Page 1 of 1

Cam Timing: Discuss

Posted: Jun 29, 2007 5:25 PM

by turbodan

Generally speaking, what would the effect be of retarding the camshaft timing by a tooth with a stock NA cam and pulley on a turbocharged engine? Would I be better off advancing timing? Or is stock generally ideal?

Re: Cam Timing: Discuss

Posted: Jun 29, 2007 6:09 PM

by Rich Euro M5

turbodan wrote:Generally speaking, what would the effect be of retarding the camshaft timing by a tooth with a stock NA cam and pulley on a turbocharged engine? Would I be better off advancing timing? Or is stock generally ideal?

On SOHC engines retarding the cam timing will typically shift the torque curve down in RPM. Advance does just the opposite, shifts it higher. An adjsutable cam gear will allow you to play with this and set it exactly where you want it.

Rich

Posted: Jun 29, 2007 6:53 PM

by turbodan

That sounds a lot like how it works for NA engines.

Posted: Jun 29, 2007 8:00 PM

by Jeremy

You expected it to work differently?

Jeremy

PS - One whole tooth is probably WAY too much to change it by.

Posted: Jun 29, 2007 8:26 PM

by turbodan

I know you can do better with a turbo specific cam than you can with a NA cam in a turbo application. I was thinking about how (or if) an NA cam could be timed to work better with the extra pressure on the intake side. I was hoping there might be some easy power in there with something like that.

Posted: Jun 29, 2007 10:58 PM

by Jeremy

It's easier with twin cam motors, as you can change the intake and exhaust cam timings indepedantly of each other.

With a single cam, the only way to change such things is custom grind a cam. or settle for moving both intake and exhaust timing simulataneously.

Jeremy

Posted: Jun 30, 2007 9:42 AM

by Duke

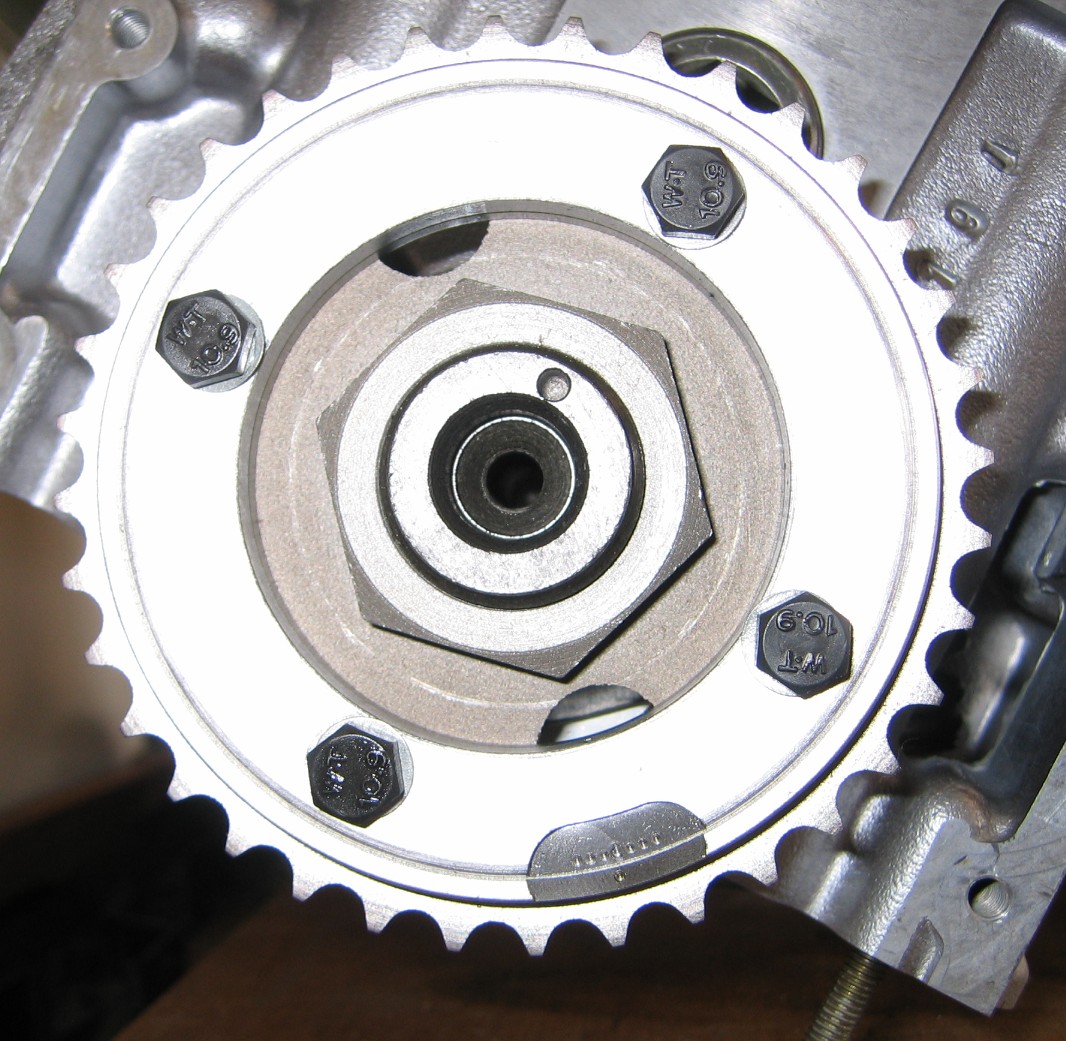

This is an adjustable cam sprocket made by Paul Burke.

I have my timing 2 degrees advanced.

You can modify the intake and exhaust timing separately with valve clearance adjustment. This is very limited though.

Posted: Jun 30, 2007 3:44 PM

by Devinder

Rich,

I think it's the other way around. SOHC (or DOHC where the lobe centerlines cannot be adjusted separately) will move the peak power point down in rpm when advanced and up when retarded. Maybe we're talking about the same thing but using different definitions for retarded and advanced. When I say advanced, I mean that the camshaft is turned futher clockwise relative to the crankshaft (when looking from the front on an M30).

The S38 is slightly different and there is lot of confusion and claims out there about the different sprockets and what they do.

Turbodan,

I think one-tooth adjustments are excessive. Most adjustable cam timing sets have 2 cam-degree adjustments up to about 6 cam-deg at most. Moving one tooth is 10 cam-deg so it's a lot more than most adjustable sprockets you can get. That said, I know people who have driven around with the cam off by one tooth and didn't really notice it.

Duke,

Looks like a sprocket sandwich. Is there a positive drive engagement hidden in there or is it just friction that drives the sprocket?

Devinder

Posted: Jun 30, 2007 4:03 PM

by Rich Euro M5

Devinder wrote:Rich,

I think it's the other way around. SOHC (or DOHC where the lobe centerlines cannot be adjusted separately) will move the peak power point down in rpm when advanced and up when retarded. Maybe we're talking about the same thing but using different definitions for retarded and advanced. When I say advanced, I mean that the camshaft is turned futher clockwise relative to the crankshaft (when looking from the front on an M30).

The S38 is slightly different and there is lot of confusion and claims out there about the different sprockets and what they do.

Devinder

Devinder we're saying the same thing just slightly differently. I said the torque curve will move down in RPM, you're saying the Peak power will move down in RPM. In actual practice on my retired Turbo Brick. The low end torque also improved when I retarded the cam in relation to the carnshaft. So it's like the entire torque curve shifts down in RPM.

Rich

Posted: Jun 30, 2007 4:14 PM

by Duke

Devinder wrote:Duke,

Looks like a sprocket sandwich. Is there a positive drive engagement hidden in there or is it just friction that drives the sprocket?

Devinder

Yes, it is indeed a sprocket sandwich. No positive engagement. The four bolts and raised areas around the bolts on the cover plate hold the sprocket in place with fiction. The raised areas act as a puck clutch would in that they distort the sprocket plate an thus do not slip. I had questions about that also and Paul assured me that there is no way in hell with the bolts tightened down that the sprocket will move. Indeed, it has not.