I ran my e34 with no oil cooler at Mid Ohio and Road America on coolish days with no issues. Best oil cooler for you would be from an e24 m6.tschultz wrote:T_C_D wrote:

What do people use for oil coolers? I read about the B35 oil filter housing and cooler setup from an E32. I'd probably do this before actually bringing the car to an autocross or lapping day...

535is Homebrew Turbo (ex 633 Callaway) - 2024 Update

Re: Callaway 633CSi

Re: Callaway 633CSi

tschultz wrote:

Thanks, still lots to do! Just driving the current setup around, I can tell why MS would be the better way to go to make use of fueling and have the control for optimum drivability.

Careful what you wish for :-)

Re: Callaway 633CSi

For the immediate future, MS is off the table until I can get on top of other items like normal drivability-- finishing exhaust, suspension, brakes, alignment, heater core/waterpump. I am not driving this further than a mile from my house since I don't want to get stranded. Part of this was due to the ECU, the other is a weeping water pump.

So I took apart the ECU causing the no-start issue and found the transistor joints had cracked. After soldering, this ecu fired right up 3 times in sequence last night! I am still carrying the spare so I don't get stranded anywhere. But here's a photo I found on the subject, along with the repair procedure:

Great procedure, not always shared here in my search for "ecu solder joints cracking transistor" because it isn't an actual thread on the forum: http://e28-535i.com/technical/e28-ECU_Repair.php

I will be swapping the FPR as I think the one in this engine is bad. No change at idle with/without vacuum line hooked up, and the power delivery is not very smooth after 4500rpm (even though AFR's bounce between 11.5-12.5). After I replace this, I may try the BEGI 2025 for fuel control. To do this, I will need a 255lph pump for the flow capability and larger injectors.

I will also be soon replacing the waterpump, gasket, temp sender, and at some point, replacing the heater core. These parts are coming in today, so hopefully I can start on this soon.

I have a few other items I need to repair on both the M5 (clutch return spring is damaged), 535i (front lower control arm ball joint is bad), and X5 (Air springs on the fiancé's vehicle just failed). So I have plenty of car projects and it may take me a while to get these turbo car items completed.

The next big project will be swapping shocks and springs between cars. In my head all three of my E28 based cars need a set of shocks/springs from another car, or what I have sitting in the garage.

So I took apart the ECU causing the no-start issue and found the transistor joints had cracked. After soldering, this ecu fired right up 3 times in sequence last night! I am still carrying the spare so I don't get stranded anywhere. But here's a photo I found on the subject, along with the repair procedure:

Great procedure, not always shared here in my search for "ecu solder joints cracking transistor" because it isn't an actual thread on the forum: http://e28-535i.com/technical/e28-ECU_Repair.php

I will be swapping the FPR as I think the one in this engine is bad. No change at idle with/without vacuum line hooked up, and the power delivery is not very smooth after 4500rpm (even though AFR's bounce between 11.5-12.5). After I replace this, I may try the BEGI 2025 for fuel control. To do this, I will need a 255lph pump for the flow capability and larger injectors.

I will also be soon replacing the waterpump, gasket, temp sender, and at some point, replacing the heater core. These parts are coming in today, so hopefully I can start on this soon.

I have a few other items I need to repair on both the M5 (clutch return spring is damaged), 535i (front lower control arm ball joint is bad), and X5 (Air springs on the fiancé's vehicle just failed). So I have plenty of car projects and it may take me a while to get these turbo car items completed.

The next big project will be swapping shocks and springs between cars. In my head all three of my E28 based cars need a set of shocks/springs from another car, or what I have sitting in the garage.

Re: Callaway 633CSi

Here are a few other random photos from the swap last month.

pulling out the donor

The assembled Callaway setup (hillbilly special wood block not shown)

Installing the new engine:

So another update.

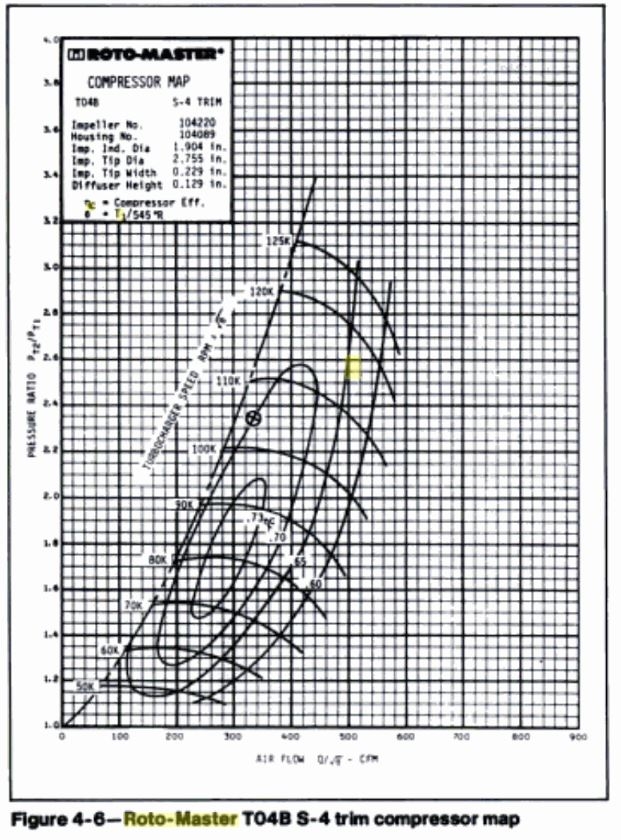

I have been in discussions with Ken H. (Lucifer's Hammer) and he was kind enough to spend some time digging for me. Based on the specs/part number on the turbo he was able to determine that the turbo in this car is a T04B S-4. I had assumed based on some posts by a member here, that it was S trim, and that the generic turbo map I found was correct. Well it is not correct. Further research (big kudos Ken) shows that this is the correct compressor map.

Unfortunately with the higher altitude and larger displacement of the B34, this moves the map further into choke. At ~485cfm and 1.8 pressure ratio, it's sitting outside the 60% island Well, unfortunately I'm gong to have to change turbo's when I want to actually drive this thing. It sucks because the manifold is a PIA, but I will figure it out when I come to that.

Well, unfortunately I'm gong to have to change turbo's when I want to actually drive this thing. It sucks because the manifold is a PIA, but I will figure it out when I come to that.

But anyway, onward with progress. Late last week, after work I spent the evening replacing the water pump. Since the swap, there had been a leak from around the water pump area--dripping off the oil pan. From all my research this indicated water pump. The shaft didn't have much play but I figured I ought to replace it. So after swapping the front control arm off my 535i (it didn't solve my clunking so I'll have to resolve that later), I started on the 633. Good news, it was pretty straight forward and I was able to get the old one out. I think the gasket may have failed, causing a slow leak. Got the mating surface nice and smooth and put the new one in. From my research on here, I went with the Saleri brand. I buttoned it up and was able to get it all back together. Good news, no more leak.

so I'll have to resolve that later), I started on the 633. Good news, it was pretty straight forward and I was able to get the old one out. I think the gasket may have failed, causing a slow leak. Got the mating surface nice and smooth and put the new one in. From my research on here, I went with the Saleri brand. I buttoned it up and was able to get it all back together. Good news, no more leak.

I replaced the coolant temp sender, but still not getting anything. I think it's bad wiring because everything was working before, and ground the sender doesn't move the gauge. I didn't want to have to track this down, but oh well. Will follow the repair procedure: http://www.mye28.com/viewtopic.php?t=34049

I drove it around the block again and still no leaks. However, with the new knowledge about the turbo size, everything made sense. The engine runs out of steam after ~4500rpm, I believe because of compressor choke. Also, the manifold and turbo seem very hot, even for 65 degree weather, which makes sense for the condition. Also, it makes sense because a very similarly sized turbo was put on all of the other Callaway models-- the M10 and other 4 cylinder VW's that Callaway modified in the early 80's. So down the road I am definitely changing the turbo, but I currently don't have the funds for it, and probably won't until next year when I got on top of my other projects.

So over the weekend I was able to do a few more items. I got some rotors in the mail and calipers from my brothers old parts car. So I installed E34 rear rotors and the calipers. Pretty excited about this as I have them on my M5. The fronts, however, will have to be rebuilt, and I will need to get rotors still.

I didn't drive it around yet because I also started on the heater core replacement (remember our mistake when pulling the engine??). Well I tore into it Saturday and spent a couple of hours on it until I stopped at my brothers house. I continued working on it yesterday for 4 hours or so. Lots of removing of parts, but I wasn't taking pictures as I really wanted to get the job done. The toughest part is getting all of the vent out of place, removing all the AC bits, and then pulling out the heater box. It took me a while to understand that there were 4 nuts/bolts holding the heater box in place. Once loose, it took another 15 minutes to get it situated on the passenger floor for core replacement. I'm glad I got it removed because I found a little friend and his home inside the box. No photos, but there were nuts, insulation, leaves and other misc stuff.

I'm pretty glad to have changed it for this reason.

Old and new.

I figured the heater didn't work well because of the heater valve, but I didn't really drive the car enough in the cold to know for sure. The valve looked pretty good (except for the brown crud in the filter), but I replaced it with a new one anyway. Now I know the heater didn't work because the heater box didn't ever get enough airflow to actually transfer heat to the cabin. So for the time being I have to finish putting the center console back in, along with the glove box and driver's kick panel. It has been a good opportunity to clean out the dirt and trash, along with getting the wiring cleaned up underneath the dash. Still have a ways to go, but I'm getting closer.

pulling out the donor

The assembled Callaway setup (hillbilly special wood block not shown)

Installing the new engine:

So another update.

I have been in discussions with Ken H. (Lucifer's Hammer) and he was kind enough to spend some time digging for me. Based on the specs/part number on the turbo he was able to determine that the turbo in this car is a T04B S-4. I had assumed based on some posts by a member here, that it was S trim, and that the generic turbo map I found was correct. Well it is not correct. Further research (big kudos Ken) shows that this is the correct compressor map.

Unfortunately with the higher altitude and larger displacement of the B34, this moves the map further into choke. At ~485cfm and 1.8 pressure ratio, it's sitting outside the 60% island

But anyway, onward with progress. Late last week, after work I spent the evening replacing the water pump. Since the swap, there had been a leak from around the water pump area--dripping off the oil pan. From all my research this indicated water pump. The shaft didn't have much play but I figured I ought to replace it. So after swapping the front control arm off my 535i (it didn't solve my clunking

I replaced the coolant temp sender, but still not getting anything. I think it's bad wiring because everything was working before, and ground the sender doesn't move the gauge. I didn't want to have to track this down, but oh well. Will follow the repair procedure: http://www.mye28.com/viewtopic.php?t=34049

I drove it around the block again and still no leaks. However, with the new knowledge about the turbo size, everything made sense. The engine runs out of steam after ~4500rpm, I believe because of compressor choke. Also, the manifold and turbo seem very hot, even for 65 degree weather, which makes sense for the condition. Also, it makes sense because a very similarly sized turbo was put on all of the other Callaway models-- the M10 and other 4 cylinder VW's that Callaway modified in the early 80's. So down the road I am definitely changing the turbo, but I currently don't have the funds for it, and probably won't until next year when I got on top of my other projects.

So over the weekend I was able to do a few more items. I got some rotors in the mail and calipers from my brothers old parts car. So I installed E34 rear rotors and the calipers. Pretty excited about this as I have them on my M5. The fronts, however, will have to be rebuilt, and I will need to get rotors still.

I didn't drive it around yet because I also started on the heater core replacement (remember our mistake when pulling the engine??). Well I tore into it Saturday and spent a couple of hours on it until I stopped at my brothers house. I continued working on it yesterday for 4 hours or so. Lots of removing of parts, but I wasn't taking pictures as I really wanted to get the job done. The toughest part is getting all of the vent out of place, removing all the AC bits, and then pulling out the heater box. It took me a while to understand that there were 4 nuts/bolts holding the heater box in place. Once loose, it took another 15 minutes to get it situated on the passenger floor for core replacement. I'm glad I got it removed because I found a little friend and his home inside the box. No photos, but there were nuts, insulation, leaves and other misc stuff.

I'm pretty glad to have changed it for this reason.

Old and new.

I figured the heater didn't work well because of the heater valve, but I didn't really drive the car enough in the cold to know for sure. The valve looked pretty good (except for the brown crud in the filter), but I replaced it with a new one anyway. Now I know the heater didn't work because the heater box didn't ever get enough airflow to actually transfer heat to the cabin. So for the time being I have to finish putting the center console back in, along with the glove box and driver's kick panel. It has been a good opportunity to clean out the dirt and trash, along with getting the wiring cleaned up underneath the dash. Still have a ways to go, but I'm getting closer.

Last edited by tschultz on May 18, 2015 11:55 AM, edited 1 time in total.

Re: Callaway 633CSi

In the future all you have to do is measure bother the compressor wheel and turbine wheel to determine capacity. It's super simple and maps are readily available. We went through this discussion in 2003. I suspect you were still in high school. LOL

The compressor wheel isn't a choke point. The turbine could be but isn't. Even with the smallish compressor wheel the turbo will support 7/8psi although not efficiently. The engine. Probably falls on its face because you have not tuned it yet. Don't give up yet.

The compressor wheel isn't a choke point. The turbine could be but isn't. Even with the smallish compressor wheel the turbo will support 7/8psi although not efficiently. The engine. Probably falls on its face because you have not tuned it yet. Don't give up yet.

Re: Callaway 633CSi

T_C_D wrote:In the future all you have to do is measure bother the compressor wheel and turbine wheel to determine capacity. It's super simple and maps are readily available. We went through this discussion in 2003. I suspect you were still in high school. LOL

The compressor wheel isn't a choke point. The turbine could be but isn't. Even with the smallish compressor wheel the turbo will support 7/8psi although not efficiently. The engine. Probably falls on its face because you have not tuned it yet. Don't give up yet.

Thanks Todd! I suppose it may be worth verifying my FPR is working properly and checking fuel pressure.

Next, getting a Warlboro pump installed sooner than later and the RRFPR may be a good idea so I know the fuel supply is not contributing to the problem.

-

daniels635turbo

- Posts: 15

- Joined: Apr 28, 2015 2:10 AM

- Location: United States

Re: Callaway 633CSi

Some good work on this, I like your persistence. Another thing to consider is the maximum cfm the head will flow through the rev range. I did a lot of research on this before I started building my engine. There are tables around with the flow rates of the heads. I was able to compare the stock B34 with the B35, then the twin cam head. Some big differences. Best to see where your head is at with flow and use the torque decrease as the max flow rate on the table for the turbo. All depends if you are looking for high hp top end, or fat torque curve that'll burn out at higher rpm. Each engine has its characteristics, best to build around those. Also you need to get a specific turbo cam, it's all wasted boost with cam timing with overlaps.

My engine will run 400hp at the wheels with 8 pounds boost, no intercooler according to Jim at the Metric Mechanic.

Read this and you will get an idea why you need a turbo cam

http://www.speedtalk.com/forum/viewtopi ... =1&t=14384

My engine will run 400hp at the wheels with 8 pounds boost, no intercooler according to Jim at the Metric Mechanic.

Read this and you will get an idea why you need a turbo cam

http://www.speedtalk.com/forum/viewtopi ... =1&t=14384

Re: Callaway 633CSi

Some thoughts:daniels635turbo wrote: Also you need to get a specific turbo cam, it's all wasted boost with cam timing with overlaps.

My engine will run 400hp at the wheels with 8 pounds boost, no intercooler according to Jim at the Metric Mechanic.

Read this and you will get an idea why you need a turbo cam

http://www.speedtalk.com/forum/viewtopi ... =1&t=14384

- Both b34 and b35 are great turbo cams. The one turbo cam I tested made more power but at the expense of drivability.

- No m30 with make 400rwhp at 8psi non intercooled.

-

daniels635turbo

- Posts: 15

- Joined: Apr 28, 2015 2:10 AM

- Location: United States

-

daniels635turbo

- Posts: 15

- Joined: Apr 28, 2015 2:10 AM

- Location: United States

Re: Callaway 633CSi

Check with Jim at the Metric Mechanic. He thinks otherwise!T_C_D wrote:Some thoughts:daniels635turbo wrote: Also you need to get a specific turbo cam, it's all wasted boost with cam timing with overlaps.

My engine will run 400hp at the wheels with 8 pounds boost, no intercooler according to Jim at the Metric Mechanic.

Read this and you will get an idea why you need a turbo cam

http://www.speedtalk.com/forum/viewtopi ... =1&t=14384

- Both b34 and b35 are great turbo cams. The one turbo cam I tested made more power but at the expense of drivability.

- No m30 with make 400rwhp at 8psi non intercooled.

-

daniels635turbo

- Posts: 15

- Joined: Apr 28, 2015 2:10 AM

- Location: United States

Re: Callaway 633CSi

And regarding cams, isn't the point to have limited overlap and longer durations?

Re: Callaway 633CSi

Is this a serious post? Either way, end of thread hyjack.daniels635turbo wrote:

Check with Jim at the Metric Mechanic. He thinks otherwise!

-

daniels635turbo

- Posts: 15

- Joined: Apr 28, 2015 2:10 AM

- Location: United States

Re: Callaway 633CSi

Fair enough. What's the OP plans with the engine?

Re: Callaway 633CSi

SO the plan with the car once I get it sorted is to be more of a track car than my 535i, which doubled as my DD. This means down the road I will probably need a bigger intercooler and bigger turbo.

But for the time being, I am working on getting it running a bit better. In part throttle conditions, I still have a slight hesitation and lean condition (~15.5:1 afr), but everything drops to 12.5 on WOT where power delivery is smooth. I am thinking of playing with the Fuel Quality Switch in the ECU to see if I can richen the mixture, before I add the RRFPR and the start messing with anything else.

According to a post on the forum here and also a Porsche website, the 535i (059 ECU) values are:

Next, I have been swapping out brakes. In anticipation of use on the track, I have the big brake upgrade from E32/E34 on the rears, where I also put on the Bilstein/Eibach rear shocks from my 535i. I'll get a couple photos, possibly tonight. This means my 535i is going back to stock height for a smoother DD ride and higher clearance for winter and snow use.

It was unfortunate to find out that the rear strut bar (jake b made) from my e28 won't fit in the E24. I will have to decide how I want to proceed. For now, likely none.

At some point I will be adding the IE 25mm front sway bar, along with replacing front control arms and shocks. Steering components are good but will need to be aligned.

The last more or less major drivability issue is oil pressure. The same symptoms were exhibited with the old motor that came out. With 20W50, the oil pressure takes a good 10-15 seconds to build, and also once warm the dle pressure drops to less than 10psi, which is where the oil pressure light comes on. I was going to try a .090 orifice/restrictor at the inlet of my turbo. Right now it is a -4AN nipple. Any thoughts on this or any reason why I shouldn't try this? I am thinking that the turbo is getting too much flow through which is limiting the pressure that's allowed to build.

With an increase in revs, the pressure does increase about 10psi per 1000rpm. I believe the oil pump is good, all the bolts were tight when we had the oil pan off... Any tips and or tricks?

But for the time being, I am working on getting it running a bit better. In part throttle conditions, I still have a slight hesitation and lean condition (~15.5:1 afr), but everything drops to 12.5 on WOT where power delivery is smooth. I am thinking of playing with the Fuel Quality Switch in the ECU to see if I can richen the mixture, before I add the RRFPR and the start messing with anything else.

According to a post on the forum here and also a Porsche website, the 535i (059 ECU) values are:

I'd like to see if the Setting #1 improves this fueling issue. In addition to the lean issues in the middle range, at WOT my mixture slowly creeps up from 12.5 to 13:1 as the revs increase. I'd like to think that the stock Motronic can control this slightly, so before messing with any other settings, I'm going to take a look at the FQS and see if it improves anything.If you mean the blue thing in the photograph, that's the Fuel Quality Switch. It is used to adjust the fuel mixture and retard the ignition timing in case you need to use substandard fuel. Notice that it has eight numbered settings. Normally you'd keep it at setting zero.

For the 535i (059 ECU):

Setting 0: Mixture 0%, Timing 0°

Setting 1: Mixture +3.9%, Timing 0°

Setting 2: Mixture -3.9%, Timing 0°

Setting 3: Mixture -6.3%, Timing 0°

Setting 4: Mixture 0%, Timing -3.1°

Setting 5: Mixture +3.9%, Timing -3.1°

Setting 6: Mixture -3.9%, Timing -3.1°

Setting 7: Mixture -6.3%, Timing -3.1°

Next, I have been swapping out brakes. In anticipation of use on the track, I have the big brake upgrade from E32/E34 on the rears, where I also put on the Bilstein/Eibach rear shocks from my 535i. I'll get a couple photos, possibly tonight. This means my 535i is going back to stock height for a smoother DD ride and higher clearance for winter and snow use.

It was unfortunate to find out that the rear strut bar (jake b made) from my e28 won't fit in the E24. I will have to decide how I want to proceed. For now, likely none.

At some point I will be adding the IE 25mm front sway bar, along with replacing front control arms and shocks. Steering components are good but will need to be aligned.

The last more or less major drivability issue is oil pressure. The same symptoms were exhibited with the old motor that came out. With 20W50, the oil pressure takes a good 10-15 seconds to build, and also once warm the dle pressure drops to less than 10psi, which is where the oil pressure light comes on. I was going to try a .090 orifice/restrictor at the inlet of my turbo. Right now it is a -4AN nipple. Any thoughts on this or any reason why I shouldn't try this? I am thinking that the turbo is getting too much flow through which is limiting the pressure that's allowed to build.

With an increase in revs, the pressure does increase about 10psi per 1000rpm. I believe the oil pump is good, all the bolts were tight when we had the oil pan off... Any tips and or tricks?

Re: Callaway 633CSi

Small update. I had to reconnect clutch master supply line on my M5 as it had popped off-- the overcenter spring assembly got damaged and it was not getting fluid to the master. The pedal felt weird (since it didn't have a fluid supply!) but I got it back together for now. I just need to get a new overcenter spring assembly (70 bucks online kinda sucks).

Anyway, onto the turbo car:

I have installed the big brake upgrade from E32/E34 all around. I am quite happy with this and it is no longer sketchy to stop.

New rotors all around, I have used pads for the moment but am thinking about race pads like PFC 06's. I don't want to spend 500 bucks on this right now, so that will have to wait.

As I mentioned, Bilsteins are switched between the 535i and this car. Now the 535i is back on stock Blue shocks, The fronts will be switched sooner than later.

I got the drivers window motor back together finally-- I switched the guts from another I had laying around and made one good one from the two (damaged) early motors I had. It took a bit of time to get that back installed, but I finally have a working driver's window and a door panel that's actually complete! I found some of the mounting screws underneath the passenger rear seat but got it all together. I also scraped off and cleaned the drivers window as it still had a sticky layer of tint from whenever the tint was removed. The window slides much smoother and looks great. It is tempting me to remove the tint from the whole car.

but got it all together. I also scraped off and cleaned the drivers window as it still had a sticky layer of tint from whenever the tint was removed. The window slides much smoother and looks great. It is tempting me to remove the tint from the whole car.

I also hooked up the heater core and test drove the car with all of this but found out that the temp control knob is damaged also. I only have full heat (and currently only through defrost vent) for the moment, so the center console will be coming out again. I'll try to fix all of the HVAC bowden cables at that time also.

Just a couple of photos since I haven't yet shared:

Additionally, I set the FQS switch to position 2 and was able to get some drivability gains by adding fuel. This lowers my AFR from ~12.5-13:1 down to 11.8-12.3:1 while boosting. I am still trying to identify why this ratio creeps up when under boost and following some suggestions, I think it has to do with maximum flow from the current injectors. I have some 24 lb's sitting in a box along with a RRFPR, but i want to continue to understand what could be the issue and what is working properly.

I rigged up a fuel pressure gauge and checked my pressures tonight. With the vacuum line on, I get ~36psi. When I disconnect it jumps to about 43psi. I believe this means it is working properly, but I am concerned that it doesn't have enough difference. I'll continue with some tinkering maybe tomorrow night.

Anyway, onto the turbo car:

I have installed the big brake upgrade from E32/E34 all around. I am quite happy with this and it is no longer sketchy to stop.

New rotors all around, I have used pads for the moment but am thinking about race pads like PFC 06's. I don't want to spend 500 bucks on this right now, so that will have to wait.

As I mentioned, Bilsteins are switched between the 535i and this car. Now the 535i is back on stock Blue shocks, The fronts will be switched sooner than later.

I got the drivers window motor back together finally-- I switched the guts from another I had laying around and made one good one from the two (damaged) early motors I had. It took a bit of time to get that back installed, but I finally have a working driver's window and a door panel that's actually complete! I found some of the mounting screws underneath the passenger rear seat

I also hooked up the heater core and test drove the car with all of this but found out that the temp control knob is damaged also. I only have full heat (and currently only through defrost vent) for the moment, so the center console will be coming out again. I'll try to fix all of the HVAC bowden cables at that time also.

Just a couple of photos since I haven't yet shared:

Additionally, I set the FQS switch to position 2 and was able to get some drivability gains by adding fuel. This lowers my AFR from ~12.5-13:1 down to 11.8-12.3:1 while boosting. I am still trying to identify why this ratio creeps up when under boost and following some suggestions, I think it has to do with maximum flow from the current injectors. I have some 24 lb's sitting in a box along with a RRFPR, but i want to continue to understand what could be the issue and what is working properly.

I rigged up a fuel pressure gauge and checked my pressures tonight. With the vacuum line on, I get ~36psi. When I disconnect it jumps to about 43psi. I believe this means it is working properly, but I am concerned that it doesn't have enough difference. I'll continue with some tinkering maybe tomorrow night.

Last edited by tschultz on Jun 10, 2015 10:08 AM, edited 1 time in total.

Re: Callaway 633CSi

Time to weed the driveway.

-

Jelmer538i

- Posts: 1222

- Joined: Feb 12, 2006 12:00 PM

- Location: Netherlands

- Contact:

Re: Callaway 633CSi

I really like this tread! Keep the updates coming!

-

offroadkarter

- Posts: 557

- Joined: Nov 03, 2014 1:00 PM

- Location: Lehigh Valley, PA

Re: Callaway 633CSi

I'd throw the RRFPR on now and see what it does. I'm not sure how well motronic will handle small injector size changes, but I have SVO injectors (30#) on my car with cause me to have an 11.4 AFR at idle. I have to send out my stock injectors, get them rebuilt and throw them back in the car.

Re: Callaway 633CSi

offroadkarter wrote:I'd throw the RRFPR on now and see what it does. I'm not sure how well motronic will handle small injector size changes, but I have SVO injectors (30#) on my car with cause me to have an 11.4 AFR at idle. I have to send out my stock injectors, get them rebuilt and throw them back in the car.

I was thinking in this scenario, you use the FQS switch in setting #2 and remove fuel to aid in idle situations. It should lean out the whole range so closed loop O2 feedback might be manageable, and then continue to tune the RRFPR for boosting situations.

I also know my fuel pump is stock and I'm not sure if it will be up to the task, so I'm not sure I want to try the RRFPR until I have a 255lph pump installed... Maybe some of you gurus have tried this out? I just want to make sure I've got the Motronic system as bulletproof as possible before throwing on a bandaid that covers up some of the underlying issue(s).

-

Jelmer538i

- Posts: 1222

- Joined: Feb 12, 2006 12:00 PM

- Location: Netherlands

- Contact:

Re: Callaway 633CSi

My brothers S38 turbo made 450Hp on a stock fuel pump (even on E85) so you should be fine.

Re: Callaway 633CSi

Another small update. Last night I installed the oil restrictor in the line. This helped oil pressure slightly, especially with pressure build on start up.

I used a ~.090 ID fitting and it seems to be helping to maintain pressure in the system. My turbo line is sourced from a tapped oil filter housing, this was there when I bought the car, so I transferred it over to the new B34 engine. My oil pressure signal comes from a sensor at the stock sender location at the back of the valve cover. I imagine since the main supply was being split between the turbo and the head, the turbo was getting slightly more flow, decreasing the overall pressure. On cold starts after sitting for a day or more, I think this meant the pump had to supply maximum flow that the turbo would accept before being able to build pressure in the head. If facing uphill, that was taking up to 10 seconds.

With the restrictor in place, pressure builds more quickly than before when revving. Idle pressure is slightly better, although it still trips the 7psi indicator light when hot. I think this is about as good as I am going to get with this pump-- I don't want to restrict flow to the turbo any more than it already is....

Also, I drove around with my fuel pressure gauge on the windshield. A good 35 psi at idle, bumping up slightly when driving around (especially when at 0 psig and under boost). Would it be wise to add a check valve to this line so the FPR doesn't see boost pressure? Maybe this isn't important?

Also good to see was that pressure was staying close to 30psi for a good 5 minutes after shutting down the engine.

Good to know Jelmer-- I'll stick with it for the time being and buffer it with high quality fuel until I get a better idea of the reliability of the stock pump.

Lastly, I unplugged the microfueler for the test. It seems it makes no difference for running conditions! I am not sure if this means it is wired wrong, or if something in the board is fried. For the time being, I will remove it. Just one less variable to mess with. I am sure it could be useful for meth injection, but for the time it makes sense not to worry about.

Tonight I will be working on switching shocks/springs on my M5 to Bilstein/ H&R sport. Then the fronts on my 535i before I get to a suspension refresh on the 633.

I used a ~.090 ID fitting and it seems to be helping to maintain pressure in the system. My turbo line is sourced from a tapped oil filter housing, this was there when I bought the car, so I transferred it over to the new B34 engine. My oil pressure signal comes from a sensor at the stock sender location at the back of the valve cover. I imagine since the main supply was being split between the turbo and the head, the turbo was getting slightly more flow, decreasing the overall pressure. On cold starts after sitting for a day or more, I think this meant the pump had to supply maximum flow that the turbo would accept before being able to build pressure in the head. If facing uphill, that was taking up to 10 seconds.

With the restrictor in place, pressure builds more quickly than before when revving. Idle pressure is slightly better, although it still trips the 7psi indicator light when hot. I think this is about as good as I am going to get with this pump-- I don't want to restrict flow to the turbo any more than it already is....

Also, I drove around with my fuel pressure gauge on the windshield. A good 35 psi at idle, bumping up slightly when driving around (especially when at 0 psig and under boost). Would it be wise to add a check valve to this line so the FPR doesn't see boost pressure? Maybe this isn't important?

Also good to see was that pressure was staying close to 30psi for a good 5 minutes after shutting down the engine.

Good to know Jelmer-- I'll stick with it for the time being and buffer it with high quality fuel until I get a better idea of the reliability of the stock pump.

Lastly, I unplugged the microfueler for the test. It seems it makes no difference for running conditions! I am not sure if this means it is wired wrong, or if something in the board is fried. For the time being, I will remove it. Just one less variable to mess with. I am sure it could be useful for meth injection, but for the time it makes sense not to worry about.

Tonight I will be working on switching shocks/springs on my M5 to Bilstein/ H&R sport. Then the fronts on my 535i before I get to a suspension refresh on the 633.

Re: Callaway 633CSi

Finally had a chance to get the temp gauge working again! I'm not sure if it was wonky because of a bad connection on the BLAU "Tempo" connector. I cleaned that off at the same time as running new wiring to the fusebox Violet/Brown. I'm thinking it was just a bad contact on the back side of the cluster but I will re-investigate next time I look at the car. I believe my fan-clutch is going bad, temp gauge is running slightly above 12 o-clock. In my experience a nice working cooling system will sit at 11 nicely.

I developed a coolant leak at the heater valve. I think the old housing was damaged. Replaced that today and it is looking leak free. Slow progress, but getting closer to the end goal little by little.

I developed a coolant leak at the heater valve. I think the old housing was damaged. Replaced that today and it is looking leak free. Slow progress, but getting closer to the end goal little by little.

Re: Callaway 633CSi

Progress, that's more than I can say for myself... I may end up just dropping the m30b35 in and not doing turbo yet.. :/

Re: Callaway 633CSi

Indeed!

Well, the temp sender issue was related to the connection at the back of the cluster as I thought. The extra lead I ran isn't necessary, but now it works.

Last night I fixed my headlights. For some reason the low beams would not work except with the high beam switch on the turn signal stalk. I traced it back to the low beam relay pin 30. This pin should always be hot but it was not getting power from the lead that came through the high beam relay. Something in my fusebox must be damaged, I'm not sure. Anyway, a quick jumper wire and things are working as they should be.

I also tested the FPR and found that when the return line was plugged, pressure spiked. According t the Bentley, this means the FPR wasn't working correctly. Put the spare in and it is working properly. Pressure was close enough for operating, but it wasn't regulating as it should have.

Sorry no pictures still.

Driving around the block I had the system running about 4psi. It gets moving once the turbo spins up, but spool up is slow. I want to make a pressure tester and verify that all of my piping has no leaks. Little by little we will get there!

I also found that one of the shocks I was planning to install is damaged. It blew on my 535 months ago it seems. Right now that one shock can't be compressed by hand, so the ride was super stiff (especially for a DD). Thinking about sending them both in to Bilstein for rebuild...

Well, the temp sender issue was related to the connection at the back of the cluster as I thought. The extra lead I ran isn't necessary, but now it works.

Last night I fixed my headlights. For some reason the low beams would not work except with the high beam switch on the turn signal stalk. I traced it back to the low beam relay pin 30. This pin should always be hot but it was not getting power from the lead that came through the high beam relay. Something in my fusebox must be damaged, I'm not sure. Anyway, a quick jumper wire and things are working as they should be.

I also tested the FPR and found that when the return line was plugged, pressure spiked. According t the Bentley, this means the FPR wasn't working correctly. Put the spare in and it is working properly. Pressure was close enough for operating, but it wasn't regulating as it should have.

Sorry no pictures still.

Driving around the block I had the system running about 4psi. It gets moving once the turbo spins up, but spool up is slow. I want to make a pressure tester and verify that all of my piping has no leaks. Little by little we will get there!

I also found that one of the shocks I was planning to install is damaged. It blew on my 535 months ago it seems. Right now that one shock can't be compressed by hand, so the ride was super stiff (especially for a DD). Thinking about sending them both in to Bilstein for rebuild...

Re: Callaway 633CSi

Finally took some time to use a multimeter and measure my O2 sensor voltage. I measured my existing O2 only to find it was not even producing a reference voltage. So i have been driving with it basically unplugged. Just drove it around the block this way and everything seemed quite normal.

I have the AEM UEGO in P4 mode (0-1V), however whenever I connect the signal the car starts to idle crappy and not want to run. But when disconnected, I am getting idle readings of right about .430 (~14.5:1, see below).

I got a bracket to mount the front spoiler and finally have it supported. So I took the spoiler off to have it blasted and then I'll probably paint it with some spray cans... I'm not sure if I want to spray the airdam or not. I think it might be kinda cool to have a bronzit spoiler with the bronzit pin stripes. I'm leaning towards taking off the red ones, they just don't work. Thoughts?

And since I have been bad about getting any sort of photos, here a few with the Style 42's mounted. I had been waiting until I could get wheel locks for them. I really want to get the euro bumpers on and finalized, it's all just taking more time than I expected. I think I would now put more value on a clean running put together car for sale than I would have in the past... This stuff takes a ton of time and money to get things right...

Oh and in the mean time I got shocks and springs swapped on the M5. Bilstein and H&R. This photo was taken right after. I'll probably bring the shock to the top perch (it's second from the top right now). The rears give a bit more bounce than I was expecting (esp compared to my Eibach's), so i'm a bit unhappy with that, but oh well maybe the perch setting will help. Also the front end looks a bit high so there's mroe reverse rake than I like, but the ride is quite comfortable with the progressive coils). I will do something with the front end sooner than later, I just hadn't been happy with the Pfeba front spoiler that I had before.

I have the AEM UEGO in P4 mode (0-1V), however whenever I connect the signal the car starts to idle crappy and not want to run. But when disconnected, I am getting idle readings of right about .430 (~14.5:1, see below).

I wanted to investigate this because I was wondering why my AFR's slowly creep up above 5000rpm. I think this is due to the extra airflow from the turbo pulling me above the WOT 12.5:1 default (that or I have a injector oring seal that is sucking in air). But anyway, I am having a tough time getting up to even a measly 4-5psi. What i think is happening is that I have a charge pipe leak. I'm going to get a pressure/leak tester and verify that my charged pipes aren't leaking. If the problem persists, I may swap injectors to rule out the injector oring as a leak point.Lambda...AFR....(Gasoline) Analog Output...............Voltage Modes

(λ)........AFR.....LED "ON" Range........P0.........P1.........P2.........P3....... P4

1.008......14.75.....14.625-14.875........ 2.375....2.375......1.475.....0.238.....0.410

I got a bracket to mount the front spoiler and finally have it supported. So I took the spoiler off to have it blasted and then I'll probably paint it with some spray cans... I'm not sure if I want to spray the airdam or not. I think it might be kinda cool to have a bronzit spoiler with the bronzit pin stripes. I'm leaning towards taking off the red ones, they just don't work. Thoughts?

And since I have been bad about getting any sort of photos, here a few with the Style 42's mounted. I had been waiting until I could get wheel locks for them. I really want to get the euro bumpers on and finalized, it's all just taking more time than I expected. I think I would now put more value on a clean running put together car for sale than I would have in the past... This stuff takes a ton of time and money to get things right...

Oh and in the mean time I got shocks and springs swapped on the M5. Bilstein and H&R. This photo was taken right after. I'll probably bring the shock to the top perch (it's second from the top right now). The rears give a bit more bounce than I was expecting (esp compared to my Eibach's), so i'm a bit unhappy with that, but oh well maybe the perch setting will help. Also the front end looks a bit high so there's mroe reverse rake than I like, but the ride is quite comfortable with the progressive coils). I will do something with the front end sooner than later, I just hadn't been happy with the Pfeba front spoiler that I had before.