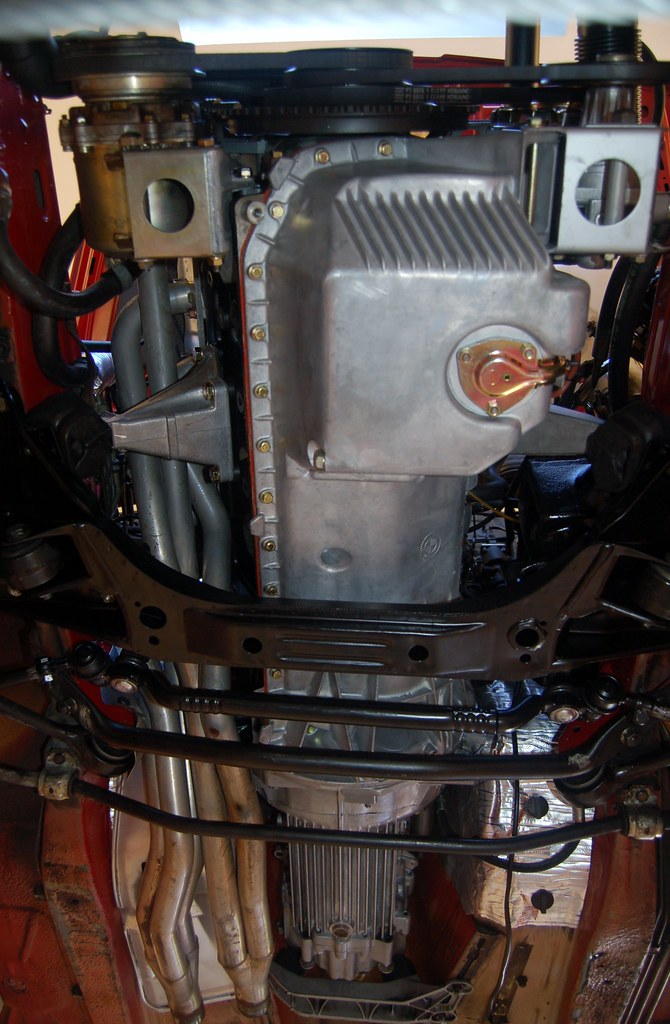

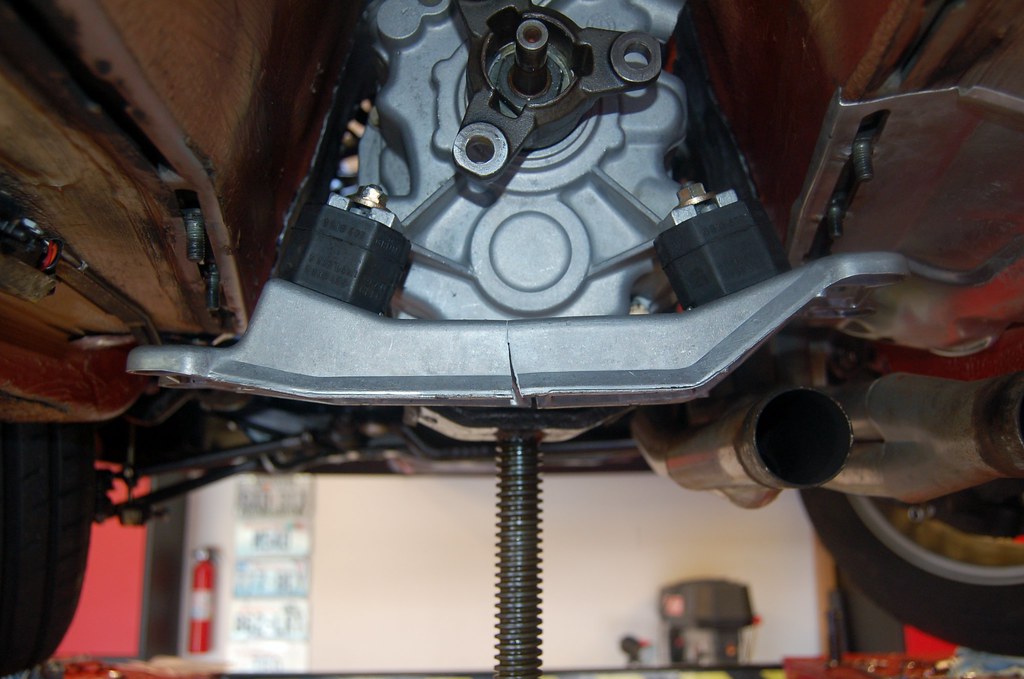

This morning was all about the transmission.

My son was supposed to help me, but he got invited up to some shindig on an island and left early this morning. Good thing he left two of his buddies at our house. They helped me get the transmission on the transmission jack. My back is not capable.

They also helped me test fit the transmission to ensure I could get to all the bolts with the socket extensions I have on hand. I can.

I'd never installed a clutch or transmission before so I took my time double checking everything (and Bentley's). Those of you who are master-class probably could do what I did in about 20 minutes, but it took me about half a day.

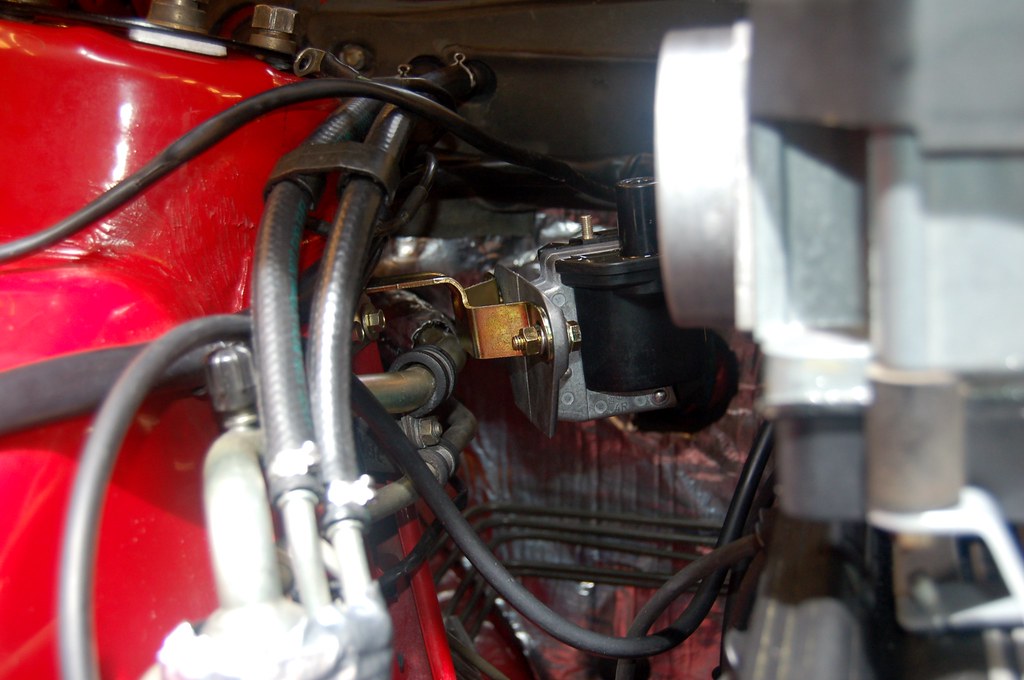

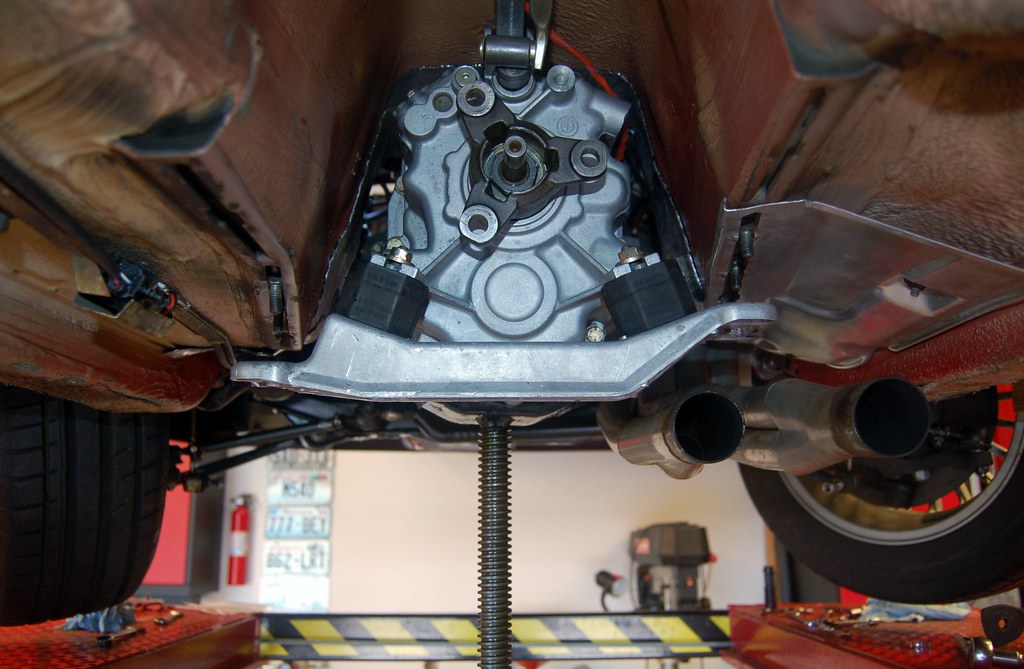

Got the short-shift kit assembled.

Doing it was a bit of 2 step forward 1 back. Notice in the pic of the transmission above the direction the long side of the shift-rod bushing is pointing? That's backwards. The guy who replaced the seals on the transmission put it on backwards. I couldn't figure out why the shift-rod wouldn't fit right. I looked at my old photos and saw the thing pointed the other way and the shift-rod went on the right. I then figured out how to get the bushing off (remove the ring that covers the pin, push the pin out).

I also had trouble with the UUC bushings for the shift lever end of the rod. They wouldn't fit (I'm glad I took my time and did a test fitting; it would have sucked to discover this later). A little emory paper on the end was all it took.

The B34 has two flywheel reference sensors that attach to the tranny. The B35 does not. I didn't like having those holes uncovered so I went to Ace hardware and bought a collection of caps that might fit. The rubber stoppers would have worked no matter what, but they would have felt ghetto so I was hoping...

The plastic ones with the 3 ribs fit perfectly. Heh.

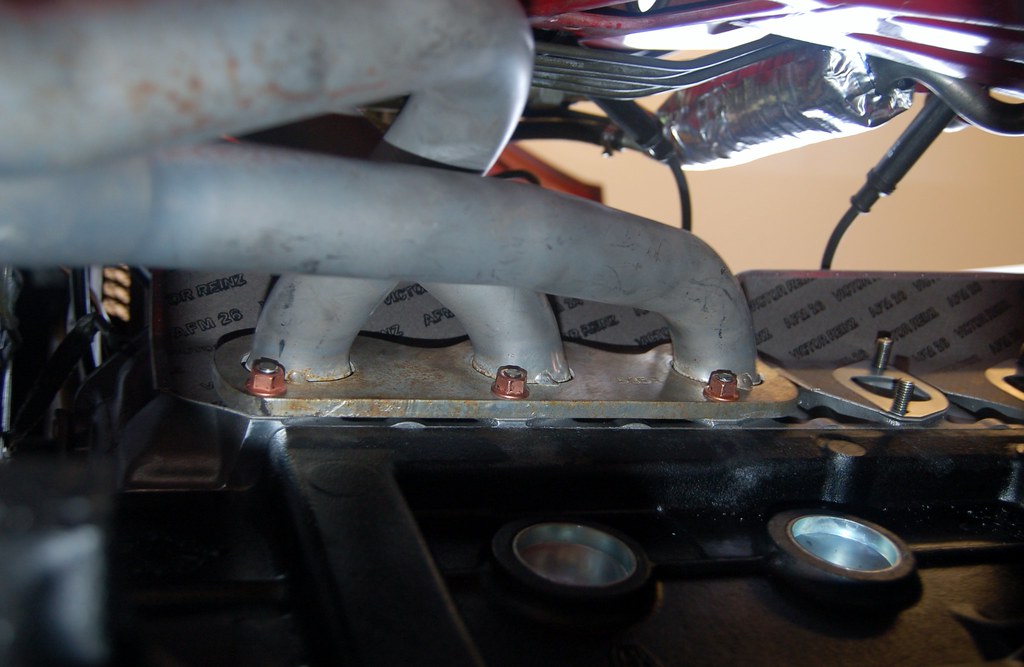

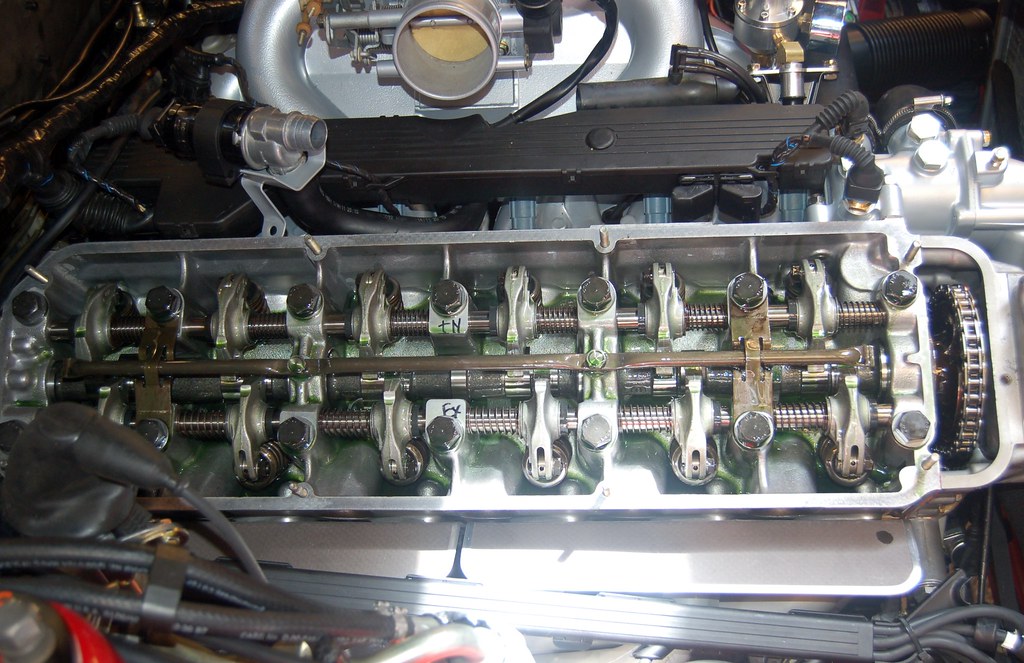

Next, following @tn535i's advice on testing the runout on the flywheel, I hooked up my new indicator (always love an excuse to get a new tool!) and measured (using old bolts so that the loctite on the new ones would not be used up). The runout was hardly measurable (+/-0.010mm).

Clutch is in.

The list:

- Mount the B35 coil (DONE).

- Put new coolant overflow tank in and connect (DONE).

- Tighten belts (DONE).

- Attach fuel hose from tank to rail (DONE).

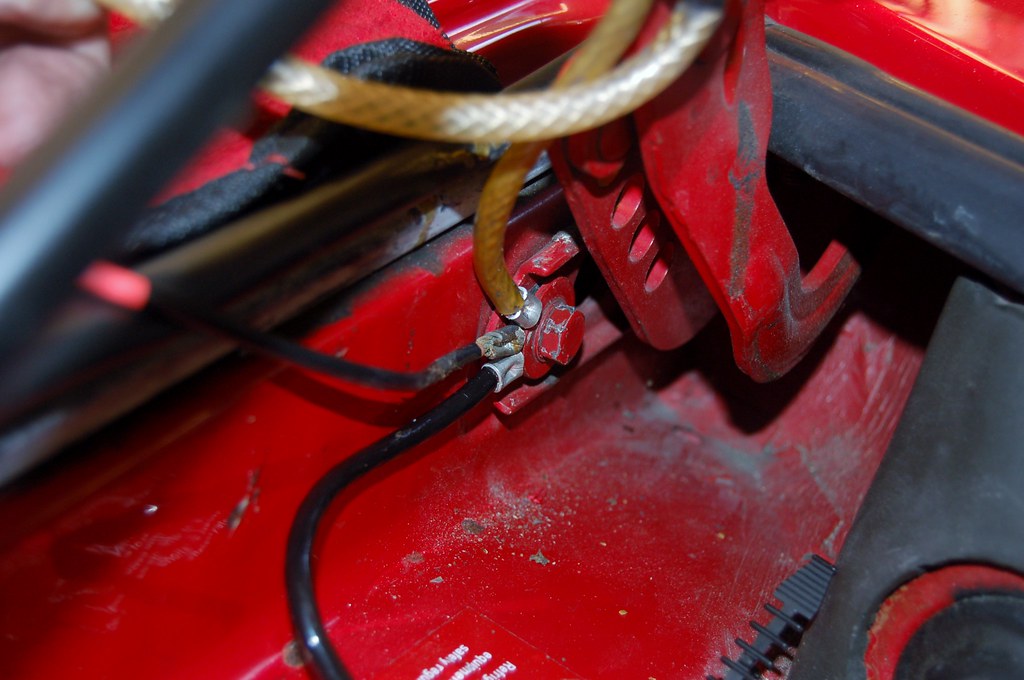

- Connect new grounds for wiring harness on RHS (DONE).

- Put new wiper tank in and connect (DONE).

- B35 bellhousing has hole w/ plastic cap. Plastic cap wants to fall out. Buy cap at Ace hardware that fits! (DONE)

- Install short-shift kit. (DONE)

- Install lightened & balanced flywheel and new clutch. (DONE)

- Attach transmission.

- Put radiator back in.

- Drop in the new in-tank fuel pump.

- Final attach AFR (waiting for the UPS man for some brass fittings).

- Reattach strut bar.

- Install rebuilt driveshaft.

- Attach headers.

- Reinstall exhaust. (once the car is drivable I'm taking it into a shop and having the exhaust rebuilt)

- Fill fluids. Bleed brakes, PS, clutch.

- Install plugs.

- Put air filter housing in.

- Put in 179 ECU and plug it in.

- Remember to tighten steering column nut (I have a piece of tape on the dashboard where I wrote "don't forget steering nut!").

- Cross fingers and start it up. 20 minutes, then re-torque head bolts.

- Have beer.