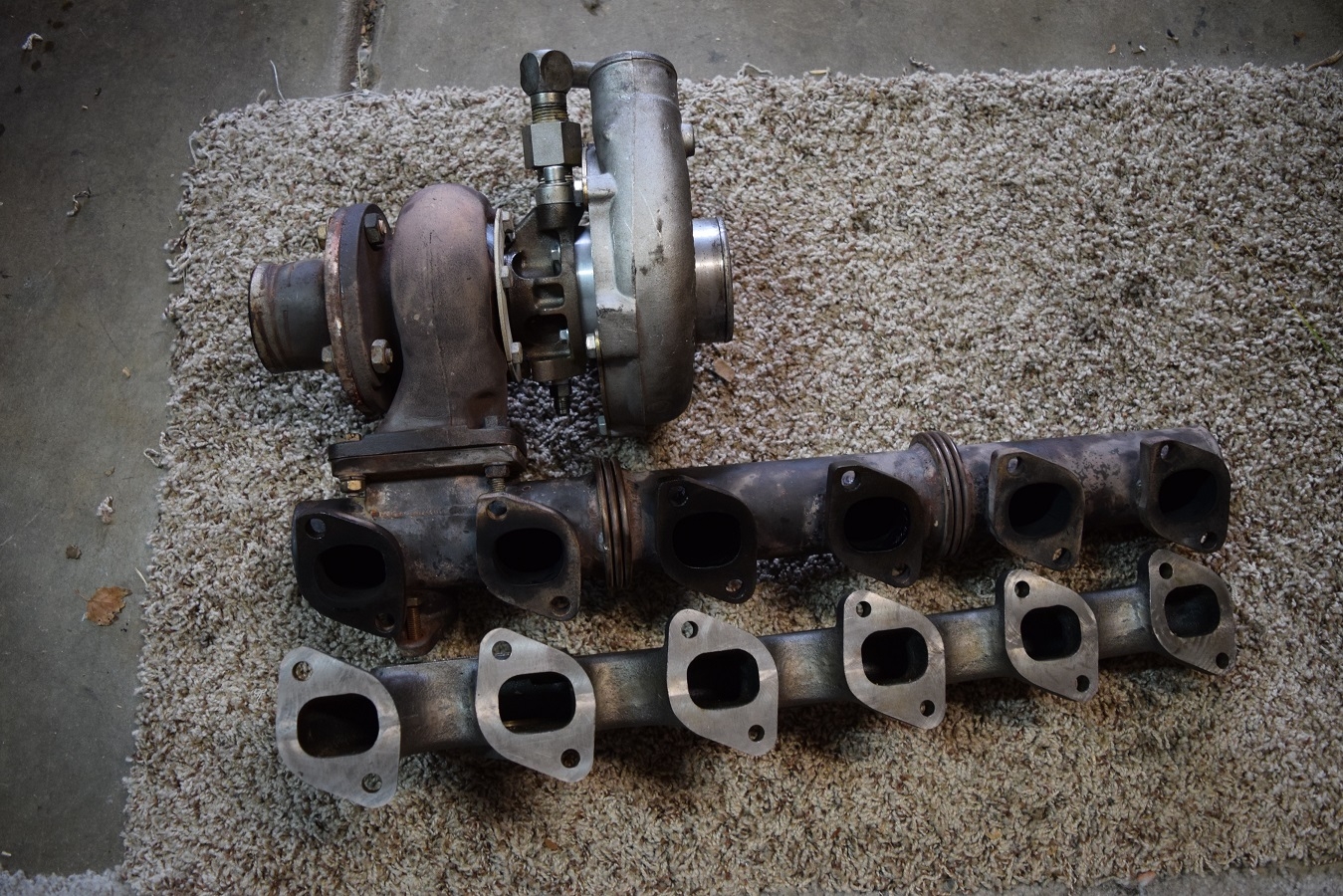

With that in mind I decided to compare a TCD turbo manifold I picked up earlier this year to my Callaway manifold:

Upon initial inspection, you can see the callaway manifold is really just a few of cylinders welded together and then connected to some openings that are connected to the mounting flanges. I noticed right away that the TCD manifold has smooth features and appears to be easier to mount due to the shape of the flow path.

So reading on turbo exhaust design via Maximum Boost and noted the following:

-heat retention and exhaust temperatures are key to the velocity of exhaust gases

-Thicker exhaust manifolds will lose heat faster than thin

-Manifolds with more surface area will conduct/lose more heat

-Reducing ambient airflow around the manifold will minimize heat loss

-Manifold heat wrap will retain too much heat and likely cause structural damage

-Heat distribution inside the manifold is important

-Sharp corners will cause localized hot spots and cause additional heat loss

-Reversion of cylinder events can cause back pressure and reduce performance

-Tube size is important. Always select the smaller diameter to increase exhaust velocity

-Streamlining flow in the manifold is important

-design passages to maintain constant velocity is beneficial

And from some other research:

-Manifolds with long runners have been found to produce more power but less torque than manifolds with short runners

-Manifolds with short runners radiate less heat as they have less surface area so engine bay cooling is less of an issue and as less heat energy is lost more is available to drive the turbine - efficiency

-Manifolds with short runners give faster turbo spooling or pickup time than manifolds with long runners.

-Manifolds with equal length runners space the individual pulses of energy from exhaust ports evenly in time - this minimizes the possibility of reversion

-Runners on turbo manifolds should be of smaller diameter than normally aspirated manifolds, ideally the same size as exhaust ports so that exhaust gas pulse speed from the port is maintained, a larger diameter runner will slow down exhaust gasses by allowing them to expand and slow down before reaching the turbine

-Runners of unequal length cause turbulence as it takes finite time for an exhaust gas pulse to pass down the runner.

-There should be no steps in the flow of gasses through the manifold at any point, all joins should be matched and smoothed to minimise turbulence and eliminate hot spots.

So upon further inspection it appears the TCD turbo manifold is designed better than my callaway unit. Some more photos for comparison:

In my measurements, the turbo will sit slightly closer to the block, but it will also move the turbo forward. It will move the turbo up slightly as well.

I think this means more clearance for the compressor outlet/intercooler pipe and both the motor mount and front subframe, a little extra height for the oil drain tube, and more clearance for compressor inlet tube.

I'm going to try to install it on the car when I reassemble. The smooth flow path, better clearance and better access to mounting studs all makes me think want to do this from the fitment perspective. From the design perspective it appears obvious that the smooth flow path should improve performance as well. The lack of sharp edges should minimize heat loss and the pulses should actually be directed towards the turbine rather than arbitrarily into the wall of a pipe. Lastly, the wastegate and turbine are also closer to the flow path and have less of a turn to make.

Re: 633CSi Turbo - 11/24/2017 - Not Really Callaway Anymore

Posted: Nov 26, 2017 8:21 AM

by George

If you’re having issues with the harness, they should appear in your data logs by the way of dropping out...unlesss power to the ECU is being interupted. I switched to the m50 tps earlier this year after the response time became super laggy.

I would highly recommend having whatever manifold you use ceramic coated. It’s an easy way to reduce underhood temps. After some frustration last year, I came up with a method to first install the TCD manifold on the motor and then the turbo. Much easier to tighten the lower manifold nuts this way. Let me know if you need any tips/tricks.

Re: 633CSi Turbo - 11/24/2017 - Not Really Callaway Anymore

Posted: Dec 08, 2017 11:27 AM

by Nebraska_e28

I'd run the TCD over Callaway any day for better efficiency and less backpressure at higher boost levels. On the other hand, if keeping with the original Callaway theme that's another thing. Of course safe boost would be your best friend. Comments from an novice.

Re: 633CSi Turbo - 11/24/2017 - Not Really Callaway Anymore

Posted: Dec 11, 2017 12:37 AM

by Shadow

Nebraska_e28 wrote:I'd run the TCD over Callaway any day for better efficiency and less backpressure at higher boost levels.

but is that factually correct though?

Re: 633CSi Turbo - 11/24/2017 - Not Really Callaway Anymore

Posted: Dec 11, 2017 10:56 AM

by T_C_D

Shadow wrote:Nebraska_e28 wrote:I'd run the TCD over Callaway any day for better efficiency and less backpressure at higher boost levels.

but is that factually correct though?

I never put both manifolds on a flow bench but common sense probably prevales.

Re: 633CSi Turbo - 11/24/2017 - Not Really Callaway Anymore

Posted: Dec 23, 2017 1:11 AM

by tschultz

Since the last post was so many words, I tried to get a bunch of photos for this update:

With the head out to be reworked, I spent some time cleaning up the block. For some reason, there was a lot of build up on the deck, but going slowly I used a razor blade to get it all smooth to the touch.

Considering the suggestions for these on this board and a few other individuals, I decided to send the manifold off to be ceramic coated by a shop here in Denver since I was waiting on the head anyway. Once I got it back, I felt silly because I realized I should have also done the turbine housing.

Here is the TCD manifold with gaskets-- to show what I was writing about earlier.

And the Callaway manifold for comparison. It is slightly lighter than the TCD, but overall seems like poor flow path design.

My spare head that I thought had a good cam ended up being scored due to somebody who tightened down the banjo bolts and didn't replace the crush washers. The rebuilder didn't want to reuse it.

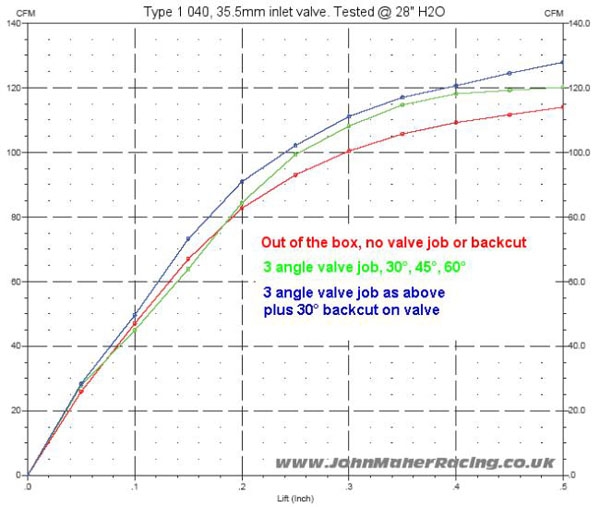

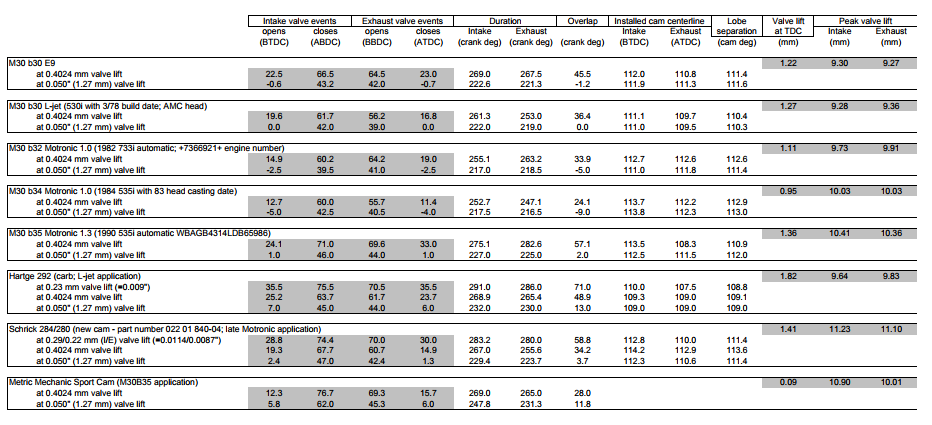

So I did some research on cams. Below is a great comparison via Devinder. The cam profile detail isn't easy to find:

The B35 cam was the best choice for bang for the buck for a replacement. It should change the power profile of the engine from more torque than hp to about even. This cam has the higher lift which should also allow the turbo to get more air through the engine. I wanted to get larger valves but the machinist didn't feel comfortable doing it. From my research it should shift power up about 400rpm in the curve and the additional flow should net some percentage of power also. I'll do a comparison to my VirtualDyno plots a couple pages back.

The head back from the shop:

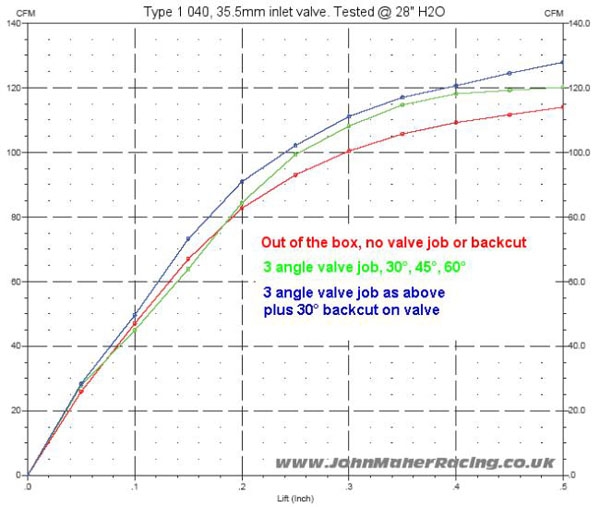

3 Angle Valve grind on all 12 valves (~10% flow increase). I don't think he could do a back cut but that would have been awesome if he did:

I also went with ARP head studs as an upgrade, but elected for stock Elring gasket. So far I torqued in 3 stages to 80 ft-lbs, but wasn't sure about going to 90. The lubricating grease seems to be some useful stuff. It took me a while to apply it to washers, bolt threads and nuts as instructed.

I also adjusted the valves. .010 on intake and .012 exhaust on the valve side per Mark Hutto

I tried to mount the turbo in the same orientation as with the Callaway manifold, but hit an unexpected snag. I found that the compressor housing hits the block in the orientation as the Callaway turbo manifold. After wrestling with it for probably 45 minutes, I finally got it clocked to an orientation that would work, which is the orientation for TCD intercooler.

I'm going to have to look at it and route the piping differently to use my air to air. So here are the parts otherwise all mocked up.

I have to look at the wastegate dump and see about getting that pipe remade. I didn't fit the exhaust but that may have to be adjusted slightly also. Good news was everything else seemed to fit about the same (I expected that).

This is the space I am lookign to route the compressor outlet... maybe around the inlet pipe and down the frame rail to the intercooler piping. It's going to take a bit more time that I expected. It will also look homebrew silly, but I think that's pretty funny as long as it functions well.

I also need to add fluids, reconnect cap/rotor/plugs/wires, and rewire a few items to work with MS2. Right now all but the TPS use harness adapters.

Re: 633CSi Turbo - 12/22/2017 - Not Really Callaway Anymore

Posted: Dec 23, 2017 12:55 PM

by tig

I'm really enjoying this thread. So much here I have no practical knowledge of, but intense curiosity for. Thanks for all the writeup and pics!

Re: 633CSi Turbo - 12/22/2017 - Not Really Callaway Anymore

Posted: Dec 23, 2017 2:03 PM

by tschultz

cek wrote:I'm really enjoying this thread. So much here I have no practical knowledge of, but intense curiosity for. Thanks for all the writeup and pics!

Good to hear Charlie, thanks! Interesting to see this too because I admire the thoroughness (and cleanliness) of your builds also

Re: 633CSi Turbo - 12/22/2017 - Not Really Callaway Anymore

Posted: Dec 23, 2017 6:37 PM

by George

The manifold looks good with the ceramic coating. Nice work. The e24 chassis is pretty tight with the TCD m30 manifold. I ran into the same issu last winter when pulling my turbo. It's tight but it fits. What does the intercooler look like? The core suppurt hangs pretty low on these cars so you should be able to go low without it being the lowest problems.