Page 10 of 24

Posted: Apr 22, 2014 2:46 AM

by tig

wkohler wrote:It is much easier and safer to pull the motor out the top. You are overthinking it. I bought a two post lift to drop subframes. At this rate, that will never happen.

Actually, if you have a 4 post lift, and want to be able to use it for pre- and post-op work, I don't think "easier" is true.

Here's the problem:

You can't pull the engine from the top while the car is on the 4 post lift. At least I can't with MY lift. Why?

Because the hoist legs won't go under the car when it's on the lift. The lift is in the way.

If you say "oh, just raise the lift a couple of inches". Now you've got the problem that the car is 6-8" higher than it would be if it were just on the ground. And I know my hoist (which is a pretty typical hoist) is "challenged" at getting the engine/tranny out even with the car at normal height (it doesn't stretch high enough).

Worse, there's not enough room in my garage at the front of the lift to maneuver the hoist. I could put the car on backwards, but that doesn't fix the first problem and negatively impacts my OCD.

Next if I remove the engine with the car in the driveway or other garage stall I still want to use the 4 post lift for things like removing the exhaust and driveline first and then working on the underside of the car after the engine is out I have to get the car onto the lift without an engine in it. Not impossible, but not easy either.

Now for "safe"? Please be specific on what part of the plan is more safe than generally using a 4 post lift and bridge jack well within design and specifications?

Posted: Apr 22, 2014 3:17 AM

by slimdevil27

I'm not saying it can't be done but...doing that way is ten times harder than it needs to be. How are you going to support the engine as you lift the car off it? With jack stands on the oil pan? I don't see how to securely hold the engine while you unbolt it, not to mention it still needs to be lifted slightly to remove the motor mounts and brackets before it will come out the bottom.

I will bring my engine hoist and my electric winch over. Pull the engine in the driveway and winch it onto the rack.....backwards and crooked

Posted: Apr 22, 2014 9:14 AM

by tig

slimdevil27 wrote:I'm not saying it can't be done but...doing that way is ten times harder than it needs to be. How are you going to support the engine as you lift the car off it? With jack stands on the oil pan? I don't see how to securely hold the engine while you unbolt it, not to mention it still needs to be lifted slightly to remove the motor mounts and brackets before it will come out the bottom.

I will bring my engine hoist and my electric winch over. Pull the engine in the driveway and winch it onto the rack.....backwards and crooked

Look, I really appreciate the help, but it's kinda frustrating that you are making a big deal out of this and clearly not reading what I wrote. I explained how I would support the engine above: with 4 jack stands. 2 on the subframe and 2 on the transmission.

I don't understand what the motor mounts have to do to with anything. They don't have to be undone until the car is raised above the engine and the engine is ready to be lifted away from the subframe with the hoist, the very last step.

The offer to bring your hoist over is generous and I would love another set of hands/eyes. If I change my mind and go with using a hoist, I'll do it in the driveway and I have an 18 year old who's capable of helping me push the car up on to the lift after.

The ONLY part of this that seems like more work to me than pulling from the top is disconnecting the suspension pieces. I need to disconnect those anyway while the engine is out because I plan on powder coating them. So it's a wash.

Posted: Apr 22, 2014 9:25 AM

by tig

FWIW, this is one of the places where I read about dropping the engine.

http://www.m535i.org/officers/ra/38.html

His technique is slightly different than my plan; I might use it. Specficially instead of supporting the engine/tranny on jack stands and lowering the lift to have them be actually supporting things before unbolting the subframe:

Use the hoist to put upward tension on the the engine from above (lift can be 8-12" or so off the ground), unbolt the subframe, lower engine to the pallet, disconnect hoist, use lift to raise car the rest of the way.

Nice thing about this is the pallet has wheels on it. I need to figure out where to get one of those rolling pallets.

Posted: Apr 22, 2014 11:00 AM

by slammin_e28

Your lift does bring about various complications.

I'd say drop it from the bottom. Undo the upper strut mounts, subframe, trans mount/crossmember, driveshaft, sway bar, control arms and lift the car up off the assembly. Don't even have to pull the front wheels. However I've only ever done this with a two post lift.

I always had trouble getting the hoist under my car for the simple reason the legs hit the control arms. Had to lift it up Anyway. Last time I took the engine/trans out thru the top (e32 hood struts FTW).

Or just make the radiator core support removable like I did on my e30. Even just the upper portion so you can retain structural integrity of the lower part, if your worried about that. E34s came factory with removable rad supports. Makes life so much easier, especially if you plan on R&Ring the engine in the future.

Posted: Apr 23, 2014 12:45 AM

by slimdevil27

Look, I really appreciate the help, but it's kinda frustrating that you are making a big deal out of this and clearly not reading what I wrote.

Guilty as charged. I've never pulled a subframe on a 4 post, plenty on a two post, but my gut reaction was that it looked over complicated and dangerous.

It's not the way I would do it, so it sucks. Wanting to powder coat things is just a lame excuse to do it your way

Posted: Apr 27, 2014 1:11 AM

by tig

On Thursday I had run the gas tank down close to empty. I parked Vlad on the lift and drove my wife's 135i on Friday.

This morning I was going to meet a guy restoring an E9 and wanted to show him Vlad so I figured I'd use a bit more gas. It wouldn't start. I actually think I really ran it out of gas or the in-tank pump has died and that's that. No doubt it is time to pull the engine.

After watching the Sounders trounce Colorado I dove in. Step one was to unpack my new toy, an

underhoist stand.

Getting the IE exhaust off the car was a BITCH. Even with my trusty stand. It might have been slightly easier if I had help, but pulling the exhaust off the headers was just a bear. I ended up using a bunch of PB Blaster and used my heat gun to heat up the exhaust piping so it would expand a little. My back is shot as a result. But I got the damn thing off.

FWIW, I'm seriously considering constructing a new exhaust as part of this project. I really don't like the way the IE fits and I want to build something just a little more subdued sound-wise. The guy restoring the E9 I saw today had fabricated a killer exhaust from magnaflow parts and he's hooking me up with the guy who helped him weld it.

I took tons of pictures of the drive shaft before removing it. I keep learning (!) that I simply can't take enough pictures. I also used a paint pen to mark where everything was aligned, even though I'm putting in a new 'reman' drive shaft. Just in case.

I used Bentley to guide me in removing the drive shaft. I came out easily. I need to order new nuts for the flanges.

Took a picture of how the vibration damper was installed. The Realoem diagram shows it installed backwards to this. Hmmm...

If I find time tomorrow, the plan is to drain and remove the radiator and start removing other stuff. I doubt I'll get enough time with my son to actually drop the engine, but it's possible.

Posted: Apr 27, 2014 9:41 AM

by wkohler

Wait, so why didn't you figure out why the car wouldn't start? The in-tank pump will not prevent a car from starting.

Also, throw that vibration damper away. The RealOEM diagrams for the Euro cars show it in a little trash can in the corner.

Posted: Apr 27, 2014 11:58 AM

by pleasefixitup

don't forget a new guide bushing in your driveshaft. have fun getting the old one out.

Posted: Apr 27, 2014 11:58 AM

by wkohler

pleasefixitup wrote:don't forget a new guide bushing in your driveshaft. have fun getting the old one out.

Grease gun.

Posted: Apr 27, 2014 12:42 PM

by tig

pleasefixitup wrote:don't forget a new guide bushing in your driveshaft. have fun getting the old one out.

Thanks. Not quite sure what that is, but now at least I know it'a something.

Posted: Apr 27, 2014 1:10 PM

by tig

wkohler wrote:Wait, so why didn't you figure out why the car wouldn't start? The in-tank pump will not prevent a car from starting. .

Thanks for giving me shit about that. You are right I should have tested so I knew for sure. I just did a quick test of the fuel pump (relay trick) and the main pump is running, but not pumping anything. I ran it out of gas (which was my goal, I just didn't expect to run it ALL the way. I guess my goofing around with the mixture this week, to make it run richer worked and it was getting shittier gas mileage thus my calculations of how much gas was left was off).

To further verify I did the 'ole "take the gas cap off, bounce the rear of the car, and listen for sloshing" test. No sloshing.

Posted: Apr 27, 2014 2:24 PM

by johnnye23

Damn if you didn't take so many pictures and feel the need to post it all you would probably be done by now.

Not exactly ground breaking modifications going on.Feeling grumpy today , carry on.

Posted: Apr 27, 2014 2:27 PM

by tig

johnnye23 wrote:Damn if you didn't take so many pictures and feel the need to post it all you would probably be done by now.

Not exactly ground breaking modifications going on.Feeling grumpy today , carry on.

Posted: Apr 27, 2014 2:35 PM

by tig

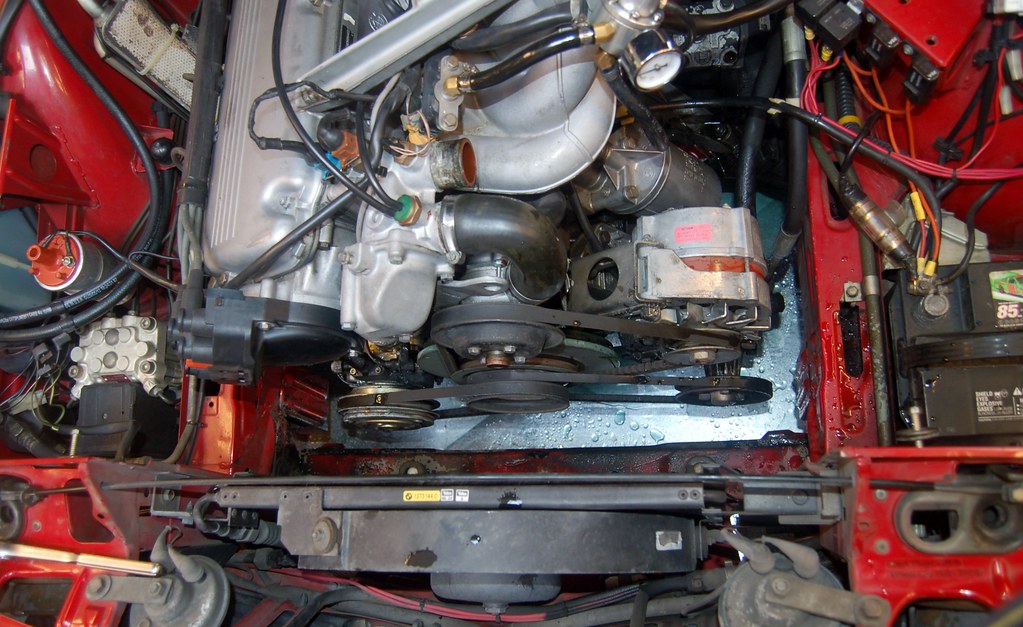

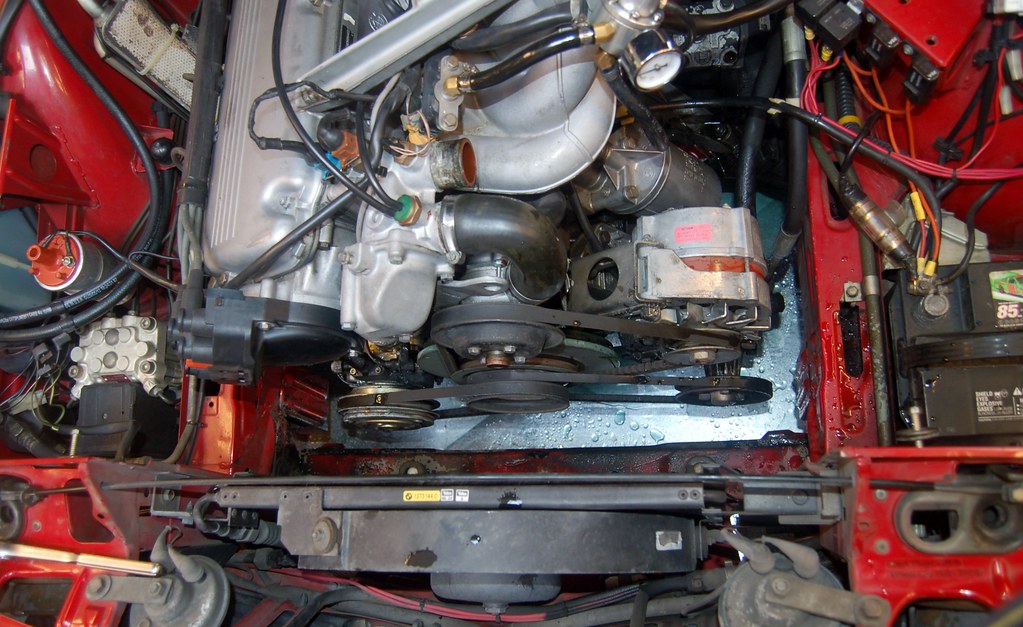

Got the coolant drained, pulled the radiator, and started disconnecting other stuff. PS pump, cap, fuel, etc...

I'm at the point that I need to pull the strut brace off to make things more accessible. I am getting it powder coated black since I bought it used and slightly rusty.

Tons of pictures so that I can refer back. For example, I have no idea what this wire is for and don't yet know if the B35 harness has a connector for it.

Family is home so I'll either get help from my son now, or I'll have other stuff to do the rest of the day. We'll see...

Posted: Apr 27, 2014 4:56 PM

by vinceg101

Posted: Apr 27, 2014 9:00 PM

by tig

Got some help from my son this afternoon. We got everything disconnected except steering.

After jacking the car up on the lift using the bridge jack, and leaving it supported by jack stands at the front jack points, we did a few tests to see how my large jack stands would work under the subframe.

In the picture above the car (subframe) is just barely touching the the jackstands. The weight of the front of the car is still entirely supported by the jackstands at the jackpoints. We did a test where we lowered the lift such that the car was supported only by the subframe. It seems like it will work fine.

One only tricky part will be getting the u-joint off the steering box. I could pull the kickpanel in the dash, and pull the steering column out, but it seems easier to just loosen the u-joint nut/bolts at the steering column and then as we raise the car from the sub-frame, ensure it slides of the splines. We thought about figuring out how to suspend the steering box if we unbolted it from the subframe, but just couldn't come up with anything.

Either way we'll have to drain the brake/steering fluid (which I have to do anyway because I'm going to replace the bomb while I'm in there).

Posted: Apr 28, 2014 2:08 AM

by vinceg101

Just a question, but do you have anything that secures those front jack stands to the lift?

I'm sure you do this all time, but from where I'm sitting it looks pretty precarious if they're just sitting there on the edge of the lift. Especially if your under there torquing away on something.

Other than that, thanks for the detailed set of "instructions"; this is helping my research.

Posted: Apr 28, 2014 11:30 AM

by tig

vinceg101 wrote:Just a question, but do you have anything that secures those front jack stands to the lift?

I'm sure you do this all time, but from where I'm sitting it looks pretty precarious if they're just sitting there on the edge of the lift. Especially if your under there torquing away on something.

Other than that, thanks for the detailed set of "instructions"; this is helping my research.

Reasonable question. The jackstands are primary and have about 2" of space between their legs and the edge of the lift ramps. It's highly unlikely that any sort of force could be strong enough to laterally shift the car 2", but just in case, the bridge jack is positioned under the frame rails as backup. It can't be any further forward than it is, or the transmission won't be able to drop, and it's forward of the center-of gravity but not so much that I'd make *it* primary. So it's backup. I also have the wheels under the rockers as a 2nd backup.

Posted: Apr 28, 2014 12:23 PM

by vinceg101

cek wrote:vinceg101 wrote:Just a question, but do you have anything that secures those front jack stands to the lift?

I'm sure you do this all time, but from where I'm sitting it looks pretty precarious if they're just sitting there on the edge of the lift. Especially if your under there torquing away on something.

Other than that, thanks for the detailed set of "instructions"; this is helping my research.

Reasonable question. The jackstands are primary and have about 2" of space between their legs and the edge of the lift ramps. It's highly unlikely that any sort of force could be strong enough to laterally shift the car 2", but just in case, the bridge jack is positioned under the frame rails as backup. It can't be any further forward than it is, or the transmission won't be able to drop, and it's forward of the center-of gravity but not so much that I'd make *it* primary. So it's backup. I also have the wheels under the rockers as a 2nd backup.

Ah, I see the bridge jack now. I somehow inferred from your write-up that the bridge jack was at the rear (don't know why I would have thought that).

Carry on.

Posted: Apr 28, 2014 12:38 PM

by Mike W.

That's an awfully damn clean engine to be pulling out.

Looks like you really keep up on it, usually only the new one going in is nice and shiny.

Posted: Apr 29, 2014 10:07 PM

by tig

Yea. I have a big ?? about what I'm going to do with the old engine. Current plan is to store it and find an chassis that would love a high mileage turbo and use it as an excuse to learn forced induction, of which I know nothing except general principles.

Posted: May 03, 2014 6:58 PM

by tig

Not a ton of time to wrench today...

I freed the AC compressor and used zip ties to hold it in a place where the hoses aren't being strained and it'll be out of the way.

I've never done transmission work before so I'm just kinda plodding along. I read Bentley on how to remove the shift linkage and that's coming along. The rubber boot had a rip in it already and basically fell apart in my hand as I pushed the wire for the backup sensor through.

I'll be ordering a new one. While I'm at ordering parts, what other shifter related parts are worth replacing while in there? I have half a mind to do a short shift kit. I liked the one that was on my 540 M-Sport (UUC) but don't have any issues with the way this car shifts either.

Recall that I do have a new clutch and clutch kit...

Posted: May 03, 2014 7:58 PM

by tig

I'm still contemplating the drop or out the top plan.

While under the car today I planned on taking off the tie rod arms. Then I realized my rod end puller really won't fit in there easily. I also don't have a 17mm spanner for loosening the bolts on the drag links. What originally seemed like a straight forward task became harder.

Since my son is off reffing lacrosse today I'm solo so I can't really pull the engine anyway I figured I'd toy around with how the hoist would work with the car on the lift in the garage.

I can def make it fit in front of the car, and assuming I could lift the engine & transmission high enough to clear the top of the AC condenser I could maneuver the hoist around the front of the car (or lift the car all the way up on the lift and just go under).

However, my hoist has poor "reach" when set for 1/2 ton and the engine will want to come forward ~6" once there's tension on it and the mounts are undone. The engine/transmission are about 500lbs, right? That's 1/4 ton... maybe I can put the hoist at 1/4 ton still be w/in safety margins?

If I did that then there'd not be a reach problem, but it might be more tricky maneuvering the hoist w/ engine hanging on it around the front of the car.

Posted: May 03, 2014 9:27 PM

by elcrazon

I pulled a m30 from my e24 using that hoist, presuming it's the one from harbor freight, in the 1/4ton position and it worked fine, though I had the bumpers off and it was still a bit tight. I'd guess you probably have about the same clearances due to the much deeper front clip on the e24. Use of a load leveler was pretty much essential to get the right angles, but I had mine much closer to the boom since the hook wasn't attached by a length of chain. When I put it back I used a Torin hoist that had ~5" more reach on the arm, and that made it a bit easier to maneuver.

Posted: May 04, 2014 9:13 AM

by Nanajoth

I suggest pulling the hood, I pulled mine by myself and rubbed the underside of the hood which was no big deal since I am doing a repaint. I was not using a leveler, which would help you out. I also had the front jacked up on the lowest setting on a pair of jack stands.

Posted: May 06, 2014 2:09 AM

by mitch5

From my experience, the best way for pulling the m30 with trans attached was to just undo the hood shocks(where they attach to the car) and just stick the hood straight up. I would suggest pulling the engine in the drive way where you have lots of open space. By time you extend the boom and lift the engine to clear the core, you will have very little room in a garage.

Posted: May 06, 2014 2:16 AM

by wkohler

Yeah, get the car off the lift. That's not helping. Get everything unbolted using the lift, roll the car outside, put the hood straight up and go from there. I didn't put the hood straight up when I did it, but I pulled just the engine. Reason being, I was going to leave it in the car when I sent it to the yard but a friend needed a motor. Otherwise, I'd have done motor and trans together. Here I was with a car that had no suspension on it and couldn't move facing outward in my garage. I soon discovered that the garage door was in the way, so I had to put the floor jack under the front subframe, remove the stands and lower the car as far as it would go. It was tricky but it went like butter.

I did everything myself.

Posted: May 07, 2014 7:49 PM

by John McA

Load leveler closer to engine, is better, up to a point. Jack stands? Check.

I pulled m30 and 5sp tranny w/o messing with hood this way and solo too - I think this really is a better single person deal to do..

Just take it slow, check it out multiple times, stay focused and, don't imbibe. With the trans it's likely close 1 kip (1000lbs) and, has value. Have an engine stand ready. I first mounted it (the stand) on the side of the block and, found it more stable plus able to do the work on the flyw side.

Good Luck,

Great pics,

John McA

Re: Noob M30B35 Build. 2014-05-24: Engine is out!!!

Posted: May 24, 2014 7:08 PM

by tig

Woo-hoo!!!!!

With the help of CJ and his buddy we dropped the engine out today. It went pretty much as I planned.

I'll do it through the bottom again, but next time I'm removing the headers first.

I plan on putting the new engine in through top though without the transmission attached.