Balancing S38 ITBs

Re: Balancing S38 ITBs

Nice to see some interest in giving the Mantismanometer a try. I realize it would be fun to tune the cars here at the house, but it is far more practical to ship the tool. I am going to update the backing plate so it can folded into a flat rate box and draft up some assembly and operational instructions. I have a couple ideas to allow you to quickly unfold and set it up without draining the oil.

I should be able to get it repackaged some time this week.

Dean

I should be able to get it repackaged some time this week.

Dean

Re: Balancing S38 ITBs

Dean, this is an outstanding writeup! Thank you for sharing the process and the results.

Aaron, if the Mantismanometer comes East I'd be happy to help with the transfer fees. S38-Balance-Fest. That would make for a hell of a wrenching weekend.

Aaron, if the Mantismanometer comes East I'd be happy to help with the transfer fees. S38-Balance-Fest. That would make for a hell of a wrenching weekend.

Re: Balancing S38 ITBs

It would be interesting to see how it baselines against the Hg CarbTune as well. demetk and I have been talking about balancing mine for some time but so far we haven't made the time. With enough sets of ITBs there would be critical mass to get this done.

Re: Balancing S38 ITBs

I'm up for a San Diego/Orange County Balance Fest. Hell, I would even host it at my house and supply the food and drinks.

Re: Balancing S38 ITBs

I am in the south east so too far away for a get together in PA or NY, but I am very interested in renting the tool when it becomes available. If there are any others in the SC,NC, GA area who want to try to coordinate let me know. If not, I'm happy to just rent it as an individual. Please add me to the list.

Thanks,

Eric

Thanks,

Eric

Re: Balancing S38 ITBs

I have the Carbtune if you guys are interested in possibly setting up a borrow program. I used bought it and used a few years back to sync the throttle bodies on my 1993 M5. It was a little tricky at first, but I was able to get mine spot on perfect, and my car ran amazingly smooth and strong afterwards. I do remember noticing gas mileage well into the mid 20's after this was done. At the same time I adjusted my valves, and cleaned my MAF with cleaner. These added up to a big difference.

Re: Balancing S38 ITBs

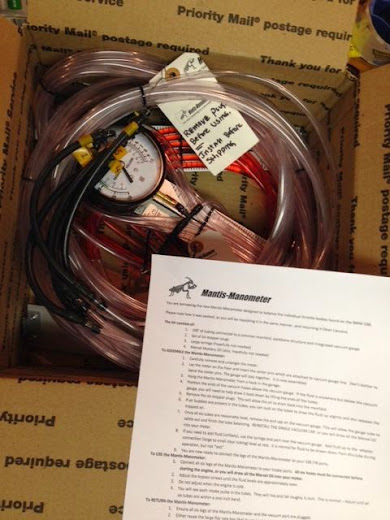

I had a chance to repackage the Mantis-Manometer into a shippable tool by removing the 1x6 board and mounting it to a 4' straight edge. The official Mantis-Manometer Gen II is now available for borrowing!

It works just like before. There are small cotter pins located every 12 inches to allow it to fold into a flat rate box.

Here is a very short video of the tool in use.

https://youtu.be/P5Z5fYuUjy4

And a full set of assembly and set up instructions are included below and properly formatted, printed and in the box.

I do have several folks that would like to borrow the Mantis-Manometer, so I think it is most prudent to require a small deposit on top of the shipping costs. I am assuming it will be $15.00 to ship. I would like a $50 deposit, which I will return $45.00 (paypal and misc). So, if you are still interested at this stage, I will be asking $15.00 to ship plus $50.00 for a deposit for a total of $65.00.

I am thinking this will encourage folks to return it quickly, so others can share.

The better option is to come by, hang out and have a beer, or invite the Mantis-Manometer and owner to a local S38 tune day:)

Thank you for everyone's contribution to this project.

Fun,fun,

Dean

PS: If I can figure out how to link a .pdf, below you would see the instructions, pretty formatting, a cool logo and nice text...

------------------------------------------------------------------------------------------------------------------------------

You are borrowing the new Mantis-Manometer designed to balance the individual throttle bodies found on the BMW S38.

Please note how it was packed, as you will be repacking it in the same manner, and returning it Dean.

The kit consists of:

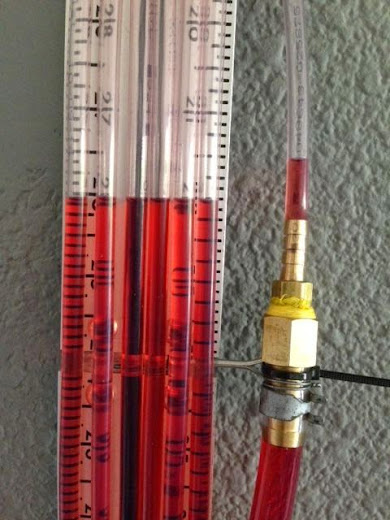

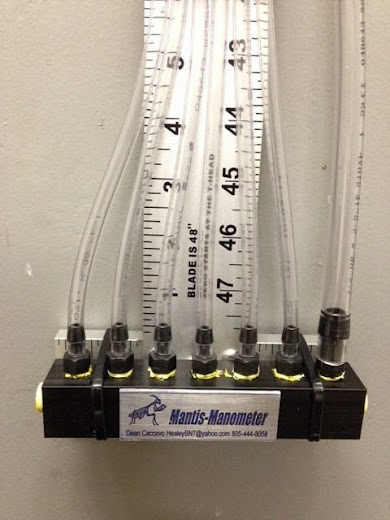

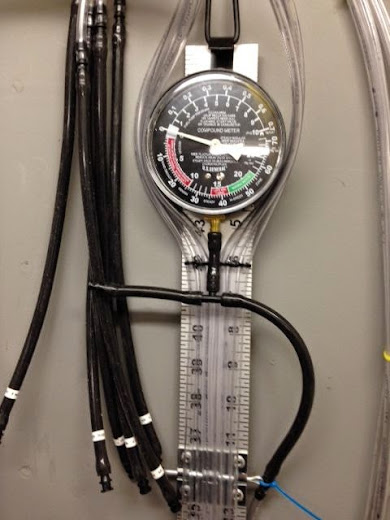

1. 100’ of tubing connected to a common manifold, backbone structure and integrated vacuum gauge

2. Set of six stopper plugs

3. Large syringe (hopefully not needed)

4. Marvel Mystery Oil (also, hopefully not needed)

To ASSEMBLE the Mantis-Manometer:

1. Carefully remove and untangle the meter.

2. Lay the meter on the floor and insert the cotter pins which are attached to vacuum gauge line. Don’t bother to bend the cotter pins. The gauge will stay together. It is now assembled.

3. Hang the Mantis-Manometer from a hook in the garage.

4. Position the ends of the vacuum hoses above the vacuum gauge. If the fluid is anywhere but below the vacuum gauge, you will need to help draw it back down by lifting the ends of the tubes.

5. Remove the six stopper plugs. This will allow the oil to drain back into the manifold.

6. If air bubbles are present in the tubes, you can suck on the tubes to draw the fluid up slightly and this releases the trapped air.

7. Once all six tubes are reasonably level, remove the end cap on the vacuum gauge. This will allow the gauge tube to settle out and finish the tube balancing. REINSTALL THE SINGLE VACUUM CAP, or you will draw all the Marvel Oil into your motor.

8. If you need to add fluid (unlikely), use the syringe and port near the vacuum gauge. Add fluid up to the adapter connection (large to small clear tubing) level at rest. It is normal for fluid to be drawn down from this tube during operation, but not “lost”.

9. You are now ready to connect the legs of the Mantis-Manometer to your S38 ITB ports.

To USE the Mantis-Manometer:

1. Connect all six legs of the Mantis-Manometer to your intake ports. All six hoses must be connected before starting the engine, or you will draw all the Marvel Oil into your motor.

2. Adjust the bypass screws until the fluid levels are approximately even

3. Do not adjust when the engine is cold.

4. You will see each intake pulse in the tubes. They will rise and fall roughly ½ inch. This is normal – Adjust until all six tubes are within a one inch band.

To RETURN the Mantis-Manometer:

1. Ensure all six legs of the Mantis-Manometer and the vacuum port are plugged.

2. Either reuse the large flat rate box that it was sent in, or locate another one. Do not kink the tubes.

3. Enjoy your newly balanced motor. Take photos. Post to the thread. Suggest improvements. Provide comments.

4. Send the tracking number to HealeyBN7@yahoo.com.

5. When the box is received, I will refund your deposit

Thank you, Dean

It works just like before. There are small cotter pins located every 12 inches to allow it to fold into a flat rate box.

Here is a very short video of the tool in use.

https://youtu.be/P5Z5fYuUjy4

And a full set of assembly and set up instructions are included below and properly formatted, printed and in the box.

I do have several folks that would like to borrow the Mantis-Manometer, so I think it is most prudent to require a small deposit on top of the shipping costs. I am assuming it will be $15.00 to ship. I would like a $50 deposit, which I will return $45.00 (paypal and misc). So, if you are still interested at this stage, I will be asking $15.00 to ship plus $50.00 for a deposit for a total of $65.00.

I am thinking this will encourage folks to return it quickly, so others can share.

The better option is to come by, hang out and have a beer, or invite the Mantis-Manometer and owner to a local S38 tune day:)

Thank you for everyone's contribution to this project.

Fun,fun,

Dean

PS: If I can figure out how to link a .pdf, below you would see the instructions, pretty formatting, a cool logo and nice text...

------------------------------------------------------------------------------------------------------------------------------

You are borrowing the new Mantis-Manometer designed to balance the individual throttle bodies found on the BMW S38.

Please note how it was packed, as you will be repacking it in the same manner, and returning it Dean.

The kit consists of:

1. 100’ of tubing connected to a common manifold, backbone structure and integrated vacuum gauge

2. Set of six stopper plugs

3. Large syringe (hopefully not needed)

4. Marvel Mystery Oil (also, hopefully not needed)

To ASSEMBLE the Mantis-Manometer:

1. Carefully remove and untangle the meter.

2. Lay the meter on the floor and insert the cotter pins which are attached to vacuum gauge line. Don’t bother to bend the cotter pins. The gauge will stay together. It is now assembled.

3. Hang the Mantis-Manometer from a hook in the garage.

4. Position the ends of the vacuum hoses above the vacuum gauge. If the fluid is anywhere but below the vacuum gauge, you will need to help draw it back down by lifting the ends of the tubes.

5. Remove the six stopper plugs. This will allow the oil to drain back into the manifold.

6. If air bubbles are present in the tubes, you can suck on the tubes to draw the fluid up slightly and this releases the trapped air.

7. Once all six tubes are reasonably level, remove the end cap on the vacuum gauge. This will allow the gauge tube to settle out and finish the tube balancing. REINSTALL THE SINGLE VACUUM CAP, or you will draw all the Marvel Oil into your motor.

8. If you need to add fluid (unlikely), use the syringe and port near the vacuum gauge. Add fluid up to the adapter connection (large to small clear tubing) level at rest. It is normal for fluid to be drawn down from this tube during operation, but not “lost”.

9. You are now ready to connect the legs of the Mantis-Manometer to your S38 ITB ports.

To USE the Mantis-Manometer:

1. Connect all six legs of the Mantis-Manometer to your intake ports. All six hoses must be connected before starting the engine, or you will draw all the Marvel Oil into your motor.

2. Adjust the bypass screws until the fluid levels are approximately even

3. Do not adjust when the engine is cold.

4. You will see each intake pulse in the tubes. They will rise and fall roughly ½ inch. This is normal – Adjust until all six tubes are within a one inch band.

To RETURN the Mantis-Manometer:

1. Ensure all six legs of the Mantis-Manometer and the vacuum port are plugged.

2. Either reuse the large flat rate box that it was sent in, or locate another one. Do not kink the tubes.

3. Enjoy your newly balanced motor. Take photos. Post to the thread. Suggest improvements. Provide comments.

4. Send the tracking number to HealeyBN7@yahoo.com.

5. When the box is received, I will refund your deposit

Thank you, Dean

Re: Balancing S38 ITBs

Dean, love the sticker. I'm a little way away from being ready to undertake this. Critical to the balancing procedure is correctly adjusted valves, which is a bit of a black art since most of us are going somewhere between .012 and .014 depending on which shims give the closest gap to spec. I suppose that's one of the things that balancing addresses. In addition, setting up the butterflies and linkage mechanism is another important step before attempting to balance the bypass ports. Any plans to add this equipment to the kit/instructions? I can host a .pdf file for you if you want to include it in the thread.

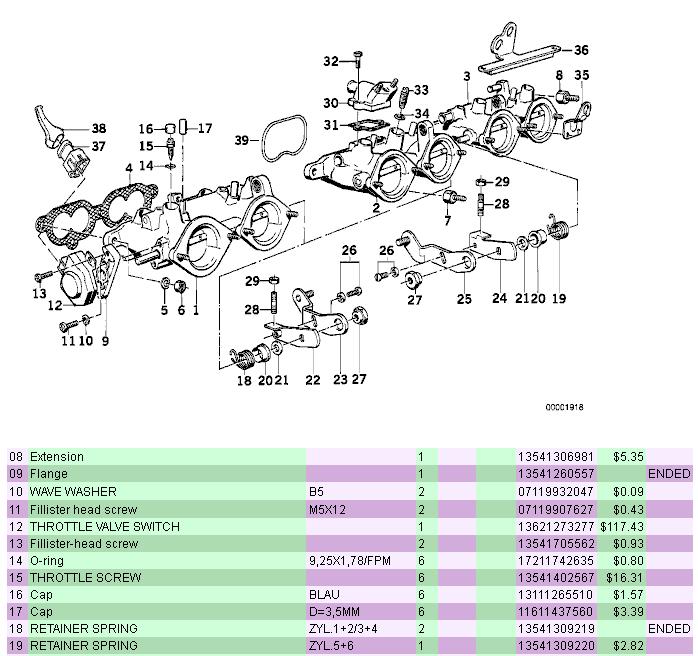

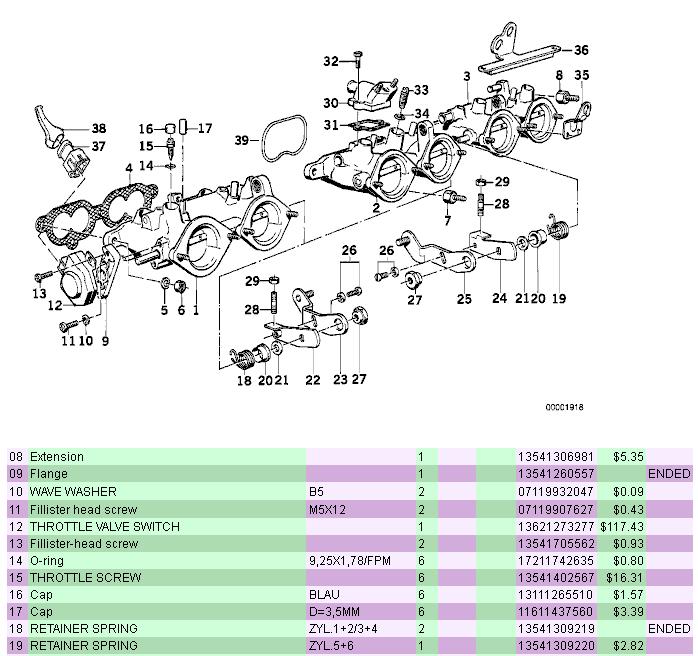

Finally, I would recommend ordering parts number 14 (o-rings) and 16 (blue caps) ahead of time. Compromised o-rings can invalidate the adjustments.

Finally, I would recommend ordering parts number 14 (o-rings) and 16 (blue caps) ahead of time. Compromised o-rings can invalidate the adjustments.

Re: Balancing S38 ITBs

Those are great ideas. I agree that we should include prerequisite tuning guides/instructions to cover the valve adjustment and mechanical linkage.ahab wrote:Dean, love the sticker. I'm a little way away from being ready to undertake this. Critical to the balancing procedure is correctly adjusted valves, which is a bit of a black art since most of us are going somewhere between .012 and .014 depending on which shims give the closest gap to spec. I suppose that's one of the things that balancing addresses. In addition, setting up the butterflies and linkage mechanism is another important step before attempting to balance the bypass ports. Any plans to add this equipment to the kit/instructions? I can host a .pdf file for you if you want to include it in the thread.

Finally, I would recommend ordering parts number 14 (o-rings) and 16 (blue caps) ahead of time. Compromised o-rings can invalidate the adjustments.

My technique uses 12" metric feeler gauges from McMaster and the "difference" spreadsheet to select the correct shims. I modified the spreadsheet a bit with some excel tricks so you can quickly see which valves need attention and which are in spec. I would be happy to share my version of the spreadsheet, but I am partial to the shim bucket tool, pick and shim set:). I had to add material to the shim tool (welding to the inside of hook) and some grinding to get it to perform properly.

Agree that we should cover is the mechanical linkage, especially since I found the BMW book method to introduce errors as you reattach the linkage. I used a Chinese dial indicator and modified a standoff post to allow repositioning on the throttle bodies. If it is needed, I could include this in the kit. I'll have a little time to work on the instructions later today/tomorrow. If I can send you the .pdf, for hosting and reviewing that would be great!

The blue caps always looked out of place to me, so I left them off. It's hard to imagine a villain sneaking into the garage, opening the hood and adjusting the bypass ports...

I didn't replace the orings - ugh, but I see I have this size on the workbench. Another excuse to use the Mantis-Manometer

All the credit for the name/logo goes to you!

Dean

-

Tinkwithanr

- Posts: 108

- Joined: Feb 04, 2014 12:26 PM

- Location: Ohio

Re: Balancing S38 ITBs

First off, great idea and execution! I've still got a few things I need to check off the list before I get to balancing the throttles, but I know how I'm going to do it when the time comes.

I do have another question that I don't think has been addressed in the thread yet. Referencing the RealOEM diagram above, what is the function of the larger brass plug (#33) ? Is there a proper method for adjusting this? While ordering the O-rings for the individual plungers it seems like it might be a good idea to go ahead and refresh/adjust this larger one as well.

I do have another question that I don't think has been addressed in the thread yet. Referencing the RealOEM diagram above, what is the function of the larger brass plug (#33) ? Is there a proper method for adjusting this? While ordering the O-rings for the individual plungers it seems like it might be a good idea to go ahead and refresh/adjust this larger one as well.

Re: Balancing S38 ITBs

I would love to. I'm in the neighborhood!

Re: Balancing S38 ITBs

I pulled together my thoughts on the mechanical linkage adjustment and updated the .pdf. I am including a dial indicator, stand off boss and TPS bridge. The kit is heading out for the first time this weekend to Michael - macsm5 in No.Cal. Yeah.HealeyBN7 wrote:

Agree that we should cover is the mechanical linkage, especially since I found the BMW book method introduces errors as you reattach the linkage. I used a Chinese dial indicator and modified a standoff post to allow repositioning on the throttle bodies. If it is needed, I could include this in the kit. I'll have a little time to work on the instructions later today/tomorrow. If I can send you the .pdf, for hosting and reviewing that would be great!

Dean

If anyone wants to review the instructions, I can send the pdf via email.

Dean

Re: Balancing S38 ITBs

I would not mind seeing your instructions and might have some ideas to include. Did you resolve the question of getting the on/off idle (TPS control) transition just right? I'm not sure I've seen a good procedure or target for this or I've missed it. I just unplug the TPS and adjust the big idle bypass screw to raise the rpm 100-200. But if the screw is too far open or closed and can't do this it means the base throttle setting isn't right. On an M30 that's easy as pie to fix but not so much on the ITB's. I'm due to do a valve adjustment and go back through mine again soon and plan to sort this one aspect out. Would like to see one full set of instructions that cover all the little details from valve adjustment through balance. I've been using a few different sources and my own interpretation.

Another example is the 'best' valve shim gap. I've used 'spec' on the intake but slightly more open on the exhaust per some of the experts. Is that still the consensus?

Another thing might be the AFM bypass screw setting? Closer to rich... or lean... or anywhere in between so that the computer will still dither? For example if you intentionally drive it rich so that it cannot dither the idle feels smoother but probably not best.

Lately my car has sometimes had longer cranking time before firing. It might be fuel pressure which I need to check or it could be back to this base throttle setting business. I think that and ICV home position effects this also when it is stone cold which is when it does this.

While I may never rent your tool (I'll use my own double and move back and force or build a Mantis style) I am very thankful for reads like this and thinking this is the best S38 related tech thread in a while.

Regardless of the little quirks, what wonderful motors these are and interesting for those who enjoy the tuning and tinkering. I've just been driving my S38 6er after having set most of the winter and while there are a few things to sort out it's one of the most captivating cars I've ever driven.

Sorry for the long winded reply.

Another example is the 'best' valve shim gap. I've used 'spec' on the intake but slightly more open on the exhaust per some of the experts. Is that still the consensus?

Another thing might be the AFM bypass screw setting? Closer to rich... or lean... or anywhere in between so that the computer will still dither? For example if you intentionally drive it rich so that it cannot dither the idle feels smoother but probably not best.

Lately my car has sometimes had longer cranking time before firing. It might be fuel pressure which I need to check or it could be back to this base throttle setting business. I think that and ICV home position effects this also when it is stone cold which is when it does this.

While I may never rent your tool (I'll use my own double and move back and force or build a Mantis style) I am very thankful for reads like this and thinking this is the best S38 related tech thread in a while.

Regardless of the little quirks, what wonderful motors these are and interesting for those who enjoy the tuning and tinkering. I've just been driving my S38 6er after having set most of the winter and while there are a few things to sort out it's one of the most captivating cars I've ever driven.

Sorry for the long winded reply.

Re: Balancing S38 ITBs

PM me with your email and I'll send the document. It would be great if we had a comprehensive best practices paper on the subject!

Dean

Dean

Re: Balancing S38 ITBs

Thanks to ahab, the Mantis-Manometer instructions are hosted here...

Instructions for Use

The kit comes with a printed copy of the instructions and the return address.

Please let me know if you anything that is not clear or needs improvement.

Dean

Instructions for Use

The kit comes with a printed copy of the instructions and the return address.

Please let me know if you anything that is not clear or needs improvement.

Dean

Re: Balancing S38 ITBs

Hi Dean,ahab wrote:Dean, love the sticker. I'm a little way away from being ready to undertake this. Critical to the balancing procedure is correctly adjusted valves, which is a bit of a black art since most of us are going somewhere between .012 and .014 depending on which shims give the closest gap to spec. I suppose that's one of the things that balancing addresses. In addition, setting up the butterflies and linkage mechanism is another important step before attempting to balance the bypass ports. Any plans to add this equipment to the kit/instructions? I can host a .pdf file for you if you want to include it in the thread.

Finally, I would recommend ordering parts number 14 (o-rings) and 16 (blue caps) ahead of time. Compromised o-rings can invalidate the adjustments.

In your instructions re: mechanically synchronizing the throttles, you mention to replace the o-ring in the main idle adjuster, in the RealOEM diagram AHAB posted is the main idle adjuster part number 33 and the main idle adjuster "o" ring to replace number 34?

Thanks!

Re: Balancing S38 ITBs

Hi Dean,ahab wrote:Dean, love the sticker. I'm a little way away from being ready to undertake this. Critical to the balancing procedure is correctly adjusted valves, which is a bit of a black art since most of us are going somewhere between .012 and .014 depending on which shims give the closest gap to spec. I suppose that's one of the things that balancing addresses. In addition, setting up the butterflies and linkage mechanism is another important step before attempting to balance the bypass ports. Any plans to add this equipment to the kit/instructions? I can host a .pdf file for you if you want to include it in the thread.

Finally, I would recommend ordering parts number 14 (o-rings) and 16 (blue caps) ahead of time. Compromised o-rings can invalidate the adjustments.

In your instructions re: mechanically synchronizing the throttles, you mention to replace the o-ring in the main idle adjuster, in the RealOEM diagram AHAB posted is the main idle adjuster part number 33 and the main idle adjuster "o" ring to replace number 34?

Thanks!

Re: Balancing S38 ITBs

Michael,

Yes. That is correct. The main idle adjustment is the big screw or part number 33 and the o-ring is 34 (11631271346). For some reason, BMW Real OEM didn't list the size of this o-ring as they have for others, but you may be able to match it if you have access to an assortment.

Good luck and let us know how it goes!

Dean

Yes. That is correct. The main idle adjustment is the big screw or part number 33 and the o-ring is 34 (11631271346). For some reason, BMW Real OEM didn't list the size of this o-ring as they have for others, but you may be able to match it if you have access to an assortment.

Good luck and let us know how it goes!

Dean

Re: Balancing S38 ITBs

Mantis whereabouts...

Currently it is on loan to Michael (macsm5) - NoCal - Expected return May 4-5.

Brad (bdalessio) is next on the list - NoCal

Then Eric (ronin) - Spartanburg, South Carolina

Once it is back in SoCal after Eric, perhaps we can schedule in the local sessions.

Sound fair?

Let me know if I missed anyone.

Dean

Currently it is on loan to Michael (macsm5) - NoCal - Expected return May 4-5.

Brad (bdalessio) is next on the list - NoCal

Then Eric (ronin) - Spartanburg, South Carolina

Once it is back in SoCal after Eric, perhaps we can schedule in the local sessions.

Sound fair?

Let me know if I missed anyone.

Dean

Re: Balancing S38 ITBs

Well....I wasn't planning on making another Mantis, but this copy is going to Brad. Thank you Brad!

It has a few improvements:

This version uses nylon barbs on a larger 7 vs 6 port manifold. The larger manifold eliminates 90 degree fittings. The nylon barbs provide a better seal to the vinyl tubing and eliminate the wire ties. I also added thicker (by 1mm OD) high temperature silicone hose to the ends of the vacuum tubes. I think this is a necessary improvement to ensure the business end doesn't deform from heat.

There is also a machined aluminum barb fitting on the large hose. I had to make this one in the lathe as I could not find a 3/16 to 3/8 reducer barb.

It was a good exercise to see how much it cost to make and how much time it takes - too much of both.

Brad should get his Mantis by the end of the week. Eric - I guess you will be next in for the rental as soon as Michael and Brad are finished.

Dean

It has a few improvements:

This version uses nylon barbs on a larger 7 vs 6 port manifold. The larger manifold eliminates 90 degree fittings. The nylon barbs provide a better seal to the vinyl tubing and eliminate the wire ties. I also added thicker (by 1mm OD) high temperature silicone hose to the ends of the vacuum tubes. I think this is a necessary improvement to ensure the business end doesn't deform from heat.

There is also a machined aluminum barb fitting on the large hose. I had to make this one in the lathe as I could not find a 3/16 to 3/8 reducer barb.

It was a good exercise to see how much it cost to make and how much time it takes - too much of both.

Brad should get his Mantis by the end of the week. Eric - I guess you will be next in for the rental as soon as Michael and Brad are finished.

Dean

Re: Balancing S38 ITBs

If you are talking to me, Eric, then just let me know. If you meant a different Eric, that is ok, just let me know where I fit in the schedule. The new and improved version sounds nice. Looking forward to it.

Take care,

Eric

Take care,

Eric

Re: Balancing S38 ITBs

FYI - The Manometer Kit It is on the road again for a quick loan to David as MinneapM635 in Minneapolis. Should be back and available in a couple weeks.

By the way, shipping seems to have gone up to $20 with insurance. sorry.

Dean

By the way, shipping seems to have gone up to $20 with insurance. sorry.

Dean

-

Das_Prachtstrasse

- Posts: 5616

- Joined: Sep 10, 2006 7:06 AM

- Location: Melbourne, Doooown Under

Re: Balancing S38 ITBs

What an incredibly fantastic thread. This information is invaluable and will prove to be a cornerstone of mine once this ITB'd M30 is off the ground. Dean, I would be very much appreciative if you would allow me to replicate your design for my own uses as despite my eagerness, international shipping on a borrowed part is folly. Failing that, if you could perhaps be swayed into manufacturing another that would be even more excellent as I'll be needing this tool in due time, and it would be highly useful to those local S38 owners in the click. You'd have to be sure to install the ruler upside down, though.

Re: Balancing S38 ITBs

I may have a wait until I retire to make another one, but in the mean time feel free to knock off a copy for you and your friends down under. I am thinking that you should be able to figure out all the bits by looking at the pictures. If you need something special let me know. When I put together the second kit for Brad I was shocked how quickly the parts totaled to more then a couple hundred dollars. You of course could save some money of you reused your personal fuel pressure gauge and dial indicator, but be aware that buying the fittings in small quantities is just not frugal.

It is a fun weekend project - get to it!

Dean

It is a fun weekend project - get to it!

Dean

-

MinneapM635

- Posts: 3

- Joined: Oct 12, 2011 11:46 AM

Re: Balancing S38 ITBs

Got the Mantis on Monday and immediately plugged it in to get a baseline of where I was at. Last time I synched the throttles was probably 2013 and I used a single mechanical gauge and with all the pulsing, and pinching of the lines, it probably wasn't the best. Here's a video of the readings without any adjustment. Warning, I am a novice at taking and posting videos online... AND keeping my garage tidy.

https://youtu.be/KXkaAa2kSFo

A few quick adjustments and the result:

https://youtu.be/hnNzKgXWEpI

This was without any of the prerequisite "remove the screws, replace o-rings, bottom out and turn out 1 turn" baseline adjustment. So, I set off to do just that last night and wouldn't you know, the o-ring on the idle speed adjustment screw basically disintegrated upon removal of the screw. So, replacement rings ordered on fast shipment. I hope to have the Mantis back in the mail by Monday/Tuesday next week.

Dean, I give credit to you for the tool in the description of the videos. Let me know if you would like me to remove or add any other information. Want to make sure you get the appropriate credit for this great tool.

Thanks,

Dave

https://youtu.be/KXkaAa2kSFo

A few quick adjustments and the result:

https://youtu.be/hnNzKgXWEpI

This was without any of the prerequisite "remove the screws, replace o-rings, bottom out and turn out 1 turn" baseline adjustment. So, I set off to do just that last night and wouldn't you know, the o-ring on the idle speed adjustment screw basically disintegrated upon removal of the screw. So, replacement rings ordered on fast shipment. I hope to have the Mantis back in the mail by Monday/Tuesday next week.

Dean, I give credit to you for the tool in the description of the videos. Let me know if you would like me to remove or add any other information. Want to make sure you get the appropriate credit for this great tool.

Thanks,

Dave

Re: Balancing S38 ITBs

Thanks for the feedback Dave. Looks like you mastered it in short order and the results look great.

It doesn't fix all S38 problems (TPS actuation, ICV response, worn linkage or misalignments, valve clearances, etc), but if the basics are already covered, after tuning, the car should idle a bit more smoothly and if need be you can replace the rotten o-rings or any of the worn ITB components and re-tune to return to a stable flow.

Nice job on the videos! Thanks for linking them to the forum.

Dean

It doesn't fix all S38 problems (TPS actuation, ICV response, worn linkage or misalignments, valve clearances, etc), but if the basics are already covered, after tuning, the car should idle a bit more smoothly and if need be you can replace the rotten o-rings or any of the worn ITB components and re-tune to return to a stable flow.

Nice job on the videos! Thanks for linking them to the forum.

Dean

Re: Balancing S38 ITBs

Hey Dean,

Fairly new to this board and the S38 world. Got the valves adjusted, new cap, new TPS, etc. Still idles rough and down on power. On to throttle syncing. Still loaning out the Mantimanometer? Would love to use it!

Also, when adjusting the butterfly closing gap, does the .01 refer to .01 in or .01 mm? I'm hoping inches otherwise the dial gauge i have doesn't read that fine!

Thanks!

Fairly new to this board and the S38 world. Got the valves adjusted, new cap, new TPS, etc. Still idles rough and down on power. On to throttle syncing. Still loaning out the Mantimanometer? Would love to use it!

Also, when adjusting the butterfly closing gap, does the .01 refer to .01 in or .01 mm? I'm hoping inches otherwise the dial gauge i have doesn't read that fine!

Thanks!

Re: Balancing S38 ITBs

Hello Alim!

So sorry we never got to meet in Santa Fe, but I will be back next summer.

Have you checked all the following baseline items:

-Coolant Temp Sensor

-Correct Spark plugs (gapped properly)

-Crankshaft/RPM sensor

-Fuel Pressure Regulator

-Oxygen Sensor

-Check for any vacuum leaks?

all best,

Jeff

So sorry we never got to meet in Santa Fe, but I will be back next summer.

Have you checked all the following baseline items:

-Coolant Temp Sensor

-Correct Spark plugs (gapped properly)

-Crankshaft/RPM sensor

-Fuel Pressure Regulator

-Oxygen Sensor

-Check for any vacuum leaks?

all best,

Jeff

Re: Balancing S38 ITBs

Hey Jeff,

Next summer for sure!

Replaced Coolant Temp Sensor, Spark Plugs, and O2 sensor. Checked Crankshaft and Camshaft sensors, as well as FPR. I think I got most of the vacuum leaks. I can read 8 - 9 inHg of vacuum from the EGR port, so I think I should be ok there.

Comes down to AFM and/or throttle bodies now. Actually, I wish I could've swapped AFM's with you to see if that was the culprit. I will probably just do the MAF conversion now, though. I've only heard great things about it.

Next summer for sure!

Replaced Coolant Temp Sensor, Spark Plugs, and O2 sensor. Checked Crankshaft and Camshaft sensors, as well as FPR. I think I got most of the vacuum leaks. I can read 8 - 9 inHg of vacuum from the EGR port, so I think I should be ok there.

Comes down to AFM and/or throttle bodies now. Actually, I wish I could've swapped AFM's with you to see if that was the culprit. I will probably just do the MAF conversion now, though. I've only heard great things about it.

Re: Balancing S38 ITBs

I would be happy to lend it to you. The gap is measured in inches.alim_h wrote:Hey Dean,

Fairly new to this board and the S38 world. Got the valves adjusted, new cap, new TPS, etc. Still idles rough and down on power. On to throttle syncing. Still loaning out the Mantimanometer? Would love to use it!

Also, when adjusting the butterfly closing gap, does the .01 refer to .01 in or .01 mm? I'm hoping inches otherwise the dial gauge i have doesn't read that fine!

Thanks!

Since you say that you are down on power, In don't think balancing the ITBs will make much difference. It could help with idle smoothness and transition off idle issues, but once the butterfies are partially cracked the bypass screws are no longer in play and any performance issues would come from somewhere else.

Before you balance the ITBs you should make sure your valves are properly adjusted. If you plan on doing that later it will impact the ITB adjustments.

Let me know when you want it sent over. We will need to exchange emails off line so you can paypal me for shipping and a small deposit. Also, if you don't need the dial indicator, all the better. Turns out it is now the only one I have:)

Dean

Re: Balancing S38 ITBs

HealeyBN7 wrote:

Since you say that you are down on power, In don't think balancing the ITBs will make much difference. It could help with idle smoothness and transition off idle issues, but once the butterfies are partially cracked the bypass screws are no longer in play and any performance issues would come from somewhere else.

Dean

HealeyBN7 wrote:I reset the OBC MPG tracker before heading out to work this morning. 80 mile round trip. Mostly 80 MPH freeway on the way into work. Traffic on the way home. I haven't see this average before, except in the wife's '84 528e.

Now that's a measurable improvement even on crappy California summer gas blend.

Dean

So what you are saying is that this was due to a difference in your driving style and not your throttle adjustment, sounds misleading.

Re: Balancing S38 ITBs

You are kidding, right? You took two sentences from this thread separated by seven months and re-ordered them, one as a self report, and the other in response to helping a fellow M5 owner that has an AFM issue and you drew the conclusion that I am trying to be misleading???Nanajoth wrote:HealeyBN7 wrote:

Since you say that you are down on power, In don't think balancing the ITBs will make much difference. It could help with idle smoothness and transition off idle issues, but once the butterfies are partially cracked the bypass screws are no longer in play and any performance issues would come from somewhere else.

DeanHealeyBN7 wrote:I reset the OBC MPG tracker before heading out to work this morning. 80 mile round trip. Mostly 80 MPH freeway on the way into work. Traffic on the way home. I haven't see this average before, except in the wife's '84 528e.

Now that's a measurable improvement even on crappy California summer gas blend.

Dean

So what you are saying is that this was due to a difference in your driving style and not your throttle adjustment, sounds misleading.

If there is something amiss about the process, method or tools described for balancing the ITBs please do share.

Dean

Re: Balancing S38 ITBs

I am curious as to how you gained the extra MPG when you stated that adjusting the ITBs will not help you as far as performance goes and the bypass screws are no longer involved. It looks misleading when you state in the beginning of the thread that you gained all sorts of mileage and compare it to a 528e, then down the road say that this process will not help with performance issues. There is nothing wrong with your adjustment process.

Re: Balancing S38 ITBs

I think the problem is confusion by the term "performance". I equate performance with power, torque and acceleration, not on idle or off idle efficiency/mileage. See if this helps.Nanajoth wrote:I am curious as to how you gained the extra MPG when you stated that adjusting the ITBs will not help you as far as performance goes and the bypass screws are no longer involved. It looks misleading when you state in the beginning of the thread that you gained all sorts of mileage and compare it to a 528e, then down the road say that this process will not help with performance issues. There is nothing wrong with your adjustment process.

On my M5 the ITBs were fairly far out of adjustment (both the butterflies and the bypass screws). The car struggled (surged) at very low freeway speeds and the ECU/LM2 indicated that it was hunting (...wasting gas). Returning the ITBs to their proper synchronization allowed for much smoother light throttle drive-ability and the resulting "OBC" mileage under ideal conditions. Unfortunately, I don't drive that way most of the time, but you could. If you have an S38 and use the right pedal then you know they are capable of returning you to the filling station in quick order. My mileage has been averaging 18.5-19.5.

The purpose of this thread was not to improve S38 mileage. That was just an observation to demonstrate that the ITBs are no longer "fighting" with each other. I was looking for a repeatable way to adjust the ITBs for on idle smoothness and help with an off idle transition step. The book method of moving the vacuum gauge from port to port was not returning repeatable results.

Regarding Alim's car, he is describing "performance issues" across the power band. Adjusting the ITBs at idle or just off idle really won't have any impact at all at full or part throttle. In off line discussions with Alim it sounds like he may have a bad AFM. I offered to loan him my spare AFM for testing. I recommended that he find the root cause of the "low on power" issue first before investing the in the time to fine tune the ITBs.

Dean

Re: Balancing S38 ITBs

That makes sense, thank you for clarifying.

-

wjtesquire

- Posts: 16

- Joined: Aug 07, 2010 8:42 AM

- Location: Charleston, SC

Re: Balancing S38 ITBs

Wow! Dean was kind enough to share the Mantis Magic Manometer with me and look at the results:

Before:

https://www.youtube.com/watch?v=x91Dia4 ... load_owner

After 5 minutes of adjusting:

https://www.youtube.com/watch?v=nINNnME ... load_owner

I can't tell you how much smoother and more refined my car is running now. I will report back with the MPG data as soon as I can verify it. I highly recommend every S38/M88 owner use this tool. Huge improvements in idle and acceleration.

Before:

https://www.youtube.com/watch?v=x91Dia4 ... load_owner

After 5 minutes of adjusting:

https://www.youtube.com/watch?v=nINNnME ... load_owner

I can't tell you how much smoother and more refined my car is running now. I will report back with the MPG data as soon as I can verify it. I highly recommend every S38/M88 owner use this tool. Huge improvements in idle and acceleration.

Re: Balancing S38 ITBs

Wow. That sounds smoother too!

Re: Balancing S38 ITBs

My car will sound a bit like the first video if the idle is too low (700 ish) and more like the second at a slightly higher idle (900 ish). I wonder if the idle speed also came up before and after. The S38 is supposed to idle a little higher than most think it should based on other motors. But the balance (or lack of) is really apparent and much improved. I've done mine differently (2 at a time, many measurements/adjustments) but I'm due for a valve adjust and balance and I need to get set up like this.

Good stuff.

Good stuff.

-

wjtesquire

- Posts: 16

- Joined: Aug 07, 2010 8:42 AM

- Location: Charleston, SC

Re: Balancing S38 ITBs

I had my idle set higher so it would not struggle when the ac compressor cycled on. With the compressor off, I would see the idle speeds of about 900 rpm. When the a/c compressor cycled on the RPM would dip to about 700. After sync I set the idle to 700 and it doesn't change when the a/c compressor cycles on.

Re: Balancing S38 ITBs

That is really smooth then for 700 rpm. Nice. But I think BMW would say the idle speed on the S38 should be closer to 800-900 range. It also sounds like it is not dithering but the clip is only a few seconds. Did you look at the O2 output to see if it dithers from rich to lean every few seconds? If not you are supposed to adjust the AFM air bypass until it can dither.

-

wjtesquire

- Posts: 16

- Joined: Aug 07, 2010 8:42 AM

- Location: Charleston, SC

Re: Balancing S38 ITBs

I just calculated my fuel consumption over the last two tankfuls after using the manometer and averaged 16.6 miles per gallon. That is up from 14.3!

Re: Balancing S38 ITBs

Would a motorcycle synchronizing tool like the http://www.motionpro.com/product/08-0411 do a similar job as the MantisManometer?

Re: Balancing S38 ITBs

Yes, but you need six ports. Not many six cylinder bikes out there:)Bhart wrote:Would a motorcycle synchronizing tool like the http://www.motionpro.com/product/08-0411 do a similar job as the MantisManometer?

Dean

Re: Balancing S38 ITBs

I've done it with just two port manifold. Almost like using a vacuum gauge but you balance 5 to one master cylinder that you pick, #1 for example. You might have to go through a couple times but you can certainly get it quite good. You'll want some sort of restrictor to take the bounce out and you must be sure to clamp off any tube you remove or the fluid may get sucked out. ATF is good to use because it's easy to see, low viscosity, and if you suck it into the engine it shouldn't hurt anything.

The six port manifold is probably much better.

The six port manifold is probably much better.

Re: Balancing S38 ITBs

Made my first attempt with the mantis this evening. Boy were my cylinders off. I was able to even them out with the cylinder screws, but it looks like I'm going to have to tweak some of the other variables to get it right, as my vacuum average isn't quite right, and my idle speed is quite high.

My valves are adjusted, I set my butterfly valves with a dial indicator and all are resting on the stopper, my adjustment screws have been cleaned out and the seals replaced, and all the rubber intake boots have been replaced. There aren't many places left to have an intake leak. I currently have my idle speed screw tightened all the way and my idle speed is still high with one of the individual cylinder screws tightened all the way down, so I'm at the limit of the screws adjustment range.

I'm thinking 3 variables are left: intake leak (either in something that affects all cylinder, or in the boot or few seals that each cylinder intake has), butterfly valves are adjusted wrong allowing too much air to go past them when they are closed, idle valve is malfunctioning (stuck fully open), or there is some ECU variable at work (the war chip does have a tab for idle speed). I have some investigation to do this week/weekend.

My valves are adjusted, I set my butterfly valves with a dial indicator and all are resting on the stopper, my adjustment screws have been cleaned out and the seals replaced, and all the rubber intake boots have been replaced. There aren't many places left to have an intake leak. I currently have my idle speed screw tightened all the way and my idle speed is still high with one of the individual cylinder screws tightened all the way down, so I'm at the limit of the screws adjustment range.

I'm thinking 3 variables are left: intake leak (either in something that affects all cylinder, or in the boot or few seals that each cylinder intake has), butterfly valves are adjusted wrong allowing too much air to go past them when they are closed, idle valve is malfunctioning (stuck fully open), or there is some ECU variable at work (the war chip does have a tab for idle speed). I have some investigation to do this week/weekend.

Re: Balancing S38 ITBs

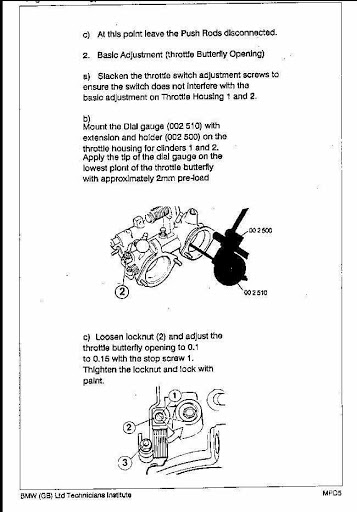

Double check the butterfly gap specs. If you read back through the thread I think there was some confusion on how it was quoted in the instruction sheet. It is not clear enough.

The gap should be .1mm-.15mm. That's about .004in - .006in. Mine was happier on the "closed" side of the adjustment.

Here is a photo of the service manual.

Sorry for any rework this caused you. I'll get the pdf updated.

Dean

The gap should be .1mm-.15mm. That's about .004in - .006in. Mine was happier on the "closed" side of the adjustment.

Here is a photo of the service manual.

Sorry for any rework this caused you. I'll get the pdf updated.

Dean

Re: Balancing S38 ITBs

I had done the adjustment in the past, so I didn't use your part of the kit for it. I'll go through the butterfly adjustment again and hopefully that fixes it. If memory serves me, I already adjusted it to as closed as possible (I've had trouble getting my idle speed low enough since the rebuild), but I will try to do it more carefully with your tool. I think I'll just put them all at full closed (butterfly resting against the intake runner) to see if I can get the idle lower than 800 rpm to verify that there's not something else that also needs to happen to lower the idle to the right rpm. I'll try to do that tonight.

Re: Balancing S38 ITBs

Have you checked your TPS to make sure it is sending the idle signal or even jumpered it on the harness side to force the signal. Does the War chip still have the provision to jumper the TPS input and put the computer in open loop mode without idle control. This is where you should be balancing everything anyway.

I'm not a fan of micrometer adjustment of the mechanical linkage. I would unplug the TPS to see where the default ICV position allows it to idle. If too high (>1000) I will close down the t/b's and sort of balance the t/b's with a gauge before fine tuning. I'll bet this is where you are right now. If you have adjusted the t/b's you'll loose it as soon as you tweak anything mechanical and have to repeat. So if that's the case just start over. I would set all the bypass screws about 1-1.5 turns open then balance the mechanical movement of the t/b's using a vac gauge and trying to hit about 900-1000 rpm on a warm engine with the TPS inputs bridged to run in open loop. Once the mechanical adjustment is about right you can proceed back through the individual adjustments. Then remove the jumper on the TPS harness and adjust the mixture on the AFM bypass to get slightly rich. Then re-adjust the TPS switch if needed and plug that back in. It should now be in idle control and dithering and you can use the big idle bypass screw to get the speed you want, but it should be about right.

If the t/b's are too far open the ICV will not close enough to bring the idle down and this may be where you are now.

If the t/b's are too far closed the ICV can't open enough to raise idle on a cold engine and keep it running right.

You need to be at the proper mid point in the ICV range or actually just above mid point with ICV slightly closed on a warm engine IMO.

I don't think you ever get there with measurement of the t/b's.

I'm not a fan of micrometer adjustment of the mechanical linkage. I would unplug the TPS to see where the default ICV position allows it to idle. If too high (>1000) I will close down the t/b's and sort of balance the t/b's with a gauge before fine tuning. I'll bet this is where you are right now. If you have adjusted the t/b's you'll loose it as soon as you tweak anything mechanical and have to repeat. So if that's the case just start over. I would set all the bypass screws about 1-1.5 turns open then balance the mechanical movement of the t/b's using a vac gauge and trying to hit about 900-1000 rpm on a warm engine with the TPS inputs bridged to run in open loop. Once the mechanical adjustment is about right you can proceed back through the individual adjustments. Then remove the jumper on the TPS harness and adjust the mixture on the AFM bypass to get slightly rich. Then re-adjust the TPS switch if needed and plug that back in. It should now be in idle control and dithering and you can use the big idle bypass screw to get the speed you want, but it should be about right.

If the t/b's are too far open the ICV will not close enough to bring the idle down and this may be where you are now.

If the t/b's are too far closed the ICV can't open enough to raise idle on a cold engine and keep it running right.

You need to be at the proper mid point in the ICV range or actually just above mid point with ICV slightly closed on a warm engine IMO.

I don't think you ever get there with measurement of the t/b's.

Re: Balancing S38 ITBs

My tps works, and I was doing the tuning with it jumpered. I think setting the bypass screws to the default position and using the butterfly stoppers isn't a bad idea to get it close, but another thing to keep in mind is that I'm not just adjusting idle here, ideally you want the throttles all in the same position so that at all other throttle positions are as closely matched as possible. I think the two goals with the mechanical linkage are that the butterflies don't rest against the intake wall (slowly wearing down the aluminum, or potentially binding and getting stuck), and setting them all to the same angle. If their resting angle is not to spec but you can get your idle rpm, afr, vacuum and wot angle correct, I think that's the way to go.

After writing the above I think my current plan is: set bypass screws and idle speed screw to default, adjust using the butterfly stoppers to get the vacuum readings as close as possible, then go in and measure the butterflies and try to set them to the average reading (so if 1-2 is .8, 3-4 is 1.1, and 5-6 is 1.2, I'll try to set them all to 1.03), then check WOT to make sure they're close at the other end of their range, and then use the bypass screws to fine tune. I think this should work assuming that I don't run into the limit of the bypass screw range (maybe I should start with more than 1 turn when doing the butterfly stopper adjustment), but it's possible that one of the intakes is worn so much that in same position as one of the other sets, it just lets too much air flow past the butterfly to let it stay at the same angle as the other two sets.

After writing the above I think my current plan is: set bypass screws and idle speed screw to default, adjust using the butterfly stoppers to get the vacuum readings as close as possible, then go in and measure the butterflies and try to set them to the average reading (so if 1-2 is .8, 3-4 is 1.1, and 5-6 is 1.2, I'll try to set them all to 1.03), then check WOT to make sure they're close at the other end of their range, and then use the bypass screws to fine tune. I think this should work assuming that I don't run into the limit of the bypass screw range (maybe I should start with more than 1 turn when doing the butterfly stopper adjustment), but it's possible that one of the intakes is worn so much that in same position as one of the other sets, it just lets too much air flow past the butterfly to let it stay at the same angle as the other two sets.

Re: Balancing S38 ITBs

I think you have a good plan. Absolutely agree you don't want any of the throttle plates completely closed so checking that out is a good idea. I think if they were fully closed you would need to open the bypass screws way far though. I think the adjustments you'll be making won't make a whit's difference at WOT, maybe at cracked throttle. For that try using the manometer both at idle and with the throttles all just off idle slightly, maybe 1500 rpm or so with a load on it from A/C, and if all is well you should get good balance both ways. If not you may have some slack to dial out of the linkages. Of course all that testing with bridge on TPS so it will not try to dither.

I think we may all measure the closed throttle position slightly differently and that is why I don't bother anymore. Factory trained with factory tools might work but I don't have that option. I tried my best the first time around I did this and got poor results because with the TPS unplugged my engine ran way too fast, maybe 1500 rpm. So I had to close down the t/b's ever so slightly with mechanical linkages in order to get the control range back and also off idle transition right, I think that's about 1000 roughly with TPS unplugged.

The M30 has the exact same issues and I follow the same procedure. Warm engine, unplug TPS, adjust throttle to about 1000 rpm in open loop, adjust and plug back in TPS. On the M30 you are done at that point... easy... maybe check the AFM bypass air.

I think we may all measure the closed throttle position slightly differently and that is why I don't bother anymore. Factory trained with factory tools might work but I don't have that option. I tried my best the first time around I did this and got poor results because with the TPS unplugged my engine ran way too fast, maybe 1500 rpm. So I had to close down the t/b's ever so slightly with mechanical linkages in order to get the control range back and also off idle transition right, I think that's about 1000 roughly with TPS unplugged.

The M30 has the exact same issues and I follow the same procedure. Warm engine, unplug TPS, adjust throttle to about 1000 rpm in open loop, adjust and plug back in TPS. On the M30 you are done at that point... easy... maybe check the AFM bypass air.