9mil M106 E24 Build Thread (Pic Heavy)

Posted: May 30, 2014 2:47 PM

So I have been building a 1987 635csi over the last 3 or so years and I finally had some POC success the other day so I thought it was time to share the whole story – or build thread. I have posted numerous quandary threads over the internets and while I am not going to try to link to them, I am sure I will litter this thread with those reference points in the hopes that someone won’t have to re-live a mistake I have already made.

Here is the build summed up… I took a great running car and disabled it for about 3 years and made it very complex and somewhat useless I tend to have that effect on machinery at times.

So here is the “Build Sheet” I made to provide my tuner so he wasn’t totally guessing on items:

Phil Fortune – 1987 BMW 635CSI with euro M106 Turbo motor.

M106 (M30 Based motor with 8.0:1 CR) with Crank-up rebuild with maybe 3 miles on it. (bearings, crank polished and checked, block dipped and checked, Head rebuilt- All stock parts used and all commonly replaced parts were replaced)

Compression #’s are all between 140-150 with all cylinders below 5% leak down (as one 4.21.2014 on new motor)

745i Manifold

K27 modified with 35r wheel and total rebuild including hot side wheel 2.10.2014

FMIC

LC1 wideband

38mm Tial WG with 10lb big yellow spring and currently dumps to atmosphere

30lb injectors - BOSCH 0-280-150-934 (appear to be high impedance)

3in turbo back with magnaflow muffler- no-cat

Hks BOV

KnockSense (standalone)

External temp and boost gauge

BPR7ES – gapped at .030 (additional in car as fuel load is fouling-Will have new set in)

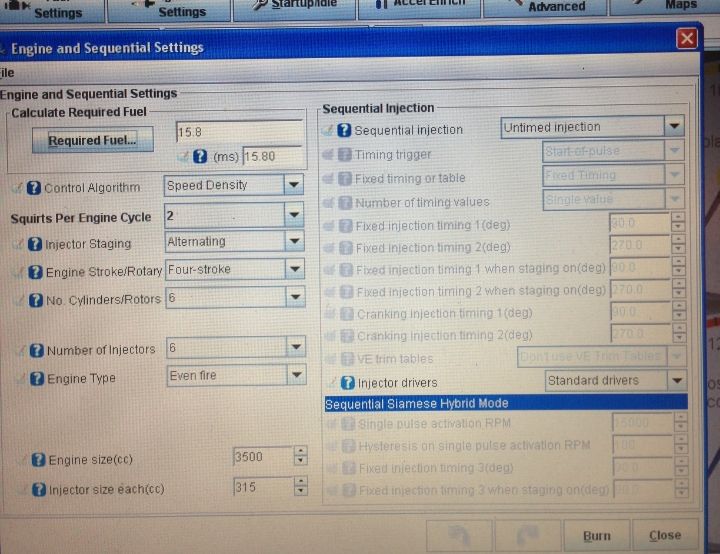

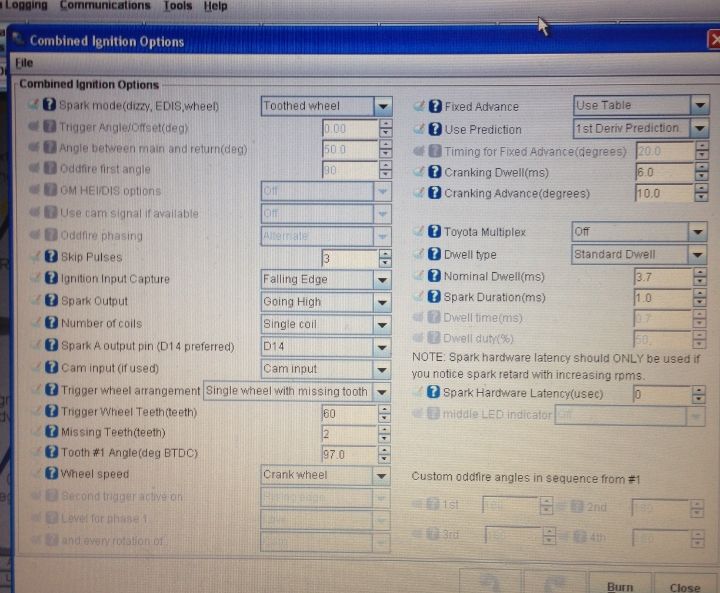

MS2 with GoatHumper adapter board, 174 motronic harness swap, 6 pin TPS,E34 coilpack

Idle Control valve on car- not used, cracked throttle plate

No accessories hooked up currently to MS as additional power needs to be supplied to daughterboard and accessories re-configured. (Symtech setup ICV PWM was setup for MS1 chip and Boost Control – both currently not functional)

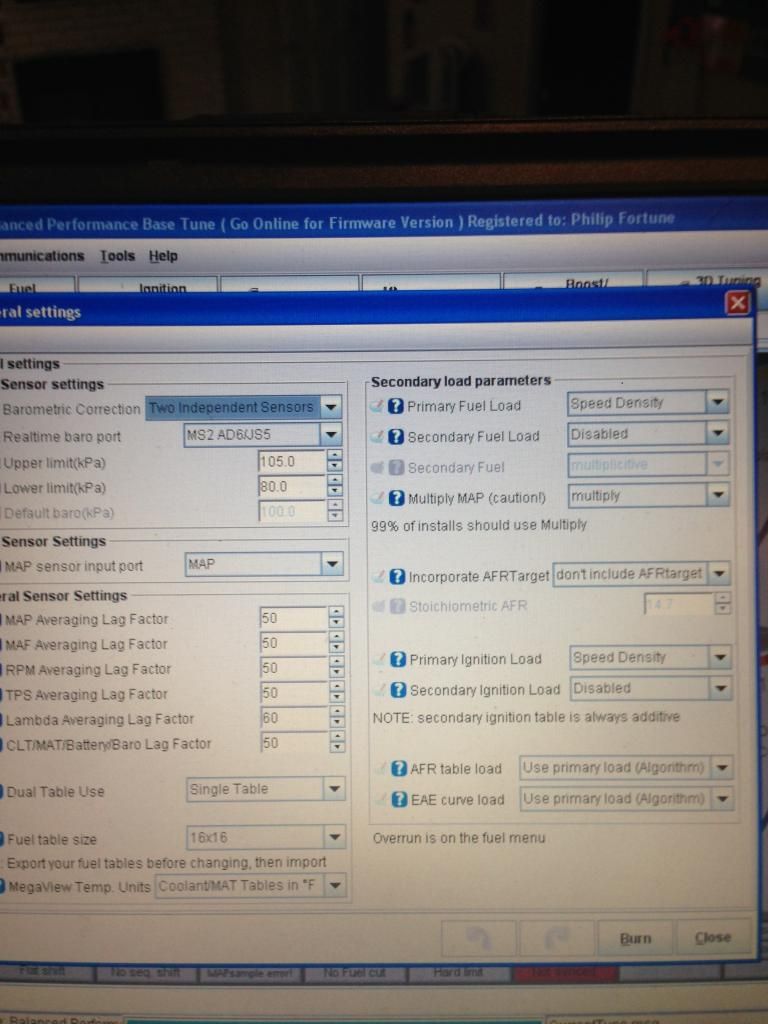

MS Sensors- 2.5 bar MAP (MPX4250AP – K0833AH) GM IAT, , LC1 is being used for 02 input on MS, 6 pin BMW TPS, Bosch ICV- not used currently.

Random sensors in car- Dash Temp not working(external temp gauge to drivers left) tach not working. Oil level not hooked up (oil pressure is) coolant level works.

So here are a few pics of the process and a few mistakes along the way!

Before I took it apart

Cleaned

Where it started to go bad!!!!

Plugs after about 2 minutes of run time

Lots of problems with this Turbo- the oil was the least of it….

35r upgrade

On way to dyno

On Dyno

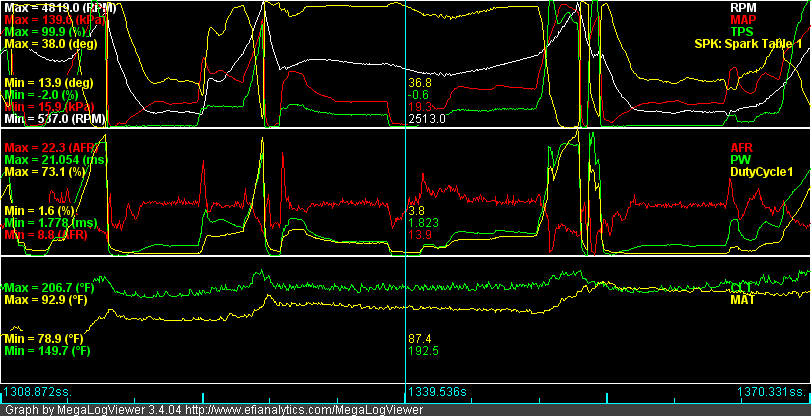

So on 5/20/2014 out of shear frustration, I carted the car up to Balanced Performance just outside of Atlanta (referred by DIYAutoTune) and had Chris review all the base settings and spend a few minutes on the dyno making it somewhat drivable. The point here was to flesh out some of the issues that are tough to chase down by yourself while you’re behind the wheel. I wanted to verify some aspects of the motor as it was brand new, cooling system, oiling, turbo systems, exhaust, intake tracks, all the sensors – before sending the car for paint and putting the new suspension on…. I couldn’t spend another dollar on this thing until I knew the heart was going to be useable.

So the good news is we were able to get the settings in the ballpark and do a little tuning- again, not looking for power, but just making it somewhat drivable- I didn’t want to blow it up quite yet! It spent about 1.5 hours getting the settings and working through a little tutorial for future use and about an hour on the dyno. I was really worried about overheating and she got hot, but always cooled right down – as I hadn’t even really burped the system, just opened the breather port and blew in the reservoir to make sure the radiator was full.

The Temp gauge has really been a hindrance to getting this thing going (yes, I have the gauge via MS- but I done want to have my comp. open all the time and that isn’t a fix really) I had it rebuilt, tested all kinds of senders and finally was so weary of any information I was getting from the on-board gauge, I picked up cheapo digital gauge that came with a M14 sender on the Ebays and that took care of that! I will still need to figure out the dash gauge- along with the Tachometer- but that will take a little more research.

So that leaves me at what is left and the issues I found at the dyno… Issues I know about:

1) Exhaust leaks- I need cutting rings for the exhaust manifold (I think someone mentioned using stock m30 manifold gaskets with the M106 manifold as the cutting rings are uber expensive???) there is also a leak at my wastegate adapter I think- that will take some engineering again.

2) Intake leaks- I think there were a few little bypass leaks that I need to work on- like the ICV that is not being used. That hose was collapsing under vacuum at idle I noticed.

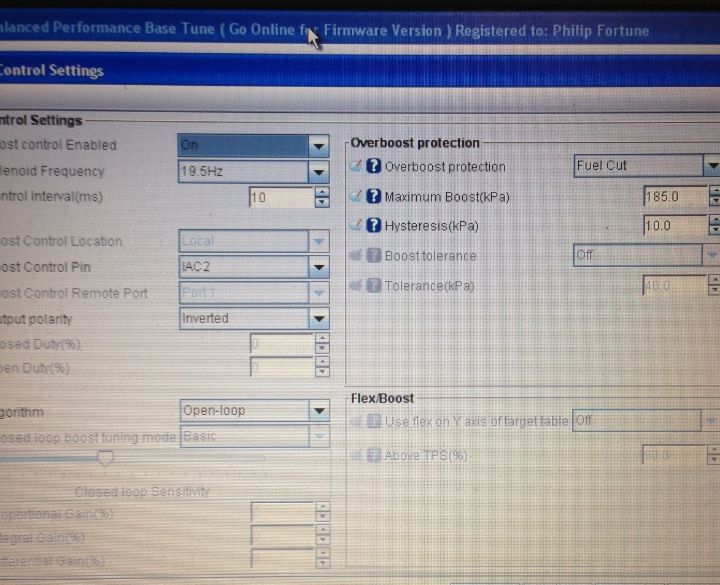

3) Boost control – This is one of the biggest issues and I have already ordered the solenoid and my MS was set up for boost control, so a quick jumper from JS9 to S12c and I should have it on the IAC2… I did just replace my WG spring and diaphragm so I really hope that is holding correctly. I will remove and inspect.

4) Upgraded Radiator –This was a suggestion by the tuner, but I am wondering if going to a waterless cooling system might do the trick instead???? Any insight here?

5) Upgraded intercooler- I have a 28”x7”x2.5” and it was hot, real hot…. So I need to do some calculations and see what I can fit in there. It was pretty hot in the dyno room as well.

6) Bigger injectors- looking or some 42lbs to replace my 30lbs… I knew this was coming and im not really sure how I ended up with the 30lbs in the first place!

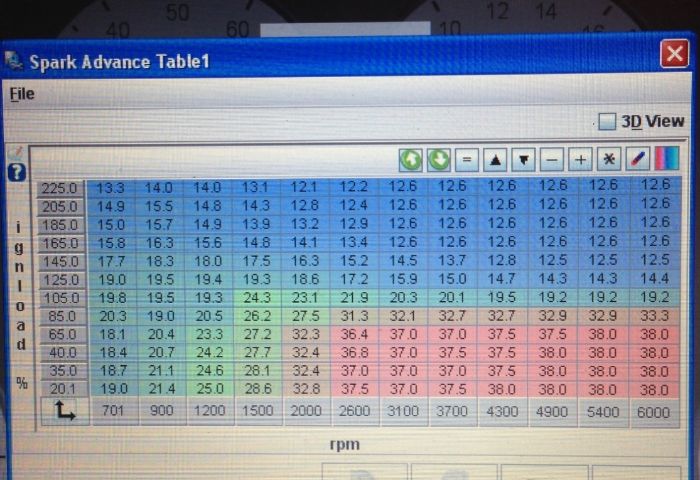

7) Confirm Timing – we couldn’t get a clear shot at the timing mark but it appeared to be about 17deg out….. my timing tables are very conservative and this will be addressed after I get some of these items fixed.

8) Oil Cooler- the motor I bought didn’t come with one and truthfully, I plugged the holes on the oil filter and totally forgot about it until we were sitting on the dyno. This might help in overall cooling as well. Not sure if I will go stock of a universal kit- but I have to do something.

9) Oil filler cap- under acceleration it allows oil to seep pass, dripping down onto the manifold- convenient I know! I am hoping this is a cap issue and not an oil passage/ oil pooling issue.

10) Breather catch can – currently dumps into a Natural Light can- as you can’t hide money! And I need to get it back into the intake tract I think.

11) Intake to turbo- its cobbled together and needs some love thrown at it- and a welder.

12) Random Smoking…. So there is obviously some black smoke when you go full throttle- but there is some random blue smoke here and there… sometimes under start up, sometimes at idle- it was REALLY bad before I had Chris go through the settings. It would foul out the plugs in about 3 minutes of idle (MS thought it was at 7PSI at idle- so dumping fuel) …. Im not sure if this is a new motor thing, startup enrichment fuel burning off, valve guides or rings. Rings are new and the head APPEARED to be rebuilt when I got it, so the guide seals can’t be verified- so the head may be coming off anyway. I am just going to have to play with it I guess and rule things out.

13) Solder up some loose ends on my harness- the TPS was acting kind of wacky- dropping to -2% and moving around a little off throttle- I have an extra I can see if it is the TPS.

14) Verify cam and TDC is correct

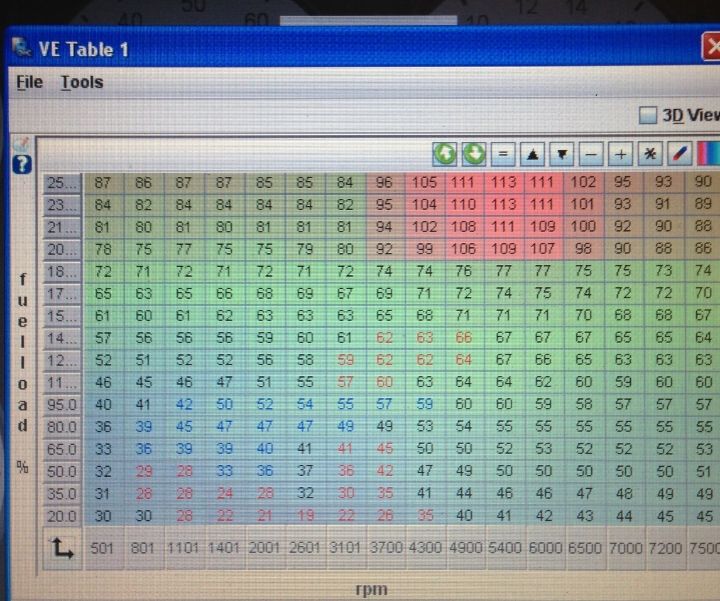

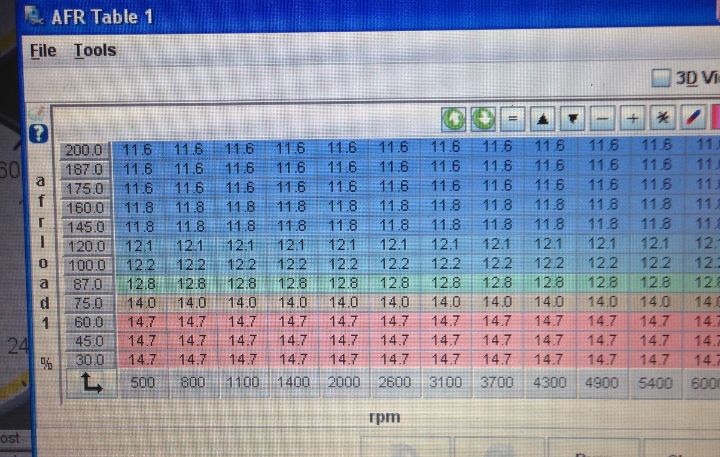

So the plan is to fix the above and try again- this time on the dyno with purpose. I will be posting the graphs and the datalogging and welcome some critiquing. Remember though, we were very conservative on everything in an effort to make it run correctly- so I know the timing map will get a little more aggressive and we will be shooting for about 10lbs of boost.

Here is the build summed up… I took a great running car and disabled it for about 3 years and made it very complex and somewhat useless I tend to have that effect on machinery at times.

So here is the “Build Sheet” I made to provide my tuner so he wasn’t totally guessing on items:

Phil Fortune – 1987 BMW 635CSI with euro M106 Turbo motor.

M106 (M30 Based motor with 8.0:1 CR) with Crank-up rebuild with maybe 3 miles on it. (bearings, crank polished and checked, block dipped and checked, Head rebuilt- All stock parts used and all commonly replaced parts were replaced)

Compression #’s are all between 140-150 with all cylinders below 5% leak down (as one 4.21.2014 on new motor)

745i Manifold

K27 modified with 35r wheel and total rebuild including hot side wheel 2.10.2014

FMIC

LC1 wideband

38mm Tial WG with 10lb big yellow spring and currently dumps to atmosphere

30lb injectors - BOSCH 0-280-150-934 (appear to be high impedance)

3in turbo back with magnaflow muffler- no-cat

Hks BOV

KnockSense (standalone)

External temp and boost gauge

BPR7ES – gapped at .030 (additional in car as fuel load is fouling-Will have new set in)

MS2 with GoatHumper adapter board, 174 motronic harness swap, 6 pin TPS,E34 coilpack

Idle Control valve on car- not used, cracked throttle plate

No accessories hooked up currently to MS as additional power needs to be supplied to daughterboard and accessories re-configured. (Symtech setup ICV PWM was setup for MS1 chip and Boost Control – both currently not functional)

MS Sensors- 2.5 bar MAP (MPX4250AP – K0833AH) GM IAT, , LC1 is being used for 02 input on MS, 6 pin BMW TPS, Bosch ICV- not used currently.

Random sensors in car- Dash Temp not working(external temp gauge to drivers left) tach not working. Oil level not hooked up (oil pressure is) coolant level works.

So here are a few pics of the process and a few mistakes along the way!

Before I took it apart

Cleaned

Where it started to go bad!!!!

Plugs after about 2 minutes of run time

Lots of problems with this Turbo- the oil was the least of it….

35r upgrade

On way to dyno

On Dyno

So on 5/20/2014 out of shear frustration, I carted the car up to Balanced Performance just outside of Atlanta (referred by DIYAutoTune) and had Chris review all the base settings and spend a few minutes on the dyno making it somewhat drivable. The point here was to flesh out some of the issues that are tough to chase down by yourself while you’re behind the wheel. I wanted to verify some aspects of the motor as it was brand new, cooling system, oiling, turbo systems, exhaust, intake tracks, all the sensors – before sending the car for paint and putting the new suspension on…. I couldn’t spend another dollar on this thing until I knew the heart was going to be useable.

So the good news is we were able to get the settings in the ballpark and do a little tuning- again, not looking for power, but just making it somewhat drivable- I didn’t want to blow it up quite yet! It spent about 1.5 hours getting the settings and working through a little tutorial for future use and about an hour on the dyno. I was really worried about overheating and she got hot, but always cooled right down – as I hadn’t even really burped the system, just opened the breather port and blew in the reservoir to make sure the radiator was full.

The Temp gauge has really been a hindrance to getting this thing going (yes, I have the gauge via MS- but I done want to have my comp. open all the time and that isn’t a fix really) I had it rebuilt, tested all kinds of senders and finally was so weary of any information I was getting from the on-board gauge, I picked up cheapo digital gauge that came with a M14 sender on the Ebays and that took care of that! I will still need to figure out the dash gauge- along with the Tachometer- but that will take a little more research.

So that leaves me at what is left and the issues I found at the dyno… Issues I know about:

1) Exhaust leaks- I need cutting rings for the exhaust manifold (I think someone mentioned using stock m30 manifold gaskets with the M106 manifold as the cutting rings are uber expensive???) there is also a leak at my wastegate adapter I think- that will take some engineering again.

2) Intake leaks- I think there were a few little bypass leaks that I need to work on- like the ICV that is not being used. That hose was collapsing under vacuum at idle I noticed.

3) Boost control – This is one of the biggest issues and I have already ordered the solenoid and my MS was set up for boost control, so a quick jumper from JS9 to S12c and I should have it on the IAC2… I did just replace my WG spring and diaphragm so I really hope that is holding correctly. I will remove and inspect.

4) Upgraded Radiator –This was a suggestion by the tuner, but I am wondering if going to a waterless cooling system might do the trick instead???? Any insight here?

5) Upgraded intercooler- I have a 28”x7”x2.5” and it was hot, real hot…. So I need to do some calculations and see what I can fit in there. It was pretty hot in the dyno room as well.

6) Bigger injectors- looking or some 42lbs to replace my 30lbs… I knew this was coming and im not really sure how I ended up with the 30lbs in the first place!

7) Confirm Timing – we couldn’t get a clear shot at the timing mark but it appeared to be about 17deg out….. my timing tables are very conservative and this will be addressed after I get some of these items fixed.

8) Oil Cooler- the motor I bought didn’t come with one and truthfully, I plugged the holes on the oil filter and totally forgot about it until we were sitting on the dyno. This might help in overall cooling as well. Not sure if I will go stock of a universal kit- but I have to do something.

9) Oil filler cap- under acceleration it allows oil to seep pass, dripping down onto the manifold- convenient I know! I am hoping this is a cap issue and not an oil passage/ oil pooling issue.

10) Breather catch can – currently dumps into a Natural Light can- as you can’t hide money! And I need to get it back into the intake tract I think.

11) Intake to turbo- its cobbled together and needs some love thrown at it- and a welder.

12) Random Smoking…. So there is obviously some black smoke when you go full throttle- but there is some random blue smoke here and there… sometimes under start up, sometimes at idle- it was REALLY bad before I had Chris go through the settings. It would foul out the plugs in about 3 minutes of idle (MS thought it was at 7PSI at idle- so dumping fuel) …. Im not sure if this is a new motor thing, startup enrichment fuel burning off, valve guides or rings. Rings are new and the head APPEARED to be rebuilt when I got it, so the guide seals can’t be verified- so the head may be coming off anyway. I am just going to have to play with it I guess and rule things out.

13) Solder up some loose ends on my harness- the TPS was acting kind of wacky- dropping to -2% and moving around a little off throttle- I have an extra I can see if it is the TPS.

14) Verify cam and TDC is correct

So the plan is to fix the above and try again- this time on the dyno with purpose. I will be posting the graphs and the datalogging and welcome some critiquing. Remember though, we were very conservative on everything in an effort to make it run correctly- so I know the timing map will get a little more aggressive and we will be shooting for about 10lbs of boost.