Page 3 of 14

Re: Callaway 633CSi

Posted: May 25, 2015 12:28 PM

by daniels635turbo

And regarding cams, isn't the point to have limited overlap and longer durations?

Re: Callaway 633CSi

Posted: May 26, 2015 12:00 PM

by T_C_D

daniels635turbo wrote:

Check with Jim at the Metric Mechanic. He thinks otherwise!

Is this a serious post? Either way, end of thread hyjack.

Re: Callaway 633CSi

Posted: May 26, 2015 1:58 PM

by daniels635turbo

Fair enough. What's the OP plans with the engine?

Re: Callaway 633CSi

Posted: Jun 02, 2015 10:08 AM

by tschultz

SO the plan with the car once I get it sorted is to be more of a track car than my 535i, which doubled as my DD. This means down the road I will probably need a bigger intercooler and bigger turbo.

But for the time being, I am working on getting it running a bit better. In part throttle conditions, I still have a slight hesitation and lean condition (~15.5:1 afr), but everything drops to 12.5 on WOT where power delivery is smooth. I am thinking of playing with the Fuel Quality Switch in the ECU to see if I can richen the mixture, before I add the RRFPR and the start messing with anything else.

According to a post on the forum here and also a Porsche website, the 535i (059 ECU) values are:

If you mean the blue thing in the photograph, that's the Fuel Quality Switch. It is used to adjust the fuel mixture and retard the ignition timing in case you need to use substandard fuel. Notice that it has eight numbered settings. Normally you'd keep it at setting zero.

For the 535i (059 ECU):

Setting 0: Mixture 0%, Timing 0°

Setting 1: Mixture +3.9%, Timing 0°

Setting 2: Mixture -3.9%, Timing 0°

Setting 3: Mixture -6.3%, Timing 0°

Setting 4: Mixture 0%, Timing -3.1°

Setting 5: Mixture +3.9%, Timing -3.1°

Setting 6: Mixture -3.9%, Timing -3.1°

Setting 7: Mixture -6.3%, Timing -3.1°

I'd like to see if the Setting #1 improves this fueling issue. In addition to the lean issues in the middle range, at WOT my mixture slowly creeps up from 12.5 to 13:1 as the revs increase. I'd like to think that the stock Motronic can control this slightly, so before messing with any other settings, I'm going to take a look at the FQS and see if it improves anything.

Next, I have been swapping out brakes. In anticipation of use on the track, I have the big brake upgrade from E32/E34 on the rears, where I also put on the Bilstein/Eibach rear shocks from my 535i. I'll get a couple photos, possibly tonight. This means my 535i is going back to stock height for a smoother DD ride and higher clearance for winter and snow use.

It was unfortunate to find out that the rear strut bar (jake b made) from my e28 won't fit in the E24. I will have to decide how I want to proceed. For now, likely none.

At some point I will be adding the IE 25mm front sway bar, along with replacing front control arms and shocks. Steering components are good but will need to be aligned.

The last more or less major drivability issue is oil pressure. The same symptoms were exhibited with the old motor that came out. With 20W50, the oil pressure takes a good 10-15 seconds to build, and also once warm the dle pressure drops to less than 10psi, which is where the oil pressure light comes on. I was going to try a .090 orifice/restrictor at the inlet of my turbo. Right now it is a -4AN nipple. Any thoughts on this or any reason why I shouldn't try this? I am thinking that the turbo is getting too much flow through which is limiting the pressure that's allowed to build.

With an increase in revs, the pressure does increase about 10psi per 1000rpm. I believe the oil pump is good, all the bolts were tight when we had the oil pan off... Any tips and or tricks?

Re: Callaway 633CSi

Posted: Jun 09, 2015 11:34 PM

by tschultz

Small update. I had to reconnect clutch master supply line on my M5 as it had popped off-- the overcenter spring assembly got damaged and it was not getting fluid to the master. The pedal felt weird (since it didn't have a fluid supply!) but I got it back together for now. I just need to get a new overcenter spring assembly (70 bucks online kinda sucks).

Anyway, onto the turbo car:

I have installed the big brake upgrade from E32/E34 all around. I am quite happy with this and it is no longer sketchy to stop.

New rotors all around, I have used pads for the moment but am thinking about race pads like PFC 06's. I don't want to spend 500 bucks on this right now, so that will have to wait.

As I mentioned, Bilsteins are switched between the 535i and this car. Now the 535i is back on stock Blue shocks, The fronts will be switched sooner than later.

I got the drivers window motor back together finally-- I switched the guts from another I had laying around and made one good one from the two (damaged) early motors I had. It took a bit of time to get that back installed, but I finally have a working driver's window and a door panel that's actually complete! I found some of the mounting screws underneath the passenger rear seat

but got it all together. I also scraped off and cleaned the drivers window as it still had a sticky layer of tint from whenever the tint was removed. The window slides much smoother and looks great. It is tempting me to remove the tint from the whole car.

I also hooked up the heater core and test drove the car with all of this but found out that the temp control knob is damaged also. I only have full heat (and currently only through defrost vent) for the moment, so the center console will be coming out again. I'll try to fix all of the HVAC bowden cables at that time also.

Just a couple of photos since I haven't yet shared:

Additionally, I set the FQS switch to position 2 and was able to get some drivability gains by adding fuel. This lowers my AFR from ~12.5-13:1 down to 11.8-12.3:1 while boosting. I am still trying to identify why this ratio creeps up when under boost and following some suggestions, I think it has to do with maximum flow from the current injectors. I have some 24 lb's sitting in a box along with a RRFPR, but i want to continue to understand what could be the issue and what is working properly.

I rigged up a fuel pressure gauge and checked my pressures tonight. With the vacuum line on, I get ~36psi. When I disconnect it jumps to about 43psi. I believe this means it is working properly, but I am concerned that it doesn't have enough difference. I'll continue with some tinkering maybe tomorrow night.

Re: Callaway 633CSi

Posted: Jun 10, 2015 1:09 AM

by T_C_D

Time to weed the driveway.

Re: Callaway 633CSi

Posted: Jun 10, 2015 1:53 AM

by Jelmer538i

I really like this tread! Keep the updates coming!

Re: Callaway 633CSi

Posted: Jun 10, 2015 3:52 PM

by offroadkarter

I'd throw the RRFPR on now and see what it does. I'm not sure how well motronic will handle small injector size changes, but I have SVO injectors (30#) on my car with cause me to have an 11.4 AFR at idle. I have to send out my stock injectors, get them rebuilt and throw them back in the car.

Re: Callaway 633CSi

Posted: Jun 10, 2015 5:53 PM

by tschultz

offroadkarter wrote:I'd throw the RRFPR on now and see what it does. I'm not sure how well motronic will handle small injector size changes, but I have SVO injectors (30#) on my car with cause me to have an 11.4 AFR at idle. I have to send out my stock injectors, get them rebuilt and throw them back in the car.

I was thinking in this scenario, you use the FQS switch in setting #2 and remove fuel to aid in idle situations. It should lean out the whole range so closed loop O2 feedback might be manageable, and then continue to tune the RRFPR for boosting situations.

I also know my fuel pump is stock and I'm not sure if it will be up to the task, so I'm not sure I want to try the RRFPR until I have a 255lph pump installed... Maybe some of you gurus have tried this out? I just want to make sure I've got the Motronic system as bulletproof as possible before throwing on a bandaid that covers up some of the underlying issue(s).

Re: Callaway 633CSi

Posted: Jun 11, 2015 1:53 AM

by Jelmer538i

My brothers S38 turbo made 450Hp on a stock fuel pump (even on E85) so you should be fine.

Re: Callaway 633CSi

Posted: Jun 11, 2015 12:57 PM

by tschultz

Another small update. Last night I installed the oil restrictor in the line. This helped oil pressure slightly, especially with pressure build on start up.

I used a ~.090 ID fitting and it seems to be helping to maintain pressure in the system. My turbo line is sourced from a tapped oil filter housing, this was there when I bought the car, so I transferred it over to the new B34 engine. My oil pressure signal comes from a sensor at the stock sender location at the back of the valve cover. I imagine since the main supply was being split between the turbo and the head, the turbo was getting slightly more flow, decreasing the overall pressure. On cold starts after sitting for a day or more, I think this meant the pump had to supply maximum flow that the turbo would accept before being able to build pressure in the head. If facing uphill, that was taking up to 10 seconds.

With the restrictor in place, pressure builds more quickly than before when revving. Idle pressure is slightly better, although it still trips the 7psi indicator light when hot. I think this is about as good as I am going to get with this pump-- I don't want to restrict flow to the turbo any more than it already is....

Also, I drove around with my fuel pressure gauge on the windshield. A good 35 psi at idle, bumping up slightly when driving around (especially when at 0 psig and under boost). Would it be wise to add a check valve to this line so the FPR doesn't see boost pressure? Maybe this isn't important?

Also good to see was that pressure was staying close to 30psi for a good 5 minutes after shutting down the engine.

Good to know Jelmer-- I'll stick with it for the time being and buffer it with high quality fuel until I get a better idea of the reliability of the stock pump.

Lastly, I unplugged the microfueler for the test. It seems it makes no difference for running conditions! I am not sure if this means it is wired wrong, or if something in the board is fried. For the time being, I will remove it. Just one less variable to mess with. I am sure it could be useful for meth injection, but for the time it makes sense not to worry about.

Tonight I will be working on switching shocks/springs on my M5 to Bilstein/ H&R sport. Then the fronts on my 535i before I get to a suspension refresh on the 633.

Re: Callaway 633CSi

Posted: Jun 15, 2015 5:18 PM

by tschultz

Finally had a chance to get the temp gauge working again! I'm not sure if it was wonky because of a bad connection on the BLAU "Tempo" connector. I cleaned that off at the same time as running new wiring to the fusebox Violet/Brown. I'm thinking it was just a bad contact on the back side of the cluster but I will re-investigate next time I look at the car. I believe my fan-clutch is going bad, temp gauge is running slightly above 12 o-clock. In my experience a nice working cooling system will sit at 11 nicely.

I developed a coolant leak at the heater valve. I think the old housing was damaged. Replaced that today and it is looking leak free. Slow progress, but getting closer to the end goal little by little.

Re: Callaway 633CSi

Posted: Jun 15, 2015 8:54 PM

by Neel

Progress, that's more than I can say for myself... I may end up just dropping the m30b35 in and not doing turbo yet.. :/

Re: Callaway 633CSi

Posted: Jun 18, 2015 10:31 AM

by tschultz

Indeed!

Well, the temp sender issue was related to the connection at the back of the cluster as I thought. The extra lead I ran isn't necessary, but now it works.

Last night I fixed my headlights. For some reason the low beams would not work except with the high beam switch on the turn signal stalk. I traced it back to the low beam relay pin 30. This pin should always be hot but it was not getting power from the lead that came through the high beam relay. Something in my fusebox must be damaged, I'm not sure. Anyway, a quick jumper wire and things are working as they should be.

I also tested the FPR and found that when the return line was plugged, pressure spiked. According t the Bentley, this means the FPR wasn't working correctly. Put the spare in and it is working properly. Pressure was close enough for operating, but it wasn't regulating as it should have.

Sorry no pictures still.

Driving around the block I had the system running about 4psi. It gets moving once the turbo spins up, but spool up is slow. I want to make a pressure tester and verify that all of my piping has no leaks. Little by little we will get there!

I also found that one of the shocks I was planning to install is damaged. It blew on my 535 months ago it seems. Right now that one shock can't be compressed by hand, so the ride was super stiff (especially for a DD). Thinking about sending them both in to Bilstein for rebuild...

Re: Callaway 633CSi

Posted: Jun 22, 2015 8:53 PM

by tschultz

Finally took some time to use a multimeter and measure my O2 sensor voltage. I measured my existing O2 only to find it was not even producing a reference voltage. So i have been driving with it basically unplugged. Just drove it around the block this way and everything seemed quite normal.

I have the AEM UEGO in P4 mode (0-1V), however whenever I connect the signal the car starts to idle crappy and not want to run. But when disconnected, I am getting idle readings of right about .430 (~14.5:1, see below).

Lambda...AFR....(Gasoline) Analog Output...............Voltage Modes

(λ)........AFR.....LED "ON" Range........P0.........P1.........P2.........P3....... P4

1.008......14.75.....14.625-14.875........ 2.375....2.375......1.475.....0.238.....0.410

I wanted to investigate this because I was wondering why my AFR's slowly creep up above 5000rpm. I think this is due to the extra airflow from the turbo pulling me above the WOT 12.5:1 default (that or I have a injector oring seal that is sucking in air). But anyway, I am having a tough time getting up to even a measly 4-5psi. What i think is happening is that I have a charge pipe leak. I'm going to get a pressure/leak tester and verify that my charged pipes aren't leaking. If the problem persists, I may swap injectors to rule out the injector oring as a leak point.

I got a bracket to mount the front spoiler and finally have it supported. So I took the spoiler off to have it blasted and then I'll probably paint it with some spray cans... I'm not sure if I want to spray the airdam or not. I think it might be kinda cool to have a bronzit spoiler with the bronzit pin stripes. I'm leaning towards taking off the red ones, they just don't work. Thoughts?

And since I have been bad about getting any sort of photos, here a few with the Style 42's mounted. I had been waiting until I could get wheel locks for them. I really want to get the euro bumpers on and finalized, it's all just taking more time than I expected. I think I would now put more value on a clean running put together car for sale than I would have in the past... This stuff takes a ton of time and money to get things right...

Oh and in the mean time I got shocks and springs swapped on the M5. Bilstein and H&R. This photo was taken right after. I'll probably bring the shock to the top perch (it's second from the top right now). The rears give a bit more bounce than I was expecting (esp compared to my Eibach's), so i'm a bit unhappy with that, but oh well maybe the perch setting will help. Also the front end looks a bit high so there's mroe reverse rake than I like, but the ride is quite comfortable with the progressive coils). I will do something with the front end sooner than later, I just hadn't been happy with the Pfeba front spoiler that I had before.

Re: Callaway 633CSi

Posted: Jun 25, 2015 10:49 PM

by tschultz

Spent some time taking apart the center console. Found the temp control knob seized. The temperature knob spun, but the linkage between the two was damaged. A new one is coming to my house.

Today, i spent the afternoon mounting up the rear euro bumper. Pretty happy with the fitment considering I eyeballed it after a test fit. After I drilled the holes, I thought I could have mounted the chrome above the extended tail panel. It wasn't meant to be and so it is tucked underneath. Very tight clearance under the euro rear valance, so it will likely stay where it is at...

I'm trying to determine if I'm going to stick with the euro side trim covering or try to modify the US panel. Either way, some photos:

Getting the US trim panels removed was a bonus when I did it originally, so i'm probably going to stick with the Euros...

Re: Callaway 633CSi

Posted: Jul 11, 2015 1:58 PM

by tschultz

I had to head out of town for work for about a week, so I didn't get as much done as I wanted.

However I have another update for the time being. I mounted my rear Zender spoiler. I used the two studs to bolt it to the trunk, along with 3M double sided tape. unfortunately the edges are still lifting slightly, so I may have to try it again or use an adhesive instead. Onto some overdue photos:

I also spent some time cleaning up my bumper and airdam to be painted. This was definitely a DIY job as I don't need it to be perfect, but I think it came out pretty good. I just need to get the bumper aligned nicely on the passenger side. I just used a spray can enamel and a clear coat to get some sheen. Good enough for a track car, I am liking how it is coming along.

The front will be going down once I replace the shocks/springs, but that won't happen until I install a new TCD turbo and get my exhaust/ downpipe cleaned up.

I know it's dirty

City lights all hooked up. You can see the alignment issue that I need to fix.

Re: Callaway 633CSi

Posted: Jul 13, 2015 1:07 PM

by tschultz

Bad news:

I had been hearing a creaking/clunking noise which sounded like it was coming from my drivers side rear window. I removed the seat and after not finding anything for a while, I noticed something shifting which i got in and out of the car.

The rear subframe bushing mount seems to have separated from the underbody. See pictures below:

Can I have this welded and repaired? Any suggestions/advice greatly appreciated.

At some point I was going to install a cage, but that was quite a ways off in my mind. Maybe I need to do some structural reinforcement sooner than later...

Re: Callaway 633CSi

Posted: Jul 14, 2015 6:15 PM

by marc79euro645

A small sandblaster rig is real good at cleaning up areas like that. Then just mig in some more metal.

Re: Callaway 633CSi

Posted: Jul 14, 2015 7:22 PM

by tschultz

marc79euro645 wrote:A small sandblaster rig is real good at cleaning up areas like that. Then just mig in some more metal.

Good suggestion, thanks! I found a welder guy locally who seems experienced enough to be able to handle this job.

I'll double check and see if he has a portable blaster to clean it up.

Since I am hesitant to drive the car, i was hoping to swap injectors. Well it was raining so I took a quick walk around. More slow progress to come later...

https://youtu.be/6PEVT0WAabU

Re: Callaway 633CSi

Posted: Jul 15, 2015 2:30 PM

by tschultz

After it finished raining, I decided last night to install the 24lb injectors. The old ones were quite dirty and probably came out of a junkyard car or something. I started it up and put the FQS switch at setting#3 (-6% fuel) to get close to stoichiometric. It was running slightly rich, so I attached the o2 sensor and now idle right at 14.7-15.0!

I drove around the block and the engine revs smoother than before and seems just a bit more happy. I'm glad I didn't need to adjust the AFM spring (I'd rather keep that stock if possible) to make this all work.

Stays right around 11AFR with WOT which may be slightly rich, but then creeps to ~13 when the additional air moves through the engine. Right now I'm running ~8psi and will be installing the RRFPR (BEGI 2025) as soon as the fittings come in -- I want to be able to add fuel as more air is forced in.

I ran some calculations and think these injectors might be just up to the task. I'll explain my logic below, please correct me if I am making an assumption that isn't valid, I just want to get it recorded in my notes on the web.

Code: Select all

For Stock M30B34, target boost pressures are: 6psi, 8psi and 10psi (we'll do all three just for comparison purposes)

Elevation: ~5000ft Air Pressure: ~12.2psia

Pr 6psi = 1.49, Pr 8psi = 1.65, Pr 10psi = 1.82

According to Corky Bell's intro book, we multiply the Pr by the NA engine airflow capacity. The very definition of Pr is a ratio of the amount of airflow in the intake charge as compared to the original airflow value. So at 10psi (Pr=1.82), we are moving roughly 82% more air than stock. If this is the case, I argue that we can increase our fuel by approximately 82% to match and keep stoichiometric combustion and roughly the same running characteristics throughout the fuel map.

I found specs for the stock M30B34 injectors to be 17.6lb/hr @ 3bar (43.5psi) fuel pressure.

My replacement Ford injectors are 24lb/hr @ 39psi, or 25.3lb/hr @ the same 43.5/3bar as above.

If I extrapolate to 10psi boost, I use the following equation

(fuel pressure * fuel injector rating required)/ fuel injector size = fuel pressure required

[43.5psi * (17.6lb/hr * 1.82)] / 25.3lb/hr = ~55psi fuel pressure required via the FMU to run 10psi boost with these injectors and fuel pressure

Right now I get nice running characteristics with the settings mentioned above, smooth running, right on 14.7 AFR. The only problem is fuel when the turbo starts to move more air. Now since I believe my calculations are correct, I believe my injectors can handle the above usage and with the proper fuel pressure should be able to provide the required fuel. FYI this engine is fully stock otherwise, so 10psi is my maximum limit, I will likely be running 8psi only.

If I keep normal operation at 3bar fuel pressure, and tune my BEGI to run 55psi fuel pressure at 10psi boost, I should be able to increase my fuel proportionally the same amount as the air I am moving and use these injectors.

The above are theoretical approximations, but I will assume this is a maximum value of air flow due to intake restrictions, air density losses due to heat and other misc items. Assuming we are moving less volumes of air due to restriction and efficiency issues, and less fuel due to other restrictions, I think this sounds about right.

Basically, keeping 55psi as my upper limit of fuel pressure with the RRFPR, These injectors are good for a maximum 10psi. Thoughts?

Re: Callaway 633CSi

Posted: Jul 15, 2015 2:39 PM

by mitch5

Wire wheels from harbor freight will strip it to bare metal fast. They are the heavy duty ones that go on a grinder. For 20 bucks you can get the grinder and a wheel.

I have been following this thread for awhile and honestly I would say go buy a used Lincoln mig welder with c02. It looks like you have quiet a few cars with projects.

Re: Callaway 633CSi

Posted: Jul 18, 2015 1:22 PM

by tschultz

Still waiting for fittings to come in to install my Begi. Also waiting on my welder contact will come to fix my rear subframe mount issue (he won't come until next weekend).

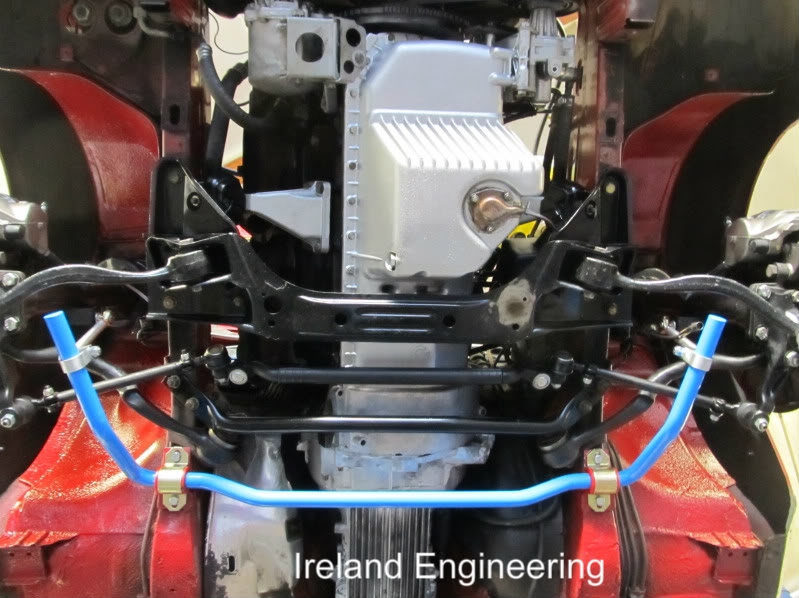

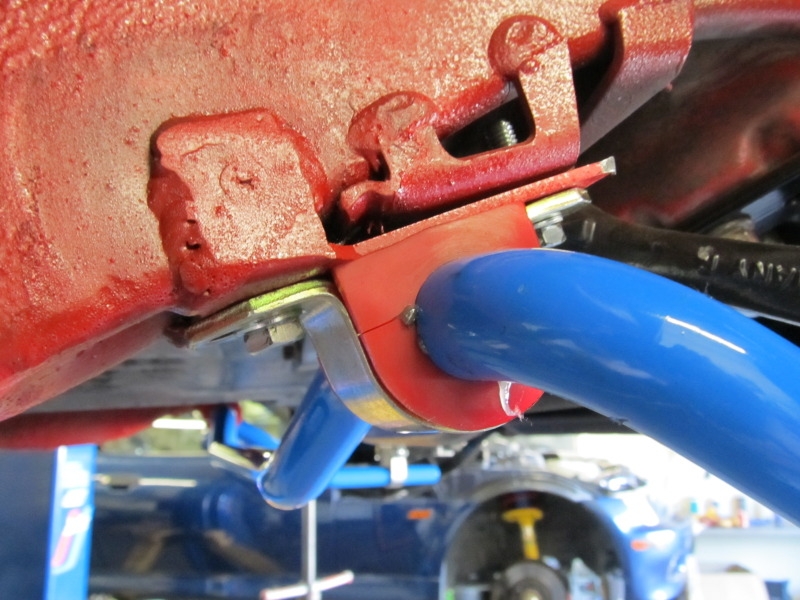

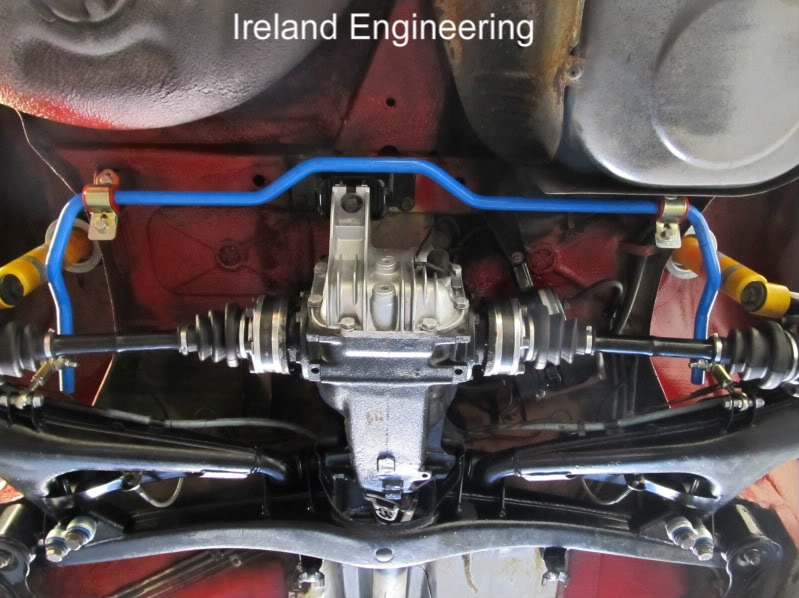

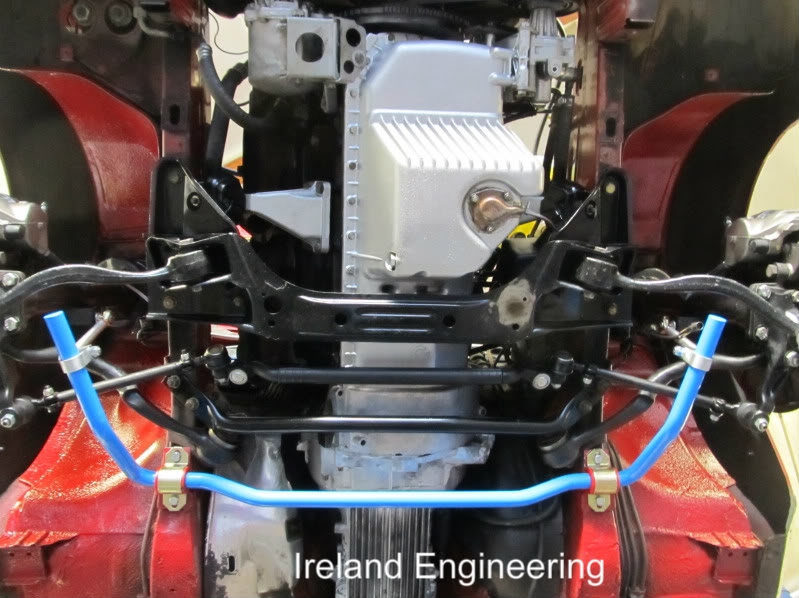

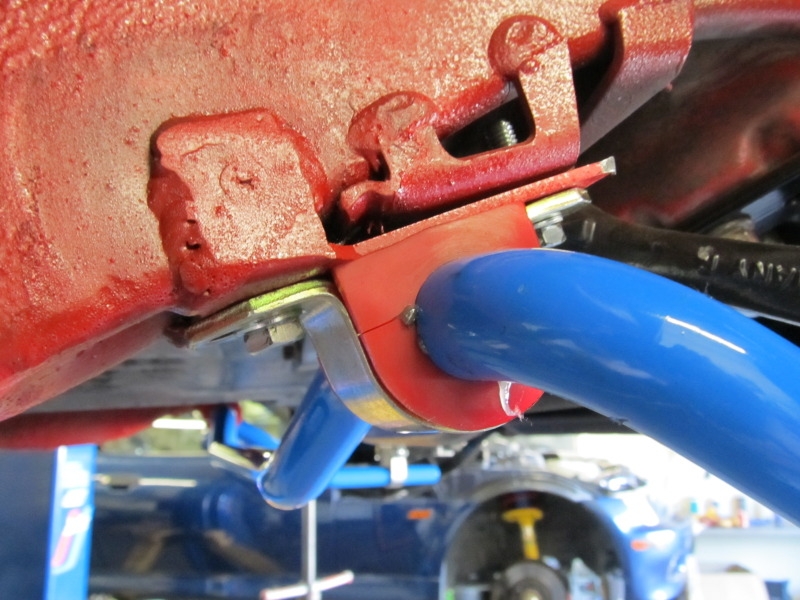

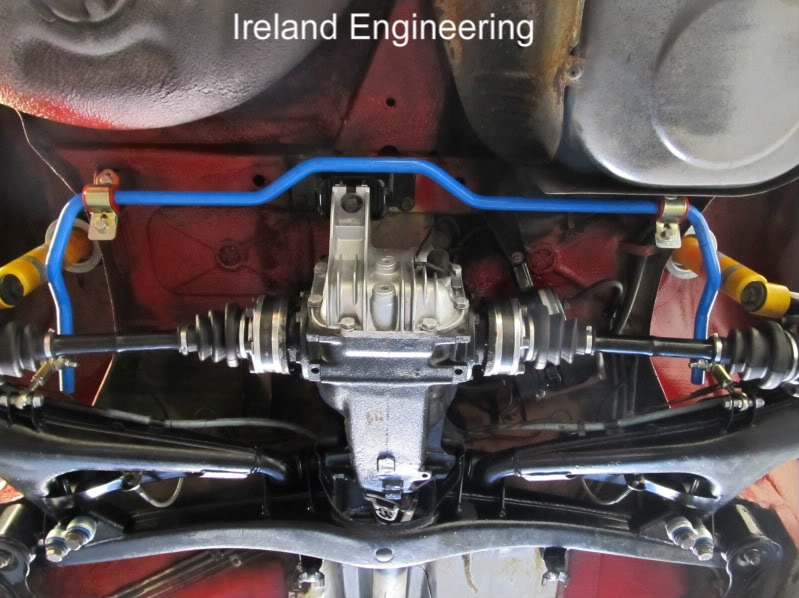

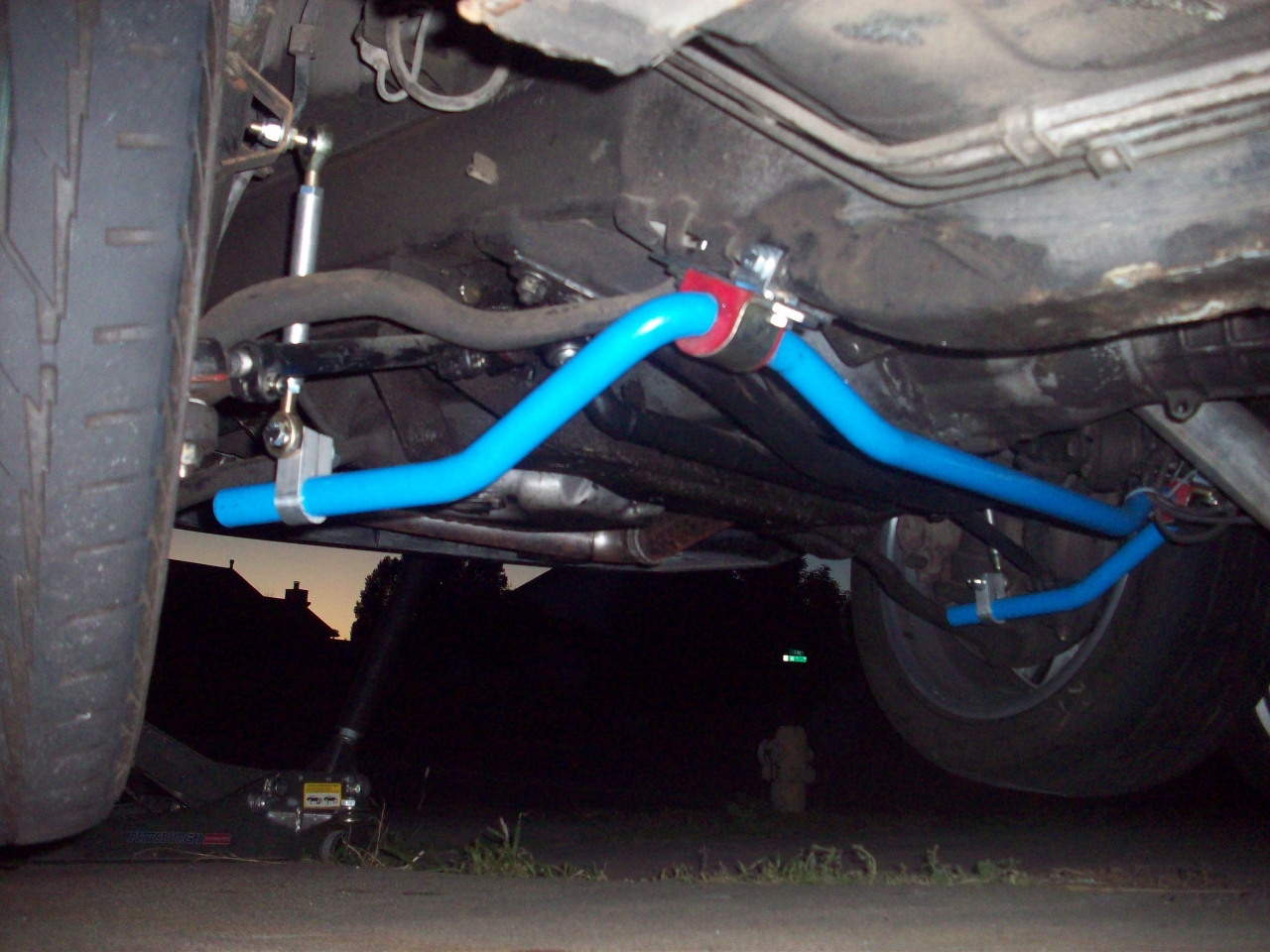

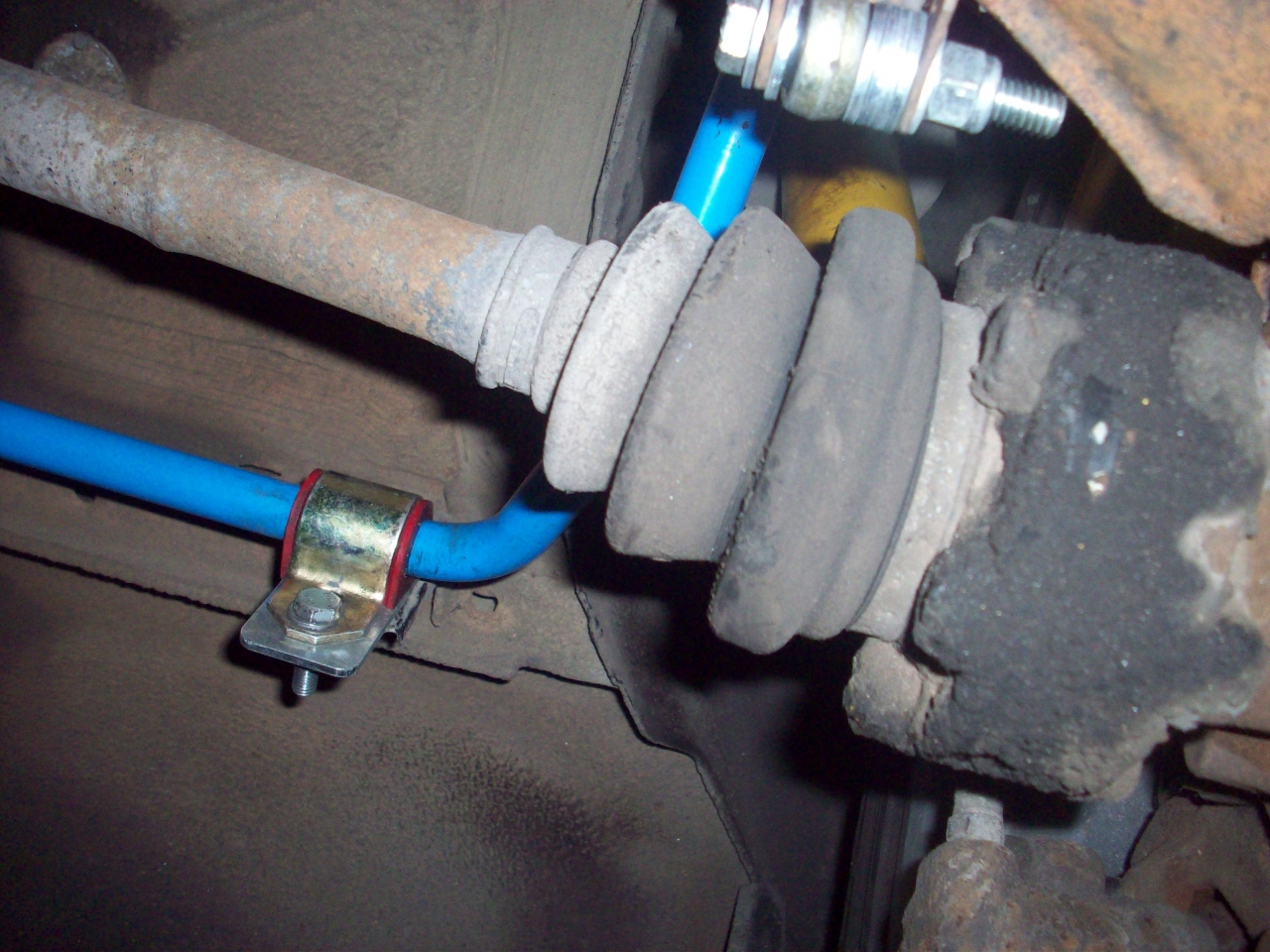

In the mean time, I mounted the IE rear sway bar. I was able to fit it to the early 533/633 style mounting ear even. I haven't driven the car yet, but I'd like to have the welder reinforce this as well when he comes out to my place.

The front, I need to continue modifying the frame rail so the new bracket can be mounted flush. Once flush, I can drill through and mount the bolt. Anyway, waiting to get these issues fixed before trying it out and driving the car. I'd like to keep everything reversible until I'm sold that I want to go forward with these bars...

Some great photos of these bars for later reference (not my cars). These are from Jeff at IE. Notice how the frame rail has to be pounded in to fir, sort of a silly design...

I am not the most happy with this design, especially since it contacts the control arm when trying to get to full lock (Kohler has mentioned this before).

From another poster here:

I don't want to weld unless I know I want to keep the 25mm bar... (IE or E28 M5)

And another customer who bolted them

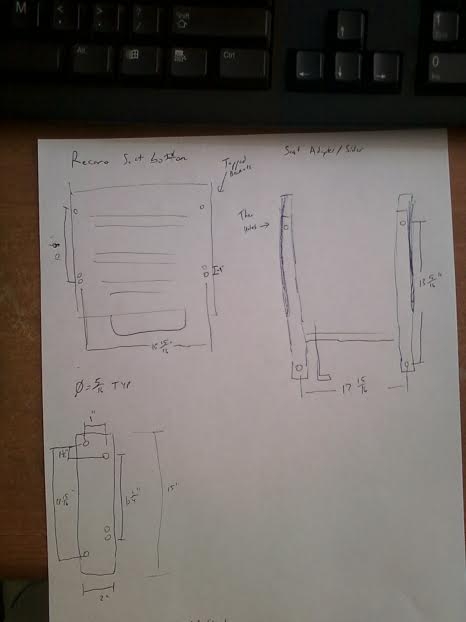

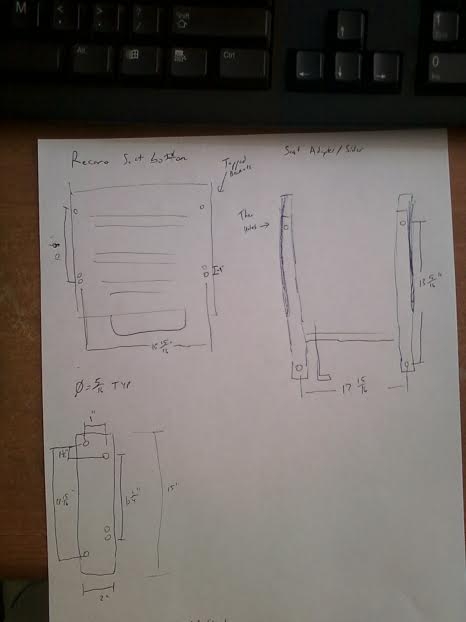

In the mean time I picked up some E21 Recaros from a friend. These seats are awesome (I have them in my Euro 635)! Not sure if/when I would have them recovered but my friend says he will get me some replacement foam for what I paid him. I couldn't wait to try them out in my car this morning.

I was thinking that the comfort bases/sliders would work with these seats, but they are too wide so I need adapters. I took some measurements and plan to make my own.

Re: Callaway 633CSi

Posted: Jul 23, 2015 8:15 AM

by tschultz

Part way finished with the IE sway bar in the front. Putting the other bolt through tonight. You can see the low hanging downpipe (which is getting closer and closer to becoming priority #1).

Also, my co-worker helped me make these after I put together my measurements. Going to try to install one or both seats tonight also.

More updates to follow later tonight.

Re: Callaway 633CSi

Posted: Jul 24, 2015 12:53 PM

by tschultz

My welder is supposed to come this weekend to fit my cracked rear subframe mount. I'm also going to have him weld my rear sway mounts and get them reinforced as much as possible.

In the mean time got my sway bars both mounted, the front I finished up last night and got it tight to the frame rail.

The rear is also on, but here's a comparison of the 19mm vs the stock 14.5mm unit.

It's so tiny, I now understand why the car felt like a big whale when matched with the PO's random cut rear springs and blown shocks. I haven't yet driven the car with the new bars, but will once the repair is complete.

Also a glamour shot of the Recaro seat brackets. My coworker made them real nice, .250" AL.

They fit perfectly also

Putting a radio in the car and awaiting fittings so I can finally install the BEGi. They sent me the wrong fittings (i want 5/16" ID barb x 1/8" mNPT, I got 1/8" ID) last week, so I'm sitting around waiting. But not I think I have a bonus couple of fittings to use as spare boost ports if I get a tee somewhere.

Re: Callaway 633CSi

Posted: Jul 25, 2015 3:13 PM

by tschultz

I know I have been bad about laoding pictures, so I took some today after installing my (old) radio and putting the glovebox and knee panel in place. I have previously fitted the Recaro seats, even though the Driver's needs to be redone. The main pieces missing from the interior are the ebrake surround and the rear seat for access during the repair when the welder comes tomorrow.

Some pictures of the 24# injectors that my brother gave me. They are from Ford crown vic's

The front sway bar after mounting the other night.

The rear sway bar/mount.

The front window all fixed and door panel all back together. I found almost all the pieces in the mess from when I bought the car. Nice to have the window working properly again.

The seats installed. You can see the custom brackets. The good news is that seating position is great.

Cockpit and laughable gauge pod. I wired this up in this position and at least it is functional! At some point I will probably upgrade to something that isn't damaged and looks better, but it works for now.

the trunk cleaned up pretty well, including the toolkit, tire lug wrench and spare which is such a far cry from when I bought it.

Passenger side. This seat I was going to put on the drivers side, but it only has a tilt lever on the outside bolster.

And of course, an engine bay shot

I drove it around the block because I couldn't resist with the new bars. It is

sooo much better. Even with clapped out shocks and the stock springs, the front of the car feels so much more agile than before. It is much more accepting to change directions and feels much more similar to the M5's handling characteristics.

Additional video once i get the subframe mount fixed.

Adding a signal line onto the BOV helped to open and hold close the valve during normal operation. At the moment, it will run up to 8/9psi with my current settings. Fueling is good (11-12.5) up until the higher revs where it starts to go lean (13-13.5). I obviously haven't driven it hard up top because of this.

My biggest concern is intermediate throttle between WOT and below. Up until the threshold throttle position, I see 14-15 AFR's even if accelerating slightly. I am hoping the RRFPR will help aid this in boost related settings, but that leaves the transition when boost in less than 0psi (but more than -15psi).

Or maybe the RRFPR will operate at a manifold conidition in he range and not just +psig??

I am just wondering in the scenario where I am on boost and I left off briefly and then continue with part throttle where theres still engine load/accelerating may 2/3's). This scenario is where I see the lean condition and it worries me.

Should I take the plunge and adjust my AFM to richen over the entire rev range??

Any thoughts?

Re: Callaway 633CSi

Posted: Jul 29, 2015 10:34 AM

by tschultz

A couple photos of Frank the welder doing his job. The issue must have been there a while as there were a few locations he couldn't weld due to the lack of thickness in the metal. But in all he got a good 3-4" of weld in there. He used carbon/stick welding and it took about an hour

Cleaned up, you can see about 3/4" of the way around the welds had been damaged/cracked.

Here's a short video on my way into work.

I really only got on the gas in second gear. Running 8psi and O2 sensor disconnected. It idles right about 14.7 in 70/80 temperatures, but it was about 50 this morning.

The camera placement allows you to see the gauges. On transition throttle and -10-0psi, you can see AFR's in the ~13-14 range. I am hoping to remedy this with the RRFPR. Under WOT the larger injectors give about 10-11:1 AFR until the turbo starts moving air. As I understand this is rich, but maybe still acceptable. Once reaching 5+psi AFR's go lean, and this is where the RRFPR will really help.

https://youtu.be/9aw1Uw0aPNE

You can see oil pressure flickers at 7/8 psi at hot idle. Is this something to be concerned with? I'm running 20W50 conventional...

Once in the revs at this temperature, I see anywhere from 10-40psi oil pressure.

Curious to hear you guys' thoughts on this and overall drivability. Going to try the RRFPR but I now have MS in the back of my mind as a future upgrade.

Re: Callaway 633CSi

Posted: Jul 29, 2015 7:54 PM

by LeiseyJr

When the motor was out did you check the timing chain guides?

Re: Callaway 633CSi

Posted: Jul 29, 2015 9:04 PM

by tschultz

No, total unknown engine.

I know they wear, but there really haven't been many M30 failures of this type that I know of...

Re: Callaway 633CSi

Posted: Jul 29, 2015 9:42 PM

by LeiseyJr

tschultz wrote:No, total unknown engine.

I know they wear, but there really haven't been many M30 failures of this type that I know of...

They don't just wear they disengrate and fall apart. My motor was a known running motor but the tensioners were gone. What can happen is the pieces that do crumble end up in the oil pump pick up screen and clog. Reducing flow and casuing the low oil pressure at idle and under a certain RPM. Did you see any bits in the oil pan?