Page 2 of 4

Posted: Feb 12, 2009 10:58 PM

by cvillebimmer

The turbo is out of the car. Only took about an hour this time...

Do the following two statements make sense about the source of the screeching sound?

1) It can't be the throwout bearing because the sound happens at a standstill with clutch in or out.

2) It can't be the waste gate because the sound will happen at no throttle letting the revs fall from 4500-4000. This is the case while driving or sitting still.

The turbo shaft has some side to side play, but it's nothing like the failure first time around. It spins freely, but I can hear a grinding sound if I push in or pull out on the shaft while turning the wheel.

I'm 99% sure the screech was coming from the turbo. Why it's screeching remains a mystery. I'm dropping it off to be inspected tomorrow, but I'm beginning to think this turbo isn't rebuildable.

Anyone have a known good K27 lying around? Thanks for all the help.

Posted: Feb 13, 2009 1:22 AM

by Brad D.

If it makes grinding noises axially, the thrust bearing is probably hosed.

Posted: Feb 13, 2009 11:30 PM

by altus22

Big Bronze Rim wrote:If it makes grinding noises axially, the thrust bearing is probably hosed.

That sounds like the issue. Could that be caused by excessive back pressure pushing the turbine wheel axially?

Posted: Mar 08, 2009 9:26 AM

by cvillebimmer

Hi guys, need some ideas...

Turbo is back in. The shop replaced the exhaust housing and tested the internals. The screech gone. That's the good news.

I'm still struggling with the shuddering issue. My waste gate will hold 10psi steady as a rock as long and all is great as long as I'm willing to ride the brakes to keep the revs below about 3300 rpm. Above 3300 rpm, the car shudders almost as if it's missing. This is at WOT, AFRs are around 12.

Thinking excessive back pressure from the exhaust could be the issue, I took the saws-all to it. I chopped it pre-cat and plugged the o2 sensor into the bung I had been using for the wide-band. The problem remains, but at least I can hear it now and rule out exhaust as my problem. Best I can describe it is a popping sound. Almost like back firing, definitely not like detonation.

I don't believe it's the waste gate, but haven't completely ruled it out either. When I took it out to inspect it, the plunger is really stiff. To push it in, I had to put it on the bench and give it a good push with my palm. I'm not losing boost when the popping starts, but I am losing power.

Thanks in advance for any suggestions. Drive the car off a cliff is starting to sound like a good suggestion

. I'm not ready to throw in the towel though.

Posted: Mar 08, 2009 3:53 PM

by George

cvillebimmer wrote: Best I can describe it is a popping sound. Almost like back firing, definitely not like detonation.

I had a problem that sounded similar to this. I was running out of fuel. Are you sure your fuel supply is adequate?

Posted: Mar 08, 2009 6:35 PM

by cvillebimmer

thesixerkid wrote: I had a problem that sounded similar to this. I was running out of fuel. Are you sure your fuel supply is adequate?

Could the opposite be true? The LC1 was showing 11s at the time the shuddering started, occasionally even high 10s. Also interesting that it doesn't seem to matter if I'm at 2psi or 10psi. When I cross that 3300rpm point, the shuddering starts.

Posted: Mar 08, 2009 7:11 PM

by George

This is where megasquirt would be huge, because you could datalog. Try leaning it out to 12:1 and see what happens.

Posted: Mar 08, 2009 7:29 PM

by babisbabou

Nice project there hope it runs well after this problem is solved!!

Posted: Mar 09, 2009 9:04 AM

by cvillebimmer

thesixerkid wrote:This is where megasquirt would be huge, because you could datalog. Try leaning it out to 12:1 and see what happens.

I'll have to wait until I get my exhaust in since I currently have no bung for the wideband. TCD hooked me up with a 3" straight through setup with no CAT. It has a small resonator that looks like a CAT, which hopefully will pass inspection. Just visual inspection, no sniffer test here.

I might try swapping the plugs to see if that makes any difference. It's cheap enough and I did run these plugs during and after I popped the HG.

Posted: Mar 10, 2009 3:39 PM

by cvillebimmer

Here's a couple ideas, any thoughts?

I understand the pulse generator connected to the #6 spark plug tells the DME which set of injectors to fire. Maybe I damaged it when I took the head out? A long time ago I broke the pulse generator wire. I ran the car for over a week that way without any noticeable problems. I don't know what, if anything, that would tell me now.

Maybe Camshaft Position/Reference Mark Sensor has gone south? I assume this would be more of an it runs or doesn't run situation...

I don't want to try leaning it out until I have the new exhaust installed and my wide band back in. I'm hoping to rule out a couple things before that happens.

Posted: Mar 10, 2009 4:28 PM

by George

cvillebimmer wrote:

Maybe Camshaft Position/Reference Mark Sensor has gone south? I assume this would be more of an it runs or doesn't run situation...

I'd have to say that your right about the cam sensor. It wouldn't produce a problem just at 3300 rpm. I still think you need to lean a little fuel out.

Posted: Mar 12, 2009 4:51 PM

by cvillebimmer

On the off chance that it was the plugs, I replaced mine with a set of NGK BPR7ES. Idle seemed a little smoother, but the problem still exists.

How's this for weird... Keep in mind, I have no exhaust on the car, just the downpipes with the O2 sensor plugged in where the wideband used to be. So when the popping noise, which I can best describe as a miss or a backfire, and shuddering started, it was enough to make my hazards and interior lights come on. Hazards went off after hitting the button a couple times. Only way I could get the interior lights off was to open the door and close it again. I would guess it's just from the vibration of having no exhaust, otherwise I have an evil electrical gremlin.

With a little luck I'll have a snazzy 3" tcd exhaust installed next week and I can get back to some real testing instead of taking random stabs in the dark.

When do you say enough is enough and just cut your losses and move on? Is that even an option here

Posted: Mar 24, 2009 10:32 PM

by cvillebimmer

It works, it works, it works!

In short, MSD 6AL and blaster coil solved the problem. Picked up both on ebay for $120. I have learned the hard way what spark blowout sounds like. Sheesh...

Thanks for everyone's help and suggestions along the way. I finally get to enjoy it for a while.

Posted: Mar 24, 2009 11:26 PM

by George

Congratulations. Now drive the hell out of it.

edit: was the MSD bolt on, or did you need to make some alterations to get it to fit?

Posted: Mar 24, 2009 11:33 PM

by cvillebimmer

thesixerkid wrote: was the MSD bolt on, or did you need to make some alterations to get it to fit?

It's sort of floating at the moment. It's pinned between my intake pipe and the inner fender. The connections are also twisted together and covered with electrical tape

. I expected this wouldn't solve my problem, and wanted to able to go back to stock if needed. I actually look forward to bolting it up right. It will fit nicely on top of the wheel well.

Posted: Mar 24, 2009 11:36 PM

by cvillebimmer

thesixerkid wrote:Congratulations. Now drive the hell out of it.

I look forward to needing a new clutch.

Posted: Mar 24, 2009 11:47 PM

by George

cvillebimmer wrote:thesixerkid wrote: was the MSD bolt on, or did you need to make some alterations to get it to fit?

It's sort of floating at the moment. It's pinned between my intake pipe and the inner fender. The connections are also twisted together and covered with electrical tape

. I expected this wouldn't solve my problem, and wanted to able to go back to stock if needed. I actually look forward to bolting it up right. It will fit nicely on top of the wheel well.

So does the MSD blaster coil bolt right up to the existing plug wire?

Posted: Mar 24, 2009 11:52 PM

by cvillebimmer

thesixerkid wrote:cvillebimmer wrote:thesixerkid wrote: was the MSD bolt on, or did you need to make some alterations to get it to fit?

It's sort of floating at the moment. It's pinned between my intake pipe and the inner fender. The connections are also twisted together and covered with electrical tape

. I expected this wouldn't solve my problem, and wanted to able to go back to stock if needed. I actually look forward to bolting it up right. It will fit nicely on top of the wheel well.

So does the MSD blaster coil bolt right up to the existing plug wire?

Not exactly. It's about twice as long, but the same width. It is currently zip-tied to the stock mounting bracket, which will probably do just fine. How have others mounted the coil?

Posted: Mar 25, 2009 10:26 AM

by cvillebimmer

Took the long way to work today... and loved every minute of it!

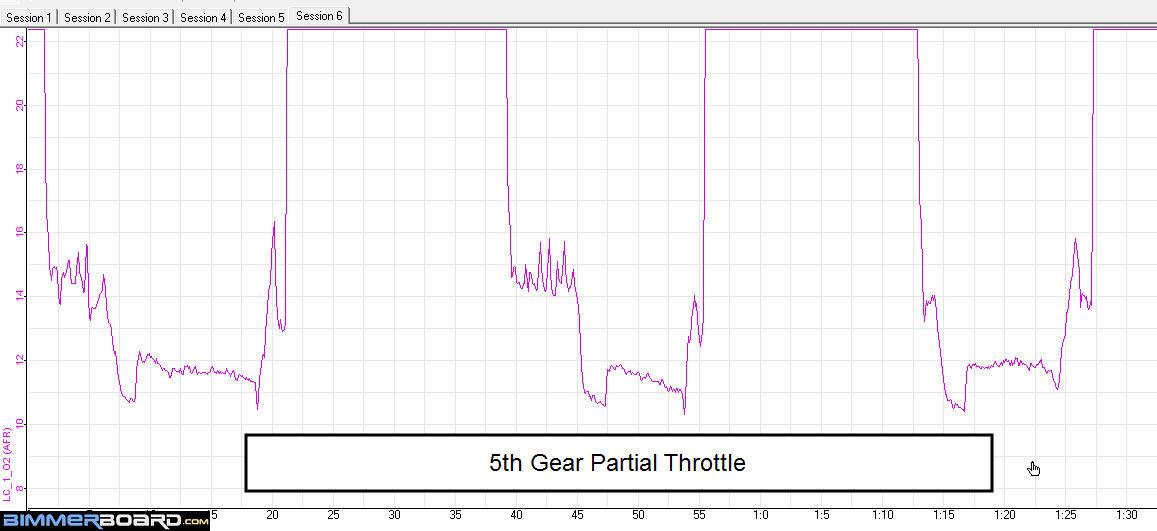

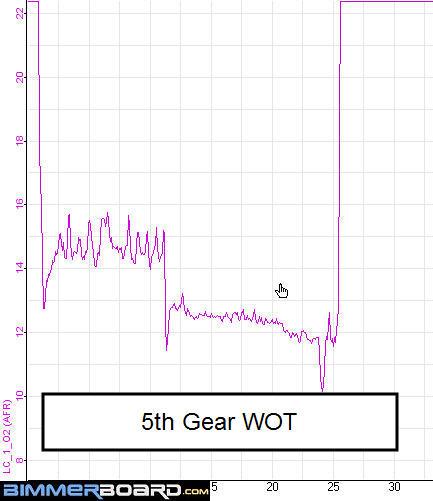

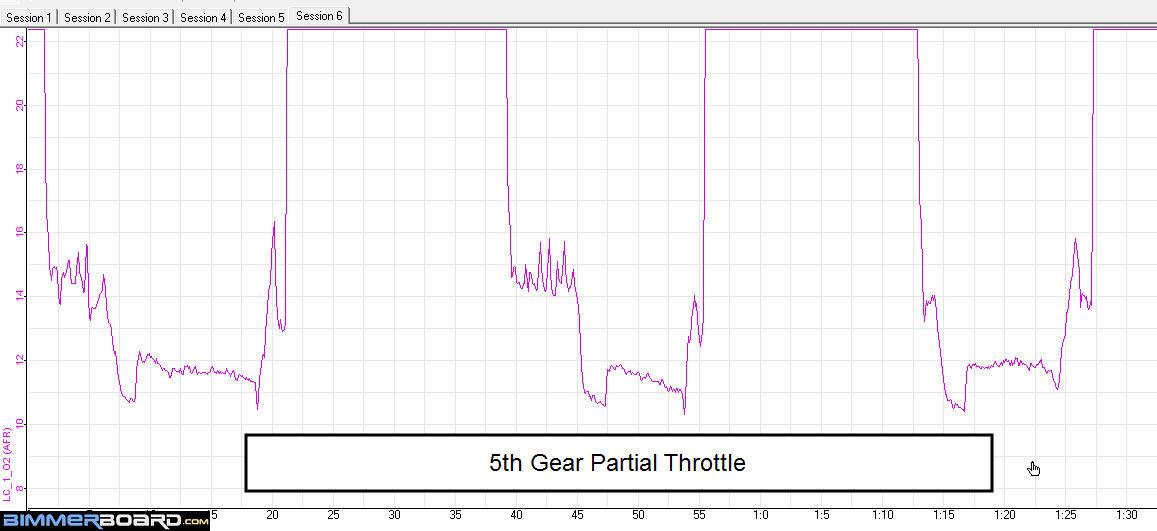

Here are my ARs after 12 clicks tightening the AFM and the Begi is dialed all the way out. Fuel pressure reaches 60 psi at 10 psi of boost. Think it looks okay or should I tighten up the AFM a bit more? Part throttle boost seems a little rich to me. Maybe dial up the fuel pressure a little for the WOT runs?

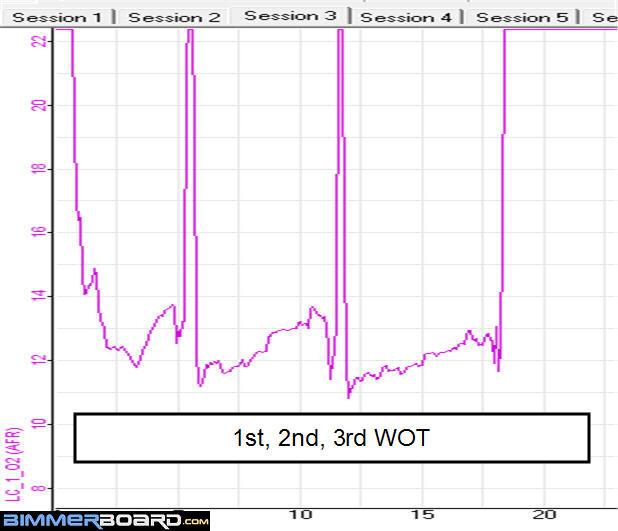

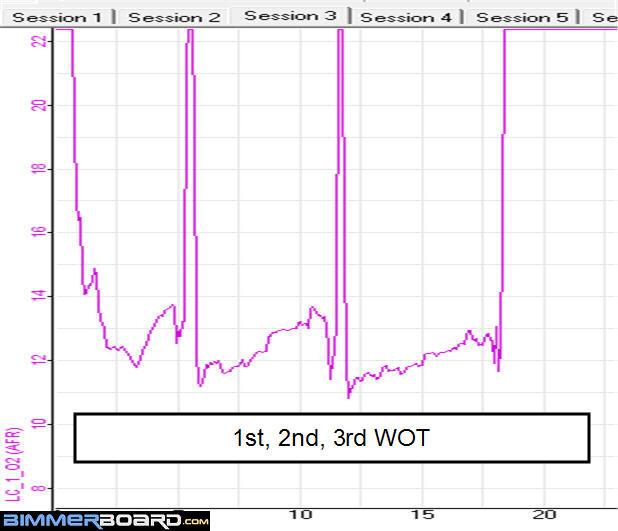

1st, 2nd, 3rd WOT to 6000 rpm...

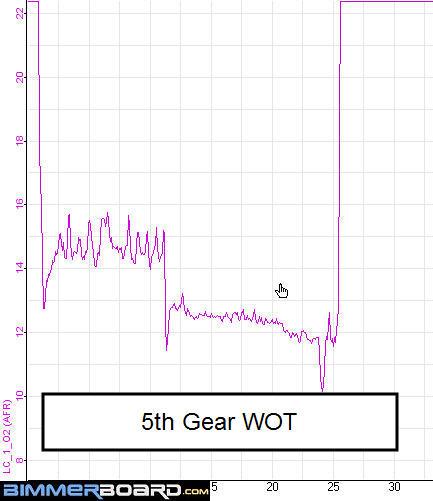

5th Gear WOT

5th Gear Part Throttle

And just for fun. Not an ideal viewing angle, but it's alright and definitely stealthy. I know, I need to fix the peeling panel...

Posted: Mar 25, 2009 11:31 AM

by Brad D.

It looks like it is leaning out as rpm increases in each gear (1st, 2nd and 3rd). Is boost falling off at the top of each gear? This would put less pressure on the RRFPR and cause it to be slightly leaner. The 5th gear WOT pull looks pretty good for a FMU based car. I'd probably tune it a tad richer than 12.5ish:1( I usually target 12:1), but since it dips down below 12 near the top end it's probably livable.

Posted: Mar 28, 2009 10:16 AM

by Patrick McHugh

I was told by TCD that if it has a 1 and a 3 in it, it's bad. I would try to keep it under 12.5 all the time under boost.

Posted: Oct 22, 2009 11:39 PM

by cvillebimmer

Hard to believe the last post to this thread was in March. My how time flies...

So here goes round 3 with the turbo car. It's too late and I'm too tired for details, but here's a little eye candy. Clean engines are so pretty.

Posted: Oct 23, 2009 5:51 PM

by gkrea1

They do look good, clean and tidy on a stand, ready for service, full of potential. It reminds me of baseball spring training when all of the young rookies have rockets for arms, quick bats, and fly around the bases, and nothing is proven. What a great time of the year! And what a fun time in the motor build!

Posted: Oct 23, 2009 5:54 PM

by Brad D.

Andrew, that looks quite tasty! I like the finish on the valve cover and intake. Is it powdercoated? I'm looking forward to hearing your progress.

Posted: Oct 23, 2009 5:54 PM

by T_C_D

Awesome! Email me the #. Was i right?

Posted: Oct 24, 2009 10:57 PM

by cvillebimmer

Big Bronze Rim wrote: Is it powdercoated?

Just good ole high temp ceramic (flat) in a rattle can. The intake manifold is semi-gloss. Although I prefer the flat, I may change it to semi-gloss just because the flat is so hard to keep clean.

gkrea1 wrote:They do look good, clean and tidy on a stand, ready for service, full of potential. It reminds me of baseball spring training when all of the young rookies have rockets for arms, quick bats, and fly around the bases, and nothing is proven. What a great time of the year! And what a fun time in the motor build!

And a rookie I am... Having a clean engine on the stand is freaking awesome! I had to do some work on the Ranger today just so I could get my hands dirty.

I made a little more progress today, but first some background.... The head is a rejuvenated b35 original to the car. The block is from an early production e32 and has been rebuilt from pan to head gasket by Paul Burke at Imgineering. Highlights included:

- 8.8:1 forged turbo pistons

- Lightest OEM m30 crank (will have to get details from Paul on that)

- New timing parts and adjustable cam gear

- Modified OEM Goetze head gasket with ARP sutds

This block is a better choice for an FI build than the later m30 blocks found in most e32s and all e34s. It was caste with all the mounting pads to fit different chassis of the era and conveniently has a pad for the turbo oil return on the e23 745i. Nice to know that if I get bored of the e32, I have plenty of options if I want to do a transplant. There are some other differences in the casting that make early blocks less prone to cracking than the later ones. Hopefully Paul will add his two cents about that.

Now some pics... I need a different fitting for the oil return and a few inches of oil rated hose. Anyone have some scrap? It's so close!

Paul did such a nice job with the block that I just couldn't bear to put dirty mounts on it. They've been cleaned and hit with some ceramic paint too. The waste gate is killing me, but I don't really want to paint it.

Posted: Oct 24, 2009 11:24 PM

by mooseheadm5

Napa will have oil hose.

Posted: Nov 15, 2009 9:52 PM

by cvillebimmer

The kitchen sink sprung a leak this morning. Most would regard this as a nuisance, but for me it was a great excuse to make the 50 mile round trip today to the Home Depot! The trip takes you over the blue ridge mountains and has a nice long steady interstate incline. Considering I inspected the car yesterday from radiator to differential and rechecked the torque on the head studs but didn't have time for a test drive, I'm thanking the plumbing gods for the first opportunity push into boost.

Everything looks good at startup and everything is still looking good 10 miles into the trip. AFR is bouncing around 14.7 as it should, so I ease into the throttle just enough to push into positive territory. AFR drops to the low 11s and fuel pressure approaches 60psi. I ease off and it settles right back at 14.7. I did this several times and it felt great! It sure doesn't take long to be going WAY too fast.

During one of the positive pressure jaunts, the CEL came on. It went off before reaching my destination, so I guessed it was 1222 (rich or lean condition).

Things got a little weird on the way home. After about 30 minutes and a quick inspection for leaks (none yet), I start up the car and immediately notice was that my idle AFR is 12.x. I'm thinking that's very odd, but as soon as I begin to move the AFR went back to where it should. As I approach the first traffic light, AFR goes back down to 12.x. I continue onto the highway and a few moments later the CEL comes back on. After about 5 minutes, it doesn't go off so I pull over and do a stomp test which reveals code 1221 suggesting a faulty O2 sensor.

Not wanting to believe I could have fried my O2 sensor with less than 2000 miles on it, I reset the ecu. Start it up again, still rich, but no CEL. I proceed to drive home making no less than 5 more stops to mess with the AFM. Long story short, the car will not hold a proper AFR and the CEL is back on with 1221.

Does this strike anyone else as an odd way for an O2 sensor to fail?

Thanks for reading!

Posted: Nov 20, 2009 2:51 PM

by cvillebimmer

I continue to have troubles with my ARs under certain conditions and a repeated 1221 error (code details below). For those just tuning in (no pun intended), I'm running motronic 1.3 with an RRFPR and O2 clamp.

My AR’s are right where they should be except for the following situations:

1. Very light cruise as in 50mph on a flat, ARs are high 15s – low 16s (as soon as vacuum decreases to ~14in or so, it flutters around 14.7. It drops to the 13s as you get on the gas and approach atmospheric and falls to 11.5-12.5 under boost.)

2. Warm idle is rich, 12.5 -13

I installed a new O2 sensor yesterday in hopes to eliminate the CEL 1221 code. I drove 40 miles on the new sensor, mostly N/A but flirting with positive pressure just enough to get the ARs to dip momentarily. No CEL until after the first extended time in boost (4th gear 5 seconds +/-). The CEL stayed on and the ECU stored 1221.

Today I reset the ecu and the 1221 code came back after just 3 miles of in town driving, no boost. So, something is definitely not quite right. I'll recheck the continuity of the sensor plug to the ECU pin out. If there is no problem there, I'll try removing the O2 clamp. Anyone else experience anything like this? Any tips?

I'm so friggin close I can taste it, but I'm scared to push it with the CEL.

1221 code:

This code is stored when the engine temperature is >70C and the Oxygen Sensor value is out of range or not present. Check the Oxygen Sensor wiring and the operation of the sensor. The value should fluctuate between 0.02 and 0.85V. Slow fluctuation indicates a polluted Oxygen sensor and negative values indicate a damaged sensor. Note: Cars without Catalytic Convertors will incorrectly store this code.

Posted: Nov 20, 2009 3:05 PM

by turbodan

This seems normal for a Motronic turbo motor. You cant expect the run significantly oversized injectors, a wound up AFM, an RRFPR and expect it not to get upset. The thing is that you have M1.1 to deal with, which makes a point of letting you know the AFRs are deviating beyond the limits of adaptation.

The good news is that the check engine light isn't anything more than an annoyance. As long as the AFR doesn't lean out under boost theres nothing to really worry about.