Burned carpet

Burned AC case

Dash out

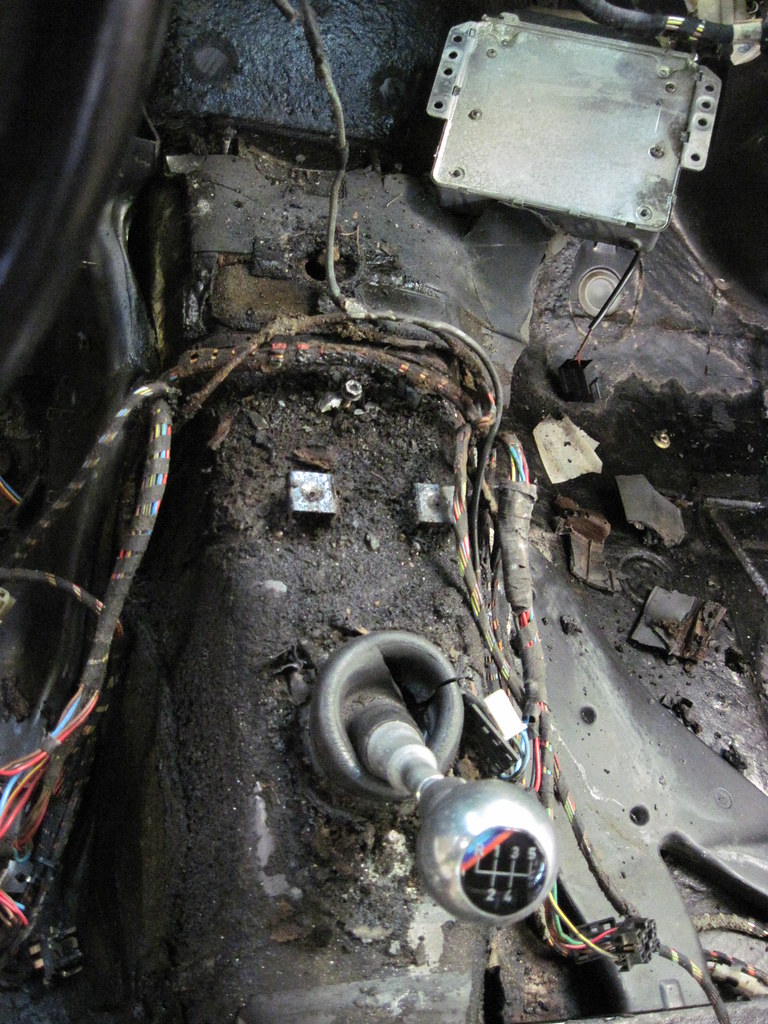

Crispy wiring

AC and heater cases out. Almost all the wiring in these pics is heat damaged. Some is completely burned, some is melted together, and some of it has hardened from the heat and I do not trust it.

I have ordered a new Behr heater core since it is silly to go this far and not replace it. It'll only cost me $90, and I won't have to worry about it for decades, so I'd call that a good investment. Happily a quick lube of the heater blower and it is good to go, so I can ignore that for now. I am OK with using a used AC evaporator and associated stuff because I do not have to remove the dash to access those parts if they require replacement in the future.

I rid the seat control circuit of shorts so now I can move the seats with the switches, which will make pulling the carpet a cinch.