Page 11 of 18

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 4:32 PM

by BuzzBomb

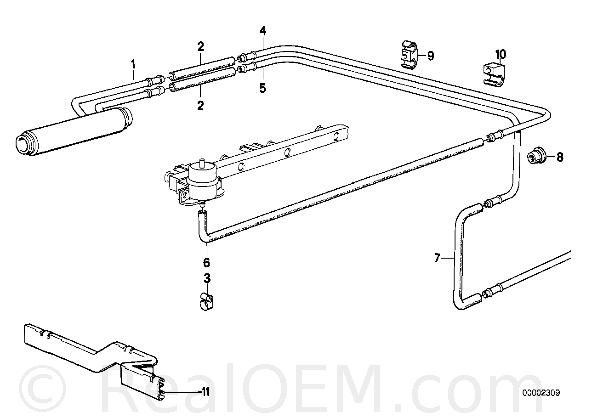

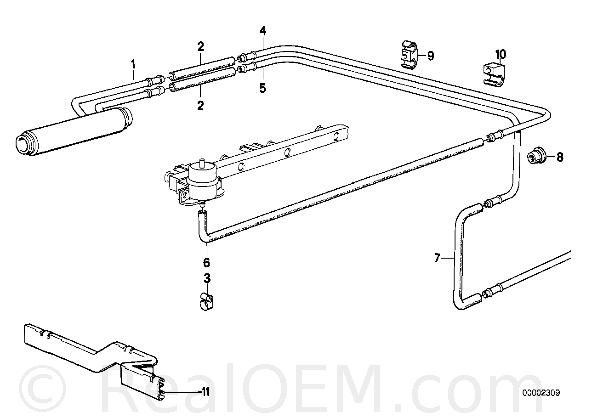

cek wrote:This diagram confuses me.

I thought the FPR end of the fuel rail was the "exit". If that's right then the fuel cooler cools the fuel on it's way back to the tank!?

You are correct. Logically it doesn't make sense in a performance sense, but maybe they were taking the passive-aggressive approach by thinking it would be a bad idea to return hot fuel to the tank, which would possibly raise the temp of fuel being delivered to the engine? Or in extreme conditions they thought it might vapor lock on it's way back to the tank. If I had it in my car, I'd probably reverse plumb it.

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 4:45 PM

by tig

Thanks BuzzBomb. That sorta makes sense.

Even though I've replaced my heater valve I don't remember how the hoses hook up. RealOEM isn't much help and I don't have any good pictures.

This is the new hose, that I believe goes from the outlet (bottom) of the heater valve to the heater core.

1) This goes to the TOP nipple on the heater core, right?

2) This new hose with the hook is too long. I assume I need to cut it even though it has wider sections on the end. Is that right?

3) The output of the head (gooseneck) goes to the input on the heater valve. Right?

EDIT:

I found my old hose. It's clear it was hooked to the lower nipple on the heater core. It's way too short to have been connected to the top nipple.

Does it matter? Logically it makes sense to me you'd want the lower nipple of something that holds fluid to be the "exit". So it is possible that the PO had this hooked up backwards. Again RealOEM and my pics are no help.

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 4:52 PM

by buzby

I used to work with industrial engines, taking automotive gasoline engines and converting to industrial use. They were also EPA certified and operated with three way catalyst. Cooling the fuel on the return is correct. Once engine has run a while the return fuel increases in temperature, if not cooled in extreme situations can cause to much vapor in fuel tank, unwanted expansion of the fuel and heat the returning fuel to engine. This can cause power de-rate, vapor lock and other issues.

Dave

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 6:20 PM

by tig

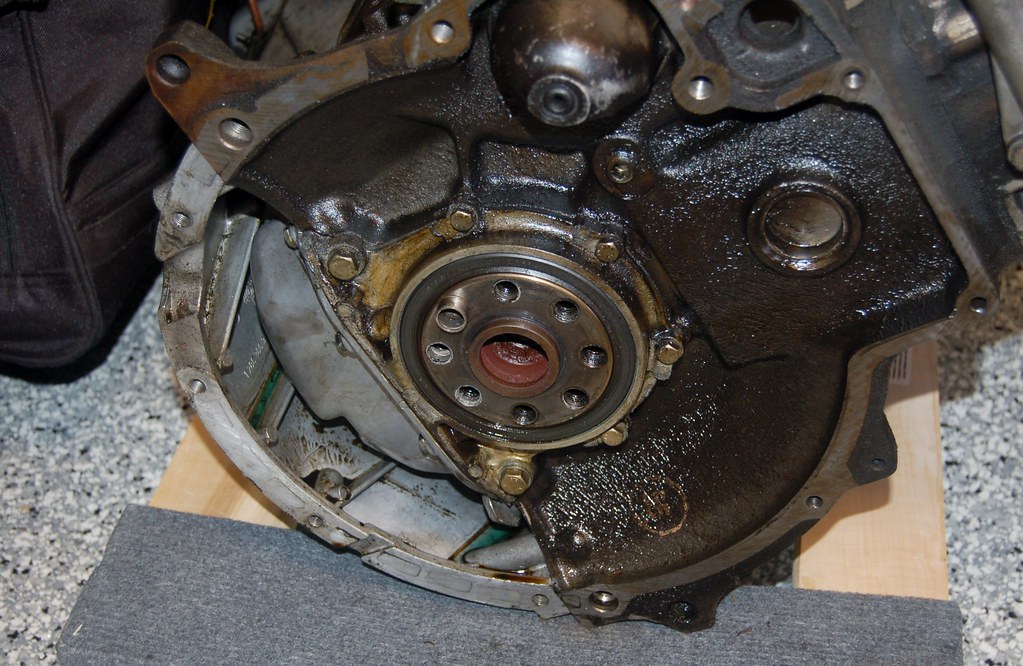

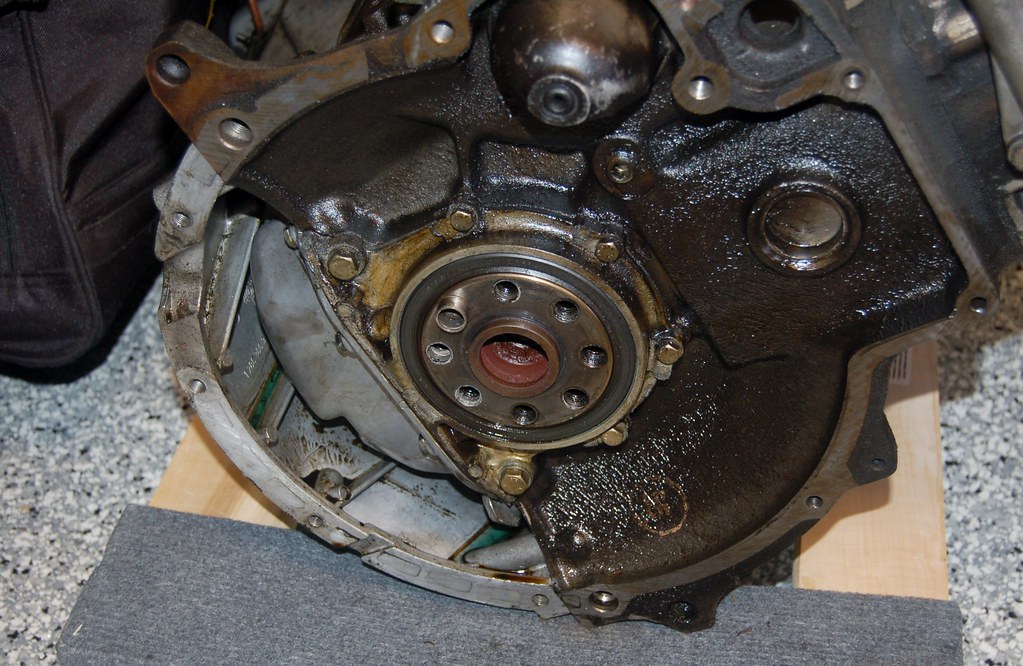

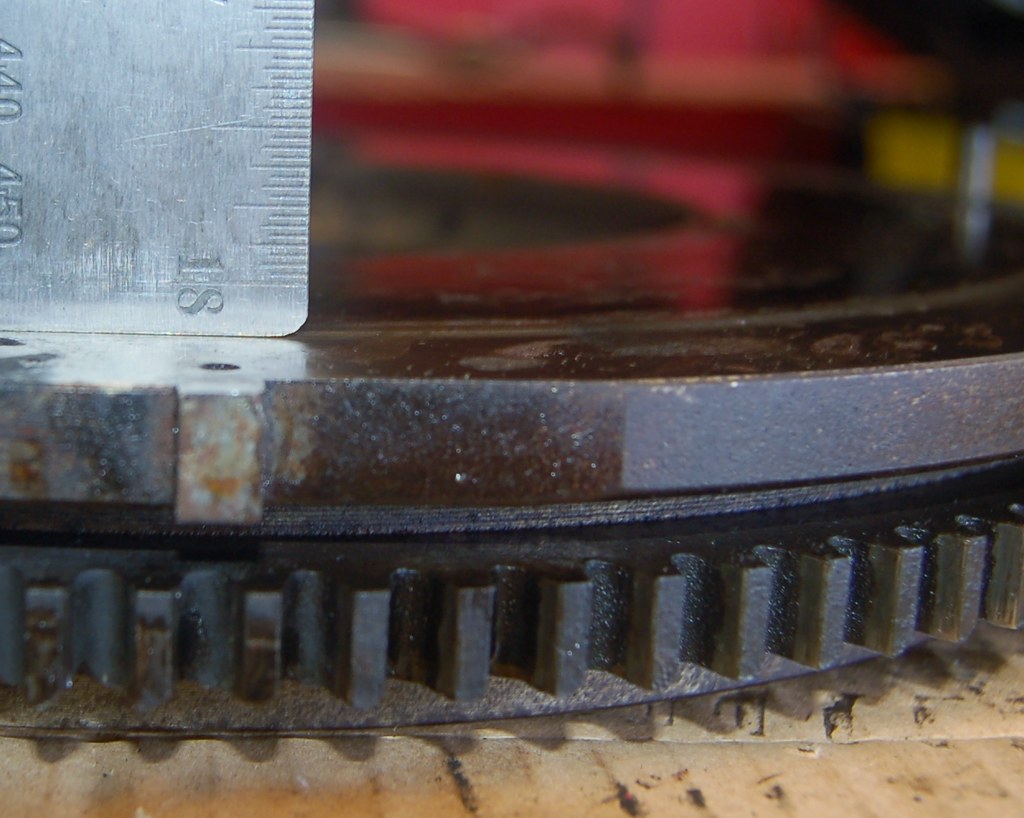

I pulled the clutch off the old engine.

Interesting to see the wetness in there; not horrible, but the main seal was leaking as I suspected.

You'll recall that the REAL reason for this project is Vlad's starter was failing to engage. I had read that replacing the B34 start was such a bitch that I decided to spend a year building a whole new engine instead. Anyhoo, I was curious about how the starter was actually failing. The teeth on the flywheel are fine. The teeth on the starter are fine too. So I guess it is the solenoid just not engaging all the way all the time.

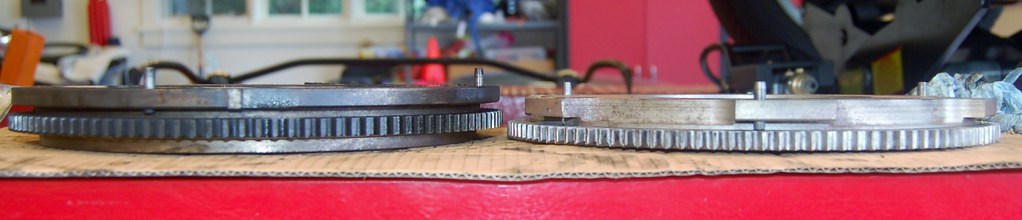

Old clutch. I have no idea if this is 'a lot of wear', 'moderate wear', 'no wear'. What do you experts say? Do people buy used clutches? What's this thing worth?

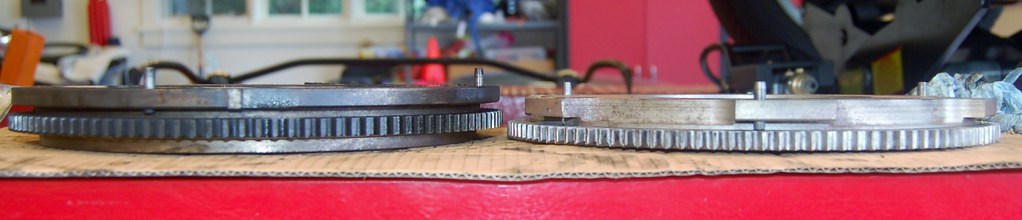

Lightened flywheel. vs stock E28/B34 flywheel.

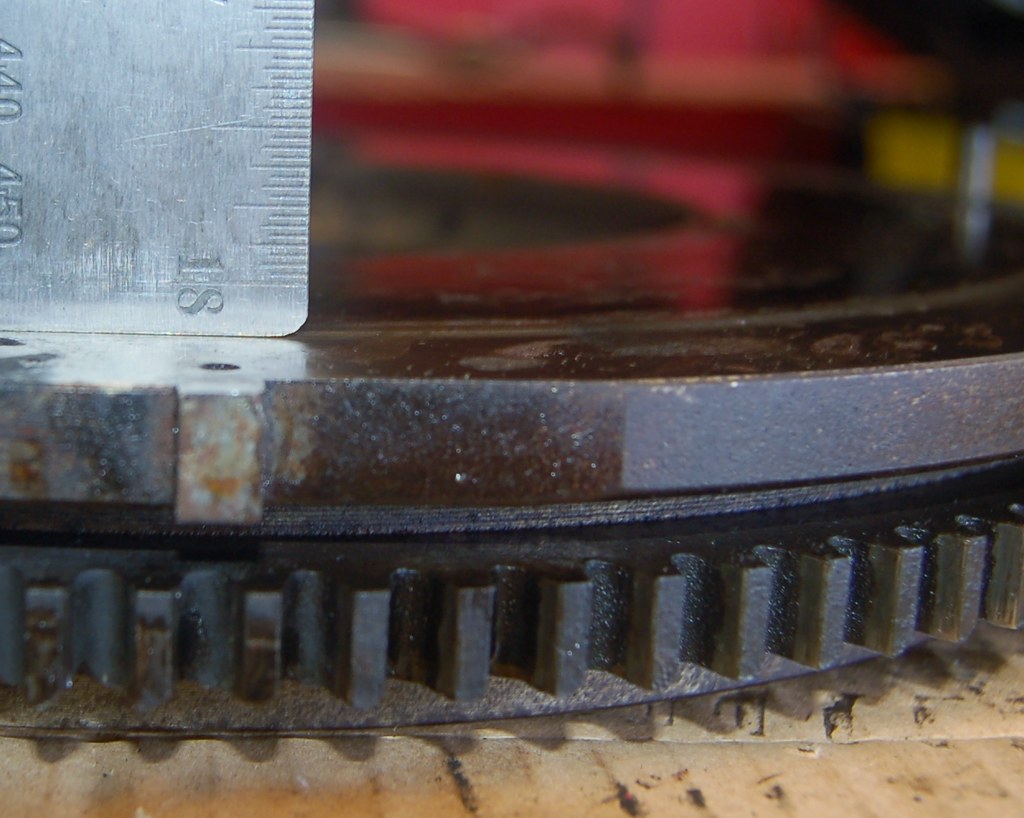

It's not super clear in this pic, but the 'lip' for where the PP touches is maybe 1/4 a millimeter. This shows it better.

I'm still going to take both flywheels to my machinist and have him help make the call, but I can't believe that much material will have an impact on how tight the PP holds the clutch.

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 6:59 PM

by tig

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 7:26 PM

by tn535i

On the fuel cooler. If you want to move heat from the fuel to something else it works best to do that on the hottest fuel with the greatest delta. That would be the return.

On the flywheel. I suggest again you put it on the crank with old bolts and snug it up and check runout. If the runout is minimal then work with it but if it's excessive you have a problem that won't go away regardless of what you do unless you machine the whole friction surfacr flat and rebalance. My biggest intial fear was runnout then the surface finish then the step. A new clutch probably means step is not a ig deal and you might get a liitel less life. There should be a spec for thickness on an old disc and yours does not look too bad. I'm thinking it has been replaced and the old flywheel also machined sometime reducing the step. I think this is common.

Not sure your machinist can check runnout as well as you can bolted to the actual crank. The precision and quality of a BMW crank is outstanding and the mounting surface of both parts should be very clean when going together.

Looking good.

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 28, 2014 8:07 PM

by dsmith

On the heater hose, yes bottom of heater core and cut to length.

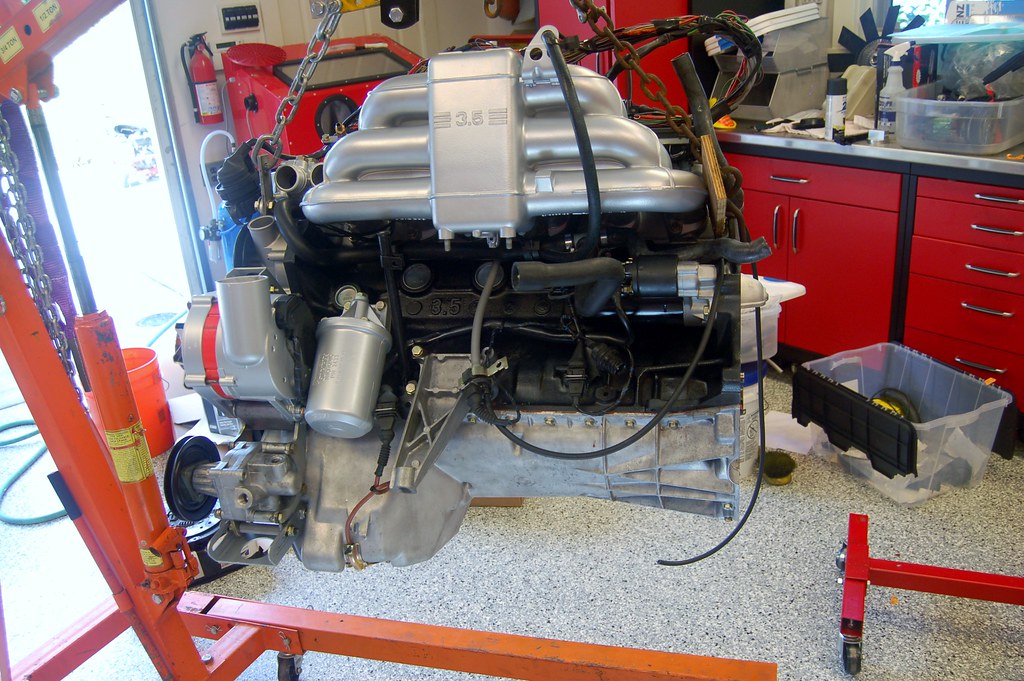

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 28, 2014 11:21 PM

by tig

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 3:34 AM

by wkohler

Congrats. It looks better in the car than it did on a stand.

Spec on a new clutch is 10mm. The discs really never seem to wear out. Pressure plates get old and stuff but none of the BMW mechanics I know have ever replaced a clutch on an M30 due to wear.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 6:24 AM

by kzolee

cek wrote:THE ENGINE IS IN!

*****

My job after dinner tonight is to get the wiring harness wrapped up.

Looks fantastic!

Don't forget the engine ground points, like me before first start...

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 10:59 AM

by trevmmeister

Is the head cover even bolted on?

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 11:25 AM

by wkohler

trevmmeister wrote:Is the head cover even bolted on?

No because he's going to need to refresh the head before it's done. Those are designed to be able to be removed or installed while the engine is in the car.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 11:27 AM

by unt0uchable

That looks fan-fuckin-tastic! You must be relieved. Looks right at home in there all shiny and nice and shit.

Going to take a video of the first attempt at starting?

Can't to hear it roar.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 12:26 PM

by tig

trevmmeister wrote:Is the head cover even bolted on?

No the valve cover is not bolted on. There's no oil in there yet (just assembly lube). I'll be putting in special break in oil, running it for 20min, then final torque of head bolts and a check of valve adjustment. Then new oil. Then drive.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 12:28 PM

by tig

kzolee wrote:cek wrote:THE ENGINE IS IN!

*****

My job after dinner tonight is to get the wiring harness wrapped up.

Looks fantastic!

Don't forget the engine ground points, like me before first start...

Yea, I have these on my list. Thanks for the reminder...I'm sure I've fforgot something...

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 12:29 PM

by tig

unt0uchable wrote:That looks fan-fuckin-tastic! You must be relieved. Looks right at home in there all shiny and nice and shit.

Going to take a video of the first attempt at starting?

Can't to hear it roar.

Yep, it'll either be a candidate for America's funniest home video or epic. Next weekend is the goal.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 3:10 PM

by tig

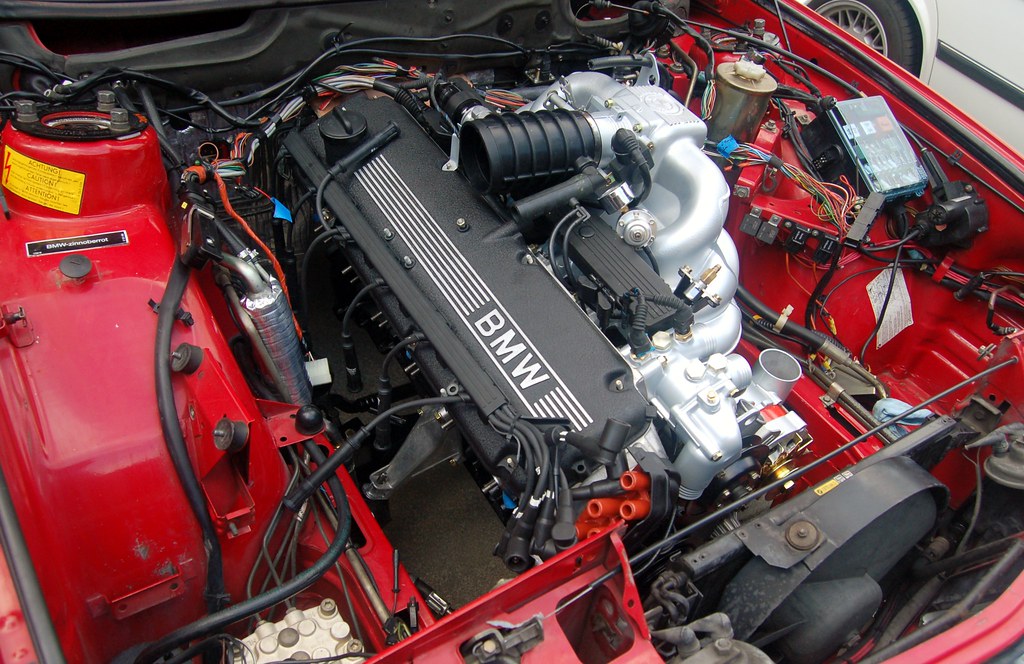

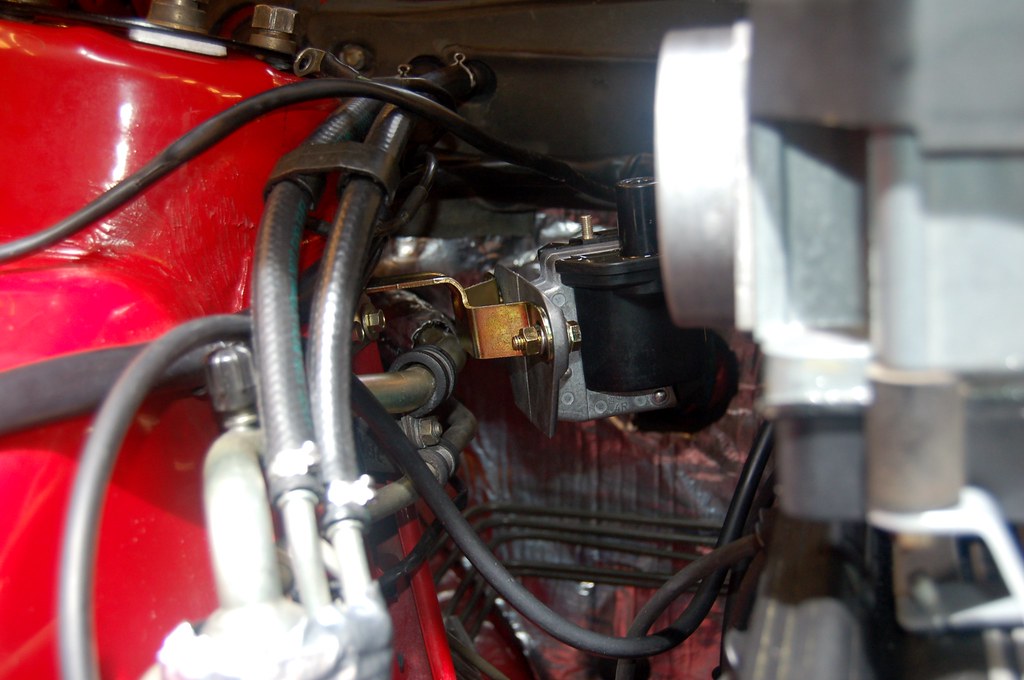

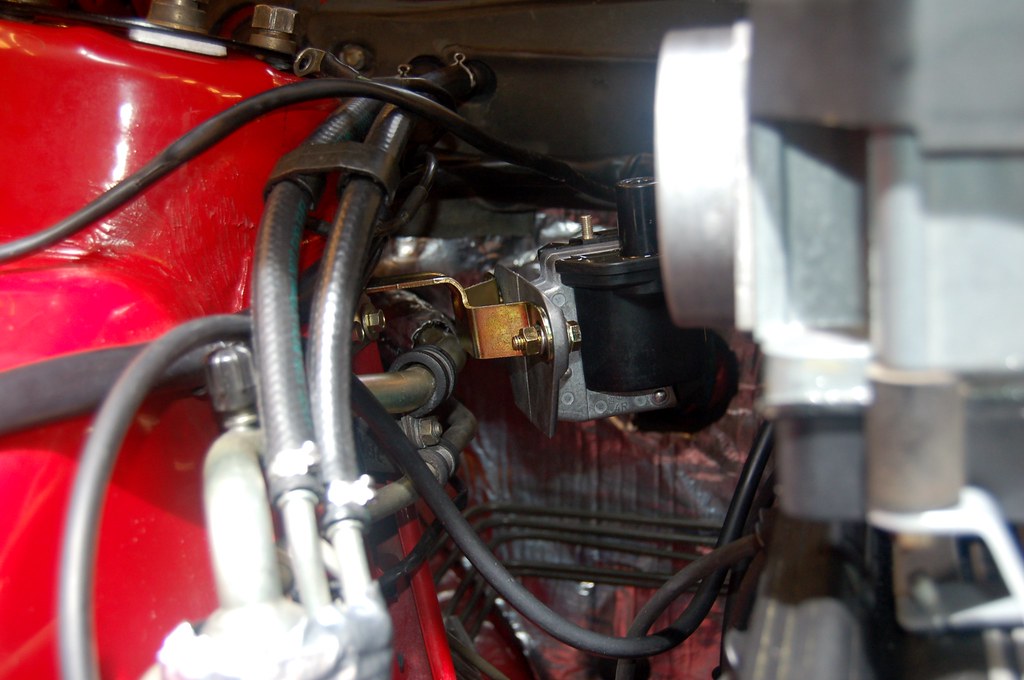

Coil.

The B35 coil is different than the B34 coil and the B35 plugs want you to mount it near the firewall.

I've seen others do this with custom brackets and with just bolting it to one of the nuts that holds the fuel cooler lines.

From the donor 735i grabbed this bracket, which I had thrown in with everything to get zync plated. I didn't remember what it was for, and I can't find it on the 735i diagrams on RealOEM, but I'm assuming it was the bracket that held the coil in place on the E32.

I bent it 90 degrees and I have three choices of where I can mount it.

One, on the firewall; either using one of the studs that hold the insulation in place or with some self tapping screws. This will be the easiest to mount and mostly 'out of the way'. Downside it it will be lower and thus closer to the headers; heat might be a concern.

Two, right above where the fuel cooler lines are held to the fender. This will be relatively easy to mount; two self-tapping metal screws/bolts. Downside is it will be a PITA to get to #5 & #6 spark plugs.

Three, farther to the rear; even more out of the way. But getting a drill in there to tap the holes for screws will be impossible.

Any thoughts or suggestions?

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 29, 2014 3:49 PM

by tig

tn535i wrote:On the flywheel. I suggest again you put it on the crank with old bolts and snug it up and check runout. If the runout is minimal then work with it but if it's excessive you have a problem that won't go away regardless of what you do unless you machine the whole friction surfacr flat and rebalance. My biggest intial fear was runnout then the surface finish then the step. A new clutch probably means step is not a ig deal and you might get a liitel less life. There should be a spec for thickness on an old disc and yours does not look too bad. I'm thinking it has been replaced and the old flywheel also machined sometime reducing the step. I think this is common.

Not sure your machinist can check runnout as well as you can bolted to the actual crank. The precision and quality of a BMW crank is outstanding and the mounting surface of both parts should be very clean when going together.

I don't know what runout is or how to measure it. Bentley's lists a "Clutch disc runout" but doesn't show where you measure it. Please advise. Thanks.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 4:33 PM

by tig

Hmmm... New AC belt is too short. Somehow I got a 13x810mm belt (I believe from Blunt).

I'm using the B34/E28 compressor.

RealOEM calls for 12.5x800mm for the E28 and 12.5x855 for the E32.

The 865mm long belt I have for the PS pump is WAY too long, so the E32 belt, at only 10mm smaller will likely be too big too.

Can you buy belts in arbitrary lengths? I figure 820-845 will be about right.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 6:41 PM

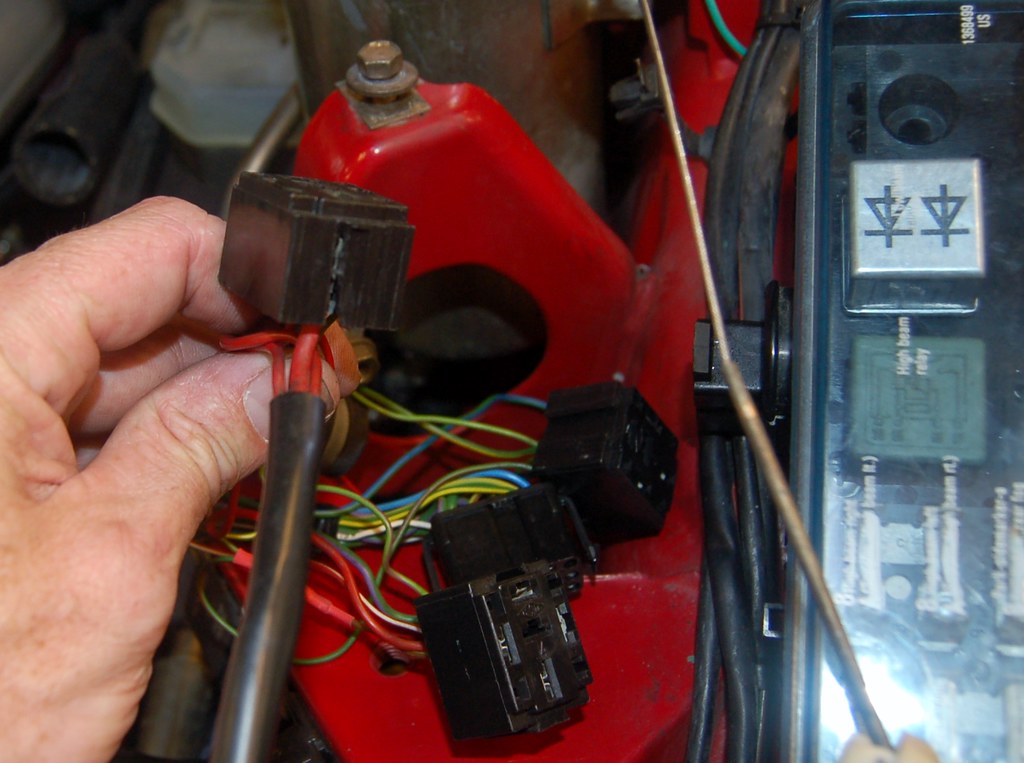

by tig

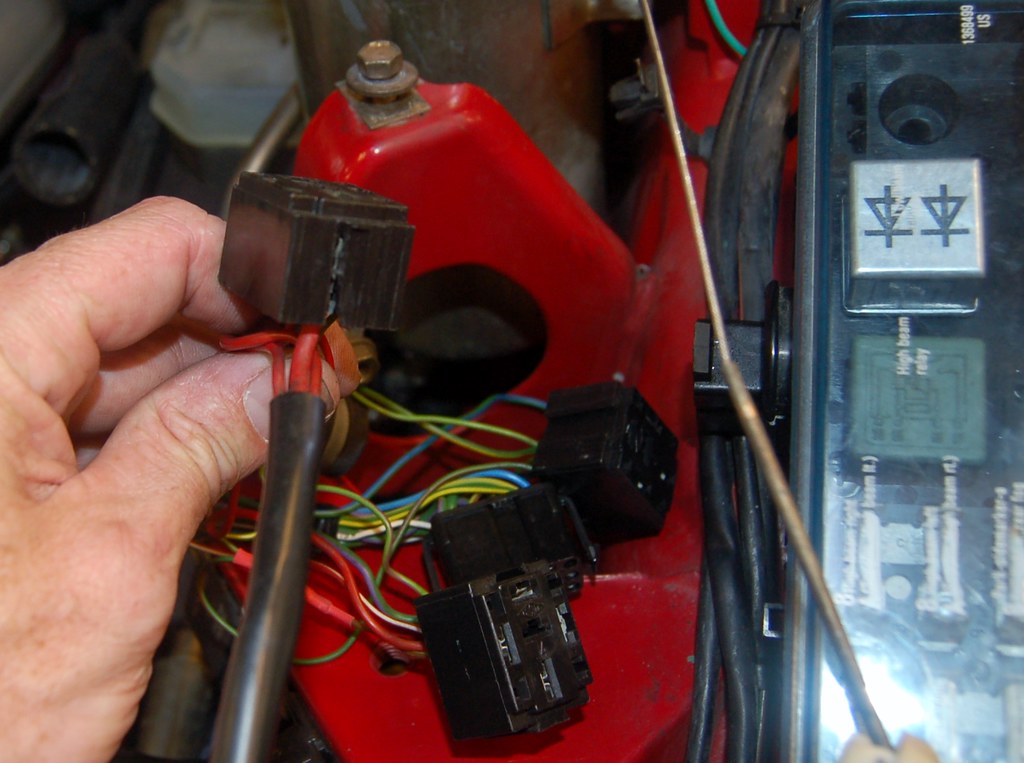

Crud. I wished I would have noticed this when I was splicing it in. The main relay connector from the donor B34 harness is busted and wont attach to the fuse box!

I need to find a replacement stat. Anyone local to Seattle have a B34 harness you'd be willing to snip about 4" off of?

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 7:57 PM

by tig

The M30B35 Swap FAQ does not explain the whole air filter housing thing very well.

It appears the choices are:

Use the B34 housing

- Must use B34 rubber boot between the AFM/MAF and throttle body.

- Can't use B35 valve cover mounting points for AFM, but must mount AFM to B34 air filter housing bracket.

- Looks oldskool next to the the modern B35 motor and hides the sexy powder coated B35 valve cover.

Use the B35/E32/E34 housing

- Requires heavy modification to the filter housing mounts welded to the fender, for which I can't find any pictures or instructions about.

- Uses mounts on top of valve cover.

- Sits so close to the valve cover that it actually rubs on the spark plug wires. Bob (Das Paracutefarfugnugen) had his #1 wire wear through.

- No obvious way to make it 'fit' to the headlight backing.

- Looks factory and better looking compared to the E28 housing. Sexy powder coated B35 valve cover is visible.

Use a cone style filter with custom extension tubing

- All the 'experts' say these filters are crap and the world will end if they are used.

- Must spend $$$ on fabricating tubing a heat shield. Some say TCD carries a kit, but I don't see it on the site.

- Looks sexy as hell (but not OE) compared to the E28 housing. Sexy powder coated B35 valve cover is visible.

Who else has done the B35/E32/E34 housing? Do you have instructions and pictures that show how you made it fit? Does it ACTUALLY fit (I'm super skeptical).

For now I'm going with the orignal B34 parts just to get running. This is muy disappointing.

Lots of stuffs hooked up this afternoon. Wire harness (mostly) wrapped (see previous post

). Coolant hoses mostly in place. Etc...

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 29, 2014 10:13 PM

by Crazy_Canuck

cek wrote:Can you buy belts in arbitrary lengths? I figure 820-845 will be about right.

Yes, yes you can!

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 2:58 AM

by kzolee

cek wrote:Coil.

The B35 coil is different than the B34 coil and the B35 plugs want you to mount it near the firewall.

It is different, but functionally the same. You can use the B34 coil on its original location.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 3:11 AM

by kzolee

cek wrote:

Who else has done the B35/E32/E34 housing? Do you have instructions and pictures that show how you made it fit? Does it ACTUALLY fit (I'm super skeptical).

It fits, I did it also.

Here's some information:

http://www.mye28.com/viewtopic.php?t=101481

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 3:12 AM

by tig

kzolee wrote:cek wrote:Coil.

The B35 coil is different than the B34 coil and the B35 plugs want you to mount it near the firewall.

It is different, but functionally the same. You can use the B34 coil on its original location.

Not if you want to use the B35 spark plug harness, unmodified.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 3:15 AM

by tig

kzolee wrote:cek wrote:

Who else has done the B35/E32/E34 housing? Do you have instructions and pictures that show how you made it fit? Does it ACTUALLY fit (I'm super skeptical).

It fits, I did it also.

Here's some information:

http://www.mye28.com/viewtopic.php?t=101481

That thread was spectacularly un-helpful. Thanks for confirming that it fits.

You have an 87 535is with a fuel cooler? It fits there? What did you have to modify to make it fit and be secure?

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 3:58 AM

by kzolee

A photo of my installaion of the B32 airbox:

cek wrote:kzolee wrote:cek wrote:Coil.

The B35 coil is different than the B34 coil and the B35 plugs want you to mount it near the firewall.

It is different, but functionally the same. You can use the B34 coil on its original location.

Not if you want to use the B35 spark plug harness, unmodified.

Yes, with B35 harness you need to relocate.

I have crappy cell phone pic of my solution:

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 4:04 AM

by kzolee

cek wrote:

That thread was spectacularly un-helpful. Thanks for confirming that it fits.

You have an 87 535is with a fuel cooler? It fits there? What did you have to modify to make it fit and be secure?

My car was originally an M20 car, with no options (No ABS, A/C....) There is no fuel cooling.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 5:58 AM

by Das_Prachtstrasse

I just realized I never got back to you in regards to the airbox, so here's a few pics of how I did it in my car. Apologies for the poor lighting, I need to replace the fluro's in the garage. I should also make it noted that this install was only ever intended to be temporary until I installed the new engine with the ITB's, so the quality of the bracketry and the fitment in general isn't something I'm proud of, but could be improved easily with a little intuition. Apologies also for the appalling state my engine bay is in at the moment. Hasn't received any love for a long time.

Anyway, I made a simple bracket to mount to the side of the box using the factory rubber at the top, and mounted to the OEM coil location on the bottom. The underside of the box sits on another small T shaped bracket which mounts to the frame rail through a small hole that's otherwise unused from the factory stamping. I can remove the airbox and take a picture of that if you need. The bellmouth sits nicely just below the RH high beam, and has a decent flow of air from behind the headlights. If it were a more permanent install, I'd have included a small plastic guide to direct the air from behind the kidney's. The first three plug wires are no problem provided you wrap them in cloth tape, or some of that curly hard plastic stuff you find on home appliance cords otherwise they will eventually chafe on the airbox heat shield, as it IS a tight fit. I also put a small piece of adhesive loop sided velcro on the body to prevent the aft airbox clip from chafing the paint, due basically to laziness. It doesn't touch the body as it sits, and would clear easily if Id made the lower bracket a few mm taller but I didn't care enough to properly amend it.

I also mounted my B35 coil to the factory bracket left behind after the M20 coolant tank removal. Works nicely, and isn't too close to the exhaust manifold however I'm guessing you wont have this bracket.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 11:55 AM

by tig

Bob, you are a scholar and a gentleman. Thanks a ton for these pics and description. Immensely helpful.

So you didn't have to butcher the OE brackets on the fender that hold the B34 airbox? They look to be in the way on my car.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 11:56 AM

by tig

kzolee wrote:A photo of my installaion of the B32 airbox:

It looks like, in your install, the airbox is farther away from the front part of the valve cover than Bob's. Can you explain?

Re: Noob M30B35 Build. 2014-06-23: I beat the wiring harness

Posted: Jun 30, 2014 12:17 PM

by tn535i

cek wrote:I don't know what runout is or how to measure it. Bentley's lists a "Clutch disc runout" but doesn't show where you measure it. Please advise. Thanks.

https://www.google.com/search?q=magneti ... B480%3B360

You need something like one of these kits and an innexpensive import works fine. I think mine came from Enco. The mag base goes on the block and you adjust the arms so the lever or stem runs perpendicular to the friction surface. Rotate the flywheel looking for changes. It would have been easier still out of the car but too late. These things are also ideal for checking hubs and rotors btw.

Bentley says maxiam axial runout is .1mm (.004") at outer diameter. Personally I would try to get it to 1/2 or less since whenever I've measured one before removing it is almost undetectable runout.

Also a quote from Bentley says "If the flange height has been reduced to zero clearance during machining, the flange surface of the flywheel must machined until some clearance exists. See figure 5-6. BMW does not list the specification for this flange height." I guess we need someone to measure a new flywheel to give guidance. I would try to replicate the flange height of a new flywheel.

Bentley also says the minimum flywheel thickness for a 535 is 26.5mm (1.043") and I think yours is now much thinner than this. What does that mean? My guess is too thin results in hot spots and warping. This is another reason to avoid the way that flywheel is machined as I think hot spots develop in the areas of less mass, every 60'.

But I really don't know from experience what happens.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 12:39 PM

by kzolee

cek wrote:kzolee wrote:A photo of my installaion of the B32 airbox:

It looks like, in your install, the airbox is farther away from the front part of the valve cover than Bob's. Can you explain?

Bob has a MAF, and his airbox is positioned in a little different angle.

But both our cars were M20 originally, so we had a bit easiest job...

I took some photos for You of the current position. As Bob, I have also a temporary bracket. I have also put a piece of adhesive under the airbox.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jun 30, 2014 7:11 PM

by Das_Prachtstrasse

I've got the airbox positioned closer to the valve cover due to the extensive washer bottle relay preventing it from moving across further, as you can see if you look closely. With the old regular washer bottle in there, it was a much better fit with the bell mouth positioned nicely between the two headlights, and a fair bit more room between the plug wires, as per kzolee's pic. Again, if I'd intended on the fitment being permanent, I'd have relocated the headlight washer relay to allow a little more room.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jul 01, 2014 11:17 AM

by tig

So that I can more easily play with my wideband gauge(s) I welded in an extra O2 sensor bung.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jul 01, 2014 2:21 PM

by BuzzBomb

cek wrote:So that I can more easily play with my wideband gauge(s) I welded in an extra O2 sensor bung.

Before you continue, test fit an 02 sensor into your new bung, and make sure the probe reaches fully into the exhaust stream. A drivability problem was recently solved because of a bung that was too tall, keeping the 02 sensor from correctly interpreting the exhaust gasses. I know it sounds crazy, but I wouldn't believe it either if I didn't see it for myself.

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jul 01, 2014 4:59 PM

by tig

Will do. Thanks!

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jul 04, 2014 10:44 AM

by tig

I took Vlad's old flywheel and the lightened one back to my machinist. He analyzed them and recommended milling the step in the lightened one. Picked it up yesterday.

The list:

- Mount the B35 coil.

- Put new wiper tank in and connect.

- Put new coolant overflow tank in and connect.

- Tighten belts.

- Put radiator back in.

- Drop in the new in-tank fuel pump.

- Final attach AFR.

- Reattach strut bar.

- Attach fuel hose from tank to rail.

- Install short-shift kit.

- Install lightened & balanced flywheel and new clutch.

- Install transmission.

- Install rebuilt driveshaft.

- Attach headers.

- Reinstall exhaust. (once the car is drivable I'm taking it into a shop and having the exhaust rebuilt)

- Fill fluids. Bleed brakes, PS, clutch.

- Install plugs.

- Put air filter housing in.

- Remember to tighten steering column nut (I have a piece of tape on the dashboard where I wrote "don't forget steering nut!").

- Cross fingers and start it up. 20 minutes, then re-torque head bolts.

I've lost a ton of sleep worrying about what happens if it doesn't start...

Re: Noob M30B35 Build. 2014-07-04: Will it start this weeken

Posted: Jul 04, 2014 11:19 AM

by kzolee

21. Have a beer.

Looks like a tight weekend program, good luck!

Re: Noob M30B35 Build. 2014-06-28: Engine is in!!!

Posted: Jul 04, 2014 12:26 PM

by tig

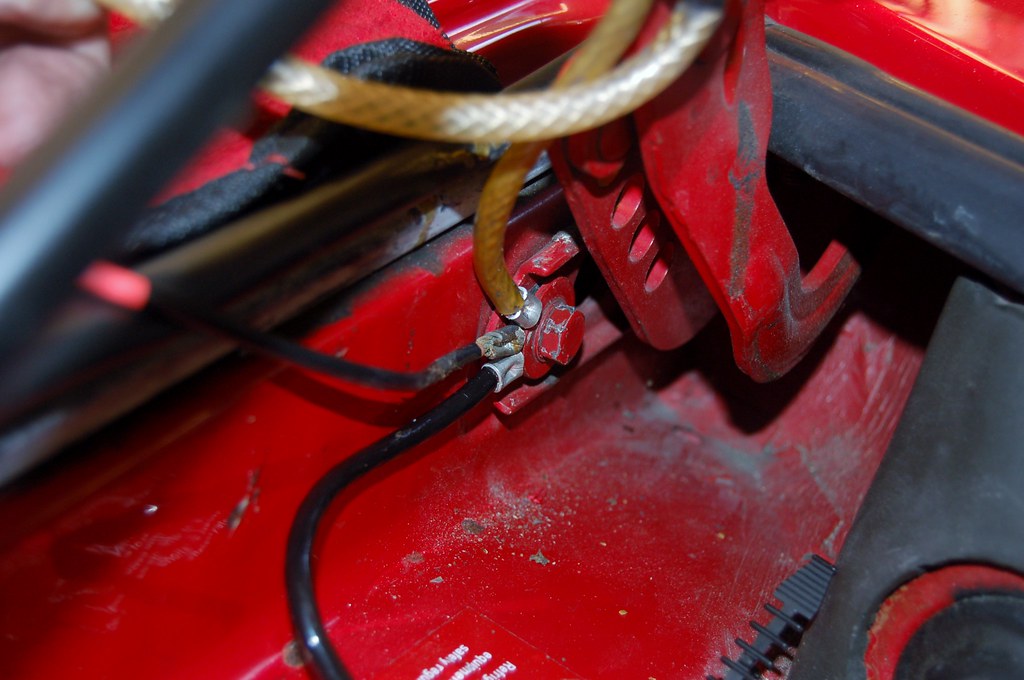

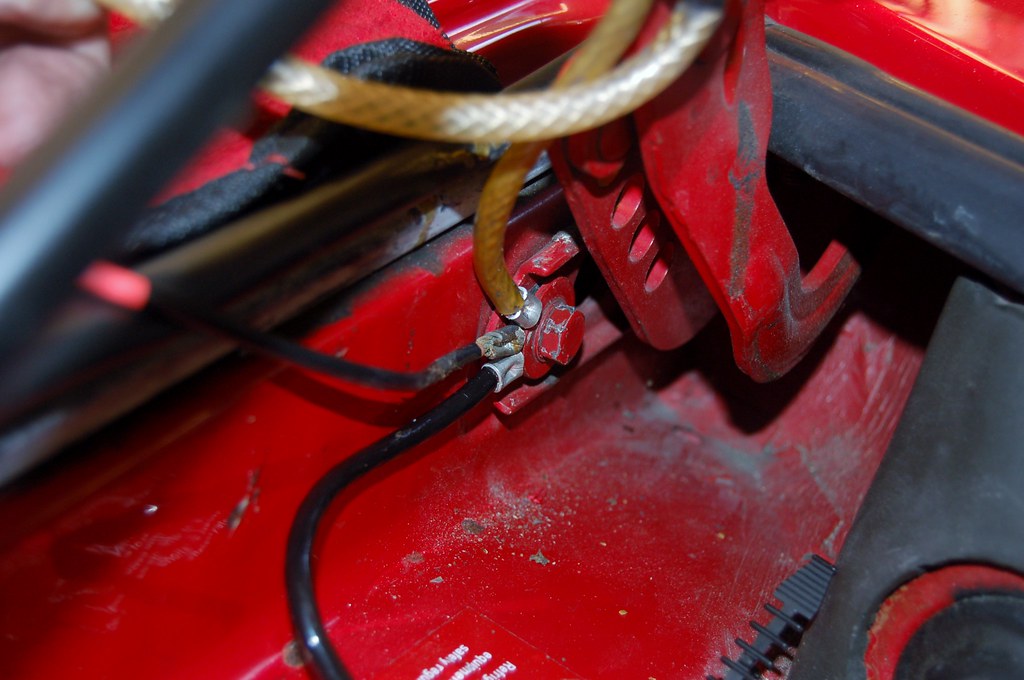

The wire for ground point from the hood to the body at the RHS hinge was just about to break.

I bought new connectors and fixed it. I wired the harness ground wires to a nut/bolt that then goes to the 2nd black 8ga wire you see in this photo providing grounding for the hanress.

Coil installation.

I can't find my coolant overflow tank cap. I have a basically new one here somewhere...

The list:

- Mount the B35 coil (DONE).

- Put new coolant overflow tank in and connect (DONE).

- Tighten belts (DONE).

- Attach fuel hose from tank to rail (DONE).

- Connect new grounds for wiring harness on RHS (DONE).

- Put new wiper tank in and connect (DONE).

- B35 bellhousing has hole w/ plastic cap. Plastic cap wants to fall out. Buy cap at Ace hardware that fits! (DONE)

- Put radiator back in.

- Drop in the new in-tank fuel pump.

- Final attach AFR (waiting for the UPS man for some brass fittings).

- Reattach strut bar.

- Install short-shift kit.

- Install lightened & balanced flywheel and new clutch.

- Install rebuilt driveshaft.

- Attach headers.

- Reinstall exhaust. (once the car is drivable I'm taking it into a shop and having the exhaust rebuilt)

- Fill fluids. Bleed brakes, PS, clutch.

- Install plugs.

- Put air filter housing in.

- Remember to tighten steering column nut (I have a piece of tape on the dashboard where I wrote "don't forget steering nut!").

- Cross fingers and start it up. 20 minutes, then re-torque head bolts.

- Have beer.