I normally post them in the Tech Talk section, however, I don't want to spam the whole board...

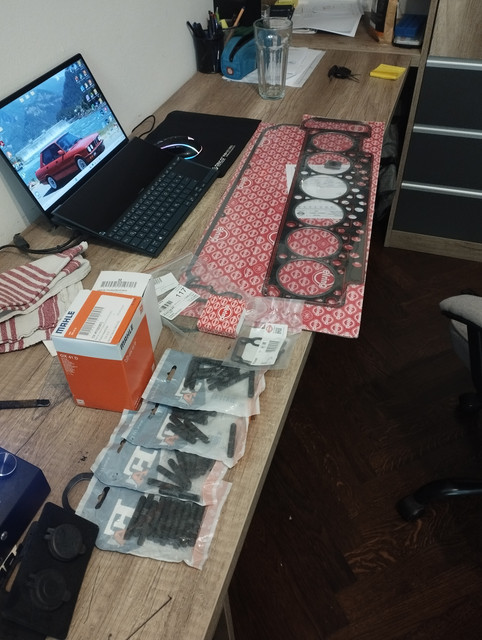

So I collected them, and I'm posting them here, hoping that you guys actually read my build thread

1. Can I use regular DIN931 bolts in the engine?

I think I've heard someone do this in an S38 for main bolts. Is 10.9 just 10.9? Or do you think that there would be a quality difference between OEM bolts and cheap regular 10.9s from the local hardware store?

For head bolts, I suspect this is a no-go, they are too long and they are thinner in the middle.

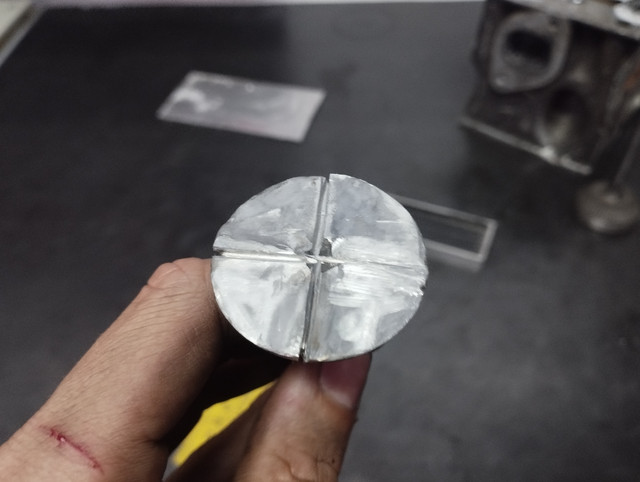

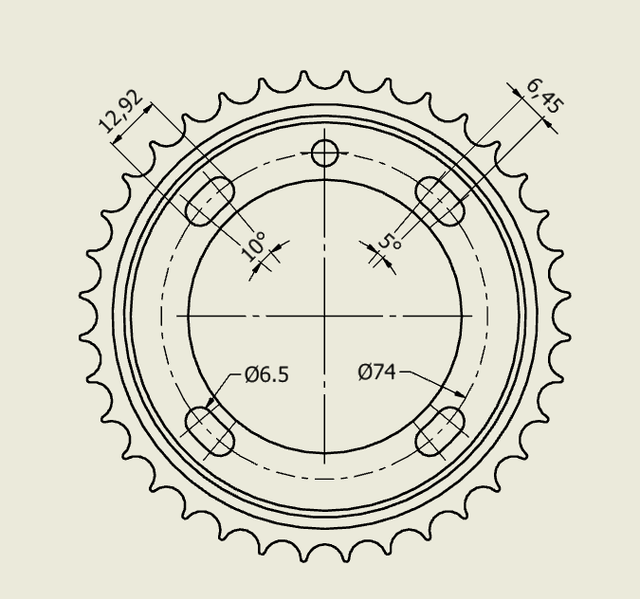

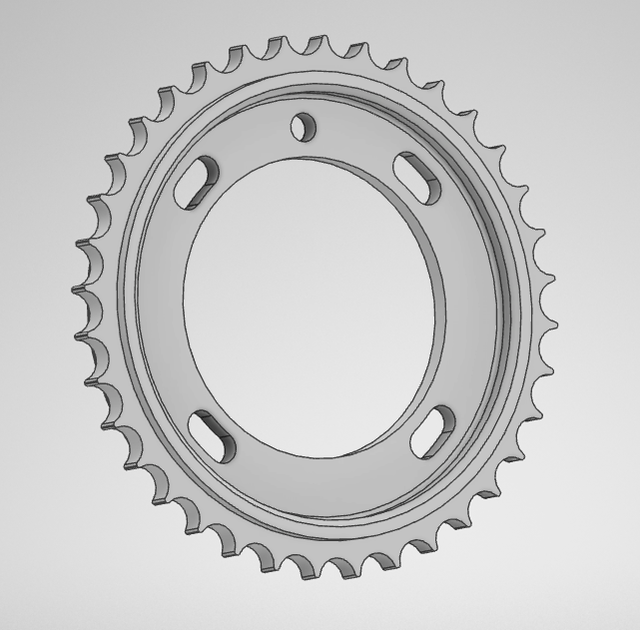

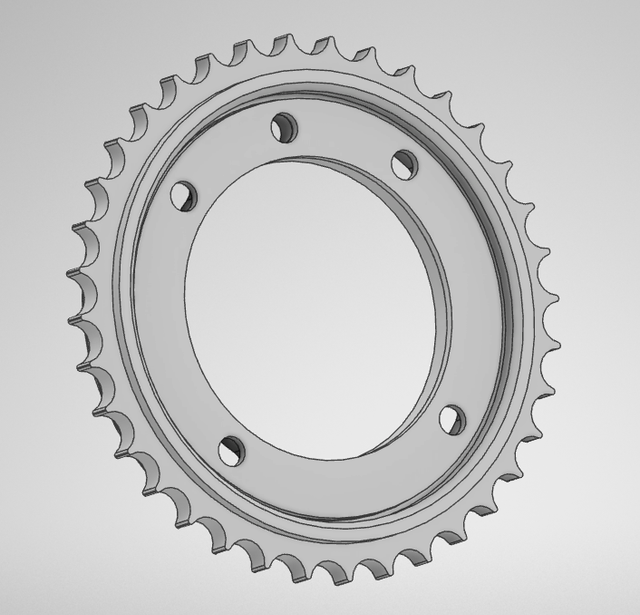

2. Would it make sense to get my flywheel and clutch combination balanced?

The flywheel is brand new, made from billet steel and has been balanced at the factory. The clutch is a new Sachs S38B36 clutch. Are these both balanced enough not to cause any trouble when combined? Or should I get them balanced together? Would it make a difference (smoother running?)

3. What do you guys think of running a smaller water pump pulley?

My current one (OEM on the B35) is 130mm, it's the smaller of the two M30 pulleys. But the S38 had 112 and 102mm versions. The water pump impeller is the same on the M30 and S38 water pumps, so I figured this could be a good upgrade for people who mostly use their cars on the street (for track users, the higher rpm would just create more drag and won't flow more after a point).

4. When it comes to a V-belt, which diameter counts when calculating the ratio?

Outer diameter? "Inner diameter" (OD - 2x belt depth)? Middle (OD - Belt depth (2x 0.5))?

5. Would I cook my R8 coils without a heat shield?

I can't use the stock exhaust gaskets and the new gaskets don't have the shield part. (I discussed this a bit more in a previous post)

6. Should I open up my exhaust ports?

The headers I bought are larger than the original ports on my M30. They are 41.5mm OD tubing that are 1.5mm thick, so 38.5mm ID.

The B35 ports have an area of 1081mm2, so its equivalent diameter is 37.099 ~37mm. I would need to open up the exhaust ports "roughly" 0.75mm all around. This sounds OK to me, I don't think the port velocities will get too low especially since I plan to push a lot more air trough. And even if it was a touch too big, I guess it's still better than having a lip? Let me know!

7. Is there a way to fix the oil filter housing's drain valve if it's bad (lets oil flow down?)

So far on most forums they just state that you should replace it (but another used unit can also malfunction..)

8. Can you recommend me a MATERIAL for heat shielding my underbody tunnel?

Not an exact product - I will probably have problem finding it in my country. I'm just looking for materials that adhere well enough and are heat resistant enough to be used on the outside... Transmission tunnel's right side, where the exhaust is.

9. Which clutch cylinder should I use?

My transmission came from an E34 and I've reused the cylinder on it, but I just realised it is 22.2mm instead of the E28's 20.64mm. It did not cause any troubles, but I guess I should swap to one from an E28? That would result in the engagement point being higher, and the clutch pedal being heavier? The clutch master is 19.05mm on both the E28 and the E34...

10. Stainless or regular studs?

Since my headers are made from 304, I figured that using A2 grade exhaust studs instead of 8.8 could be a good idea, because I really don't want to end up with a rusting stainless part! Of course A2 and aluminium like to galvanically corrode, but I think it should be fine with Loctite 8150 anti seize?

Thank you for your answers!

I'm finally feeling better, and now that the build is rolling lot's of thing are popping around in my head...