Me too, I have no idea where it is. Another car I should have finished but didn't because I'm retarded.wkohler wrote:I miss that E3. Where did it end up?

I weld

Re: I weld

Re: I weld

Nice progress Cek. I think you'll find it more gratifying (and addictive) the more you do it.

If you are thinking about buying used when you make the jump to Mig, another machine to keep an eye out for would be a Millermatic 200.

Mine is circa 1991 and I really like it. If you can find a clean one it is a whole lot of machine for the money.

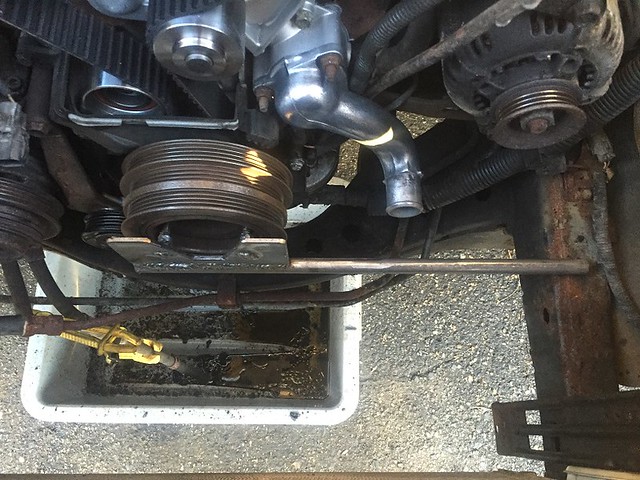

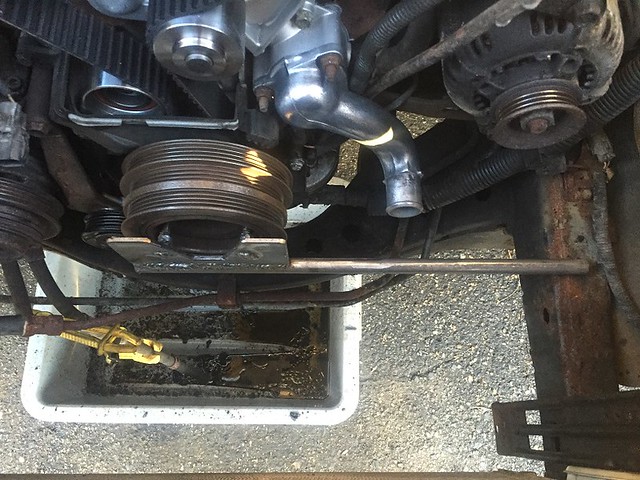

I used mine this past weekend to make a tool to hold the crank pulley while removing / re-torqueing the crankshaft bolt on our 4Runner.

Not the prettiest thing, but it did the job.

tool2

tool2

tool3

tool3

If you are thinking about buying used when you make the jump to Mig, another machine to keep an eye out for would be a Millermatic 200.

Mine is circa 1991 and I really like it. If you can find a clean one it is a whole lot of machine for the money.

I used mine this past weekend to make a tool to hold the crank pulley while removing / re-torqueing the crankshaft bolt on our 4Runner.

Not the prettiest thing, but it did the job.

tool2

tool2 tool3

tool3Re: I weld

slack wrote:Nice progress Cek. I think you'll find it more gratifying (and addictive) the more you do it.

If you are thinking about buying used when you make the jump to Mig, another machine to keep an eye out for would be a Millermatic 200.

Mine is circa 1991 and I really like it. If you can find a clean one it is a whole lot of machine for the money.

I used mine this past weekend to make a tool to hold the crank pulley while removing / re-torqueing the crankshaft bolt on our 4Runner.

Not the prettiest thing, but it did the job.

tool2

tool3

Making tools is the best.

Re: I weld

How ...er, likely homo erectus (NTTAWWT).bkbimmer wrote:Making tools is the best.

Re: I weld

Uncle Leo, HELLO.Karl Grau wrote:How ...er, likely homo erectus (NTTAWWT).bkbimmer wrote:Making tools is the best.

Re: I weld

Needs paint.bkbimmer wrote:I weld but also build.

-

Sharkpilot

- Posts: 18

- Joined: Nov 01, 2015 12:53 PM

- Location: CT

Re: I weld

I am in the process of buying a MIG as well - think I have narrowed it down to a Miller 211. Keep us updated on your learning curve.

Check out this thread on welding: http://retrorides.proboards.com/thread/119596

This guy knows what he is doing and its on a e28 M5! Also check out his other threads on how to fabricate panels.

Check out this thread on welding: http://retrorides.proboards.com/thread/119596

This guy knows what he is doing and its on a e28 M5! Also check out his other threads on how to fabricate panels.

Re: I weld

So it seems like even buying used, you’d need to spend at a minimum, $700-$1,000 for anything decent. Assuming I got any good at it, I’m not sure there’s enough welding in my future to warrant the expense.

I might be better off just flying my cousin down from Berkeley when I need welding done. He seems to have the hang of it.

I might be better off just flying my cousin down from Berkeley when I need welding done. He seems to have the hang of it.

Re: I weld

That is nice work.

Re: I weld

That was a great read. How he made this from a flat piece of steel, I'll never know. That's some skill.Sharkpilot wrote:I am in the process of buying a MIG as well - think I have narrowed it down to a Miller 211. Keep us updated on your learning curve.

Check out this thread on welding: http://retrorides.proboards.com/thread/119596

This guy knows what he is doing and its on a e28 M5! Also check out his other threads on how to fabricate panels.

Edit: next page shows he did use 2 pieces on that, but still.

Re: I weld

It's not hard if you have a few special tools, steel is easy to form.86GT635 wrote:That was a great read. How he made this from a flat piece of steel, I'll never know. That's some skill.Sharkpilot wrote:I am in the process of buying a MIG as well - think I have narrowed it down to a Miller 211. Keep us updated on your learning curve.

Check out this thread on welding: http://retrorides.proboards.com/thread/119596

This guy knows what he is doing and its on a e28 M5! Also check out his other threads on how to fabricate panels.

Edit: next page shows he did use 2 pieces on that, but still.

Re: I weld

I made this out of one piece of metal in less than thirty minutes. Patch on my e24 wheel arch.

I put a little more curve in it with my shrink before I welded it on the car.

I put a little more curve in it with my shrink before I welded it on the car.

Re: I weld

I really wish you'd make a thread on that car, I remember a few years ago you were talking about making a steel front spoiler. Are you serious about closing your shop?

Re: I weld

I close it everyday.86GT635 wrote:I really wish you'd make a thread on that car, I remember a few years ago you were talking about making a steel front spoiler. Are you serious about closing your shop?

I don't think this crappie e24 deserves a proper build thread.

Re: I weld

Brent, I will drive up to Oregon with a car full of hookers and a trunk full of beer if you'll fix what I think I'm going to find when I remove the trunk full of beer's seal/gasket.bkbimmer wrote:I made this out of one piece of metal in less than thirty minutes. Patch on my e24 wheel arch.

I put a little more curve in it with my shrink before I welded it on the car.

Yeah, I don’t how a talentless hack like me could be related to him or his brothers, who are also talented. Maybe I was adopted.bkbimmer wrote:That is nice work.

This is gate he did for the public swimming pool in Madison Wisconson.

Re: I weld

Karl Grau wrote:Brent, I will drive up to Oregon with a car full of hookers and a trunk full of beer if you'll fix what I think I'm going to find when I remove the trunk full of beer's seal/gasket.bkbimmer wrote:I made this out of one piece of metal in less than thirty minutes. Patch on my e24 wheel arch.

I put a little more curve in it with my shrink before I welded it on the car.

Yeah, I don’t how a talentless hack like me could be related to him or his brothers, who are also talented. Maybe I was adopted.bkbimmer wrote:That is nice work.

This is gate he did for the public swimming pool in Madison Wisconson.

I don't like beer, you had me a hookers.

Re: I weld

Happened to wander into a pawn shop this morning.

Saw this:

The were asking $899. It has everything that came with it but the manual and 120v power plug adapter. It does have the 230v power plug.

Got them down to $720. Cash back guarnatee w/in 7 days...

Took it home and verified the wire fed smoothly and it made a spark. Yay.

Now to get a gas cylinder and cart for it....

Saw this:

The were asking $899. It has everything that came with it but the manual and 120v power plug adapter. It does have the 230v power plug.

Got them down to $720. Cash back guarnatee w/in 7 days...

Took it home and verified the wire fed smoothly and it made a spark. Yay.

Now to get a gas cylinder and cart for it....

Re: I weld

Sweet, that will come in handy.

Re: I weld

Amazon Prime Sunday Delivery is da' bomb.

This arrived at about 1:30pm today:

https://www.amazon.com/gp/product/B00440DVE4

Assembly took about 45 minutes.

This arrived at about 1:30pm today:

https://www.amazon.com/gp/product/B00440DVE4

Assembly took about 45 minutes.

Re: I weld

Where's the Scooba tank?

-

muleskinner

- Posts: 1340

- Joined: Sep 08, 2007 11:17 AM

- Location: John Graham ATL

Re: I weld

So does this Nobel prize winner. I suppose you could call it "cold irons bound"

Re: I weld

All the dive shops were closed over the weekend.bkbimmer wrote:Where's the Scooba tank?

Re: I weld

My dive shop is open Saturday.

Re: I weld

You're almost a professional.

Re: I weld

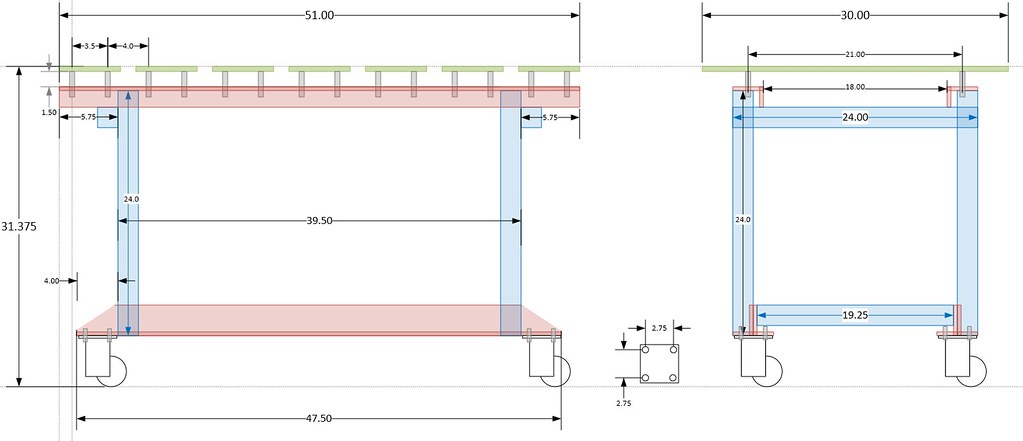

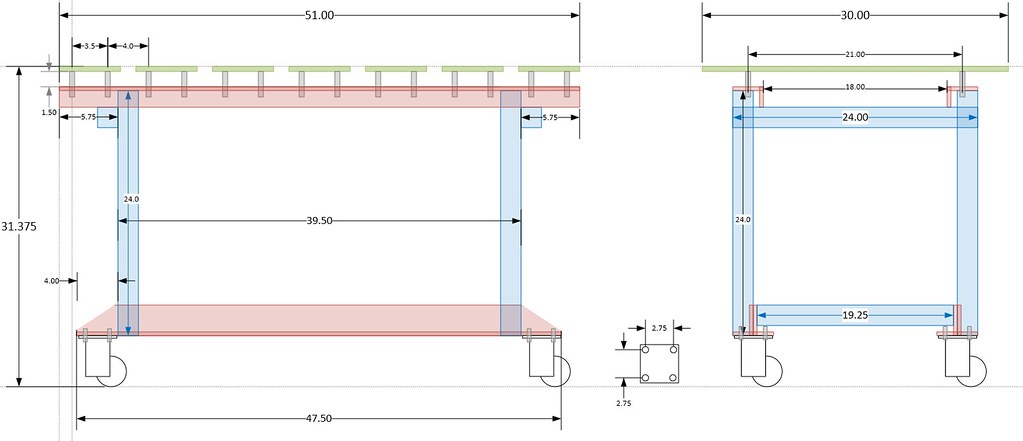

I have been collecting ideas from welding table-build threads for years. I finally settled on a design based on @AMCGuy's thread on GarageJournal.com: http://www.garagejournal.com/forum/show ... p?t=180145

His looks like this:

In my case I decided to go with beefier steel (mostly because I was unsure of what to order and decided I'd be better with thicker than too thin). I'm also making mine slightly smaller (51" instead of 60", but still 30" deep and about 32" high). I also wanted more overhang so that I could maneuver around the table easier.

My materials:

Planks: 6" x 1/2" x 30" set 1.5" apart

Long-side horizontal pieces: 3" x 2" x 3/8" angle

Short-side horizontal pieces and legs: 2" x 2" x 1/2" square tube

Casters: Heavy Duty Leveling Casters from McMaster Carr. They look like this:

The steel came last weekend and I've been practicing cutting and welding and dreaming of how the table would get laid out.

I finally got enough clarity in my head to start making drawings. I think I have it all figured out...

The design:

Green are the 6x1/2" planks.

Red are the 3x2" angle iron. Note the one for the top has the 3" side horizontal (where the bolts will go supporting the planks) and the bottom one has the 3" side vertical. The bottom one extends 4" past the legs and will be mated with a 4" section of 3x2" angle iron making a 4x4" base for each caster.

I'm mounting the short-side top horizontal member on the outside so it can serve as a receiver for tools. It will also support two 2.5" trailer hitch receivers facing out the short side (not in diagram).

Probably way more complicated (and stout) than I'll ever need, but the real point here is to have a real project to learn to weld with.

Tomorrow I'm gonna start cutting for realz!

His looks like this:

In my case I decided to go with beefier steel (mostly because I was unsure of what to order and decided I'd be better with thicker than too thin). I'm also making mine slightly smaller (51" instead of 60", but still 30" deep and about 32" high). I also wanted more overhang so that I could maneuver around the table easier.

My materials:

Planks: 6" x 1/2" x 30" set 1.5" apart

Long-side horizontal pieces: 3" x 2" x 3/8" angle

Short-side horizontal pieces and legs: 2" x 2" x 1/2" square tube

Casters: Heavy Duty Leveling Casters from McMaster Carr. They look like this:

The steel came last weekend and I've been practicing cutting and welding and dreaming of how the table would get laid out.

I finally got enough clarity in my head to start making drawings. I think I have it all figured out...

The design:

Green are the 6x1/2" planks.

Red are the 3x2" angle iron. Note the one for the top has the 3" side horizontal (where the bolts will go supporting the planks) and the bottom one has the 3" side vertical. The bottom one extends 4" past the legs and will be mated with a 4" section of 3x2" angle iron making a 4x4" base for each caster.

I'm mounting the short-side top horizontal member on the outside so it can serve as a receiver for tools. It will also support two 2.5" trailer hitch receivers facing out the short side (not in diagram).

Probably way more complicated (and stout) than I'll ever need, but the real point here is to have a real project to learn to weld with.

Tomorrow I'm gonna start cutting for realz!

Last edited by tig on Nov 29, 2016 4:00 PM, edited 1 time in total.

Re: I weld

Way to overthink it.

Re: I weld

I know, right?bkbimmer wrote:Way to overthink it.

Re: I weld

You are a way more professional looking welder than I am.