Page 1 of 4

E32 735i Build - (7/23/10 New Diff Install!)

Posted: Dec 15, 2008 11:31 PM

by cvillebimmer

Last edited: 2/9/09

I figured I'd start a clean "build thread" to compliment my new head gasket.

Video of my set up

http://www.youtube.com/watch?v=ZyQ--foasMA (added 2/9/09)

I had the head cleaned, decked, tested and replaced the worn exhaust guides. Added some additional ports to the intake manifold so everything has a dedicated vacuum/boost signal. Looks cleaner too.

This is a picture of my old* (*had less than 500 miles on it) OEM head gasket next to the OEM +.3mm head gasket I just installed. Although it's a little hard to tell from the picture, the added .3mm seems to be in the form of metal. I haven't run across any FI car with this HG, so I guess I'm the guinea pig...

+.3mm head gasket

The manifold was also cleaned up and the crack repaired. I used a little copper RTV to help out the old metal gaskets.

TCD rebuilt kkk k-27 with Garrett 60 trim compressor wheel.

Head installed with ARPs.

I did go for a quick drive and it felt better than ever. Sorry, no positive pressure yet. I've done two HG replacements in the past 2 months and I don't ever want to do another on *this* car. LC-1 comes first... Damn it's hard to keep an FI car in NA....

Re: E32 735i Build - Take 2

Posted: Dec 16, 2008 8:15 AM

by Duke

cvillebimmer wrote:I've done two HG replacements in the past 2 months and I don't ever want to do another on *this* car.

Felt your pain brother. BTDT......thats why I have a Ford V8 powered car now.

Re: E32 735i Build - Take 2

Posted: Dec 16, 2008 10:42 AM

by turbodan

Duke wrote:thats why I have a Ford V8 powered car now.

Congratulations

Re: E32 735i Build - Take 2

Posted: Dec 16, 2008 11:21 AM

by Duke

turbodan wrote:Duke wrote:thats why I have a Ford V8 powered car now.

Congratulations

Thanks!

Re: E32 735i Build - Take 2

Posted: Dec 16, 2008 2:16 PM

by gkrea1

cvillebimmer wrote:Last edited: 12/16 11:30

It looks to be well on it's way to being an solid build. Where did you source the exhaust manifold studs? I hear those are hard to come by. Did you have an entire M106 motor to cannibalize?

Ever since I drove my whale home I've thought that it is an excellent candidate for turbocharging. Not only is there plenty of room under the hood (relatively), it would add the torque these nice, heavy sedans need to really move.

Posted: Dec 16, 2008 2:20 PM

by turbodan

You can get the studs from BMW. List is $56...

Posted: Dec 16, 2008 3:43 PM

by cvillebimmer

The exhaust studs are 8mm from McMaster.com with copper sleeves to fit the 10mm holes. I didn't want to re-tap the head.

Gale from this board (another e32 project) ordered them and cut the copper tube for me. All said it done it was 20 bucks and change.

Unfortunately, there's no m106 within arms reach of me. Perhaps you'll join the turbo-whale club?

Posted: Dec 16, 2008 5:01 PM

by gkrea1

cvillebimmer wrote:Perhaps you'll join the turbo-whale club?

Ah, yes, good ol' McMaster-Carr.

No, my E32 will remain as-is. It has almost 253k miles on it and has been a solid daily driver. Just doesn't make financial sense to plow turbo money into it. the good news is, being nearly worthless on the used car market, once retired from daily driver status at about 350,000, I'll let the kids drive it in high school. Good brakes, heavy, safe, and an automatic -- a fine first car to learn on.

I do miss the torque from my first turbo. Once the kids' college is set then I'll turbocharge the E24. I hope to add SEM before their college starts to learn how to tune.

Posted: Dec 16, 2008 10:12 PM

by Brad D.

It looks great! I'm glad you've got it all back together. Hopefully this time for good so you can enjoy the fruits of labor.

Posted: Dec 17, 2008 11:37 AM

by cvillebimmer

Big Bronze Rim wrote:It looks great! I'm glad you've got it all back together. Hopefully this time for good so you can enjoy the fruits of labor.

Thanks Brad! I hope my next update is a little more exciting.

Posted: Feb 09, 2009 7:14 AM

by cvillebimmer

Hi everyone. I was really hoping to give you all the "It works!" update, sadly I cannot... It has been a challenging couple of months with my turbo project, but watching the projects on this board have kept me motivated. I have problem that I suspect to be the turbo, but hope is something else. Below is a link to my set up video that I made yesterday. It's pretty elementary, but hopefully it will help someone else who want's to do a similar set up. I'm out of ideas to solve my problem and just maybe one of the experts here will be able to say you "You dumb a$$, you forgot to _______________ ". That would really make my day!

http://www.youtube.com/watch?v=ZyQ--foasMA

Here's what's been going on...

I installed my rebuilt turbo just before Christmas and it failed after less than 200 miles having never delivered proper boost. It would manage about 5psi in 4th and 5th gear, before things went awry. At this point the car would stumble and lose power until you eased off of WOT. Assuming the turbo could not be the culprit, I diagnosed everything else. Broke down and cleaned the waste gate, tested the bypass valve, tested spark and fuel. By the time I figured out the turbo had failed, the compressor fins had severely worn down from hitting the housing and there was about an 1/8 of an inch of play on the shaft (pics below). Never made a screeching noise as one might expect, although I occasionally heard what sounded like crunching tin foil, particularly when spooling down.

I sent the turbo back to the shop in early January. They confirmed I had adequate lube and even stated the failure could not have been a result of a bad setup. However, they were not able to identify the cause of the failure. They re-rebuilt it (for free) and I re-reinstalled it last week. The car runs great in N/A conditions and my ARs are where they should be (bouncing around 14.7 at idle and cruise and drop to a steady 11.5 when entering boost). In 4th of 5th gear I can enter boost and things are good until about 5-6 psi when I experience the same stumbling behavior as last time.

With a more acute ear to the turbo and being overly cautions this time, there are three things that are really concerning.

- First, with the car standing still I hear what sounds like fins hitting housing between 4100 and 4400 rpm. This only happens with a warm engine.

- Second, I can duplicate the sound while driving in vacuum conditions through the same rpm range.

- Third, the symptoms in boost are the same as before.

The first thing I checked this time was the cold side of the turbo for play and to see if I can make the fins hit the housing. It looks and feels just fine. I fear that the turbo is on it's way out again, but I don't know how to prove that without driving it into complete failure again. I also can't explain how it could fail twice when it worked perfectly as a stock K27.

Anyone have any thoughts or ideas? I'd also be willing to pay a reputable person to fully inspect my set up, but don't know who to take it to.

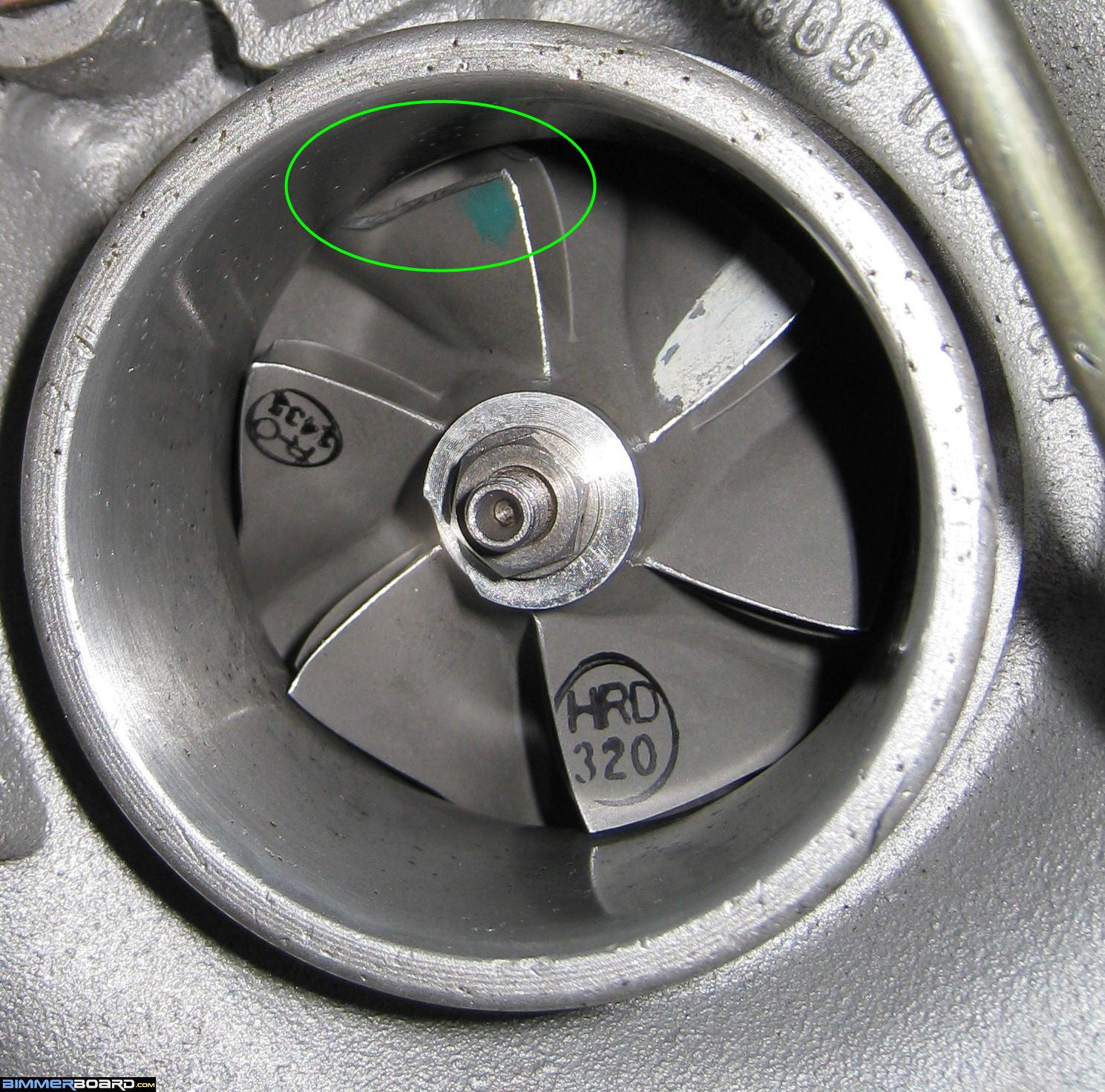

Turbo Failure:

This is what it looks like now. Based on the sound it makes, I would have bet on some noticeable wear. Maybe the rubbing is coming from inside the housing where I can't see it or on the hot side...

Posted: Feb 09, 2009 8:46 AM

by Shawn D.

Dang! That would also mean your engine is sucking on the debris!

Posted: Feb 09, 2009 8:59 AM

by cvillebimmer

Shawn D. wrote:Dang! That would also mean your engine is sucking on the debris!

Yeah... I have a magnetic tip on the oil drain plug, I haven't changed the oil yet so it will be interesting to see if anything is there. This is assuming the fin material is magnetic. Hopefully most of it is trapped in the intercooler...

Posted: Feb 09, 2009 10:26 AM

by turbodan

You really dont have much to worry about as far as debris contamination unless the wheel actually disintegrates. You might pull off some connections to look, but from the looks of things you wont find much.

For now you should hold off on condemning the turbo. If you dont have excessive shaft play, theres nothing wrong with it. Turbo failure is really pretty uncommon.

What exhaust system are you running? Is it fully un-obstructed?

Posted: Feb 09, 2009 11:21 AM

by cvillebimmer

Good to know. The silicone connection up near the intake show no signs of metal shavings.

I've mated the stock e32 to the 745i downpipes and I did suspect that could be contributing to the problem. So, I took the saws-all to it and cut it before the cat then plugged the O2 sensor into the bung I fitted to the downpipes for the LC-1. Still the same problems in boost, but at the time the comp wheel had likely already started to wear. Upon visual inspection, the cat looked fine too.

What I don't understand is what can possibly be making the screeching noise now when you go through 4100-4400 rpm at a standstill. I could be wrong, but I would suspect that back pressure shouldn't be a problem in this situation. Is there any other component that could make such a sound? I'll try to record the sound in a video and post it.

Another data point... Before I removed the turbo last time, it actually pinned itself and stopped spinning temporarily. During this time I was able to take the car to redline in N/A conditions and it was smooth and powerful. At least I was able to confirm everything seemed to work fine in N/A conditions.

Posted: Feb 09, 2009 12:09 PM

by turbodan

That exhaust might have to go. Turbines dont like back pressure, and a stock e32 735 cat and exhaust system is going to have lots of it.

If nothing else explains the turbo failure, that could be the cause.

Posted: Feb 09, 2009 12:11 PM

by George

This is really an odd situation

Just to confirm the symptoms: regardless of manifold pressure, you are getting a screeching noise from idle to approx 4400 rpm?

At first glance it would seem that the screeching noise would be made by the shaft bearings not getting enough oil, but you said that the shop confirmed there was no oil starvation...Are you measuring oil pressure? If so, where?

I'm just throwing this out there, but could

too much oil pressure cause the sounds you are describing?

My bet is on a problem relating to the oil feed.

Posted: Feb 09, 2009 1:06 PM

by cvillebimmer

Here's a link to a recording of the screech:

http://www.youtube.com/watch?v=MvE6SU4kt3g.

I made this on the way to work this morning in 3rd gear between 4000-4500 rpm on a hot engine. Very gentle acceleration and manifold vacuum the entire time. It sounds worse in the video than it does in person.

thesixerkid wrote:

Just to confirm the symptoms: regardless of manifold pressure, you are getting a screeching noise from idle to approx 4400 rpm?

The screech is

only from 4100-4400 rpm. It sounds fine up to that point and above 4500 rpm. From a standstill, I cannot produce the noise until the engine is fully warmed up.

thesixerkid wrote:

At first glance it would seem that the screeching noise would be made by the shaft bearings not getting enough oil, but you said that the shop confirmed there was no oil starvation...Are you measuring oil pressure? If so, where?

I'm just throwing this out there, but could too much oil pressure cause the sounds you are describing?

My bet is on a problem relating to the oil feed.

The oil is tapped from the oil pressure sender on the back of the head using this distribution block:

I do not have an oil pressure gauge, so I can't 100% rule out it's an oil pressure problem. When I installed the turbo, I left the oil return disconnected and confirmed I have a steady stream of oil flowing through. The flow looked like a gentle squeeze from a bottle of Aunt Jemima.

Here’s a video of the car boosting properly on the stock K27 (pre-rebuild):

http://www.youtube.com/watch?v=H6yVQlyukDE. Besides the turbo and head work, the setup us is the same.

I know it sounds like I’m trying to blame the turbo, but I REALLY do not want to take it out again. I'm still hoping for a simple explanation.

Thanks for the suggestions!

Posted: Feb 09, 2009 2:37 PM

by turbodan

If you dont have excessive shaft play and the wheels aren't contacting the housings, the turbo is okay. I think you can pretty much rule out another turbo failure at the moment.

From your video of the 9 psi run I really think the exhaust system is holding you back. Turbines require a certain pressure ratio to drive the compressor. Any increase in pressure at the turbine outlet will be two or three times higher in the exhaust manifold. I think this is what killed my old 50 trim turbo. I wouldn't even consider running a stock M20 or M30 exhaust system on my turbo car. The cat and muffler are not capable of handling the additional flow and low backpressure requirements of a turbo system.

You shouldn't worry about that sound for now. I have a feeling its completely unrelated. If you get a new exhaust system made up you will see an increase in power and your symptoms under boost might just go away.

Thats my bet.

Posted: Feb 09, 2009 2:52 PM

by cvillebimmer

I sure hope you're right, Dan! That would make me very happy if it's just restrictive exhaust.

To clarify, in the video where it is boosting well, I was not running exhaust. Just the downpipes with the O2 sensor plugged in and earplugs.

I chopped the exhaust after the first re-built, then had it put back together before the most recent install. I wish I had left it cut now... Another newbie lesson learned the hard way...

Thanks guys!

Posted: Feb 09, 2009 2:58 PM

by George

My apologies, I didn't realize the sound was only limited to the small range of 4100-4400 rpm. It would still be wise to install an oil pressure gauge. I can make you a "T" adapter that will fit inline with your feed line for like $10 if you'd like.

Posted: Feb 09, 2009 3:09 PM

by turbodan

Thats the next component to rule out at this point. The turbo seems alright. Even if you did have a wheel hitting the housing you probably wouldn't hear it. A nice new 3" downpipe and exhaust would be a good thing.

Posted: Feb 10, 2009 12:30 AM

by Jimmie G

Who did your turbo work?

Jimmie

Posted: Feb 10, 2009 9:35 AM

by cvillebimmer

Hey guys, something just isn't making sense to me and hopefully someone can explain.

I'm willing to take the saws-all to the exhaust again in order to rule that out if I have to. Dan, are you suggesting back pressure might be causing the turbo to screech. If so, does it make sense that there could be enough back pressure with the car standing still and the engine not under load to cause this to happen?

Another idea I had would be to completely bypass the turbo and I/C. I think I can relatively easily connect the suction tube coming of the AFM to the intake pipe with a couple adapters from Lowes.

Do you all think this is a worthwhile exercise before hacking the exhaust?

Posted: Feb 10, 2009 10:02 AM

by turbodan

I dont think the sound you're hearing is the turbo. You've ruled out excessive shaft play, and even if your wheels were hitting the housings I think its unlikely that there would be an audible screech from that.

Posted: Feb 10, 2009 10:08 AM

by cvillebimmer

I sure wish you were closer so could get you in the passenger's seat. With the hood up, the sound is clearly coming from the passenger's side of the engine. I guess it could be a sound coming from the transmission/flywheel/clutch? Anything other ideas? It's definitely not coming from anything belt driven.

Posted: Feb 10, 2009 10:13 AM

by turbodan

You shouldn't focus too much on the sound. Unless its rod knock or something its probably not worth fixating on. It could be a heat shield vibrating.

Weld up a new exhaust from the turbine back. With the exhaust off you can check the turbine for excessive free play. There probably wont be any.

Posted: Feb 10, 2009 11:24 AM

by russc

Wait a minute,

Your taking the oil for the turbo bearing from the port on the back of the head were the oil pressure sender is??????

That pressure is the lowest in the entire sysem!!!! Ive never seen that. Oil should be taken from the oil canister adapter housing, like all other systems do. That way you always get max pressure all the time with max oil flow to the bearing......

RussC

cvillebimmer wrote:

The oil is tapped from the oil pressure sender on the back of the head using this distribution block:

I do not have an oil pressure gauge, so I can't 100% rule out it's an oil pressure problem. When I installed the turbo, I left the oil return disconnected and confirmed I have a steady stream of oil flowing through. The flow looked like a gentle squeeze from a bottle of Aunt Jemima.

Thanks for the suggestions!

Posted: Feb 10, 2009 12:20 PM

by cvillebimmer

Your taking the oil for the turbo bearing from the port on the back of the head were the oil pressure sender is??????

That's right. Does this seem like an adequate amount of oil flow?

http://www.youtube.com/watch?v=l4tnOxvFm9k I have nothing to compare it to. I took this at idle with the oil return line disconnected from the turbo.

FWIW - This guy tapped the oil pressure sender and has boosted north of 20psi. This is an awesome build:

http://www.cardomain.com/ride/184332. He posts quite a bit on bimmerforums.

Posted: Feb 10, 2009 1:33 PM

by turbodan

Looks ample to me.