Page 2 of 3

Posted: Jan 18, 2008 2:02 AM

by turbodan

///ARINUTS... wrote:How much does a GT3076R cost new? used?

I don't think you could touch a new one for under $1000 and used ones would fetch at least $500. I paid less than $150 for my used HX35, and its been working great with no issues.

I have no problem using a garrett, I use one on my 1983 Mercedes Benz 300SD.

I thought the question was wether or not Holset turbos are "better" than Garrett turbos? My point here is that Garrett is at least as legit as Holset. I'd go as far as to say Garretts products are better, but without having any real info on the Holset turbos, I cant really say. I'm not even talking about the GT series either. The T series stuff is also quite good.

That said, I just sold my used GT2871 for 720. But lets not forget I'm talking about are the new GT series ball bearing units. I'm sure you can get a good used journal bearing T3 or T4 for the same price as a used Holset. Thats a fair comparison.

Posted: Jan 18, 2008 11:05 AM

by ///ARINUTS...

Well, we were discussing the divided turbine inlet theory also. On a big turbocharger, taking advantage of that technology will make it feel like a much smaller turbocharger in terms of spool up. Garrett uses the divided turbine housing now days too.

Since Holset was widely using that technology before the HX series ( h1c,h1e,h2d,etc.) for at least 25 years or so, they are very available. and because of that, I would say your average Holset is better than your average Garrett. The holset HX series, which also has the anti surge compressor housing, has been out since the late 80's and have been used on production vehicles since the early 90's. the garrett GT series has been out since 2000 or so? and I don't know of too many production vehicles using it. You rarely see them being sold use, and even then they fetch over $500, and new is over a grand. you can pick up an HX35 or HX40 on ebay for under $400 at any given time and day, go to a junk yard and pick up for $200 tops out of a diesel dodge ram. and they are proven to withstand the most grueling conditions. most Holsets reach the 200,000 mile mark without a rebuild. I learned a lot about holsets in the last 2 years or so, For the price you just can't go wrong, your comparison of a gt3076 proves it, thats one of the best turbos garrett has. just check this out:

http://forums.turbobricks.com/search.ph ... id=1747335

thats a search for key word holset at

www.turbobricks.com , you can also search it at

www.e30tech.com or PM ixer, he knows much more than I ever will.

I'm not saying garrett turbos are not good. On the contrary, they have and always will make good turbos. Just get a real garrett, not a knock off. But for the money spent, you just can't get much better than a Holset Hx35.

Posted: Jan 18, 2008 12:33 PM

by Brad D.

While this has absolutely nothing to do with the price/performance/suitability of the Holset, one of its downsides is that if you wan to use it you will need a custom manifold as they are typically a t3 footprint (at least the HX and HY series are IIRC) and there large housings for what they are will not fit a TCD manifold and tuck under the engine (they are also not on-center housing so it would never work). If you can fab, its not a big deal - make your own mani. If you have to buy a $1000 custom manifold to use the Holset, the cost advantage is kind of lost.

Posted: Jan 18, 2008 12:54 PM

by turbodan

Well, I guess we're going to have to agree to disagree. The divided turbine inlet has been around before Holset. Believe it or not, you can find AiResearch turbos from the 60's and 70's with divided turbines. Not that it matters. To assume that a divided turbine inlet is just better than an undivided inlet would be dumb. I dont see the need for a divided turbine inlet on a high powered gasoline engine. Sure, you can use them, but theres no reason why. Its pretty silly to expect gains from exhaust pulses when you're spooling at 3 or 4 thousand RPM.

The big turbo/quick spooling thing you're reffering to has been available for years with Garrett hybrid turbochargers. T4 compressor, T3 hot side. What a concept. You can have all the spool you want, as long as you have enough wastegate to keep things from backing up.

For almost all applications, you dont even need an anti surge compressor housing. You dont want to run one either, unless you have to. The anti surge feature works at the cost of compressor efficiency. So its costing you to run it if you dont actually need the anti surge feature. Since Garrett publishes compression maps, its easy to plot your motor out and select the right turbo. You'll find that the maps and efficiency islands are quite wide, so you'll have no problem running a conventional compressor housing.

Garrett offers divided turbine inlets on some of thier turbos for some applications. They didnt just now start offering the option, and they dont offer it for all of thier turbos because its not good for anything most of the time. As far as reliability, Garrett turbos go at least as long as Holsets, and the ball bearing units will certainly last longer under even the most extreme conditions. You dont find the GT or GT-K series in OEM applications for reasons of cost. The T series turbos and other brands work "well enough" to do the job. They're not the most efficient, they're not the best performing, but they do the job.

Still, since we have no real information on the magical Holset turbos, I really cant say how much better Garrett's products are. If there were real compression maps out there it would be easy to see that Garrett wheel designs have wider maps and function more efficiently. But, we dont have anything from Holset, so who knows how much better the average Garrett is. If you can produce some real compression maps for any Holset turbos, we could continue to discuss this. I understand that you think they're better, but I dont buy that. There are a whole lot of people hanging off of the great Holset nutsack, but noone can give you any information about them. I'll pass on that...

Posted: Jan 18, 2008 2:49 PM

by Brad D.

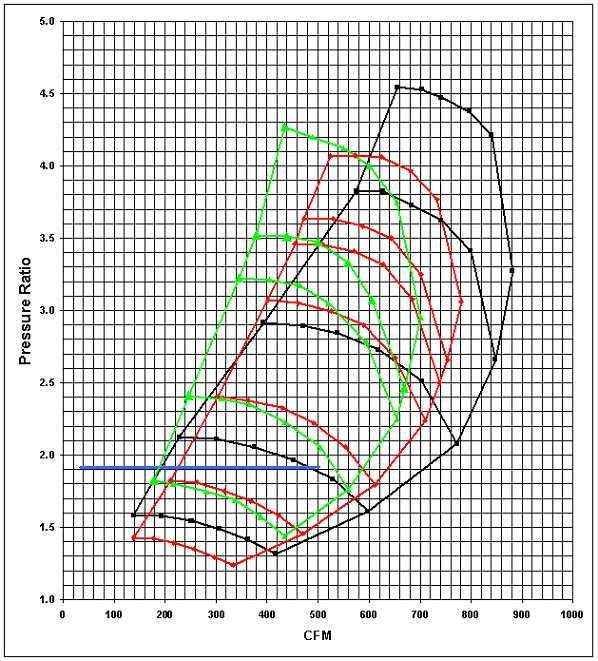

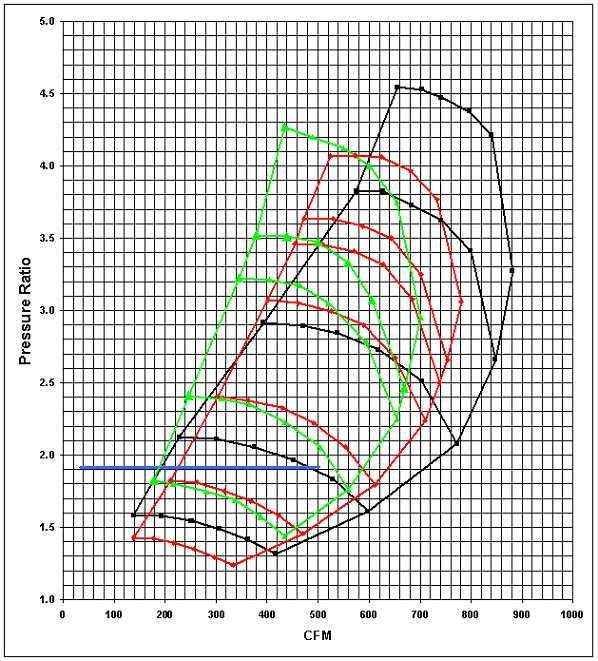

Pre-2003 HX-35 in Green. 2003 - 2004.5 HY-35 in Black. 2004.5 - Present HY-35 in Red.

I have no idea where the map came from and it sucks because it has no marked efficiency islands, so a comparison still really isn't possible.

Here is a map that is supposedly from an HY35W off of a new Cummins.

While the last map isn't bad, its definitely not anything special except it seems a bit more efficient at very high pressure ratios (its diesel application is apparent here). It seems somewhat similar to a GT30 compressor wheel but the surge line is much more favorable on the Garrett wheel.

Posted: Jan 18, 2008 8:42 PM

by ///ARINUTS...

Lets Go back to what started his geat debate.

turbodan wrote:Holset turbos are for trucks.

Do we still really believe this?

turbodan wrote: I've never had a problem with spool running undivided turbine housings. I would bet that most of the gain in spool time with divided turbines is from the reduction in cross sectional flow area . I hear a lot about maintaining exhaust pulses up to the turbine, but it seems like the only OE application of this technology is in low rpm diesel motors. I'm pretty sure that you dont really gain anything from divided inlets when your turbo is sized to spool over 3000 rpm. The actual gas flow through the turbine will spool it up, wether or not the exhaust pulses are intact will make a slight , slight difference. Like I said, it might only be worthwhile on low RPM motors.

Lets stay on topic here. I never said Holset invented the divided housing. No matter what turbo you end up using, If you have 2 identical turbos, and the only difference is the divided turbine housing, with the proper manifold, the one with the divided turbine housing will spool quicker, Why else would any one turbo supplier make the divided turbine housing? If a turbo could spool a few hundred RPM earlier, why wouldn't you use that opportunity? Divided entry turbines offer better transient response and lower exhaust back pressure than single entry turbines, neither of which are bad things. To me the single inlet turbines are a compromise imposed on people due to crappy stock turbo exhaust manifolds. The turbo in itself won't solve performance problems inherent in a bad exhaust manifold design. I call the holsets modern because most of the the time we are talking about the KKK K27 found on the 745i ( and I know, I own a 745i). and turbos like "TO4B" , those things are ancient. You could probably fit their entire compressor map within the 70% efficiency island of the HX40. ( sorry, I know, I'm going off on a tangent here ) (There are still people who think of using those things, just a few threads away there is a build thread using factory 745i parts. )

Also remember that we have an older 2 valve/cyl engine which needs more cam duration to flow as much as a modern 4 valve/cyl engine - and these GT30R ( and even the GT35R ) are aimed at these more modern engines where a smaller turbine and higher exhaust back pressure are acceptable, thats a bad thing about the Garrett GT turbos , in my opinion, for our applications. It's something you never see on a diesel Holset HX. Very small turbine housings for the fast spool but it may be right out dangerous for your engines longevity, high average cylinder pressures and high top-end exhaust back pressure is not a good thing. So we Want bigger exhaust housings, we need bigger exhaust housings, its better for our engines, and hey! they make more power, but the lag thing is always hanging over our heads, thats why we ( I ) want use the divided turbine housings, to make up for what I loose.

All things considered, I believe that using a holset HX35 or Holset HX40, and taking advantage of the divided turbine housing by keeping exhaust pulses separate, is a good cost effective way of turbo charging an m20 or an m30. They are available cheap and they are good strong turbos. If you want to do something else, hey, who am I to stop you.

That being said, it's not the only way, many people are happy with other solutions. I'm not knocking it. But I'm not looking to dump more money that what the car is worth, lets face it,

MOST E30s,E28s , E23s, E34s And E32s are not worth more than $5K, ( don't shoot me ) If you want to spend over $1000 on a turbo, thats your prerogative, but I'm happy spending much less for the same effect.

My opinion is to find a well suited turbo, ( 50-60 mm compressor inducers) As you know I would go for a used diesel turbo charger with a divided entry turbine from Garrett, Holset, Borg&Warner or Schwitzer. Then see to it that a lot of effort goes into the exhaust manifold and boost control. Just a simple manifold adapter is a very good solution. the pulses are already separated, just make something like this :

Posted: Jan 18, 2008 11:40 PM

by turbodan

///ARINUTS... wrote:Lets Go back to what started his geat debate.

turbodan wrote:Holset turbos are for trucks.

Do we still really believe this?

Sure thing. Thats what they're DESIGNED FOR.

///ARINUTS... wrote:

turbodan wrote: I've never had a problem with spool running undivided turbine housings. I would bet that most of the gain in spool time with divided turbines is from the reduction in cross sectional flow area . I hear a lot about maintaining exhaust pulses up to the turbine, but it seems like the only OE application of this technology is in low rpm diesel motors. I'm pretty sure that you dont really gain anything from divided inlets when your turbo is sized to spool over 3000 rpm. The actual gas flow through the turbine will spool it up, wether or not the exhaust pulses are intact will make a slight , slight difference. Like I said, it might only be worthwhile on low RPM motors.

Lets stay on topic here. I never said Holset invented the divided housing. No matter what turbo you end up using, If you have 2 identical turbos, and the only difference is the divided turbine housing, with the proper manifold, the one with the divided turbine housing will spool quicker.

I challenge you to prove this statement. This is tough, because it would require back to back dynos with different manifold and tuning in between. I dont think there would be any advantage of a divided inlet on a high powered gasoline application. You think otherwise. Your opinion is not correct by default.

///ARINUTS... wrote:

If a turbo could spool a few hundred RPM earlier, why wouldn't you use that opportunity? Divided entry turbines offer better transient response and lower exhaust back pressure than single entry turbines, neither of which are bad things.

You're getting good at stating things like this as fact. Seriously, where are you getting this? You're telling me a divided inlet turbine and an undivided inlet on an otherwise identical turbo will have a significant difference in back pressure? Major bogus, mang.

///ARINUTS... wrote:

To me the single inlet turbines are a compromise imposed on people due to crappy stock turbo exhaust manifolds. The turbo in itself won't solve performance problems inherent in a bad exhaust manifold design. I call the holsets modern because most of the the time we are talking about the KKK K27 found on the 745i ( and I know, I own a 745i). and turbos like "TO4B" , those things are ancient. You could probably fit their entire compressor map within the 70% efficiency island of the HX40. ( sorry, I know, I'm going off on a tangent here ) (There are still people who think of using those things, just a few threads away there is a build thread using factory 745i parts. )

Yeah, right. Here we go about the compression maps that, if they can even be found, are from unknown sources. If Holsets are more modern than T series compressors, why dont you compare them to GT series compressors? Oh, right, because they're more expensive. Thats convenient. I think you would be wrong though, if we had a real, legitimate Holset map to plot things out on.

///ARINUTS... wrote:

Also remember that we have an older 2 valve/cyl engine which needs more cam duration to flow as much as a modern 4 valve/cyl engine - and these GT30R ( and even the GT35R ) are aimed at these more modern engines where a smaller turbine and higher exhaust back pressure are acceptable, thats a bad thing about the Garrett GT turbos , in my opinion, for our applications. It's something you never see on a diesel Holset HX. Very small turbine housings for the fast spool but it may be right out dangerous for your engines longevity, high average cylinder pressures and high top-end exhaust back pressure is not a good thing. So we Want bigger exhaust housings, we need bigger exhaust housings, its better for our engines, and hey! they make more power, but the lag thing is always hanging over our heads, thats why we ( I ) want use the divided turbine housings, to make up for what I loose.

The fact of the matter is, if you have a certain size turbine housing, you will have a certain kind of spool. Someone already mentioned the high boost threshold and very abrupt spool that characterize the Holset. A large Garrett turbo will behave the exact same way.

///ARINUTS... wrote:

All things considered, I believe that using a holset HX35 or Holset HX40, and taking advantage of the divided turbine housing by keeping exhaust pulses separate, is a good cost effective way of turbo charging an m20 or an m30. They are available cheap and they are good strong turbos. If you want to do something else, hey, who am I to stop you.

That being said, it's not the only way, many people are happy with other solutions. I'm not knocking it. But I'm not looking to dump more money that what the car is worth, lets face it,

MOST E30s,E28s , E23s, E34s And E32s are not worth more than $5K, ( don't shoot me ) If you want to spend over $1000 on a turbo, thats your prerogative, but I'm happy spending much less for the same effect.

My opinion is to find a well suited turbo, ( 50-60 mm compressor inducers) As you know I would go for a used diesel turbo charger with a divided entry turbine from Garrett, Holset, Borg&Warner or Schwitzer. Then see to it that a lot of effort goes into the exhaust manifold and boost control. Just a simple manifold adapter is a very good solution. the pulses are already separated, just make something like this :

Look at this manifold. It takes the exhaust from 3 cylinders and collects them into a single tube. How much exhaust "pulse" is left at the turbine at 3500 RPM?

A true split pulse manifold that could actually maintain an exhaust pulse will be similar to a set of equal length headers. The cost of this and difficulty of fitment and fabrication will be considerable. You still havent shown that divided inlet turbines are good for anything on anything but a low-RPM, large displacement diesel motor. And we're still without anything but anecdotal observations about Holset turbos without even having made any legitimate comparisons against comparable Garrett turbos.

I've had great luck with Garrett turbos. I will never run a Holset because there is no information about them available. Its as simple as that.

I agree to disagree.

Posted: Jan 19, 2008 2:15 AM

by ///ARINUTS...

this was on a volvo forum, not sure how accurate it is.

I think this is the same thing as what Big Bronze rim posted before, he also posted another one. so there are your compressor maps. he also said this:

Big Bronze Rim wrote:While the last map isn't bad, its definitely not anything special except it seems a bit more efficient at very high pressure ratios (its diesel application is apparent here). It seems somewhat similar to a GT30 compressor wheel but the surge line is much more favorable on the Garrett wheel.

So we are comparing it to the GT30.

I personally do have a better manifold than that, but I posted that to show how simple and cost effective it could be. A simple adapter to the stock manifolds is all it takes. Big Bronze rim uses an adapter, not sure if he had the split pulse design in mind, i think he has a GT40?

This is not a mud slinging contest. I've stated my opinions and what I believe to be truth, I might be wrong and I can accept that but I am confident in what I say so I post it here to share with everyone. You can do what you like. I welcome all suggestions and I am open to hear new ideas. but I'm not going to great lengths to convince people. This is what I did and I am very happy with it.

If you want to use a 745i system on your M30, go right ahead. I own and daily drive a 745i and i also own a 325i with a split pulse tubular manifold and a HX35, I can tell you from my own experience that my 325i builds more boost quicker than my 745i ever will.

and I'll say this again, for the money spent, you can't beat a HX35. they sell regularly on ebay for around $250, I paid less than $150 for mine. show me a better turbo for that price or under $500.

Posted: Jan 19, 2008 11:53 AM

by iXer

To the original poster: I would find a turbo with a 55-60 mm compressor inducer and 60-65 mm turbine exducer. A manifold adapter is simple to build and use a single large external wastegate. Depending on boost control and turbine housing you will have full spool at about 3000 rpm in higher gears with such a turbo, with very little 'lag' from cruising speed to flooring it and having full boost.

turbodan: Saying something general like "truck turbos are designed for power at low engine speeds on large motors" is simply not cutting it on a technical level for me.

You're not convinced that a divided inlet to the turbine has advantages? It does have advantages in it's original application, faster transient response while allowing for less exhaust back pressure using larger housings without sacrificing response. Diesel application or not, it will have the same positive effect on any application. I'm stating fact, and have actually tried and seen what it can do on both small 4 cyl and large 6 cyl gasoline engines (mainly BMW and Volvo).

If all you care about is the maximum flow and have little use for transient response then it's less complicated (manifold and wastegate arrangement) to use a single-entry turbine as the application you're using it for is about maximum flow. But why would you use a single entry if you have an application where you could use the advantage of the divided entry?

I can't see from where some of you heard that these large turbos all have abrupt spool and "hit hard" at certain rpm. It is contrary to what I've seen in all of the installations where I've been involved in where we've used modern Garrett GT, Holset HX and Schwitzer turbos. They have all had divided entry turbines and map width enhancement grooves in the compressor inlet (aka 'power slit').

These features all help to give the system a low boost threshold. As an example from an install on a BMW M50 2.5 litre (stock but with 3 mm MLS gasket) is where the 'diesel' GT40 (58 in/65 out, 1.19 A/R turbine) we used gave 0.4-0.5 bar (6-7 PSI) boost instantly when flooring it in 3rd at 2500 rpm. This was with a split-pulse manifold with a single large 60 mm wastegate.

A Holset HX40 (61 mm in/65 mm out, 19 cm^2 housing) performed very similar not so strange considering the wheels and housings are physically quite matched. Full boost (1 bar) was at 3000-3300 rpm in 3rd gear.

On the contrary, pick an old TO4B or something comparably ancient, it will hit hard once it comes into efficiency and have a lot of 'lag' compared to a larger modern turbo charger.

One must also consider the volumetric efficiency of the engine, which if you compare a 4 valve/cyl to a 2 valve/cyl will look dramatically different. The 2 valve/cyl can definately be seen to have a more defined peak and this will ultimately also affect how a turbo will spool, it will "hit harder" than on a 4 valve/cyl engine of similar N/A peak power. This has not much to do with "hitting hard" in the dynosheets - an engine will behave very differently on the street, also consider the boost level used

As far as "not needing an anti surge compressor housing", it might cost compressor efficiency, I have no evidence to say it's not detrimental. But it is negligeable as far as turbine back pressure is concerned in combination with a properly sized intercooler - still efficiency on turbos with this feature is up at 75-78% which by far outperforms older style designs. I can't see where that is a bad thing. It definately broadens the operating range and it's a standard feature on any modern turbocharger in commercial applications.

The main reason you can't find anything about Holset is because they don't deal with the gasoline aftermarket much, they're about diesel applications. But there are plenty of outlets with good information - just check out any of the many Dodge diesel performance shops that deal in Cummins diesel turbo engines. You can get any size wheel and housing if you find the right place.

Saying one product is better than another is not what I had to say here, just know your facts and try to understand why a certain feature can help you.

As far as choosing one manufacturer over the other, it's about funds, availability and service. Everyone has different priorities and make different compromises based on what they know to be right.

Posted: Jan 19, 2008 7:07 PM

by turbodan

I dont want to say I "know my facts", but I can cite my sources. I dont know where you got the 75-78% efficiency figure for a Holset. If you can provide a legitimate source for that information I'd be quite excited.

I can get you some information about anti-surge compressor housings if you like. The feature is at a cost of a few percent efficiency. Thats actually a lot to give up for something you dont even need in any of our applications.

This thread is starting to read like a Holset brochure. No real facts or information, but lots of junk about how they're supposed to be better.

Posted: Jan 19, 2008 7:40 PM

by Jeremy

iXer wrote:turbodan: Saying something general like "truck turbos are designed for power at low engine speeds on large motors" is simply not cutting it on a technical level for me.

OK . . .

iXer wrote:On the contrary, pick an old TO4B or something comparably ancient, it will hit hard once it comes into efficiency and have a lot of 'lag' compared to a larger modern turbo charger.

Or you could play fair and compare a T04E housing. How hard it "hits" it fairly proportional to the A/R chosen. .8 or higher on a stock m30 hits pretty violently, boost comes on all at once. .7 or less begins to spool sooner and power delivery is much kinder. Only differences were the housings.

iXer wrote:The main reason you can't find anything about Holset is because they don't deal with the gasoline aftermarket much, they're about diesel applications. But there are plenty of outlets with good information - just check out any of the many Dodge diesel performance shops that deal in Cummins diesel turbo engines. You can get any size wheel and housing if you find the right place.

We're not talking parts availability, we're talking information. Gas or diesel doesn't matter, both use the same compressor maps when talking about the same turbo. For Garretts these are readily available, accurate, and verifiably correct. Not so much with the Holsets.

If you can read a compressor map you can find the correct Garrett for your application. With Holsets you have to guess and make assumptions about what the turbo might do.

Jeremy

Posted: Jan 19, 2008 8:02 PM

by raceaddic

turbodan wrote:I dont want to say I "know my facts", but I can cite my sources. I dont know where you got the 75-78% efficiency figure for a Holset. If you can provide a legitimate source for that information I'd be quite excited.

I can get you some information about anti-surge compressor housings if you like. The feature is at a cost of a few percent efficiency. Thats actually a lot to give up for something you dont even need in any of our applications.

This thread is starting to read like a Holset brochure. No real facts or information, but lots of junk about how they're supposed to be better.

Stop living in the past Garrett GT, Holset HX and Schwitzer (aka Borg Warner) turbos with right sized compressor have up to 78% efficiency look hear

http://www.bullseyepower.com/S200.asp

old hybrids are crap (how i know) i have been Working with rally and rallycross division 1 engines 600bhp 2L engines with 36mm restricted inlet and they use anti surge compressors and all ther Race turbos a plays same compressor wheel design as Garrett GT, Holset HX and Schwitzer

Re: I need turbo specs!

Posted: Jan 19, 2008 8:12 PM

by raceaddic

photo500 wrote:Ok guys despite the fact im in far flung Western Australia I'm going to attempt to Turbo my 535i. What I'm having trouble with is which turbo to go for. It seems alot of you use the T04 with an external wastegate and thats fine with me. The problem is I need the specs! The compressor and housing numbers etc. Does anyone have these from a setup that has minimal to no lag such as the TCD kits are meant to have. I could buy one from TCD or similar but I really would like local backup and support. But without specs I have no idea what to ask for

I plan to only run 10psi and will be using a b35 head and pistons. My manifold is the BAE type and suits the T04 with a stud adapter.(currently has T04 throat but T3 bolt holes) Help!

i suggest that you use a Borg Warner S258 58mm in and 69.5 mm out with AR 0.86 you will go nice in the 80%-76% efficiency spool nice from 2000rpm

http://www.bullseyepower.com/S200.asp

Posted: Jan 19, 2008 8:19 PM

by turbodan

Who's living in the past? I've personally run two different Garrett GT series ball bearing turbochargers. I can actually verify that a Garrett turbo is capable of 80% efficiency. Like this GT3582R:

The efficiency of Holset turbos are in question. The maps in this thread are the only ones I've ever seen, and noone knows where they came from.

Now, a 600 HP 2 liter motor is a good application for an anti-surge compressor housing. A 2.7l M20 or 3.4l M30 is a very different application. You can

easily fit these motors on a wide variety of compression maps. If your motor is operating well clear of the surge limit, what good does an anti surge housing do you? You lose a few % efficiency, and the surge limit moves even further out, but if you're already well clear of it, it does you no good.

Posted: Jan 19, 2008 8:31 PM

by raceaddic

her is a hx40 map says 75% to me and new holset series are even more efficient. how much less diesel do you think 1-2% more efficient turbo do on a truck that runs 10000K miles? 99% of all turbo development comes from truck industries..

and in pressure ratio garret gt is not even close

http://www.squirrelpf.com/turbocalc/gra ... uct_id=125

Posted: Jan 19, 2008 8:41 PM

by raceaddic

turbodan wrote: A 2.7l M20 or 3.4l M30 is a very different application. You can easily fit these motors on a wide variety of compression maps. If your motor is operating well clear of the surge limit, what good does an anti surge housing do you? You lose a few % efficiency, and the surge limit moves even further out, but if you're already well clear of it, it does you no good.

with big compressors comes surge even on a M30 i promise you that, have you tried 66mm or bigger with small AR to get nice spool?

i have and it surge like hell at 2800 rpm but with anti surge housing it was no problem..

but why learn from those that have tried

Posted: Jan 19, 2008 8:55 PM

by turbodan

The maximum pressure ratio is a worthless specification. A PR of 3 on these maps equals 30 psi of boost. How many M20/M30 turbos run anywhere near that? Even for those oddball freaks that might use more boost than that, I can find a Garrett that will work for them too, but for the most part, nobody will be anywhere near that. 30 psi and up is diesel territory.

The Garrett GT3582 has a wider map with a more favorable surge limit and a better maximum flow potential. Note that the surge limit on the Holset at a PR of 2, about 15 psi boost, is about 20 pounds/minute. The Garrett is well clear of the surge limit at 20 pounds/min at the same pressure ratio. The good part is that the GT3582 achieves peak flow at a pressure ratio of 2.5, about 22 psi. This is a great turbo for an M30.

Also note that the Garrett is about 70% efficient at 60 pounds a minute, while the Holset is blowing heat at only 60% efficiency. Ten percent is a huge difference at 60 pounds a minute. Thats a lot of air to heat up that much.

So in this case, the Garrett is clearly superior. Its less susceptible to compressor surge even with a conventional compressor housing and its more efficient up to the same amount of maximum flow. This all depends on our assuming this is a genuine Holset compression map. If it is, it shows the Garrett is better. Both turbos flow about 60 pounds a minute, so its a very good comparison.

The Holset would be good on a large displacement, low RPM diesel motor because it can support high pressure ratios at reasonable amounts of flow. Big, low RPM diesel motors dont go very far across a compression map. A gasoline motor plot will be much wider, as they are capable of running over a much wider RPM than a diesel with a 3000 RPM redline.

Posted: Jan 19, 2008 8:57 PM

by turbodan

raceaddic wrote:

with big compressors comes surge even on a M30 i promise you that, have you tried 66mm or bigger with small AR to get nice spool?

i have and it surge like hell at 2800 rpm but with anti surge housing it was no problem..

but why learn from those that have tried

I wouldnt run a turbo that would surge, its as simple as that. I would plot my engine out on a compression map before I even purchased it to avoid that problem. I can do that with Garrett turbos. I also wouldnt run a big-ass compressor with a small turbine, but thats not really relevant.

Posted: Jan 19, 2008 9:29 PM

by raceaddic

the holset map was just to show you that 75% is possible from a holset its from a 54mm inducer to match the garret you need a bigger compressor

me myself docent use holset i use Borg warner they are the most efficient turbos right now with greet spool and if you can find a garret that match the S200 and S300 series maps,,,

you need 24 psi and more to get 600rwhp from an M30B35 even with extensive porting and 284 degree camshaft. how manny hi output engines have you built? Theoris can only take you soo far.. don't get hanged up by some small % efficiency just boost up a couple of psi instead

here in Sweden we have the fastest bmws in the world and several of them use holset turbos

thats all i have to say about that

8)

Posted: Jan 19, 2008 10:15 PM

by turbodan

What about the car in your signature? 577 rwhp from an M30 at 20 psi? You dont think another 2 psi would hit 600 rwhp?

Ten percent is more than "some small efficiency number". Thats huge. You know that. That is a ton of extra heat that is going to saturate your charge cooler.

I've heard lots about the BMW's running around in sweden. I would bet money if they were and cheap and common as they are over there, we'd be right there with you.

I'm just sayin...

Posted: Jan 20, 2008 6:46 AM

by iXer

Jeremy wrote:Or you could play fair and compare a T04E housing. How hard it "hits" it fairly proportional to the A/R chosen. .8 or higher on a stock m30 hits pretty violently, boost comes on all at once. .7 or less begins to spool sooner and power delivery is much kinder. Only differences were the housings.

This is because a larger housing will move the boost threshold and spool-up to co-incide with the peak torque of the cam. If you have full boost already below 3000 rpm on an M30 you will only experience the effect of the turbos torque multiplication at first and later at 4000 rpm the cam will hit. This is much less of a "problem" on 4 valve/cyl engines, like a stock M50 which has a pretty much linear (boring) volumetric efficiency.

Jeremy wrote:We're not talking parts availability, we're talking information. Gas or diesel doesn't matter, both use the same compressor maps when talking about the same turbo. For Garretts these are readily available, accurate, and verifiably correct. Not so much with the Holsets.

It depends very much on who you talk to. I know many that have found their compressor diagrams when talking to the right person. Like I said earlier, what you get is about availability and service. Holset is not for just anyone and you have to look harder.

Jeremy wrote:If you can read a compressor map you can find the correct Garrett for your application. With Holsets you have to guess and make assumptions about what the turbo might do.

Yes, and with experience this is less of a problem. Educated guesses is often enough.

turbodan wrote:I dont want to say I "know my facts", but I can cite my sources. I dont know where you got the 75-78% efficiency figure for a Holset. If you can provide a legitimate source for that information I'd be quite excited.

You can take a look at any Garrett turbo with the MWE/power slit feature to find your numbers. Or you can look at this 15 year old Holset HX40 compressor:

I guess this is

gasoline territory ?

This was a high trim example, and if you get a high trim compressor it really favours a broad efficiency island with high peak numbers, just like your GT examples. You can get what you need from either manufacturer, if you know what you need.

The HX40 comes with two major diameters, 82 and 85 mm. They come with these inducers.

82mm = 46->60mm

85mm = 50->60mm

Depending on your power demands (inducer) and trim (flow at certain PR) you opt for certain combinations. Basically you would always prefer the larger inducers to get a "fat" efficiency island. Need less power and more response? Get something smaller than the HX40.

I really fail to see why you get hung up on low rpm diesel motors, it's about flow and not rpm and not all turbos from Garrett nor Holset are suitable for high PR. Most turbos with a compressor inducer of about 55-60 mm are found on diesel engines of 8-9 litres or more! That easily equals 6000 rpm red-line on a gasoline engine less than half that size.

Posted: Jan 20, 2008 2:25 PM

by turbodan

A Garrett T76 map from the 1960's shows a big fat 78% efficiency island. Larger turbochargers are more efficient. But I'm not talking about turbos that move 70+ pounds a minute. M20 and M30 turbos are more in the 40-50 lb/min area, where that kind of efficiency is harder to come by. Apples to apples, buddy.

I dont like making educated guesses when I can get a turbo I have all the information I need to get the right turbo. When the difference is as much ten percent efficiency where your engine actually runs, its quite significant.

Holset seems to like to map all the way out to 60%. It does make thier map look wider, but I would consider a different turbo if I was actually going to run into that extremely hot boost zone. Notice that a lot of Garrett maps stop at 65 or 70%. You really dont want to run past that.

Its not all about where the engine is going be on the map at redline either. An 8 liter diesel running between 1500 and 3000 rpm is going to flow, for example, between 60 and 80 pounds a minute. A gasoline engine that spools up at 3000 rpm and revs to 7k can run from 15 pounds a minute all the way through 45 or 50. That goes a lot further across the map than a diesel. Thats what I'm talking about.

An 82mm outer diameter is rather large for a 46mm inducer. A 50 trim T04e with a larger inducer and a smaller exducer will spool faster and make more power. Theres no need for that size exducer on a gasoline engine, which doesnt run the same kind of pressure ratio as a diesel. Seriously, who runs more than 30 psi on a gasoline engine? Not many people do. Most people run less than 20, and Garrett turbos seem to be better suited to these applications.

Different wheels designs, like the Garrett T and especially the GT series, are better suited to gasoline engines based on every compression map I've seen so far. I guess a Holset would work, but it looks like Garretts will work better.

Posted: Jan 22, 2008 1:57 AM

by photo500

A big thanks to those that have replied both on this post and via PM in regards to the actual topic. I will now go and get myself a turbo

Posted: Jan 23, 2008 10:14 AM

by iXer

turbodan wrote:A Garrett T76 map from the 1960's shows a big fat 78% efficiency island. Larger turbochargers are more efficient. But I'm not talking about turbos that move 70+ pounds a minute. M20 and M30 turbos are more in the 40-50 lb/min area, where that kind of efficiency is harder to come by. Apples to apples, buddy.

Not the point of this thread, buddy.

I'm not talking turbos that move 70+. And let's face it, there is no comparison to a modern turbocharger of the same size. That's like comparing a 2 valve/cyl engine to a modern 4 valve/cyl engine with the same peak power. Resistance to surge is probably the most noticeable characteristic of a modern compressor, other than the much broader efficiency.. and I guess turbine design, along with lighter and heat resistant materials has evolved substantially since the 1960's.

So you say we need 40-50 lb/min ? The HX40 map I posted earlier is a prime example, at 1 bar it's roughly above 70% efficiency from 20 to 50 lb/min. Compare that map to a similar sized GT turbo (82 mm comp exducer) and take a look at what the huge Dodge/Cummins diesel performance crowd are using on their 5.9 liter engines. There is plenty to go by if you need alternatives for our Australian friend. Lately Borg&Warner / Schwitzer S200, or S300, series is very impressive in this size (Bullseye Power).

turbodan wrote:I dont like making educated guesses when I can get a turbo I have all the information I need to get the right turbo. When the difference is as much ten percent efficiency where your engine actually runs, its quite significant.

Of course, if one doesn't have the time to test different turbos then it's better to go with what's true and tested. Luckily there's plenty to go by and the risk of making an educated guess that misses the meat of the efficiency island is not something I'm personally likely to make.

turbodan wrote:

...

Different wheels designs, like the Garrett T and especially the GT series, are better suited to gasoline engines based on every compression map I've seen so far. I guess a Holset would work, but it looks like Garretts will work better.

I agree to disagree, Dan. Good discussion but I'm leaving this thread, it's not going anywhere.

Posted: Jan 23, 2008 10:57 AM

by turbodan

iXer wrote:turbodan wrote:A Garrett T76 map from the 1960's shows a big fat 78% efficiency island. Larger turbochargers are more efficient. But I'm not talking about turbos that move 70+ pounds a minute. M20 and M30 turbos are more in the 40-50 lb/min area, where that kind of efficiency is harder to come by. Apples to apples, buddy.

Not the point of this thread, buddy.

I'm not talking turbos that move 70+. And let's face it, there is no comparison to a modern turbocharger of the same size. That's like comparing a 2 valve/cyl engine to a modern 4 valve/cyl engine with the same peak power. Resistance to surge is probably the most noticeable characteristic of a modern compressor, other than the much broader efficiency.. and I guess turbine design, along with lighter and heat resistant materials has evolved substantially since the 1960's.

So you say we need 40-50 lb/min ? The HX40 map I posted earlier is a prime example, with roughly above 70% efficiency from 20 to 50 lb/min. Compare that map to a similar sized GT turbo (82 mm comp exducer) and take a look at what the huge Dodge/Cummins diesel performance crowd are using on their 5.9 liter engines. There is plenty to go by if you need alternatives for our Australian friend. Lately Borg&Warner / Schwitzer S200, or S300, series is very impressive in this size (Bullseye Power).

The point you were making with the map you posted above is that Holset turbos can achieve high 7x% efficiency. You did come up with a map that shows that kind of efficiency, but not for a turbo anyone would use on an M20 or M30. Similarly large Garrett T series compressors have been capable of the same kind of efficiency for years. If you werent talking about turbos that move 70+ pounds a minute, why did you post a compression map for a turbo that flows 75 pounds a minute for an example? You see where this gets confusing?

Posted: Jan 23, 2008 12:19 PM

by iXer

turbodan wrote: If you werent talking about turbos that move 70+ pounds a minute, why did you post a compression map for a turbo that flows 75 pounds a minute for an example? You see where this gets confusing?

I can see where you got confused, the map I posted has two X-axis. One for kg/s below, and one for lbm/min above. The actual grid in the diagram is for every 5 lbm/min.

Posted: Jan 25, 2008 10:37 PM

by turbodan

Yep, I was reading that one wrong. So check this out:

You're probably familiar with the T04E 60 trim compressor. Once again, these are WWII era wheel designs. Notice the big fat 79% efficiency island. So its no feat for a 15 year old Holset to just match that.

Posted: Jan 26, 2008 1:27 PM

by Gunni

Why is there discussions about copmressors when the real disscussion is about turbine developments.

It´s well documented by the turbo manufacturers and noted as 100% normal to now only produce split housing turbines.

Because they are more efficient.

A compressor map is only 3rd of what is really going on, does it show transient behaviour? NO.

Does it show exhaust scavenging characteristics?

NO.

It only shows at what speeds and pressure ratio a compressor can flow much amount of air.

The difference between 1.3bar boost and 1bar boost is more important then 75-80% efficiency. The actual gains from

large turbine housings are ,

better scavenging that changes the VE of the engine

which means lower boost = same power, which also means lower intake temps and thus safer running.

But in order to run larger turbines you will need to make use of the pulses in the exhaust manifold to spool them. This is the same with holset and garret. And that´s why people run Holsets to make high power with relatively low boost,

They are dead cheap. easily available, easily repairable,

and they do exactly the same as more expensive turbos Turbos.

Why spend more when it´s not needed?

And you can´t say that there isn´t enough info on the Holsets anymore, almost every turbo bmw out of USA uses them now.

And it´s all well documented.

Posted: Jan 26, 2008 8:52 PM

by turbodan

This has all been brought up already, but we still lack any actual evidence that Holsets are better. I haven't even seen a dyno sheet yet. I can show you what my Garrett does on the dyno. I realize that you think Holsets have better transient behavior and provide less back pressure, but I don't just believe everything I read on the internet. I don't believe that a Holset of the same specifications as a Garrett is going to just be better. I think its a matter of having the right turbo. The right turbo isn't going to be a Holset just because its a Holset. The right turbo for me is a Garrett because I have the information I need to determine that. The T series turbos are more common than Holsets and usually cheaper used vs. used.

I guess you could say I'm tired of the Holset sackriding crew. To say "almost every" turbo BMW in the USA runs them is flat wrong.

Posted: Jan 27, 2008 11:42 AM

by Gunni

turbodan wrote:This has all been brought up already, but we still lack any actual evidence that Holsets are better. I haven't even seen a dyno sheet yet. I can show you what my Garrett does on the dyno. I realize that you think Holsets have better transient behavior and provide less back pressure, but I don't just believe everything I read on the internet. I don't believe that a Holset of the same specifications as a Garrett is going to just be better. I think its a matter of having the right turbo. The right turbo isn't going to be a Holset just because its a Holset. The right turbo for me is a Garrett because I have the information I need to determine that. The T series turbos are more common than Holsets and usually cheaper used vs. used.

I guess you could say I'm tired of the Holset sackriding crew. To say "almost every" turbo BMW in the USA runs them is flat wrong.

I said almost every one outside of the USA runs them.

And I wasn´t talking about Holsets beeing better.

I was talking about why split pulse is better.

And why you should consider running split pulse

When did the GT split pulse series arrive on the market?

And the power slit. Which they sport as well now?

Holset and other diesel turbos have had them since the early 90´s,

And the most obvious BEST turbos out there now are the BorgWarners with extended tip technology.

I will fully say that THEY are the best.

If one is building a manifold, it SHOULD be split pulse

and the turbo should be split pulse. It´s last decades technology and it´s highly beneficial. Not all turbo usage is on WOT, so with split pulse you are actually getting better transient response without stomping your leg and that is a big plus.