I got the engine running this week! Turned out my spare water pump had a leak, so I replaced it with the one that had come off the B34 engine and all was resolved.

A little scary to turn the key waiting for oil pressure or firing. But I did that recently on another car so my nervous energy was a little less. A relief when it fired! Nice to hear it Rev and be running again.

I also installed a standard Nissan radiator since the behr south african unit seemed to run a few degrees hot.

I was able to change the req_fuel value and scale my map with no problems. I decided to cut my value in half again and get a little better resolution on my fuel map, that seemed to work pretty easy! Right now I am used about 180 characters out of the 255 maximum.

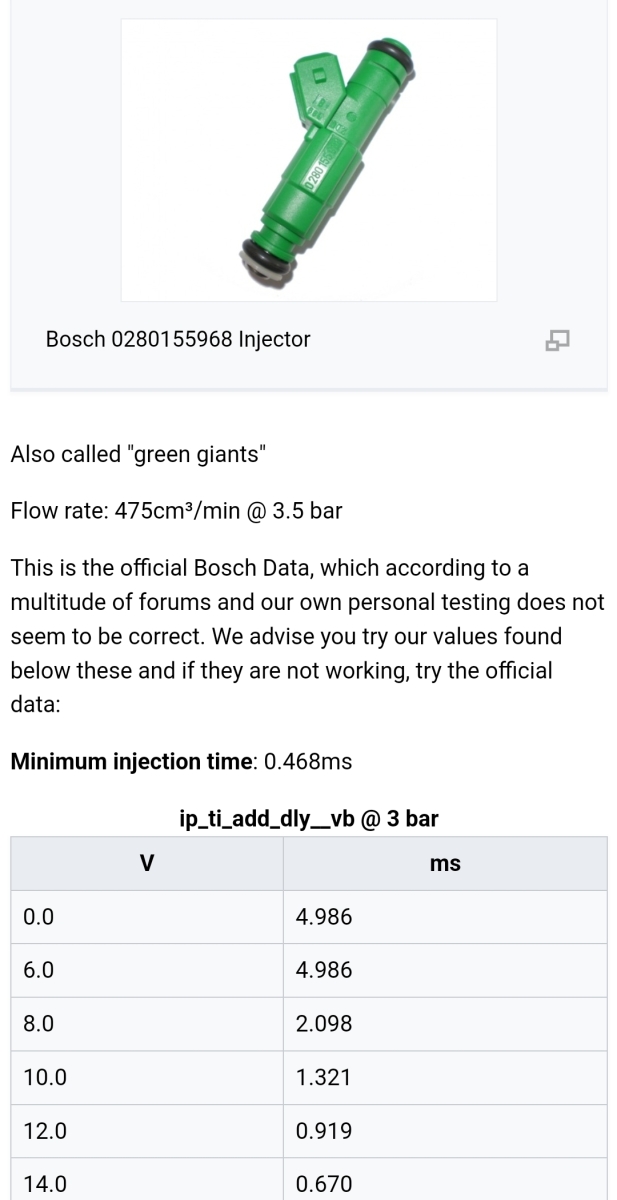

I used the dead time listed above (.763ms at 13.2V) and voltage correction of .17ms/V.

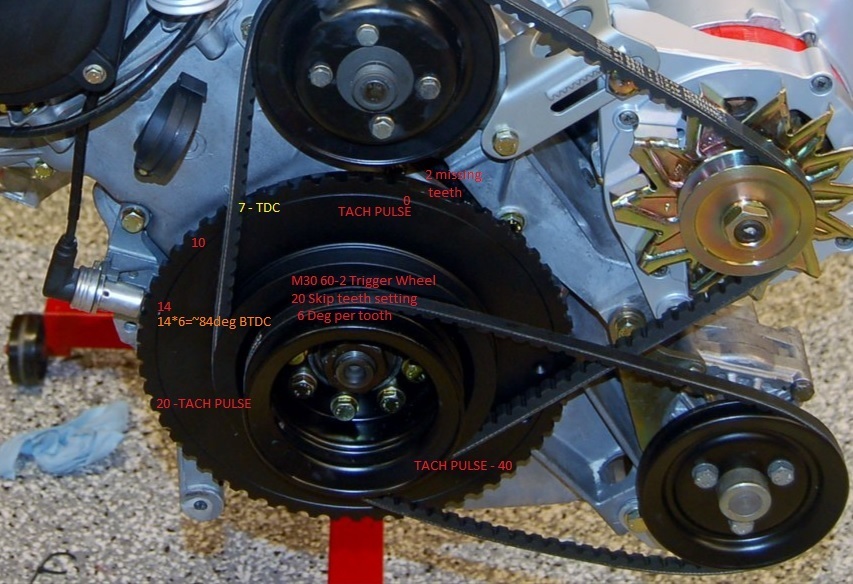

I went to check timing on my light to confirm tooth #1 angle just because this had confused me years back and I got the same result... Paint marks indicating TDC of the piston between the crank and the block. I mark near the alternator bracket which is convenient enough. Then Idle fixed advance at ~17degrees and turned on the timing light. The mark didn't line up until the gun showed ~45degrees.

I am not sure how this can be. I did this on my Ljet e28 and checked max advance without the distributor and got maximum ~38 degrees which is correct by the book. So I am pretty sure my gun and method for checking are good...

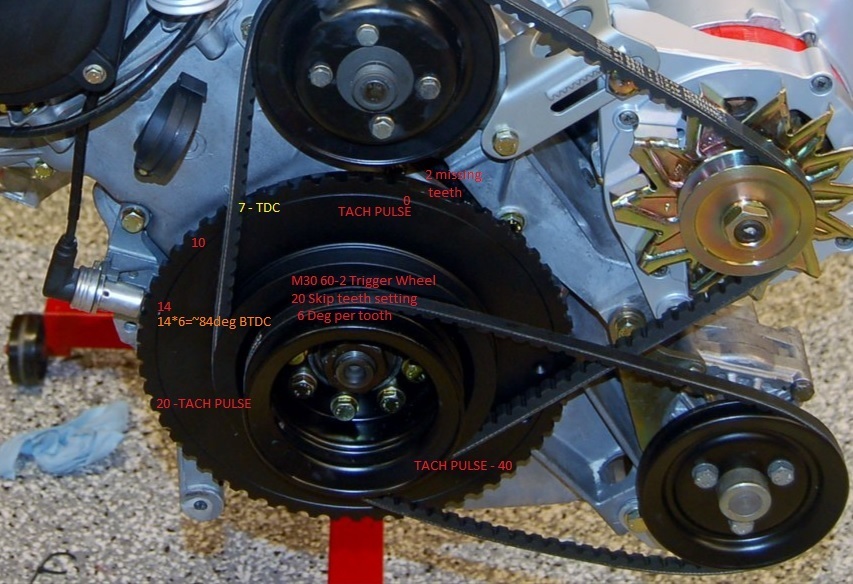

I am using falling edge triggering with the 60-2 wheel and set my trigger angle offset at 87 is based on some post by ianwood on this forum. he describes how he got to that number though I am not sure I do totally. From what I understand, and via the board FAQ, it should be about 87-89 degrees (falling edge, 84 degrees for rising edge) and I was hoping to get it timing dead on...

I checked the timing calculations in megasquirt and the only two calculations shown were base advance and cold advance, both at 17 degrees and 17.5 degrees, respectively (in my test the engine wasn't totally 100% warm).

So why the discrepancy? How else do I check this? I tried reading through this and get the 20 skip tooth setting, but not sure how it correlates to the 87-89degree setting.

https://www.useasydocs.com/details/crankwheel.htm

If Charlie's B35 build was at TDC in this picture, maybe it could be visibly making sense in this picture?

https://www.flickr.com/photos/ckindel/14444019253/

Here's my estimate, of 84 degrees based on a rough estimate that sort of makes some sense. But it doesn't convince me how to check it manually with my light.

According to a different poster on bimmerforums, this would be how to check:

The correct way to verify the timing on megasquirt is to set the timing to a fixed number. You can do this in the wheel decoder menu. Under the "fixed advanced" drop down select Fixed Advance, then set the fixed advance number to 12 degrees. Start the car and let it idle. Take a reading with your timing light. The #1 coil should be firing exactly 2 teeth before the O l T mark on the balancer. Adjust the trigger offset number until its perfect. Once you have it set turn the fixed timing off. Check it again while it is running on the timing table. It should match the ignition advance shown on the dashboard of tuner studio.

Maybe something to try but the M30 O|T is super hard to see!! If set to 89 degrees instead of 87 does this mean actual timing could be 2 degrees retarded?

Also from James of Ms extra:

Please ignore and remove the TDC pointer from your diagrams and thinking. As per the manual, set the engine to TDC and leave it there. It is intentional that the manual does not show a TDC mark on the wheel and shows the timing pointer and timing marks independantly. The Megasquirt does not care where the sensor is positioned on the engine or whether the missing tooth is at 1 o'clock, 7 o'clock or 11 o'clock.

What does matter and is critical is the number of tooth gaps between the sensor and tooth#1 when the wheel rotates in the normal direction.

turbodan wrote: Jun 16, 2024 4:13 PM

Did you have any luck with that tach output configuration?

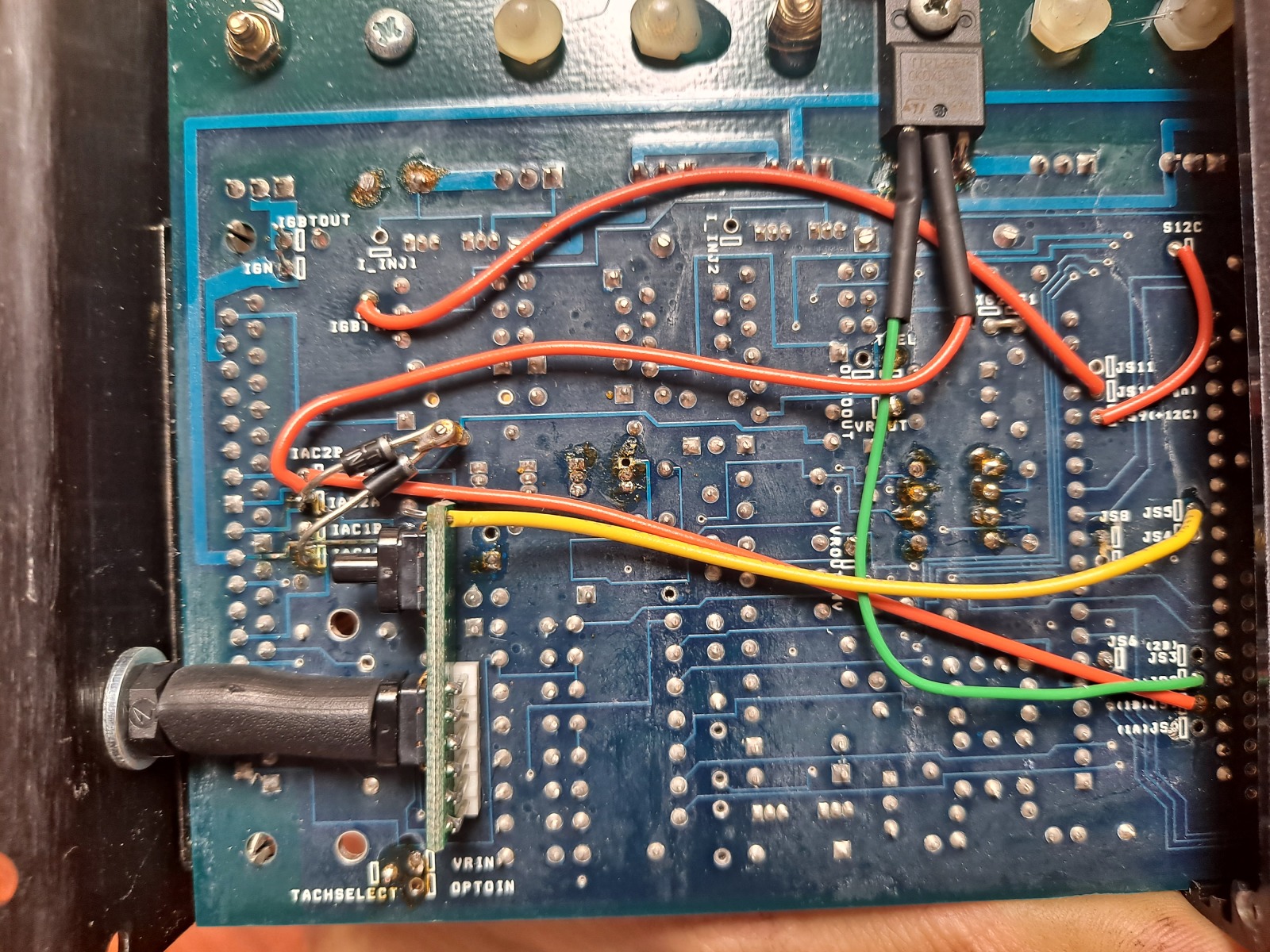

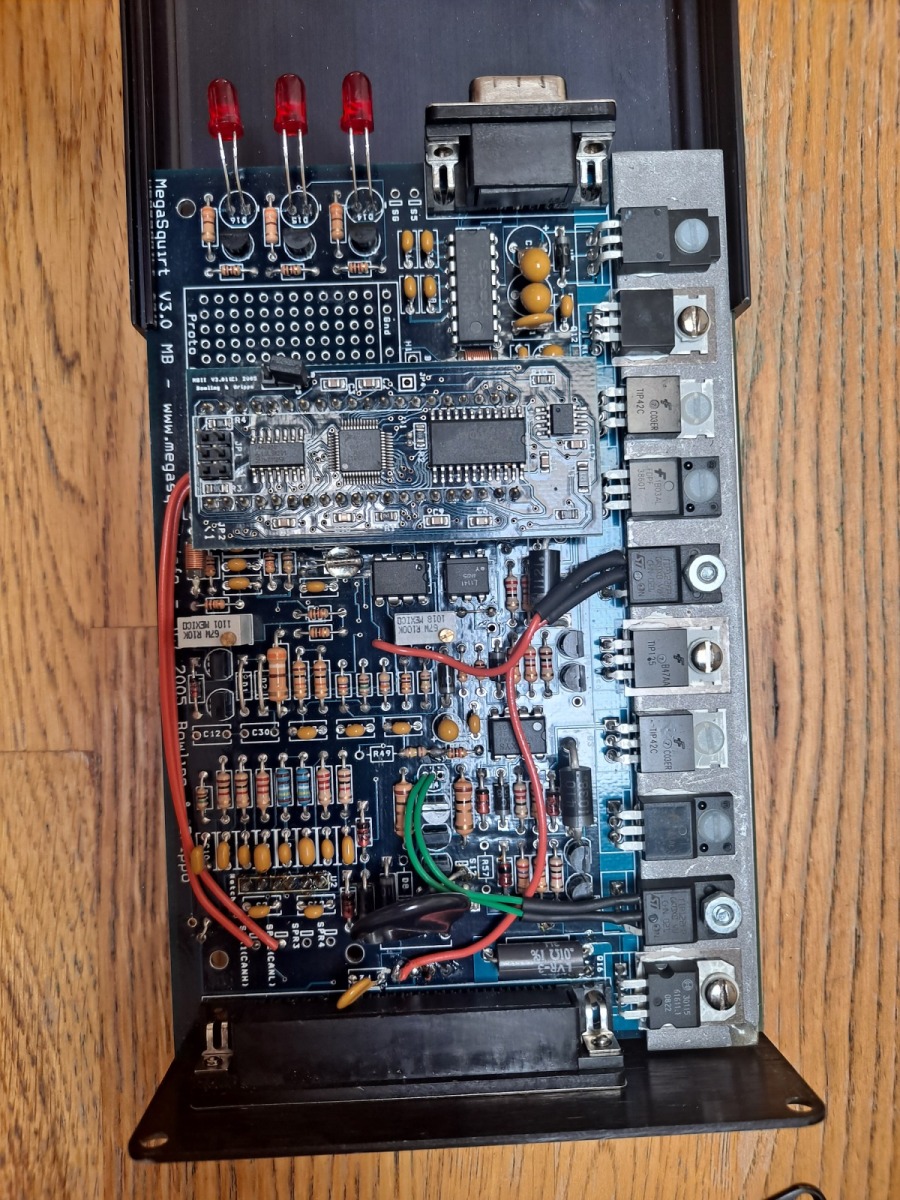

I had messaged Dan the other day about a post I read online with the tach settings. Dan's post suggested the output of the tach was being used to drive the advance and real advance wasn't as expected until the tach out setting was adjusted. My setup uses IGN (JS10). I tried to change this to off as well as a different output, and then the car just wouldn't start. So, obviously, I have to leave this setting alone.

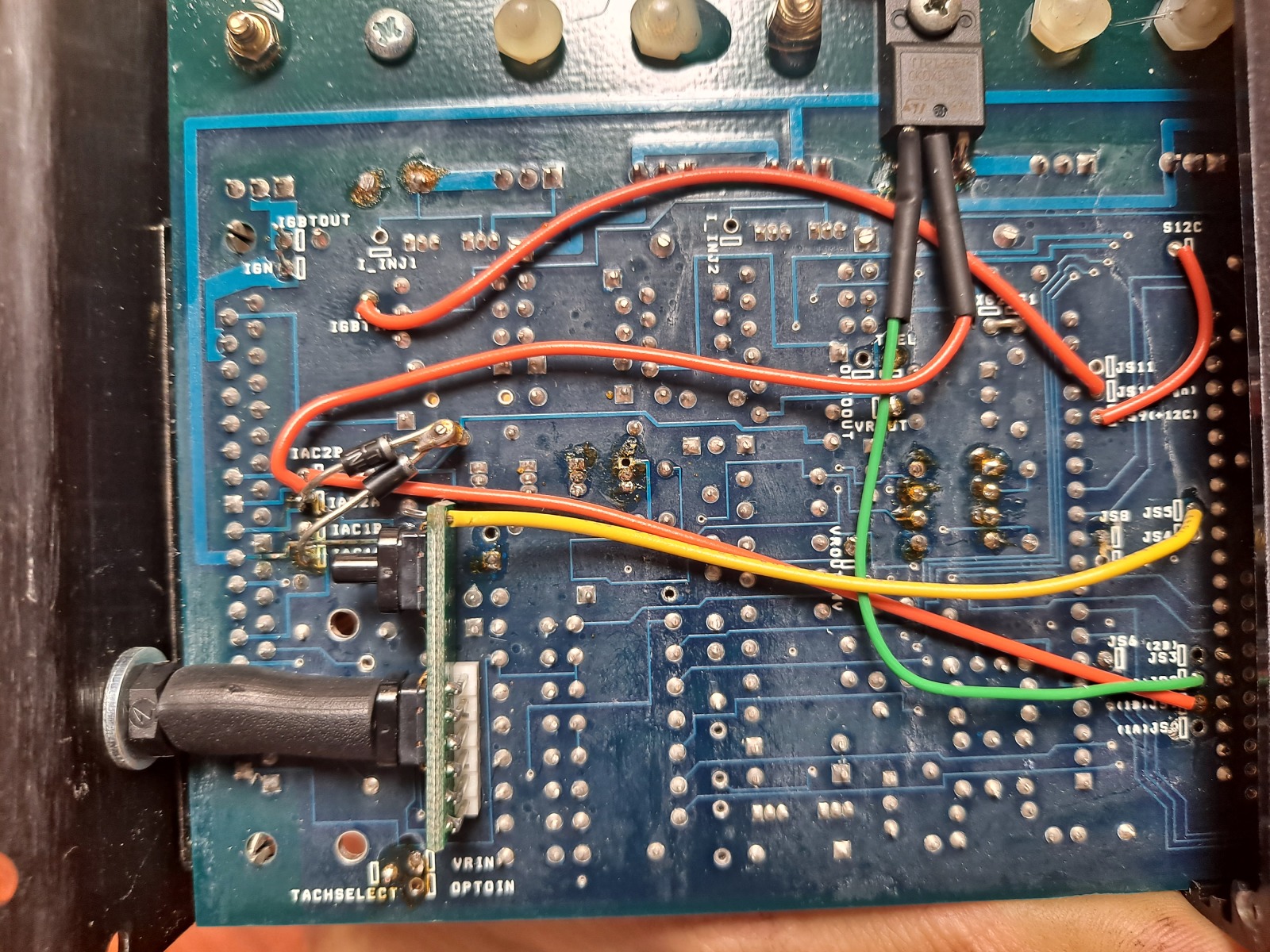

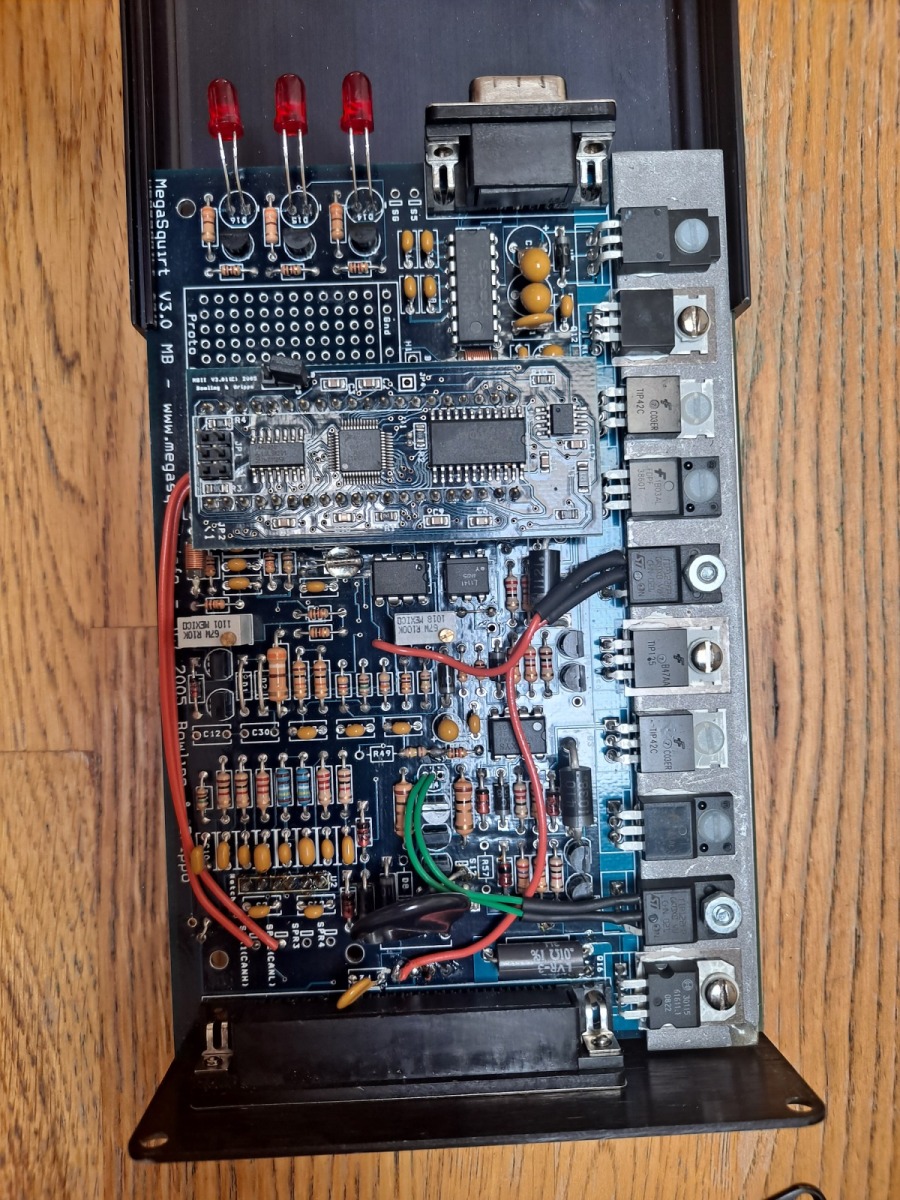

Speaking of, here's how my board is wired:

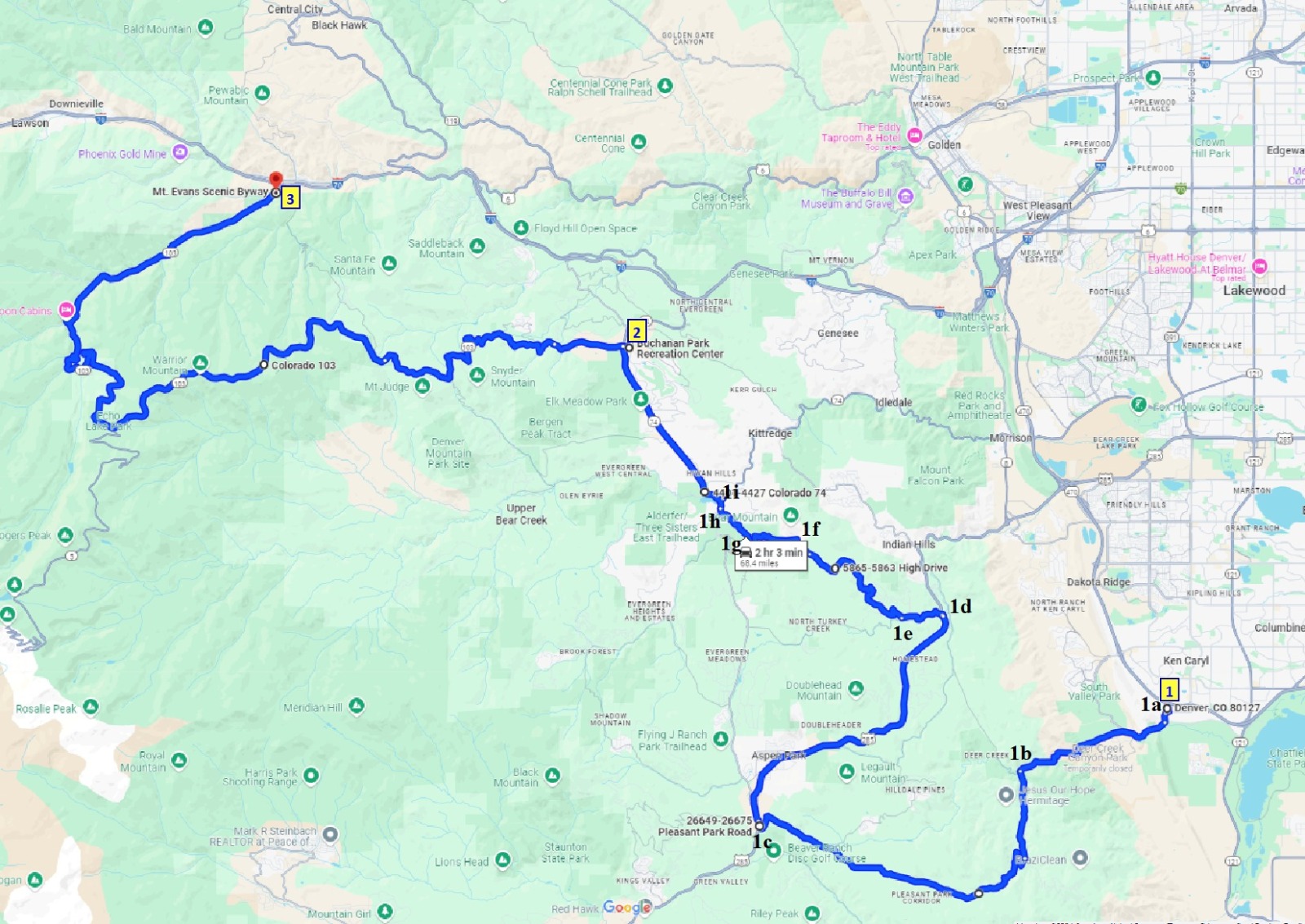

If I want wasted spark, I have to add BIP373 or equivalent, and the launch control is not wired in. I do have Map Daddy realtime baro correction and boost control, both functional features. I think my baro settings are decent based on my last mountain drive, but I am still unsure if MAT settings are correct or not. I have very little correction at this point in time (1-2% between 100F).

After starting the car, I was able to get it on the ground finally and drove it up and down the street and out of the garage.

First stop was for some new fuel!

I tried to vary the load and put about 5 miles and maybe 15 minutes run time. So the next day, I took the car out on the street and went up and down a number of times trying to check idle settings and also get some load, acceleration, deceleration and heat into the engine oil. After test driving, I had put about 50 miles on the car!

Speaking of intake temps, I have wondered if the standard intake is causing problems like heat soak. But when driving along, it seems like temps are 10-15F above ambient, which seems very reasonable to me as the sensor is in a pipe just above the valve cover and cylinder head! Moving faster benefits the A/A intercooler, and obviously slower could make it worse if stuck in traffic with no airflow.

Here's my intercooler placement. Good airflow through the front grilles and a little blockage by the bumpers, but that's about it. The standard valance and license plate mount and spoiler has a nice opening area to allow airflow through. That is the bottom edge, and you can see it with the minor crunch on the lower edge of the intercooler

Good news, the nissan radiator was holding temp of 180-190 F, only creeping up if idling in place without the fan and viscous fan cutch installed.

For break in, I am targeting a lowly 125kpa, but it sure is nice to be able to program it in the software and have the controller perfectly manage the boost level! I figure this boost level will allow the rings to be loaded plenty and I can up it later when more proven...

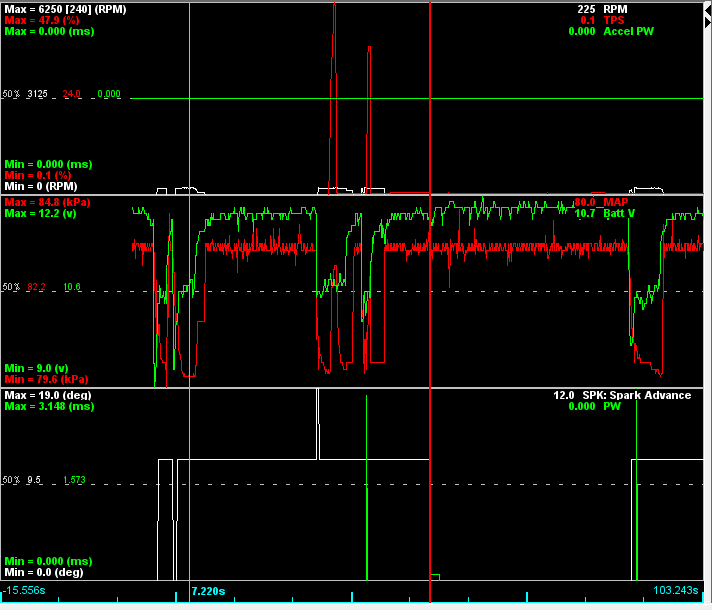

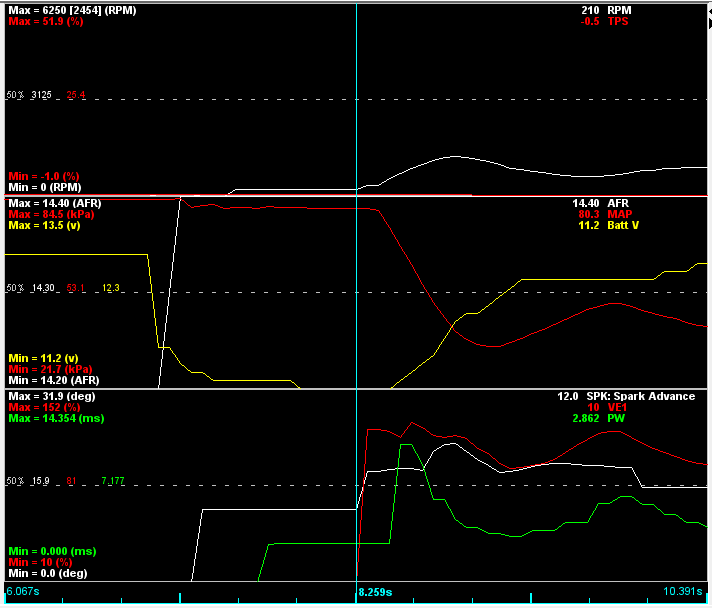

So far, I got the engine idling OK, though it seems to oscillate a little bit (200rpm every second or two) during warmup. When fully warm, the idle valve brings revs to about 1000rpm and then Closed Loop brings it down to about 800rpm. It holds fairly steady though that depends on the VE table. If idle is around 12.5:1, it seem steadier, though I am for 13.2AFR via closed loop control idle control and give 8% authority. No EGO control at idle.

Initial impression, it is running and I think just that little bit more responsive than the B34 in there before. I haven't noticed turbo lag like with the 8:1 engine...

I need to share pics but just added an oil temp gauge from Blackstar labs and placed it in place of the Rear Defroster. So it is easily visible next to the OBC... If I didn't already have gauges, I would consider their 4in1 although I just bought the oil temp gauge since I have other gauges. Slick how it mounts.

https://blackstarmanufacture.com/produkt/multigauge/

The new VDO pressure sender described above resolved my oil pressure gauge problem. I can get pictures of where these are located but right now, both are measuring from the back of the head with an adapter blackstar offered.

Update as of today. I felt confident after driving the car this past week and took the car down to see my dad and brothers. I figured it would be a good chance to get on the highway, get things up to temp and vary the load on the engine with some highway miles. Well on the highway, the engine cut out briefly though I continued driving without issue for another 10 minutes. Then, suddenly, the car shut off while cruising and afr gauge was totally lean. When I checked under the hood, my gauge (Still hooked up to the fuel supply) showed 0psi. No change when turning the ignition on/off when usually there is a priming pulse from the pump. Of course my 2 young boys were in the car and one started crying thinking we were stuck broken down there with nobody to help us.

I was working on the replacement plan and took the rear wheel off and was about to pull the pump, waiting to see if I could get a spare replaced on the side of the road when I decided to check the ignition again. Suddenly the pump was running and we had pressure! I started the engine without issue

Temps were warm, but 91 F while cruising shouldn't be problematic with a full gas tank! I put the wheel and tool back and swiftly merged back onto the highway.

I monitored oil temps for the first time and found that oil stays around 165-170 F and only started to rise while sitting in traffic where is got to about 180-185F in slow moving stop and go traffic.

I am contemplating putting a 745i oil cooler in the nose of the car under the plastic blanking plate above my intercooler. I think I can fit the 745i unit I have and slightly relocate the two horns that are sitting where it would go. I'd make some flexible lines and adapt to the 745i lines.

Any opinions? Any idea what temps the stock M30 oil cooler thermostat opens at?

I figure it would be cheap insurance for high performance driving since 1) it adds oil capacity and 2) provides actual cooling to the turbo itself as well as the engine internals. As long as oil temps are below 180 F when the cooler opens, it would aid in engine cooling and reducing stress on the radiator, not only just more consistent oil temps. Maybe it wouldn't be worthwhile after seeing temps never reach 200F, I don't know...

The car ran great the rest of the day and I put another 70 miles on it. The midrange torque is really nice and strong, even at this low boost level.

Though I do need to replace from LCAB's. I just need to disassemble, press the old ones out and reinstall. Additionally, I have a diff whine though I have thought about pulling the 3.46 and putting in a 3.25lsd. With higher boost, this may be a smarter ratio though the 3.46 isn't bad even at highway speeds.

Here's a picture from the afternoon. Obviously, I got the hood on and have the strut bar and oil/water separator in place. I may share pics depending how functional it is...

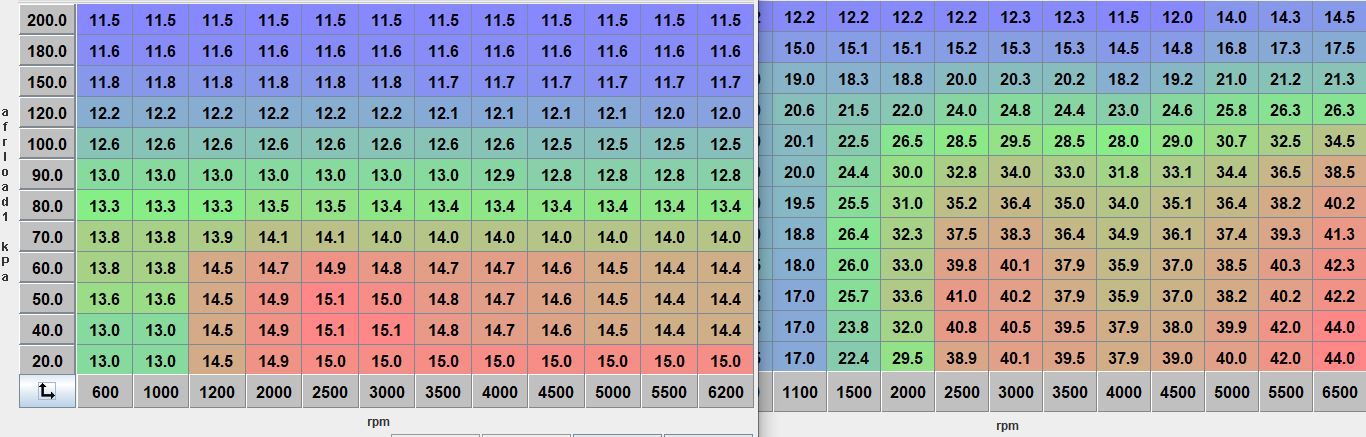

Current AFR and timing tables. I think I am pretty happy with both tables and have spent a fair amount of time on them for drivability, smoothness and safety. I may change timing depending on the 'correct' tooth #1 settings, but I know I am in the ballpark and within 3 degrees of the target.

More updates soon!